1. Introduction

In The Condition of the Working Class in England, Friedrich Engels highlighted the harsh conditions confronting British laborers, underscoring the growing gulf between the affluent middle class and the impoverished working class [1]. From the 1780s to the 1840s, Britain’s per capita GDP increased by 46%, yet real wages for the working class rose by only 12%. R. C. Allen later termed this pronounced disparity—where the growth rate of real wages lags substantially behind that of GDP— “Engels’ pause” [2].

Regarding the reason for its occurrence, Malthus offered an explanation rooted in his population theory. He argued that although technological advancements during the Industrial Revolution increased labor demand, population growth rose at a comparable rate, thereby ensuring a consistently abundant labor supply [3]. Consequently, the fundamental supply-and-demand dynamics in the labor market remained largely unchanged, precluding a marked increase in real wages [4].

In contrast, economists such as Marx and Ricardo emphasized the role of technological progress. Ricardo observed that the adoption of machinery would reduce labor demand. Building on Ricardo’s argument in his seminal work Capital, Marx further examined the consequences of technological advancement on workers, contending that as technology evolved, machines gradually supplanted human labor, thereby suppressing labor demand and leading to stagnation in real wage growth [5]. Nevertheless, contemporary perspectives suggest that technological progress does not necessarily diminish labor demand; on the contrary, it may generate new employment opportunities and, in turn, stimulate a broader increase in labor demand.

In 1954, W. Arthur Lewis proposed the dual-sector growth model, which can, to some extent, account for the emergence of Engels’ pause. In this model, an overpopulated economy is envisioned as comprising just two sectors: agriculture and industry. Because population pressures constrain the agricultural sector, surplus labor transitions from agriculture to industry. To accommodate this surplus labor, the industrial sector must expand its workforce, channeling capital primarily into enlarging production rather than raising wages. As surplus labor is gradually absorbed, the industrial sector continues to grow; its return on capital also increases, spurring further capital investment. This expansion persists until all surplus labor from agriculture is fully absorbed. During this phase, the industrial sector experiences rapid growth and rising per capita GDP, yet workers’ real wages remain stagnant—hence the so-called “Engels’ pause” [6].

However, Lewis’s model does not sufficiently account for the internal stratification of the working class, as it treats laborers as a homogeneous group of unskilled workers. In reality, during Britain’s Industrial Revolution, the labor market was markedly stratified between skilled and unskilled workers, each commanding substantially different wages. Consequently, Lewis’s dual-sector model considerably understates the heterogeneity of the labor force, thereby limiting its suitability for explaining the causes of Engels’ pause.

Building on a revised Solow growth model, R. C. Allen investigated “Engels’ pause” through the lenses of capital stock, labor-substitution elasticity, and the rate of return on capital. His findings suggest that, in Industrial Revolution–era Britain, the relatively low elasticity of substitution between capital and labor necessitated simultaneous increases in both for sustained economic growth. Moreover, the technological innovations of the time effectively functioned as an expanding labor force by enhancing worker productivity. As a result, firms prioritized enlarging their capital stocks to maintain continual growth [2].

Nevertheless, Allen also did not take into account the heterogeneity of labor or the changes in labor composition brought about by technological progress, thereby overlooking the far-reaching influence that technological advances can exert on labor market structures. However, this structural inequality in the labor market profoundly influenced wage levels in Britain.

With regard to “Engels’ pause,” Carl B. Frey proposes a new perspective based on technological progress. He classifies emerging technologies into two categories— “replacing technologies” and “enabling technologies.” During the First Industrial Revolution, before the 1850s, “replacing technologies” predominated: machines were deployed on a large scale, displacing workers and reducing labor demand, thereby causing stagnant wages and increased unemployment [7]. Nevertheless, as evidenced by a series of technological breakthroughs in the spinning segment of Britain’s cotton textile industry, the introduction and diffusion of new technologies affected different groups of workers in notably different ways. It would therefore be an oversimplification to conclude that new technologies merely suppressed labor demand and resulted in wage stagnation.

In view of these research limitations, this paper adopts the perspective of “employment-structure shifts brought about by technological innovation” to investigate whether an “Engels’ pause” emerged in the textile industry during this period and, if so, to elucidate its underlying causes. Building on these findings, the study then advances a new explanatory framework for the occurrence of “Engels’ pause.”

2. “Engels’ pause” in the cotton textile industry

To investigate whether an “Engels’ pause” occurred in Britain’s cotton textile industry during the Industrial Revolution, it is essential to examine wage levels among cotton textile workers from the early nineteenth century (the 1810s) through the 1830s. From the perspective of technological progress, the principal source of wage growth lies in the enhancement of worker productivity—namely, the increase in per capita output over a given time span. Under a piece-rate wage system, any additional income derived from higher productivity can compensate for losses caused by declining product prices, thereby allowing wages to continue rising [7].

In the spinning sector, a series of technological breakthroughs—including the spinning jenny, the water frame, and the spinning mule—dramatically elevated spinners’ productivity while substantially expanding overall output. By the time the self-acting mule came into widespread use, a spinner’s per-unit output was about eight times greater than that achieved with water frames; consequently, even though large-scale production drove down the price of cotton yarn, spinners’ wages continued to rise [8].

As successive technological advances took hold in the spinning sector, spinners’ per-unit output and wage levels both rose, thereby increasing the sector’s overall average wage. Nevertheless, comprehensive surveys of the early nineteenth-century cotton textile industry remain scarce, leading to a limited record of relevant wage data. To address this gap, the present study digitizes wage ledgers from Arkwright’s Lumford Mill and the Strutt family’s Belper Mill for the 1810s and 1830s, thereby creating a detailed dataset for further analysis.

Lumford Mill and Belper Mill were emblematic cotton-spinning factories of the Industrial Revolution, whose wage records provide a representative glimpse into the broader spinning sector of the period. Lumford Mill, founded by Arkwright in 1778 in Bakewell, Derbyshire, began as a water-powered spinning mill employing roughly 200 workers—later expanding to around 350 as production grew [9]. Belper Mill was established by Jedediah Strutt in 1776 in Belper, Derbyshire, and likewise relied on Arkwright’s water frame for spinning cotton yarn. After a fire in 1803 destroyed the original Belper North Mill, the Strutt family rebuilt it soon thereafter [10]. Initially, the new Belper North Mill continued to use the water frame, but by around 1815, maintenance records indicated a gradual transition to the spinning mule, marking a technological shift between approximately 1805 and 1815[11]. By comparing wage data from these two mills, it becomes possible to contrast wage levels and distributions under the water-frame era with those of the spinning-mule era.

Utilizing the Consumer Price Index data from the Office for National Statistics, this study calculates the real average wages at both mills for 1811 and 1835. Based on data from Arkwright’s Lumford Mill and the Strutt family’s Belper Mill, real average wages for workers increased by 32.29% over the 24-year period, corresponding to an annual growth rate of 1.19%. Specifically, male workers experienced a 39.52% increase (an annual rate of 1.38%), while female workers’ wages grew by 38.88% (an annual rate of approximately 1.35%). These findings indicate that both male and female employees in the spinning sector benefited from notable real wage gains. However, to ascertain whether an “Engels’ pause” had emerged during this period, it is essential to examine the growth rate of per capita productivity within the spinning industry over the same timeframe.

Method for Calculating Per Capita Productivity in the Textile Industry (as shown in equation 1):

\( {g_{lp}}={g_{y}}-{g_{l}} \) (1)

Previous studies have generally maintained that technological advances spurred rapid development and high expansion rates in the cotton spinning industry during the Industrial Revolution. However, Crafts and Harley challenged this view, suggesting that earlier scholarship may have overestimated the industry’s expansion. Their findings indicate that Britain’s cotton textile sector grew at an annual average rate of approximately 6.7% to 7% from the 1780s through the 1830s [12].

To accurately assess the developmental level of the cotton spinning industry during the Industrial Revolution, this study estimates the industry’s growth rate using raw cotton consumption data from 1811 to 1835. In 1811, Britain’s raw cotton consumption was approximately 900,000,000 pounds, rising to 364,000,000 pounds by 1835 [13]. According to Baines’s calculations, the spinning process resulted in a loss of about 1.5 ounces per pound of raw cotton—equating to a loss rate of roughly 9.38% [14]. Based on this estimate, Britain’s cotton yarn output was approximately 81,562,500 pounds in 1811 and increased to about 329,875,000 pounds by 1835. Over this 24-year period, yarn output expanded by 304.4%, which corresponds to an average annual growth rate of approximately 6.35%. Notably, this figure is lower than the growth rate estimated by Crafts and Harley. Nonetheless, an average annual rate of 6.35% clearly indicates a substantial expansion in Britain’s cotton spinning sector during the Industrial Revolution.

After establishing the cotton industry’s average annual growth rate, it is also necessary to determine the corresponding rate of workforce expansion within the same sector. Farnie, D. A. and other researchers estimated that, from 1815 to 1841, the labor force in Manchester and its surrounding areas involved in cotton textiles grew at an annual average rate of approximately 4.9% [15, 16]. However, as Manchester served as the epicenter of Britain’s cotton textile industry during the Industrial Revolution, its labor force expansion notably surpassed that of other regions. Consequently, Manchester’s growth rate does not accurately reflect the national average.

Accordingly, the present study reexamined the labor force growth rate in Britain’s cotton spinning industry. The analysis indicates that approximately 274,000 workers were employed in cotton spinning in 1806 [17], a figure that rose to 336,000 by 1820 and reached 691,300 by 1833 [14]. Based on these data, the annual average growth rate of the cotton spinning workforce between 1815 and 1834 is estimated at approximately 3.90%, significantly lower than the rate observed in Manchester.

Building on these findings, it is further estimated that between 1815 and 1841, labor productivity in Britain’s cotton textile industry increased at an annual rate of roughly 2.45%, amounting to a cumulative growth of 78.77% over the 24-year period from 1811 to 1835. In contrast, wage records from Lumford Mill and Belper Mill indicate that real average wages rose by only 32.29% during this period, revealing a substantial gap between productivity gains and wage growth. This discrepancy suggests that an “Engels’ pause” emerged within the spinning sector of Britain’s cotton textile industry during the Industrial Revolution.

3. Reasons behind the emergence of “engels’ pause” in the spinning sector

As the preceding analysis demonstrates, over the approximately 25-year span from the 1810s to the mid-1830s, real wage growth for workers engaged in the spinning process lagged significantly behind increases in labor productivity, indicating the emergence of an “Engels’ pause” within Britain’s cotton spinning sector. Accordingly, this section examines the factors contributing to this phenomenon.

Previously, it was noted that Belper Mill underwent a substantial technological transition between 1805 and 1815. By comparing the wage data from Lumford Mill in 1811 with that from Belper Mill in 1835, the specific impact of technological progress on workers’ wages becomes evident.

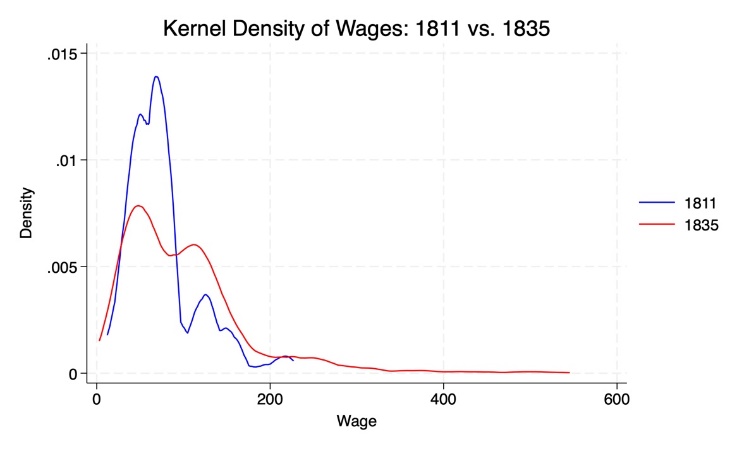

Figure 1. Kernel density estimates of wages for Lumford Mill (1811) and Belper Mill (1835)

Figure 1 illustrates that following technological advances, the wage distribution underwent a marked transformation. Notably, the density of low-income workers increased while that of medium-income workers declined sharply. In addition, wages in the high-income group increased to a certain extent, and an ultra–high-income cohort emerged. Consequently, the overall wage distribution became distinctly right-skewed, as evidenced by the increase in the skewness coefficient from 1.337733 at Lumford Mill in 1811 to 2.023547 at Belper Mill in 1835.

Table 1. Generalized entropy index for Lumford Mill (1811) and Belper Mill (1835)

Year | A(0.5) | A(1)(Theil) | A(2) |

1811 | 0.06728 | 0.13356 | 0.26794 |

1835 | 0.11124 | 0.21868 | 0.42865 |

The Generalized Entropy Index for the two periods indicates that, as technological progress unfolded, overall wage inequality intensified—a trend further compounded by the emergence of an ultra–high-income group (as shown in Table 1). Consequently, this study undertakes a detailed examination of wage trends across different income brackets.

Table 2. Changes in mean wages across different income groups (1811 vs. 1835)

Year | All | Median | Bottom 40% | Bottom 25% |

1811 | 75.569 | 46.088 | 41.779 | 35.023 |

1835 | 99.959 | 48.679 | 43.605 | 33.373 |

As Table 2 demonstrates, amid technological progress from 1811 to 1835, the real average wages of the spinning workforce in Britain’s cotton textile industry increased by 32.29% over the 24-year period. Nonetheless, while high-income earners experienced robust wage growth, lower-income segments—such as the bottom 25% and 40%—saw only modest increases or even slight declines. Specifically, the bottom 40% of earners recorded a real average wage increase of merely 4.37%, whereas the lowest 25% experienced a 4.71% decline in real average wages.

Table 3. Real average wages of the high-income group in Lumford Mill (1811) and Belper Mill (1835)

Year | Average Wage of Top 10% | Average Wage of Top 5% |

1811 | 168.062 | 184.379 |

1835 | 263.319 | 321.641 |

Growth Rate | 56.68% | 74.45% |

Annualized Growth Rate | 1.89% | 2.36% |

Compared with overall workers and lower-income earners, the high-income group at Lumford Mill and Belper Mill exhibited a markedly more pronounced rise in mean wages (as shown in Table 3). Specifically, the top 10% of earners experienced a 56.68% increase, while the top 5% saw an even larger rise of 74.45% over the 24-year period, corresponding to an average annual growth rate of 2.36%. Notably, the higher the wage level, the greater the increase—indeed, the wage growth rate among the top 5% closely approximates the 78.77% surge in labor productivity. In other words, the “Engels’ pause” phenomenon is far less evident among high-income earners.

These findings suggest that technological progress substantially boosted wages for the high-income group while exerting a relatively limited influence on the wages of lower-income workers, thereby exacerbating overall wage inequality. Consequently, the stagnation of wages within the lower-income cohort—driven by technological advancements—emerges as a key factor underlying the “Engels’ pause” in Britain’s cotton spinning sector, a point that the following discussion will examine in greater depth.

To further substantiate this argument, the following section examines changes in both wage levels and the employment scale among low-income workers at two critical junctures. To classify low-income workers in the spinning sector, it is essential to establish a wage threshold. However, prior to the Factory Inquiry Commission’s comprehensive report on Britain’s cotton textile industry in 1834, wage data for spinning sector workers were exceedingly scarce [18]. Nonetheless, an analysis of piecers’ average wages from the 1810s to the 1830s reveals that their earnings consistently remained at the lowest level without any significant increase, suggesting that even amid technological progress, wage growth for unskilled workers was relatively constrained [19]. Drawing on the period’s inflation rates and the average wage levels of piecers, this study adopts thresholds of 56.075 pence in 1811 and 88.235 pence in 1835 to designate workers earning below these figures as unskilled labor. Based on these thresholds, the real average wage and employment scale for the low-income group are subsequently calculated.

Table 4. Changes in average wages and proportion of low-income workers (1811 vs. 1835)

Year | Real average wage | Numbers | Total | Percentage |

1811 | 40.79548 | 86 | 226 | 38.0531 |

1835 | 48.83192 | 508 | 1006 | 50.49702 |

As shown in Table 4, the low-income group at Lumford Mill in 1811 had an average wage of 40.795 pence, comprising 86 workers and accounting for 38.05% of the total labor force. By 1835, at Belper Mill, the average wage for this group had increased modestly to 48.832 pence, and their numbers had expanded to 508, representing 50.50% of all workers. In effect, the share of low-income earners in the overall workforce rose by 12.45 percentage points from 1811 to 1835. In other words, while technological progress resulted in a slight increase in the real average wages of low-income workers, it also expanded their overall employment scale.

Regarding the wages of spinners—workers directly affected by technological progress—this study draws on the Royal Commission’s investigative reports, Britain’s commerce and manufacturing reports, and statistical data compiled by George Henry Wood [20, 21], while also accounting for the specific conditions at the two mills. In 1811, spinners at Lumford Mill earned an average weekly wage of 126.61 pence; by 1835, spinners at Belper Mill were earning an average weekly wage of 285.29 pence. Notably, the proportion of spinners within the overall labor force fell from 25.66% in 1811 to only 8.05% in 1835. These trends suggest that although technological progress substantially increased spinners’ average wages, the introduction and widespread adoption of new technologies also led to a dramatic reduction in spinner employment.

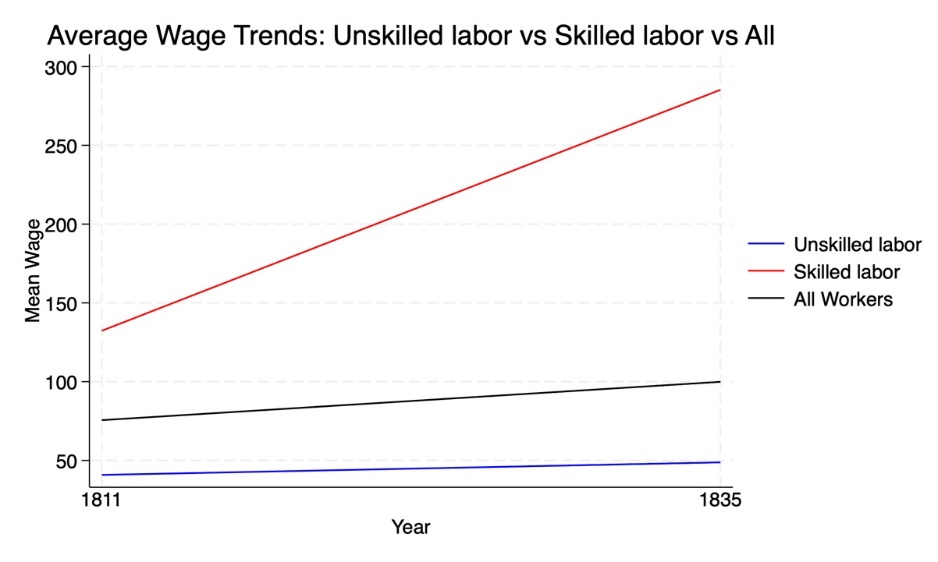

Figure 2. Changes in average wages across different income groups (1811 vs. 1835)

As illustrated in Figure 2, the wage trajectories of skilled labor, overall workers, and unskilled labor diverge markedly. The red line indicates that, driven by technological progress, the average wages of skilled labor increased rapidly, reaching 225.33% of their 1811 level by 1835. In contrast, unskilled labor experienced only modest wage increases, with average wages rising by just 19.70% over the same period. Moreover, the wage growth for overall workers more closely resembled that of unskilled labor, with an increase of 32.29% between 1811 and 1835.

According to these calculations, the overall wage trajectory of all workers closely mirrors that of the low-income group, exhibiting only a moderate upward trend. This phenomenon arises because overall average wages are influenced by high-, middle-, and low-income earners alike, and technological progress expanded the proportion of low-income workers, thereby amplifying their impact on the overall average. Although high-income workers experienced substantial wage growth, their relatively small numbers limited their effect on the aggregate wage level. Consequently, the overall wage pattern diverged markedly from that of high-earning spinners and largely paralleled the trend observed among low-income earners.

Based on the above findings, it is evident that as technological progress deepened, the continually increasing proportion of low-income workers exerted a progressively significant influence on overall average wages, with the extensive pool of low-earning labor effectively suppressing the average wage within the spinning sector. “Engels’ pause” specifically refers to the widening gap between the growth rates of real wages and labor productivity. To further elucidate this phenomenon, the following sections address two key questions: first, how technological advances affected per capita labor productivity, and second, why these advances ultimately led to an expansion of the low-income workforce within the spinning process.

First, an exploration of the transformation of production groups within Britain’s cotton-spinning sector during the Industrial Revolution is undertaken. As cotton-spinning technology advanced, the productivity of workers in the spinner segment increased significantly, prompting substantial changes in the organization of production groups. In the pre-industrial period, spinning was typically performed with a spinning wheel operated by a single spinner—most of whom were women supplying yarn to male weavers—thereby placing them in a subordinate position within the textile industry [22]. Beginning in the 1760s, however, the invention and diffusion of the spinning jenny markedly boosted spinner productivity and, consequently, their incomes, which in turn attracted men to the spinning sector. Nonetheless, because the spinning machinery of that era remained relatively small in scale, a single worker could manage all stages of production; thus, despite the notable gains in labor productivity achieved with the spinning jenny, the structure of production groups experienced only minimal change [23].

By the 1770s, Arkwright’s water frame had been introduced into the spinning sector and gradually adopted on a larger scale. Equipped with three pairs of rollers, the water frame automated tasks that were previously performed manually, such as drawing out cotton fibers [24]. This innovation not only enhanced spinner efficiency but also fundamentally transformed production methods within the spinning sector, marking the textile industry’s transition into its “great industry” phase [23]. To accommodate a factory-based mode of production and further improve efficiency, the tasks traditionally performed by spinners were subdivided. Skilled workers assumed primary responsibilities in the production process, while unskilled laborers performed auxiliary tasks and became subordinate to the skilled workers. This division of labor led to the emergence of a new role known as the “piecer.” During the water-frame era, each production group typically consisted of one spinner and one piecer.

In 1779, the invention of the spinning mule further enhanced spinner productivity. However, unlike the water frame, the spinning mule is an intermittent spinning machine that requires the spinner to manually push and pull the carriage to stretch and twist the yarn. During operation, significant friction and vibration, coupled with uneven tension on the roving, frequently resulted in thread breakage. Moreover, because the spinning mule accommodated many more spindles than its predecessors, the demand for piecers increased accordingly. Concurrently, ongoing improvements to the water frame led to progressively larger machines with additional spindles, prompting production groups in the spinning sector to expand from one piecer per spinner to two. In other words, although technological progress substantially boosted spinner productivity, the efficiency of unskilled auxiliary workers remained relatively low, necessitating an expansion of the piecer workforce to keep pace with the spinners’ rising output [25].

During the 1830s, the advent and widespread adoption of power-assisted spinning mules enabled a single spinner to operate two machines simultaneously, further enhancing productivity. Nonetheless, piecers and other unskilled workers did not experience significant improvements in productivity, which remained relatively low. Consequently, the demand for unskilled labor in the spinning sector persisted. In the era of the self-acting mule, a typical production group comprised one spinner and three to five piecers [26]. Among these, an adult piecer—often referred to as the “Master” or “Big piecer”—was responsible for supervising junior piecers, or “small piecers.” However, unlike the traditional notion of a master who formally employs or certifies apprentices [27], the big piecer did not assume such a role; moreover, being unskilled themselves, they could not facilitate the advancement of small piecers to skilled status. This arrangement effectively confined the small piecers to the unskilled sector [28].

During the first half of the nineteenth century, technological innovations in Britain’s cotton-spinning industry prompted an evolution in production groups, which subsequently reshaped the labor force structure within the spinning sector. As the industry transitioned from the water frame to the spinning mule, the mid-level income group gradually disappeared, while both low- and high-income segments expanded, leading to a marked polarization in the wage distribution. Notably, the proportion of low-income workers increased at an accelerated rate—a phenomenon attributable, as discussed above, to the growing number of piecers induced by technological progress. In other words, as technology advanced, structural changes in production groups widened wage disparities among workers, ultimately resulting in a distinctly right-skewed wage distribution.

Regarding labor productivity, spinners’ per capita output increased steadily alongside technological progress. In the 1770s, a single spinner produced 3.2 pounds of 24S yarn or 1.5 pounds of 40S yarn daily. By the 1790s, improvements to the water frame and hand mule had raised daily production to 5.8 pounds of 24S yarn or 5.3 pounds of 40S yarn per spinner. By the 1830s, the widespread adoption of power-assisted spinning mules enabled a single spinner to produce approximately 44.8 pounds of 40S yarn per day [8]. However, since the spinning sector typically operated through production groups that included piecers—who also participated in the spinning process—any assessment of per capita productivity changes must account for the evolving structure of these production teams during the Industrial Revolution.

Table 5. Changes in per capita labor productivity, 1770–1830

Year | Machine Type | Yarn Count | Labor Productivity (lbs per labor per day) |

1770 | Water frame | 24s | 1.6 |

Hand spinning mule | 40s | 0.75 | |

1790 | Water frame | 24s | 1.93 |

Hand spinning mule | 40s | 1.77 | |

1830 | Power spinning mule | 40s | 7.47~11.2 |

Resource: Compiled based on Peter Maw, Peter Solar, Aidan Kane, and John S. Lyons (2022), After the great inventions: technological change in UK cotton spinning, 1780–1835, Economic History Review, 75, 1, pp. 22–55, p44.

According to Table 5, per capita labor productivity increased substantially with technological advancements. For instance, during the hand-spinning mule era, the per capita output for each production group rose from 0.75 in the 1770s to 1.77 in the 1790s—a gain of approximately 136%. Although the water frame yielded a comparatively smaller improvement, it still achieved an increase of around 20.625% between the 1770s and the 1790s. By the 1830s, however, the widespread adoption of the power-spinning mule led to a dramatic rise in per capita labor productivity, which reached values between 7.47 and 11.2. This represents an increase of between 322.03% and 532.77% compared to the output levels of the hand-spinning mule era.

These findings indicate that per capita labor productivity in the spinning sector surged dramatically with technological progress, particularly after the introduction of the power-spinning mule, which multiplied productivity several-fold compared to the era of manual equipment. In principle, wages should exhibit a positive correlation with labor productivity; yet wage data from Lumford Mill and Belper Mill reveal that average wage growth lagged noticeably behind productivity gains. This divergence can be attributed to the fact that, while wage increases among spinners partially reflected enhancements in per capita productivity, the large-scale expansion of low-income piecer employment constrained the overall rise in real average wages—ultimately contributing to the “Engels’ pause” observed in the spinning sector.

Meanwhile, a noticeable gap emerged between spinners’ wages and the growth in per capita labor productivity. This divergence can be attributed to the rapid increase in yarn output resulting from the adoption and diffusion of new technologies, which led to a dramatic drop in cotton yarn prices. For instance, in 1805, the price of 40-count yarn was 39 pence; by 1825, it had fallen to roughly half that level [29]. Furthermore, contemporary production cost data indicate that the revenue generated from producing one pound of cotton yarn was 9 shillings in 1784, but by 1832, it had declined to 0.4 shillings. During the same period, the price of raw cotton decreased from 2 shillings to 0.6 shillings—a significant decline, though less steep than that observed for yarn [30]. These trends suggest that technological progress substantially reduced labor costs. Consequently, with the adoption of new technology, the remuneration that spinners received per pound of cotton yarn declined markedly.

These findings indicate that the emergence of the “Engels’ pause” in the spinning sector can be attributed to two main factors. First, while technological progress substantially increased spinners’ labor productivity, it also necessitated a marked expansion in the employment of low-wage piecers to accommodate the higher output levels [31]. Specifically, the relatively small group of spinners experienced significant productivity gains, whereas the much larger cohort of piecers, largely unaffected by these technological changes, showed only minimal improvements in productivity. Moreover, they were generally paid a fixed wage, which meant that their earnings did not adequately reflect increases in average labor productivity [32]. As employers sought to manage the increased output from spinners, they were compelled to hire more piecers—a surge in low-wage labor that effectively constrained the overall rise in real average wages.

Second, the advent of mass production in cotton yarn precipitated a rapid decline in unit prices, leading to a substantial drop in per-unit production income. Consequently, the gap between the steep productivity gains of spinners and their comparatively modest wage increases widened, thereby affecting the overall growth rates of labor productivity and wages in the spinning sector.

As discussed above, these technological advancements—by driving structural shifts in the labor force and altering unit returns to production—culminated in the “Engels’ pause” phenomenon.

4. Conclusion

This study focuses on Britain’s cotton-spinning sector from the early nineteenth century (the 1810s) to the 1830s, examining its wage structure and labor composition. Drawing on the research of R. C. Allen and Carl B. Frey on the “Engels’ pause” and incorporating Frey’s typology of technological progress, the study employs wage ledgers from Lumford Mill and Belper Mill to investigate why the “Engels’ pause” emerged in the spinning sector of the cotton industry during the Industrial Revolution.

The findings indicate that during the transition from the water frame to the spinning mule, Britain’s cotton-spinning industry had to expand its employment of low-productivity workers—specifically, piecers—in order to fully leverage the rising labor productivity of spinners. Although the large number of low-productivity, low-wage workers exerted downward pressure on both average wages and overall labor productivity, the synergistic effect of the highly productive spinners drove aggregate labor productivity significantly upward. In other words, within the spinning sector, a relatively small group of spinners plays a dominant role in production; their substantial productivity gains have a more pronounced effect on raising overall productivity than their high wages do on lifting the overall wage level. At the same time, the expanding employment of low-income workers exerts considerable downward pressure on average wages, outweighing the effect of their low productivity on overall labor productivity.

Moreover, as technological progress facilitated large-scale production, the per-unit return on output declined, thereby further widening the gap between the growth rates of average wages and average labor productivity. Under these conditions, the wage distribution and labor structure in the spinning sector evolved such that average labor productivity increased at a faster pace than wages, ultimately giving rise to the “Engels’ pause.” Nevertheless, continued technological advancements and broader industrial development eventually led to increased capital intensity throughout the industry, which in turn raised the average wage for the entire workforce and allowed labor productivity and wages to grow in tandem. This development explains how Britain gradually emerged from the “Engels’ pause” after the 1870s [2].

Previous studies have tended to focus on the intrinsic nature of technological progress, emphasizing that certain types of innovation directly lead to the “Engels’ pause.” In contrast, the present study demonstrates that technological progress in labor-intensive industries can also trigger the “Engels’ pause,” thereby addressing a notable gap in earlier research. However, the discussion here is confined to the “Engels’ pause” as observed in labor-intensive sectors represented by the spinning industry. It does not adequately address the phenomenon in other industries, nor does it thoroughly explore the mechanisms by which Britain eventually emerged from the “Engels’ pause” after the 1870s. These issues warrant further investigation in subsequent research

References

[1]. Engels, F. (1845). Die Lage der arbeitenden Klasse. Leipzig: Otto Wigand.

[2]. Allen, R. C. (2009b). Engels’ pause: Technical change, capital accumulation, and inequality in the British industrial revolution. Explorations in Economic History, 46(4), 418-435.

[3]. Malthus, T. (2023). An essay on the principle of population. In British Politics and the Environment in the Long Nineteenth Century (pp. 77-84). Routledge.

[4]. O’Rourke, K. H., & Williamson, J. G. (2005). From Malthus to Ohlin: Trade, industrialisation and distribution since 1500. Journal of Economic Growth, 10, 5-34.

[5]. Marx, K. (2024). Capital: Critique of Political Economy, Volume 1. Princeton University Press.

[6]. Lewis, W. A. (1954). Economic development with unlimited supplies of labour.

[7]. Frey, C. B. (2019). The technology trap: Capital, labor, and power in the age of automation. In The technology trap. Princeton University Press.

[8]. Maw, P., Solar, P., Kane, A., & Lyons, J. S. (2022). After the great inventions: Technological change in UK cotton spinning, 1780–1835. The Economic History Review, 75(1), 22-55.

[9]. Tertzakian, A. (2022). Wages, employment, and technological change in English cotton spinning, c. 1780-1850.

[10]. Fitton, R. S., & Wadsworth, A. P. (1958). The Strutts and the Arkwrights, 1758-1830: A study of the early factory system. Manchester University Press.

[11]. Rees, A. (1819). The cyclopaedia; or, Universal dictionary of arts, sciences, and literature. London Longman, Hurst, Rees, Orme & Brown.

[12]. Crafts, N. F., & Harley, C. K. (1992). Output growth and the British industrial revolution: A restatement of the Crafts-Harley view. Economic History Review, 703-730.

[13]. Knight, C. (1860). The English cyclopaedia, a new dictionary of universal knowledge. (Vol. 3). London: Bradbury and Evans.

[14]. Baines, E. (1835). History of the cotton manufacture in Great Britain. H. Fisher, R. Fisher, and P. Jackson.

[15]. Williams, M., & Farnie, D. A. (1992). Cotton mills in Greater Manchester.

[16]. Galbi, D. A. (1997). Child labor and the division of labor in the early English cotton mills. Journal of Population Economics, 10, 357-375.

[17]. Acemoglu, D., & Johnson, S. (2024). Learning from Ricardo and Thompson: Machinery and Labor in the Early Industrial Revolution, and in the Age of AI.

[18]. Factories Inquiry Commission: Supplementary Report of the Central Board of H. Maj. Commissioners Appointed to Collect Information in the Manufacturing Districts, as to the Employment of Children in Factories, and as to the Propriety and Means of Curtailing the Hours of Their Labour; Ordered to be Printed 25 March 1834. (1834).

[19]. Great Britain. (1812). An abstract of the evidence lately taken in the House of Commons, against the orders in Council: being a summary of the facts there proved: respecting the present state of the commerce and manufacturers of the country. J. M'Creery.

[20]. Wood, G. H. (1910). The History of Wages in the Cotton Trade During the Past Hundred Years (Vol. 30647). Sherratt and Hughes.

[21]. Chapman, S. J. (1904). The Lancashire cotton industry: a study in economic development. University Press.

[22]. Tertzakian, A. (2025). The Creation of a Gendered Division of Labor in Mule Spinning: Evidence from Samuel Oldknow, 1788–1792. Enterprise & Society, 26(1), 144-169.

[23]. Allen, R. C. (2009a). The British industrial revolution in global perspective. Cambridge University Press.

[24]. McNeil, I. (2002). An encyclopedia of the history of technology. Routledge.

[25]. Freifeld, M. (1986). Technological change and the ‘self‐acting’mule: A study of skill and the sexual division of labour. Social History, 11(3), 319-343.

[26]. Takei, Y. (2003). Child and juvenile labour in the English cotton industry. The Shakaikeizaishigaku, 69(4), 435-455.

[27]. Oohashi, S. (1953). Guilds and the Apprenticeship System in Late Medieval England. The Journal of Educational Sociology, 4, 28-38.

[28]. Yoshida, K. (1979). A Study on the Late 19th-Century British Cotton Industry: Focusing on the Brooklands Agreement. The Journal of the Junior College, Meiji University, 25, 1-25.

[29]. Broadberry, S., & Gupta, B. (2005). Cotton textiles and the great divergence: Lancashire, India and shifting competitive advantage, 1600-1850.

[30]. Clark, G. (2005). The British Industrial Revolution, 1760-1860. World Economic History, 1-65.

[31]. Scott, A. J. (2006). The changing global geography of low-technology, labor-intensive industry: clothing, footwear, and furniture. World Development, 34(9), 1517-1536.

[32]. Uni, H. (2015). Transformation of Labor Process and Changes in Fairness Ideals: An Experimental Approach. Japan Society of Political Economy, 52(2), 77-87.

Cite this article

Ge,B. (2025). Technological progress in the spinning sector of Britain’s cotton industry during the Industrial Revolution and the “Engels’ pause”. Journal of Applied Economics and Policy Studies,18(4),8-16.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Journal:Journal of Applied Economics and Policy Studies

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Engels, F. (1845). Die Lage der arbeitenden Klasse. Leipzig: Otto Wigand.

[2]. Allen, R. C. (2009b). Engels’ pause: Technical change, capital accumulation, and inequality in the British industrial revolution. Explorations in Economic History, 46(4), 418-435.

[3]. Malthus, T. (2023). An essay on the principle of population. In British Politics and the Environment in the Long Nineteenth Century (pp. 77-84). Routledge.

[4]. O’Rourke, K. H., & Williamson, J. G. (2005). From Malthus to Ohlin: Trade, industrialisation and distribution since 1500. Journal of Economic Growth, 10, 5-34.

[5]. Marx, K. (2024). Capital: Critique of Political Economy, Volume 1. Princeton University Press.

[6]. Lewis, W. A. (1954). Economic development with unlimited supplies of labour.

[7]. Frey, C. B. (2019). The technology trap: Capital, labor, and power in the age of automation. In The technology trap. Princeton University Press.

[8]. Maw, P., Solar, P., Kane, A., & Lyons, J. S. (2022). After the great inventions: Technological change in UK cotton spinning, 1780–1835. The Economic History Review, 75(1), 22-55.

[9]. Tertzakian, A. (2022). Wages, employment, and technological change in English cotton spinning, c. 1780-1850.

[10]. Fitton, R. S., & Wadsworth, A. P. (1958). The Strutts and the Arkwrights, 1758-1830: A study of the early factory system. Manchester University Press.

[11]. Rees, A. (1819). The cyclopaedia; or, Universal dictionary of arts, sciences, and literature. London Longman, Hurst, Rees, Orme & Brown.

[12]. Crafts, N. F., & Harley, C. K. (1992). Output growth and the British industrial revolution: A restatement of the Crafts-Harley view. Economic History Review, 703-730.

[13]. Knight, C. (1860). The English cyclopaedia, a new dictionary of universal knowledge. (Vol. 3). London: Bradbury and Evans.

[14]. Baines, E. (1835). History of the cotton manufacture in Great Britain. H. Fisher, R. Fisher, and P. Jackson.

[15]. Williams, M., & Farnie, D. A. (1992). Cotton mills in Greater Manchester.

[16]. Galbi, D. A. (1997). Child labor and the division of labor in the early English cotton mills. Journal of Population Economics, 10, 357-375.

[17]. Acemoglu, D., & Johnson, S. (2024). Learning from Ricardo and Thompson: Machinery and Labor in the Early Industrial Revolution, and in the Age of AI.

[18]. Factories Inquiry Commission: Supplementary Report of the Central Board of H. Maj. Commissioners Appointed to Collect Information in the Manufacturing Districts, as to the Employment of Children in Factories, and as to the Propriety and Means of Curtailing the Hours of Their Labour; Ordered to be Printed 25 March 1834. (1834).

[19]. Great Britain. (1812). An abstract of the evidence lately taken in the House of Commons, against the orders in Council: being a summary of the facts there proved: respecting the present state of the commerce and manufacturers of the country. J. M'Creery.

[20]. Wood, G. H. (1910). The History of Wages in the Cotton Trade During the Past Hundred Years (Vol. 30647). Sherratt and Hughes.

[21]. Chapman, S. J. (1904). The Lancashire cotton industry: a study in economic development. University Press.

[22]. Tertzakian, A. (2025). The Creation of a Gendered Division of Labor in Mule Spinning: Evidence from Samuel Oldknow, 1788–1792. Enterprise & Society, 26(1), 144-169.

[23]. Allen, R. C. (2009a). The British industrial revolution in global perspective. Cambridge University Press.

[24]. McNeil, I. (2002). An encyclopedia of the history of technology. Routledge.

[25]. Freifeld, M. (1986). Technological change and the ‘self‐acting’mule: A study of skill and the sexual division of labour. Social History, 11(3), 319-343.

[26]. Takei, Y. (2003). Child and juvenile labour in the English cotton industry. The Shakaikeizaishigaku, 69(4), 435-455.

[27]. Oohashi, S. (1953). Guilds and the Apprenticeship System in Late Medieval England. The Journal of Educational Sociology, 4, 28-38.

[28]. Yoshida, K. (1979). A Study on the Late 19th-Century British Cotton Industry: Focusing on the Brooklands Agreement. The Journal of the Junior College, Meiji University, 25, 1-25.

[29]. Broadberry, S., & Gupta, B. (2005). Cotton textiles and the great divergence: Lancashire, India and shifting competitive advantage, 1600-1850.

[30]. Clark, G. (2005). The British Industrial Revolution, 1760-1860. World Economic History, 1-65.

[31]. Scott, A. J. (2006). The changing global geography of low-technology, labor-intensive industry: clothing, footwear, and furniture. World Development, 34(9), 1517-1536.

[32]. Uni, H. (2015). Transformation of Labor Process and Changes in Fairness Ideals: An Experimental Approach. Japan Society of Political Economy, 52(2), 77-87.