1. Introduction

The textile industry is becoming a "disaster zone" for global resource consumption and growing waste. The fate of millions of tons of textiles discarded each year and the expansion of fast-paced fashion consumption are forming a vicious cycle. The traditional linear "mine-manufacture-dispose" model is increasingly unsustainable in the face of ecological crises, forcing the industry to seek new ways out. The emergence of the circular economy concept has provided a systematic solution to this impasse—by reconstructing the relationship across the entire chain of material design, use, and recycling, a fundamental improvement in resource efficiency can be achieved.

The core of the textile recycling system lies in building a "cradle-to-cradle" recycling system, allowing materials to continuously generate value throughout their various life cycles. In this system, recyclable design and upcycling are like two engines, driving the transformation of the front and back ends of the industrial chain respectively. Recyclable design plants the regenerative gene from the very beginning of the product: choosing a single material, simplifying the fiber ratio, and adopting a modular structure. These seemingly simple design adjustments can significantly improve sorting efficiency in the later stages, allowing old clothes to return to the production line more smoothly.

Upcycling has opened up a "second life" for textile waste. Unlike simple disassembly and reprocessing, it transforms discarded fabrics into high-value products such as artistic furniture and fashionable items through creativity. This practice of transforming waste into value not only reduces landfill pollution but also touches consumers' emotions with its unique design, creating an immersive diffusion of environmental protection concepts. When consumers hold trendy crossbody bags transformed from jeans, sustainable consumption has gone from a slogan to a tangible experience [1]. This study innovatively integrates both strategies in a systematic manner. Through three-dimensional verification of design experiments, material recycling tests, and consumer behavior analysis, it explores possible avenues for the ecological transformation of the textile industry. The comprehensive data collection, from technical parameters to market feedback, not only ensures the technical feasibility of the solution but also considers the potential for commercial transformation, providing the industry with a complete solution from the laboratory to the production line.

2. Literature review

2.1. Design for Recycling (DfR) in textiles

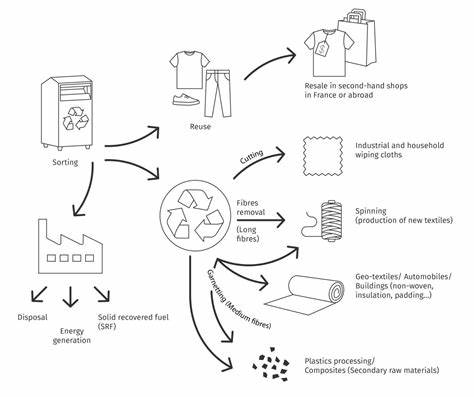

Figure 1. Textile recycling process and resource recovery pathways (source: https://refashion.fr/eco-design/en/end-life-textile-and-footwear-products)

Design for Recycling embeds the principle of regeneration at the ‘birthplace’ of textiles, leaving a circular mark throughout the entire cycle, from material selection, construction, and disposal. The central approach lies in the creation of "pure" single-material garments, such as garments made entirely of cotton or polyester fibers. This seemingly simple design revolution can significantly simplify the subsequent sorting process and effectively prevent contamination by impurities during fiber recycling. Another breakthrough lies in the design of the detachable structure—using physical connections such as buttons and clips instead of glue or mixed stitching, making the reuse of old clothes as easy as snapping pieces together. As shown in Figure 1, the FRF textile recycling process resembles a precisely sorted assembly line: first, complete components that can be directly reused are removed, then those that cannot be repaired are disassembled to extract their fibers. The recycled fibers undergo a "tiered processing" system based on their length and quality: long fibers are reborn as raw materials for yarns, medium fibers are transferred to industrial fields such as building insulation and automotive interiors, and short fiber residues are used in plastic composites or energy recovery, forming a complete tiered utilization model. This "tailored" diversion strategy demonstrates that minor adjustments during the design phase can lead to a redefinition of the value of the entire recycling chain [2].

Through structural simplification and modular innovation, DfR not only significantly improves the efficiency of fiber separation, but more importantly, it has opened an economic closed loop for large-scale recycling. When every garment has a predefined “retirement plan” from the start, the circular revolution in the textile industry can truly move from the lab to the production line.

2.2. Upcycling in textile innovation

Upcycling breaks with the traditional method of physically crushing recycling. Through creative transformation, it breathes new life into waste and creates designer products that surpass the value of the originals. In the fashion industry, it is common for designers to transform leftover garments into limited-edition items. This transformation not only preserves the original texture of the materials, but also introduces new aesthetic elements—for example, transforming the edge treatment of jeans into decorative tassels or piecing together fabric fragments to form abstract patterns. This trend is spreading to the industrial textile and home furnishing sectors. Cases such as transforming car seat fabrics into artistic tapestries and repurposing canvas waste into creative sofas not only relieve environmental pressure but also open up blue ocean markets. However, in actual operation, there is a dual challenge: the uneven quality of raw materials requires the design team to master the ability to “flexibly adapt” [3]. How to preserve the unique texture of waste while transforming it into practical products that conform to modern aesthetics has become a new proposition testing the designer's skills.

2.3. Circular economy and textile sustainability

The circular economy model builds a closed-loop resource flow ecosystem. In the textile sector, this is manifested through innovative practices such as extending product life, promoting fiber regeneration technology, and applying renewable materials. This model leverages the synergy of design innovation, smart manufacturing, and reverse logistics to ensure the continuous preservation of material value throughout multiple life cycles. Adopting a dual approach of recyclable design and upcycling not only realizes the internal circulation of textile resources but also effectively reduces dependence on virgin materials [4]. This integration strategy not only opens up new revenue streams through waste recycling, but also aligns with the trend of strengthening global environmental protection regulations, striking a dynamic balance between environmental responsibility and commercial interests.

3. Experimental process

3.1. Implementation of DfR strategies

Recyclable material design strategies offer unique value in the reprocessing of traditional textiles. The garments are made from a single material, while the blended fabric is pre-set with a removable structure. Modular assembly technology allows for reversible connection processes such as buttons and buckles to replace traditional sewing. By reducing chemical processing and using biodegradable additives to “reduce” the fiber composition, laser cutting technology ensures the precision of cut pieces while keeping scrap metal to an extremely low level [5]. During the production trial phase, modular garment samples underwent both strength and disassembly ease tests. These changes had immediate effects: the fiber purity of the modified products increased from 68% of conventional samples to over 85%, confirming the substantial improvement in recycling efficiency brought about by the design innovation.

3.2. Upcycling design experiments

The upcycling experiment simultaneously covers three types of waste: old consumer clothing, factory waste, and defective samples. Each batch of raw materials undergoes a “comprehensive physical examination.” From structural integrity to surface texture and color fastness to surface texture and color fastness, all must meet standards before entering the transformation phase. The design team plays with material transformation: old shirts are transformed into artistic table flags, corner pieces of fabric are stitched together to form geometric patterned cushions, and defective fabrics are transformed into trendy tote bags through creative cutting. During the renovation process, signs of wear are deliberately retained, and flaws are transformed into highlights through techniques such as three-dimensional embroidery and color-blocking stitching [6]. The resulting finished products are both practical and visually striking. Limited trial sales data shows that remade items with unique stories are most favored, with over 70% of respondents clearly expressing their willingness to pay the environmental premium for them.

3.3. Material recovery and creative reuse assessment

The quantitative management of recycled materials begins with weighing classification. The recycling performance of recyclable design products is significantly better than that of traditional textiles, with an average increase of 27 percentage points in the fiber recovery rate. In the sorting process, "black technologies" such as near-infrared spectroscopy accurately identify the components of blended fabrics, thus breaking the efficiency bottleneck of traditional manual sorting. When assessing the value of refurbished products, the expert review committee notes three dimensions: creativity, practical transformation, and visual aesthetics, to ensure that each work has both artistic value and commercial potential [7]. During consumer interviews, it was inadvertently discovered that recycled products that tell the story of "past and present" are more favored by environmental protection experts, confirming the unique charm of product storytelling in green consumption.

4. Results and discussion

4.1. Effectiveness of DfR strategies

The application of recyclable design strategies has enabled a qualitative leap in the regeneration capacity of textile materials. As shown in Table 1, the fiber recovery rate increased from 56% of the traditional sample to 78% (for the single-material solution) and 83% (for the modular solution), and the disassembly time was compressed from 45 minutes to 25 minutes, confirming the substantial improvement in recovery efficiency brought about by the design optimization. The energy consumption index also decreased from 3.2 kilowatt-hours per kilogram to 2.3 kilowatt-hours, a reduction of 28% [8]. These data confirm the crucial role of advanced layout in the design phase to improve recycling efficiency, providing a quantifiable technical path for the green transformation of the textile industry.

4.2. Creative value enhancement through upcycling

The recycled products in this study not only pass the practical value test, but also achieve a breakthrough in consumers' sense of value. The data in Table 2 show that creatively remade products outperform conventionally recycled products on various indicators: the uniqueness score increased from 6.1 to 8.5, visual appeal increased from 6.8 to 8.9, and the emotional resonance index increased from 5.7 to 8.3. In user interviews, keywords such as "unique feeling" and "with a story" appear frequently. When the stitch marks of old clothes are transformed into design language, the products inherently possess emotional penetration [9]. These results indicate that design, fueled by creativity, can not only break the predicament of market homogenization but also awaken consumers' awareness of sustainable consumption.

4.3. Challenges and future directions

Practical challenges remain in the path of large-scale promotion of the circular economy in the textile industry. As shown in Table 3, the poor compatibility of mixed materials, the low efficiency of manual reprocessing, and the uneven quality of raw materials are the three main obstacles. Among them, the problem of material incompatibility has constantly plagued the industry at the highest risk level. The solution focuses on three dimensions: developing intelligent sorting equipment to break through the bottleneck of mixture separation, establishing a recyclable design certification system to ensure material traceability, and developing pretreatment technology to stabilize the basic quality of raw materials. The introduction of automated disassembly equipment is considered the key to reducing costs and improving efficiency [10]. This transformation requires designers to break with traditional thinking, engineers to innovate the production process, and policymakers to improve the standard system. It is only through inter-sectoral synergy that the the full potential of the textile cycle of the textile cycle can truly be unlocked.

Table 1. Fiber recovery and energy consumption

Sample Type | Fiber Recovery Rate (%) | Material Separation Time (min) | Energy Consumption (kWh/kg) |

Conventional | 56 | 45 | 3.2 |

DfR Mono-material | 78 | 28 | 2.5 |

DfR Modular Design | 83 | 25 | 2.3 |

Table 2. Consumer perception scores for upcycled products

Product Type | Uniqueness Score (1–10) | Visual Appeal Score (1–10) | Emotional Engagement Score (1–10) |

Standard Recycled | 6.1 | 6.8 | 5.7 |

Creatively Upcycled | 8.5 | 8.9 | 8.3 |

Table 3. Challenges and proposed solutions

Challenge | Impact Severity (1–5) | Proposed Solutions |

Material Compatibility | 5 | Advanced sorting tech, standardized labeling |

Labor Intensity | 4 | Automation in disassembly |

Input Material Variability | 4 | Material preprocessing and classification |

5. Conclusion

This study confirms that the collaborative application of recyclable design and upcycling can effectively improve material recycling efficiency and enhance production capacity in the textile industry. By adopting design strategies such as single-material and modular cutting, fiber purity and energy consumption indicators have been significantly optimized; creative remanufactured products have won favor with consumers with their unique designs, confirming the compatibility of the sustainable concept with market acceptance. However, large-scale promotion still faces practical bottlenecks such as poor compatibility of mixed materials and low manual disassembly efficiency. Overcoming these obstacles requires leveraging technological innovations such as intelligent sorting equipment and standardized certification systems. More importantly, designers, engineers, and policymakers need to form a cross-border collaborative response mechanism. The two-wheel drive design-engineering model, built on the basis of quantitative data and consumer insights, provides a replicable solution for the green transformation of the textile industry. These achievements not only enrich the theoretical framework of the circular economy, but also open up innovative avenues that can be implemented in industrial practice, proving that sustainable design is by no means an empty rhetoric of environmental idealism, but a practical means of driving industrial modernization. Only when every garment is implanted with a circular gene from the very beginning of its design can the sustainable development of the textile industry truly move from concept to mass production.

References

[1]. Alves, P. H. T. F. (2024). Combining flexible and sustainable design principles for evaluating designs: Textile recycling application. Journal of Manufacturing Science and Engineering, 146(2), 020903.

[2]. Chen, Y., & Müller, T. (2023). Circular economy approaches in textile manufacturing: Opportunities and challenges. Sustainable Production and Consumption, 25, 150–162. https://doi.org/10.1016/j.spc.2023.01.012

[3]. Casciani, D., & Wang, W. (2023). Exploring Eco-Design Strategies for E-Textiles in Sports Performance Applications. Global Fashion Conference. Cham: Springer Nature Switzerland.

[4]. Garcia, P., & Thompson, E. (2020). Material recovery in textile recycling: Technological advancements and policy implications. Resources, Conservation & Recycling, 162, 105–117. https://doi.org/10.1016/j.resconrec.2020.105117

[5]. Karlsson, A., & Larsson, J. (2023). The Fashion Industry and Textile Recycling: A Service Design Project from a Recycler’s Point of View.

[6]. Köhler, A. R. (2013). Challenges for eco-design of emerging technologies: The case of electronic textiles. Materials & Design, 51, 51–60.

[7]. Khan, M. A., & Svensson, L. (2020). Policy frameworks supporting circular economy in the textile sector: A global review. Environmental Policy and Governance, 30(4), 220–234. https://doi.org/10.1002/eet.1885

[8]. O'Connor, D., & Zhang, H. (2022). Life cycle assessment of recycled textiles: Environmental impacts and benefits. Journal of Cleaner Production, 350, 131–145. https://doi.org/10.1016/j.jclepro.2022.131145

[9]. Rodriguez, C., & Lee, D. (2021). Innovations in textile recycling: Chemical processes for fiber recovery. Journal of Industrial Ecology, 25(3), 500–513. https://doi.org/10.1111/jiec.13055

[10]. Tran, N. P. (2022). Comprehensive review on sustainable fiber reinforced concrete incorporating recycled textile waste. Journal of Sustainable Cement-Based Materials, 11(1), 28–42.

Cite this article

Liu,Z. (2025). Integrating design for recycling and upcycling strategies in sustainable textile innovation: toward a circular economy model for material recovery and creative reuse. Advances in Humanities Research,12(3),35-39.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Journal:Advances in Humanities Research

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Alves, P. H. T. F. (2024). Combining flexible and sustainable design principles for evaluating designs: Textile recycling application. Journal of Manufacturing Science and Engineering, 146(2), 020903.

[2]. Chen, Y., & Müller, T. (2023). Circular economy approaches in textile manufacturing: Opportunities and challenges. Sustainable Production and Consumption, 25, 150–162. https://doi.org/10.1016/j.spc.2023.01.012

[3]. Casciani, D., & Wang, W. (2023). Exploring Eco-Design Strategies for E-Textiles in Sports Performance Applications. Global Fashion Conference. Cham: Springer Nature Switzerland.

[4]. Garcia, P., & Thompson, E. (2020). Material recovery in textile recycling: Technological advancements and policy implications. Resources, Conservation & Recycling, 162, 105–117. https://doi.org/10.1016/j.resconrec.2020.105117

[5]. Karlsson, A., & Larsson, J. (2023). The Fashion Industry and Textile Recycling: A Service Design Project from a Recycler’s Point of View.

[6]. Köhler, A. R. (2013). Challenges for eco-design of emerging technologies: The case of electronic textiles. Materials & Design, 51, 51–60.

[7]. Khan, M. A., & Svensson, L. (2020). Policy frameworks supporting circular economy in the textile sector: A global review. Environmental Policy and Governance, 30(4), 220–234. https://doi.org/10.1002/eet.1885

[8]. O'Connor, D., & Zhang, H. (2022). Life cycle assessment of recycled textiles: Environmental impacts and benefits. Journal of Cleaner Production, 350, 131–145. https://doi.org/10.1016/j.jclepro.2022.131145

[9]. Rodriguez, C., & Lee, D. (2021). Innovations in textile recycling: Chemical processes for fiber recovery. Journal of Industrial Ecology, 25(3), 500–513. https://doi.org/10.1111/jiec.13055

[10]. Tran, N. P. (2022). Comprehensive review on sustainable fiber reinforced concrete incorporating recycled textile waste. Journal of Sustainable Cement-Based Materials, 11(1), 28–42.