1. Introduction

Flexible pressure sensors possess several advantageous properties, such as transparency, flexibility, malleability, portability, and wearability, which make them suitable for various applications. They can be bent, folded, or shaped according to the user's preferences. They are well-suited for safety systems, rehabilitation, computer interfaces, music interfaces, servo motors, and strength control. These sensors can monitor several critical physical parameters, including body temperature, heart rate, and respiratory rate. Additionally, they have the potential to improve golf swings, detect walking patterns in elderly patients, and identify signs of Parkinson's disease or multiple sclerosis. Compared to other pressure sensors, such as capacitive and piezoelectric sensors, flexible pressure sensors do not require complex sensor structures and have low power consumption, a wide range of test pressures, and a simple manufacturing process. These sensors can be used in various applications, including medical examinations, sealing inspections, and physical exercise. Commercial products are already available on the market, such as intelligent clothes that can monitor the heartbeat through changes in electrical resistance to prevent heart diseases.

2. Mechanisms of Several Flexible Pressure Sensors

The pressure sensor is a device that can sense pressure signals and convert them into usable output electrical signals according to a specific pattern. Pressure is force per unit area applied in a direction perpendicular to the surface of an object. The formula is commonly written as follows:

\( P=\frac{F}{A} \) (1)

Pressure, denoted as P, is the force F exerted per unit area A of the surface of contact when two objects come into contact and exert force on each other [1]. Pressure sensors typically consist of pressure-sensitive components and signal-processing units. Based on the working principles and types of test pressure, pressure sensors can be divided into several categories that are widely used in industrial applications such as water conservancy and hydropower, railway transportation, intelligent buildings, production automation, aerospace, military, petrochemicals, oil wells, power generation, ships, machine tools, pipelines, and many other industries.

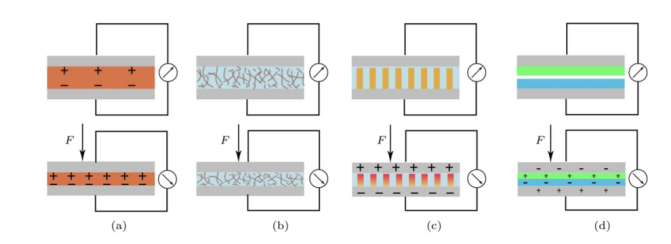

Flexible pressure sensors can be classified into four types based on sensing principles: capacitive, resistive, piezoelectric, and frictional [2]. These sensors generally consist of two layers of flexible electrodes and a functional soft material in the middle. The following section provides a detailed overview of these sensing principles.

Figure 1. Different kinds of pressure sensors: (a) Capacitive pressure sensor; (b) resistive pressure sensor, (c) piezoelectric pressure sensor; (d) triboelectric pressure sensor [2].

2.1. Capacitive pressure sensor

Capacitive pressure sensors are generally composed of electrodes and dielectric layers and belong to a type of parallel plate capacitor. Its capacitance value is

\( C=\frac{εA}{d} \) (2)

where C is capacitance, A is the area of plates, and d is the distance between the capacitor plates. ε is the permittivity of the insulator between capacitor plates.

Capacitive pressure sensors can detect static forces and offer advantages such as low energy consumption, slight signal drift, and high response repeatability [3]. The dielectric layer is crucial in optimizing capacitive pressure sensors' sensitivity and pressure response range. Without any particular structure, the sensitivity of the device is very low due to the non-compressibility of soft materials. However, introducing unique microstructures such as spherical, columnar, or conical shapes, adding a second phase, using highly elastic fabrics, introducing air gaps, or creating porous foam from dielectric materials can significantly enhance the sensitivity of capacitive pressure sensors.

2.2. Resistance-type pressure sensor

A resistive pressure sensor converts pressure changes into changes in resistance or current. According to the definition of resistance:

\( R=\frac{ρL}{A} \) (3)

ρ is the resistivity, L is the length, and A is the cross-sectional area. Its simple sensing mechanism, simple structure and preparation process, and low energy consumption have attracted widespread attention from researchers.

Resistance-type pressure sensors are generally composed of a substrate and conductive materials. The substrate typically uses elastomers, such as polyethylene terephthalate, for good flexibility and stretchability. Conductive materials have specific conductivity and need to be sensitive to pressure changes. The changes in resistance can be summarized as the following factors: changes in the shape and structure of materials. Structural deformation can lead to changes in length L and cross-sectional area A, The change in contact resistance between two materials, and the difference in the spacing of conductive phases inside the composite material.

2.3. Piezoelectric pressure sensors

The piezoelectric pressure sensor is capable of converting pressure signals into voltage signals, utilizing the piezoelectricity of materials. The piezoelectric constant, known as d33, is the most critical parameter that describes the piezoelectric properties of these materials. It reflects their ability to convert mechanical energy into electrical energy. Generally, the larger the d33, the better the piezoelectric performance of the material. This type of sensor can generate an internal voltage when subjected to pressure, and the magnitude of this voltage is proportional to the strain, making it highly suitable for use in passive pressure sensors. Piezoelectric pressure sensors exhibit excellent performance in measuring dynamic forces, with response times that can reach the microsecond level. However, measuring static forces can be challenging. Piezoelectricity may occur in crystals with anisotropic cells or in areas with different charges in the electret.

2.4. Friction electric pressure sensor

Friction electric pressure sensors were developed after the first three types of sensors. Unlike resistive and capacitive sensors, they do not require a power supply. Moreover, they offer a broader range of materials compared to piezoelectric sensors. These sensors work on frictional electrification and have several advantages, such as low cost, simple preparation process, and high output voltage. Typically, they comprise two electrodes with different materials for generating frictional electricity. An air layer is present between the two material layers. When pressure is applied, the two materials with varying sequences of charging come into contact, resulting in various electrical phenomena due to friction. This generates opposite charges on both sides of the contact interface. When the pressure is released, the two surfaces having the same amount of opposite directions automatically separate, and compensation charges are produced on the electrode surface due to electrostatic induction. The air layer between materials prevents the complete neutralization of leaders on both characters, generating a potential difference. This mechanism enables frictional electric pressure sensors to produce electrical signals upon applying and releasing pressure.

3. Flexible Pressure Sensor for Human-Machine Interaction

With the collaborative development of artificial intelligence and nano-materials, the research on flexible sensors is gradually moving towards practical applications. Flexible sensors can be applied in electronic skin perception and health detection. On the one hand, people pay more and more attention to their health status, and the demand for their health monitoring is becoming increasingly evident, including real-time monitoring of human movement behavior, heart rate and respiratory rate, pulse, and blood pressure. On the other hand, sensors can be used to build electronic skin to help people with disabilities recover the perception lost in accidents or to make robotic bionic skin [4]. The flexible piezo-resistive pressure sensor is indispensable to electronic skin perception and health monitoring. Using sandpaper as a template, a flexible PDMS(polydimethylsiloxane) base is prepared to mimic the function of natural skin. A new two-dimensional material MXene, is used as the sensing layer to obtain a device with excellent sensitivity. It can sense the robot's movement, while the device attached to the throat can measure the swallowing action, and connected to the pulse can measure the pulse and count the bending of the finger and wrist. The sub-devices are integrated into clothing or directly attached to the human skin. They measure other body parameters, including minimal skin deformations such as breathing and heartbeat [5].

Through such integrated devices, wearable electronic sensors can collect the physiological parameters of the human body. A flexible piezo-resistive pressure sensor with good stability and high peak signal-to-noise ratio was prepared using graphene as the active sensing layer [6]. At the same time, a high-precision wireless wearable pulse monitoring system is established, which can accurately collect the very weak real-time pulse signal of the human body in the state of walking or running. The wearable system is expected to provide more prosperous and accurate information for personalized health monitoring and be applied in medical diagnosis.

With the rise of modern competitive sports, the movement data collected by sensors can provide real-time physiological status and exercise effect feedback for athletes. For example, the device can be installed on the table tennis table for statistics and identification of the ball's impact speed, falling position, falling order, and the probability of dropping point, or it can be placed on the top and side of the table for detection and judgment of the edge ball. In addition, golf, baseball, and other projects also have the same digital sports applications. These studies show that it can be used as an alternative strategy to high-cost, bulky high-speed cameras.

With the aging of the population and the increasing need for children's care, flexible pressure sensors in the form of electronic skin or integrated into intelligent clothing, based on the monitoring of blood pressure, pulse, heartbeat, breathing, tremor, body movement, and other signals, as well as texture discrimination, braille tactile perception and other functions, have played an increasingly important role in patient health monitoring and disease prevention.

4. Flexible Capacitive Sensors

The definition of a capacitive sensor is that the capacitance reacts differently to the external environment. The standard capacitive sensors are parallel plate capacitors, separated mainly by an insulated dielectric layer between the upper and lower conductive electrodes.

The capacitance of a system is influenced by three significant factors: the relative area (A) of the conductive electrodes, the distance (d) between the plates, and the relative dielectric constant (ε) of the dielectric layer. When an external mechanical force is applied to the system, it causes a change in the geometric shape of the plates, leading to a corresponding change in capacitance. This type of capacitor is called a variable area and distance capacitor. Another type of capacitor is the variable dielectric constant capacitor, which experiences changes in dielectric constant due to alterations in the network between the dielectrics caused by changes in distance (d).

A flexible capacitance sensor is a sensing element with controllable parameters, which is usually closely related to wearable smart devices and human-computer interaction [7]. Sensitivity is the decisive factor for its application and development. Flexible sensors have many advantages over rigid sensors, such as higher flexibility, resolution, and faster response speed [8], making them excellent application prospects and commercial value in wearable electronic products.

Improving the sensitivity of flexible capacitance sensors is the key to research. Exploration of microstructures will significantly improve the problem of low sensitivity, improving the linear sensing range, shortening the response time, and enhancing durability. Currently, the primary microstructures [9] are porous sponge structure, array elastic structure, yarn structure, surface structure [10], microslot pattern elastic structure, sandwich structure, etc. Different systems have their advantages and disadvantages. How to learn from each other's strengths is the current research focus. For example, the array microstructure's pyramid structure [11] can effectively increase the sensor's sensitivity. Still, its application cost needs to be lowered, resulting in excessive investment in mass production, and people do not favor the application prospect.

There is a unique realization mechanism and manufacturing strategy to improve sensitivity. Micropatterns, porous fiber networks, and multiple microstructures are mainly used. For example, the special surface micropattern of the lotus leaf is used as an electrode template, and then the polystyrene microsphere is used as a dielectric layer. The resulting component has high stability and strong sensing performance. In addition, flexible capacitance sensors can be applied to pressure, tensile force, bending force, and other aspects. Research shows that the proposed capacitive tactile sensor is a promising candidate for application in health care detection, intelligent identification and security, augmented reality, and virtual reality.

Electrostatic spinning is a kind of porous nanofiber membrane technology. Due to the low Young's modulus of the fiber structure, slight pressure can lead to large compression deformation. High-length-diameter ratio carbon nanotubes are primarily used in producing sensors due to their high electrical conductivity and good mechanical properties. Researchers have invented a high-sensitivity flexible capacitive pressure sensor based on electrostatic spinning polydifluoroethylene and nanofiber membranes with carbon nanotubes. The sensor contains a flexible film coated with two layers on the top and bottom. This kind of electrospun nanofiber film can solve the shortcomings of Young's modulus elastomers of materials in capacitive sensors and avoid the problem of high contact resistance and uneven distribution of conductive filters in piezoresistive sensors. In addition, the researchers also studied whether the sensor would be affected by temperature and humidity. The sensor's performance is verified using sensor films of various thicknesses and carbon nanotubes with different additives and is committed to creating sensors with excellent performance.

The flexible capacitance sensor converts pressure stimulation into electrical signals, which can achieve more effective and intuitive seamless operation. At the same time, it has mechanical flexibility and stretchability, can collect human physiological and peripheral signals in real-time, and can quantify human perception. It can make the machine have specific perceptions from different inspirations and detect chemical, biological, and physical signs.

In summary, flexible capacitive sensors can achieve breakthroughs such as more robust perception accuracy, more comfort, more biocompatibility, feedback signal visualization, etc., and will attract widespread attention.

5. Conclusion

A pressure sensor is designed to detect and convert pressure signals into usable output signals using specific methods. These sensors typically consist of pressure-sensitive components and signal-processing units. Different pressure sensors are available to suit various testing requirements, allowing them to be utilized under diverse working conditions. Due to their versatility, pressure sensors are frequently used in industrial applications and commonly found in various industrial and commercial modules.

A flexible capacitance sensor is a sensing element with controllable parameters, which is usually closely related to wearable smart devices and human-computer interaction. Sensitivity is the decisive factor in its application and development. Compared with rigid sensors, flexible sensors have many advantages, such as higher flexibility, resolution, and faster response speed. They have excellent application prospects and commercial value in wearable electronic products.

Improving the sensitivity of flexible capacitance sensors is the key to research. The exploration of microstructures will significantly enhance the low-sensitivity problem. Different-density microstructures have different effects on sensor sensitivity, and it is found that high-density microstructures have higher sensitivity. The preparation cost of flexible pressure sensors is very high, and there is still considerable progress in the assembly, layout, integration, and packaging technology of flexible pressure sensors. Different structures have their advantages and disadvantages. How to learn from each other's strengths is the current research focus.

In a word, pressure and flexible capacitive sensors have massive room for development, such as more robust perception accuracy, higher comfort, higher biocompatibility, feedback signal visualization, etc.

Acknowledgment

These authors contributed equally.

References

[1]. Yaping Zang , Fengjiao Zhang,Chong-an Di and Daoben Zhu, “Advances of flexible pressure sensors toward artificial intelligence and health care applications,” Materials Horizons, pp.140-156.October 2014.(references)

[2]. Hou Xing-Yu, Guo Chuan-Fei. Sensing mechanisms and applications of flexible pressure sensors. Acta Phys. Sin., 2020, 69(17): 178102. doi: 10.7498/aps.69.20200987

[3]. Fenlan Xu,Xiuyan Li and so on, “Recent Developments for Flexible Pressure Sensors: A Review,” A:Physics, November 2018.

[4]. Wang Y, Chen J, Mei D 2020 Sens. Actuators, A. 307 111972

[5]. Shi Q, Zhang Z, Chen T, Lee C 2019 Nano Energy 62 355

[6]. Hammock M L, Chortos A, Tee B C, Tok J B, Bao Z 2013 Adv. Mater. 25 5997

[7]. Mao R, Yao W, Qadir A, Chen W, Gao W, Xu Y, Hu H 2020 Sens. Actuators, A. 312 112144

[8]. Xuelong Wang “Microstructured flexible capacitive sensor with high sensitivity based on carbon fiber-filled conductive silicon rubber”

[9]. Xihua Cui.“Flexible pressure sensors via engineering microstructures for wearable human-machine interaction and health monitoring applications” 2022 Apr15 DOI:10.13250/j.cnki.wndz.2021.12.001

[10]. Min Su “Textile-Based Flexible Capacitive Pressure Sensors: A Review”

[11]. Faliang He“Recent Progress in Flexible Microstructural Pressure Sensors toward Human–Machine Interaction and Healthcare Applications”18 June 2021

Cite this article

Huang,D.;Zhu,W.;Zhao,H. (2024). Flexible capacitive pressure sensors and their applications in human-machine interactions. Applied and Computational Engineering,35,253-258.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2023 International Conference on Machine Learning and Automation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Yaping Zang , Fengjiao Zhang,Chong-an Di and Daoben Zhu, “Advances of flexible pressure sensors toward artificial intelligence and health care applications,” Materials Horizons, pp.140-156.October 2014.(references)

[2]. Hou Xing-Yu, Guo Chuan-Fei. Sensing mechanisms and applications of flexible pressure sensors. Acta Phys. Sin., 2020, 69(17): 178102. doi: 10.7498/aps.69.20200987

[3]. Fenlan Xu,Xiuyan Li and so on, “Recent Developments for Flexible Pressure Sensors: A Review,” A:Physics, November 2018.

[4]. Wang Y, Chen J, Mei D 2020 Sens. Actuators, A. 307 111972

[5]. Shi Q, Zhang Z, Chen T, Lee C 2019 Nano Energy 62 355

[6]. Hammock M L, Chortos A, Tee B C, Tok J B, Bao Z 2013 Adv. Mater. 25 5997

[7]. Mao R, Yao W, Qadir A, Chen W, Gao W, Xu Y, Hu H 2020 Sens. Actuators, A. 312 112144

[8]. Xuelong Wang “Microstructured flexible capacitive sensor with high sensitivity based on carbon fiber-filled conductive silicon rubber”

[9]. Xihua Cui.“Flexible pressure sensors via engineering microstructures for wearable human-machine interaction and health monitoring applications” 2022 Apr15 DOI:10.13250/j.cnki.wndz.2021.12.001

[10]. Min Su “Textile-Based Flexible Capacitive Pressure Sensors: A Review”

[11]. Faliang He“Recent Progress in Flexible Microstructural Pressure Sensors toward Human–Machine Interaction and Healthcare Applications”18 June 2021