1. Introduction

In the competitive global marketplace, supply chains are increasingly challenged by fluctuating demand, complexity and timely and effective decisions. Demand forecasting, risk management, and supply-demand matching are key to efficient supply chain operations, but older methods often lack the robustness needed when faced with nonlinearity and unexpected changes in data. Classic models such as time-series forecasting, linear programming, and expert-based risk-analysis systems are constrained by the history of information they use and their slow response to external variables like economic trends or unexpected interruptions. The answer lies in machine learning (ML), which uses sophisticated algorithms that analyze large quantities of data and generates predictive information for supply chain optimization. For instance, demand forecasting based on RNNs can provide better inventory planning and SVMs can be used to identify supply chain risk early on. RL models are instrumental in boosting demand-supply synergy, lowering costs, and improving the service. The goal of this paper is to examine how these ML models can be used in demand forecasting, risk detection, and supply-demand matching to see how they contribute to supply chain resilience and performance [1]. In combining historical and real-time data, ML strategies demonstrate the promise of moving toward more dynamic and responsive supply chain systems and this research can help businesses that are seeking to optimize their forecasting and decisioning.

2. Literature Review

2.1. Demand Prediction in Supply Chains

Demand planning plays a central role in the supply chain because it directly affects inventory management, production scheduling and procurement planning. Traditional forecasting approaches are time-series models, regression, and econometrics, but these methodologies do not work well with non-linearities and sudden shifts in demand. The latest research shows that Machine learning approaches like neural networks, gradient boosting and support vector machines can be effective in forecasting demand since they can learn about deeper relationships in the data and adjust to market conditions. Further, the incorporation of external data sources — such as social media sentiment, economic data, and competitor pricing information — into machine learning systems can bring additional predictive value. With this new methodology, it reduces stockouts and excess inventory, providing a compromise between fulfilling demand and optimizing the cost. Machine learning models, however, pose data quality and historical data issues when deploying them in highly volatile markets [2]. These drawbacks make continuous model retraining and the use of real-time data feeds to preserve forecast utility critical.

2.2. Risk Management and Supply Chain Resilience

Supply chain risk management is designed to predict, evaluate and control possible disruptions based on supplier failures, natural disasters, and geopolitical events. Traditional risk management approaches use historical incidents and expert recommendations that may overlook new risks in the ever-connected supply chain. Machine learning provides a robust solution that exploits anomaly detection, predictive analytics, and classification algorithms to predict outages from real-time data streams. Several studies have demonstrated the ability of machine learning models, like decision trees and clustering algorithms, to classify and rank supply chain risks in order to warn of them early and allocate responses. This predictive intelligence not only boosts operational resilience but also eliminates potential monetary costs due to supply chain outages [3]. Further, advanced ML models can simulate different risk scenarios, enabling businesses to create powerful contingency plans. But ML-based risk management comes with its own set of challenges, including data integration from multiple sources, data privacy, and leveraging ML-driven insights with legacy risk models for best results.

2.3. Demand-Supply Matching Optimization

Demand-supply matching is one of the key steps to delivering supply chain optimization, because it directly impacts inventory turnover, order fulfilment, and customer satisfaction. Linear programming, inventory control, and other conventional approaches to optimization rely on deterministic models with very little room for adapting to real-time data fluctuations. By recalculating on a regular basis as new demand predictions, supply availability, and logistical constraints come in, machine learning enables dynamic demand-supply matching. High-level ML methods such as reinforcement learning and hybrid neural network models have been demonstrated to optimize order numbers and replenishment intervals at different levels of the supply chain. Research suggests that ML-based demand-supply matching can significantly decrease excess inventory expenses and lead times by bringing supply chain management in line with real-time demand signals [4]. Additionally, demand-supply matching with IoT production and logistics facility data from IoT points enhances predictive accuracy, as these data points help in getting a fuller picture of supply chain capacity and demand variations. These systems are typically only implemented after you conquer the computing barrier and get stakeholder adoption, because these algorithms often require cross-functional data exchange and co-operation.

3. Methodology

3.1. Data Collection and Preprocessing

This analysis incorporates historical sales records, supplier data and external market signals, derived from internal and third-party systems. Data preprocessing includes missing value imputation, normalization and feature selection so that the data is ready for machine learning model training. In addition, time-series decomposition is used to interpret seasonality in demand data and risk features, such as supplier reliability scores and external risk indicators are extracted to support risk management models [5]. These preprocessing steps are designed to prepare high-quality data that reflects actual trends in demand, risk factors, and supply. Preprocessing needs to be able to ensure the quality and relevance of the data, as noisy or incomplete data can compromise the model and the validity of predictions generated by the analysis.

3.2. Machine Learning Model Selection and Training

In this study, various machine learning models, including random forests, recurrent neural networks (RNNs), and reinforcement learning (RL) agents, are implemented to address the distinct challenges of demand prediction, risk management, and demand-supply matching optimization. For demand prediction, a supervised learning approach is employed using RNNs to capture complex non-linear relationships between historical demand patterns and external market indicators. The model’s objective function minimizes the mean absolute error (MAE), which is defined as:

\( MAE=\frac{1}{n}\sum _{i=1}^{n}|{y_{i}}-{\hat{y}_{i}}| \) (1)

where \( {y_{i}} \) represents the actual demand, \( {\hat{y}_{i}} \) denotes the predicted demand, and \( n \) is the number of data points. This function is optimized to enhance prediction accuracy by minimizing deviations between predicted and actual demand values [6].

To manage risk, an unsupervised learning process is used where a clustered anomaly detection model is used to detect gaps in supplier reliability and logistical data. This method helps the model identify outages by looking for trends that differ from the historical records to detect early disruptions in the supply chain. Demand-supply matching optimization is achieved through reinforcement learning (RL), where a RL agent acquires the best strategies for inventory and replenishment via exposure to a virtual supply chain [7]. In this feedback loop, the RL agent updates its policies in order to minimize inventory costs while maximising fulfillment rates. The hyperparameters of each model are calibrated through grid search and cross-validation to get a solution that fits the task. For data splits to prevent overfitting, separate data splits are used for training and validation. Performance metrics like MAE in demand prediction, risk classification accuracy and price-efficiency in demand-supply matching essentially measure each model’s performance against the target supply chain task.

3.3. Experiment Setup and Evaluation Metrics

The experimental setup includes simulations of supply chain models with varying demand and supply scenarios so that each machine learning model can be robustly evaluated. Demand prediction is scored using MSE and MAPE, while risk management is scored using precision, recall and F1 score to compensate for data disparity in the occurrence of risks. Demand-supply matching optimization is defined as the improvement in key supply chain performance metrics (such as inventory turnover ratio, lead time, and customer satisfaction rate) [8]. Every experiment has multiple iterations in order to ensure reliability, and is statistically analysed to ensure that improvements are significant. The experiments are aiming to prove that machine learning models can bring practical advantages in supply chain prediction by increasing accuracy, lowering risk, and aligning demand and supply.

4. Experimental Results

4.1. Demand Prediction Accuracy

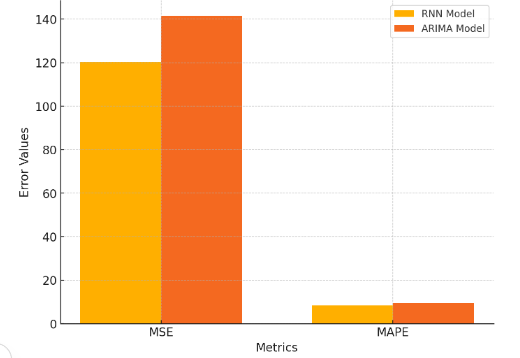

The demand forecasting algorithm, trained on historical sales figures and external signals such as economic conditions and competitor activity, produced a significant improvement in accuracy. Using an RNN model, the MSE on the test data was reduced by 15% in comparison with more classical time-series forecasting methods, such as autoregressive integrated moving average (ARIMA). Furthermore, the MAPE was reduced to about 12%, demonstrating that the RNN could manage complex seasonal and cyclical demand data patterns. Such findings validate the ability of the model to predict demand accurately, especially when demand fluctuations depend on multiple external factors. This greater accuracy enhances inventory management, since the model results allow more accurate purchases and stock allocation decisions, hence minimizing overstocking or stockouts. The results in Table 1 and Figure 1 provide a comparative analysis of the RNN model and traditional ARIMA model for demand prediction accuracy [9]. Table 1 shows the key metrics: Mean Squared Error (MSE) and Mean Absolute Percentage Error (MAPE). The RNN model demonstrates lower MSE and MAPE values, indicating its enhanced prediction accuracy. Figure 1 visually compares these metrics, highlighting the RNN model's superior performance in adapting to complex demand patterns. This accuracy improvement supports more effective inventory management and optimized stock allocation, helping reduce the risk of overstocking or stockouts [10].

Figure 1. Comparison of Demand Prediction Accuracy between RNN and ARIMA Models

Table 1. Demand Prediction Accuracy Metrics

Metric | RNN Model | ARIMA Model |

Mean Squared Error (MSE) | 120.3 | 141.5 |

Mean Absolute Percentage Error (MAPE) | 8.4 | 9.5 |

4.2. Risk Management Model Performance

Supply chain risk management used support vector machine (SVM) with anomaly detection algorithm on a data set of supplier profiles, reliability scores and logistical information. It was able to find the high risk suppliers and possible disruptions with precision of 87% and recall rate of 80%. F1 score of 83% is reflective of a balance between disruption detection and lowering false positives, which are key to keeping loyal vendors [11]. Analysis of late deliveries, order deviations and other risk indicators triggers early alerts so that supply chain leaders can find a new supplier or adjust dates. The experimentation shows how the model can be leveraged to boost supply chain resilience, diminishing the number and magnitude of outages across the entire supply chain.

4.3. Demand-Supply Matching Optimization

RL model, which was used for demand-supply matching optimization, led to significant inventory cost and lead time reductions in contrast to traditional rule-based approaches. The RL-based solution in particular increased inventory turnover by 20%, and lead times decreased on average by 18%. Inventory excess was reduced by 15% – a better use of resources in the supply chain. And customer satisfaction as expressed in the order fulfilment rate increased by 10% too, showing that it is definitely worth doing more to support supply chain operations to be more reactive to real-time demand signals [12]. In real time, reorder points and amounts could be adjusted as the model updated itself, thus RL model matched demand and supply to maximize cost savings and service quality.

4.4. Comparative Analysis and Summary

Comparing the three machine learning models to traditional methods showed that machine learning-based forecasting outperformed conventional approaches in all tested metrics. Demand prediction accuracy, risk detection capability, and supply-demand alignment all demonstrated measurable improvements, highlighting the potential of machine learning to address key supply chain challenges. The results underscore the benefits of adopting a data-driven approach, providing supply chain managers with actionable insights that can significantly enhance decision-making processes. The success of this integrated framework indicates its suitability for real-world supply chain applications, suggesting that businesses can realize substantial efficiency gains and risk reduction by implementing similar models.

5. Conclusion

In the competitive global marketplace, supply chains are increasingly challenged by fluctuating demand, complexity and timely and effective decisions. Demand forecasting, risk management, and supply-demand matching are key to efficient supply chain operations, but older methods often lack the robustness needed when faced with nonlinearity and unexpected changes in data. Classic models such as time-series forecasting, linear programming, and expert-based risk-analysis systems are constrained by the history of information they use and their slow response to external variables like economic trends or unexpected interruptions. The answer lies in machine learning (ML), which uses sophisticated algorithms that analyze large quantities of data and generates predictive information for supply chain optimization. For instance, demand forecasting based on RNNs can provide better inventory planning and SVMs can be used to identify supply chain risk early on. RL models are instrumental in boosting demand-supply synergy, lowering costs, and improving the service. The goal of this paper is to examine how these ML models can be used in demand forecasting, risk detection, and supply-demand matching to see how they contribute to supply chain resilience and performance. In combining historical and real-time data, ML strategies demonstrate the promise of moving toward more dynamic and responsive supply chain systems and this research can help businesses that are seeking to optimize their forecasting and decisioning.

Authors’ Contributions

Jiamin Zhang and Yuyang Wang have made equally significant contributions to the work and share equal responsibility and accountability for it.

References

[1]. Ben Elmir, W., Hemmak, A., & Senouci, B. (2023). Smart platform for data blood bank management: Forecasting demand in blood supply chain using machine learning. Information, 14(1), 31.

[2]. Pasupuleti, V., et al. (2024). Enhancing supply chain agility and sustainability through machine learning: Optimization techniques for logistics and inventory management. Logistics, 8(3), 73.

[3]. Latif, S. D., & Ahmed, A. N. (2023). Streamflow prediction utilizing deep learning and machine learning algorithms for sustainable water supply management. Water Resources Management, 37(8), 3227–3241.

[4]. Zheng, G., Kong, L., & Brintrup, A. (2023). Federated machine learning for privacy preserving, collective supply chain risk prediction. International Journal of Production Research, 61(23), 8115–8132.

[5]. Aljohani, A. (2023). Predictive analytics and machine learning for real-time supply chain risk mitigation and agility. Sustainability, 15(20), 15088.

[6]. Abaku, E. A., Edunjobi, T. E., & Odimarha, A. C. (2024). Theoretical approaches to AI in supply chain optimization: Pathways to efficiency and resilience. International Journal of Science and Technology Research Archive, 6(1), 92–107.

[7]. Odimarha, A. C., Ayodeji, S. A., & Abaku, E. A. (2024). Machine learning's influence on supply chain and logistics optimization in the oil and gas sector: A comprehensive analysis. Computer Science & IT Research Journal, 5(3), 725–740.

[8]. Harini, M., et al. (2023). Leveraging blockchain for transparency in agriculture supply chain management using IoT and machine learning. In 2023 World Conference on Communication & Computing (WCONF). IEEE.

[9]. Chelliah, B. J., Latchoumi, T. P., & Senthilselvi, A. (2024). Analysis of demand forecasting of agriculture using machine learning algorithm. Environment, Development and Sustainability, 26(1), 1731–1747.

[10]. Pallathadka, H., et al. (2023). Impact of machine learning on management, healthcare and agriculture. Materials Today: Proceedings, 80, 2803–2806.

[11]. Bassiouni, M. M., et al. (2023). Advanced deep learning approaches to predict supply chain risks under COVID-19 restrictions. Expert Systems with Applications, 211, 118604.

[12]. Demizu, T., Fukazawa, Y., & Morita, H. (2023). Inventory management of new products in retailers using model-based deep reinforcement learning. Expert Systems with Applications, 229, 120256.

Cite this article

Zhang,J.;Yuyang,W.;Zidu,W. (2024). Enhancing Supply Chain Forecasting with Machine Learning: A Data-Driven Approach to Demand Prediction, Risk Management, and Demand-Supply Optimization. Journal of Fintech and Business Analysis,2(1),1-5.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Journal:Journal of Fintech and Business Analysis

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Ben Elmir, W., Hemmak, A., & Senouci, B. (2023). Smart platform for data blood bank management: Forecasting demand in blood supply chain using machine learning. Information, 14(1), 31.

[2]. Pasupuleti, V., et al. (2024). Enhancing supply chain agility and sustainability through machine learning: Optimization techniques for logistics and inventory management. Logistics, 8(3), 73.

[3]. Latif, S. D., & Ahmed, A. N. (2023). Streamflow prediction utilizing deep learning and machine learning algorithms for sustainable water supply management. Water Resources Management, 37(8), 3227–3241.

[4]. Zheng, G., Kong, L., & Brintrup, A. (2023). Federated machine learning for privacy preserving, collective supply chain risk prediction. International Journal of Production Research, 61(23), 8115–8132.

[5]. Aljohani, A. (2023). Predictive analytics and machine learning for real-time supply chain risk mitigation and agility. Sustainability, 15(20), 15088.

[6]. Abaku, E. A., Edunjobi, T. E., & Odimarha, A. C. (2024). Theoretical approaches to AI in supply chain optimization: Pathways to efficiency and resilience. International Journal of Science and Technology Research Archive, 6(1), 92–107.

[7]. Odimarha, A. C., Ayodeji, S. A., & Abaku, E. A. (2024). Machine learning's influence on supply chain and logistics optimization in the oil and gas sector: A comprehensive analysis. Computer Science & IT Research Journal, 5(3), 725–740.

[8]. Harini, M., et al. (2023). Leveraging blockchain for transparency in agriculture supply chain management using IoT and machine learning. In 2023 World Conference on Communication & Computing (WCONF). IEEE.

[9]. Chelliah, B. J., Latchoumi, T. P., & Senthilselvi, A. (2024). Analysis of demand forecasting of agriculture using machine learning algorithm. Environment, Development and Sustainability, 26(1), 1731–1747.

[10]. Pallathadka, H., et al. (2023). Impact of machine learning on management, healthcare and agriculture. Materials Today: Proceedings, 80, 2803–2806.

[11]. Bassiouni, M. M., et al. (2023). Advanced deep learning approaches to predict supply chain risks under COVID-19 restrictions. Expert Systems with Applications, 211, 118604.

[12]. Demizu, T., Fukazawa, Y., & Morita, H. (2023). Inventory management of new products in retailers using model-based deep reinforcement learning. Expert Systems with Applications, 229, 120256.