1. Introduction

Grasping is the basis and prerequisite for manipulation and is the first step in interacting with other entities. For robots, using end effectors to grasp is a fundamental function which requires great precision and dexterity. In order to achieve this purpose, manipulators are designed according to the structure of the human hand. In this article, the words “robotic hand” is used to indicate such robotic end effectors which aim to achieve this goal.

Traditional robotic hands for grasping consist of rigid joints and links, mostly actuated by electric motors. They require proprioceptive sensors to collect the velocity and position of the robotic hand and exteroceptive sensors to estimate the state of the target object [1]. When a rigid robotic hand attempts to grasp an object, the first step is to obtain in advance the position and size of the target object. Then the complex algorithms calculate the force, angle, and velocity required by each rigid component [2]. However, if a soft robotic hand is applied, this complex calculation process can be greatly simplified, because the soft robotic hand has better compliance with objects, and does not need to precisely control the gripping force to prevent the object from being damaged like a rigid robotic hand [3].

The compliance of the soft hand not only simplifies the control of the gripping process, but also enables it to handle soft, fragile and easily deformable objects. The soft hand-shaped bionic parts adapt well to a variety of gripping styles while preventing damage to objects. Therefore, the compliance of soft hands makes them have a wider range of uses, especially for interaction with living organisms like fruits and human body [4].

Due to the compliance of the soft material, the actuators are also different from traditional robotic hands. Traditional robotic hands have two different actuating methods: fully actuation and underactuation (i.e., having less number of actuators than degrees of freedom). The two methods both have advantages and disadvantages [5]. Fully actuation enables the robot hands to execute commands more precisely but requires a large number of drives, while underactuation enables the robot to be more adaptable, but it is not easy to complete complex operations. As contrast, underactuation is more capable for soft robotic hands, since it can allow them to adapt to the shape of objects without active control of position, making full use of the advantages of the good compliance of soft materials. As underactuation is applied, the number of the actuators is greatly reduced. Therefore, different kinds of actuation can be used in the soft robotic hands, such as tendon-driven and soft pneumatic actuators (also referred to as fluidic elastomer actuators) [6].

Tendon-driven actuators and soft pneumatic actuators are two widely used types of actuators, which have their own advantages and limitations. This article focuses on tendon-driven and soft pneumatic actuators due to their simple structure and cost-effectivity. In the following part, two specific designs are introduced and compared in terms of actuation and structural design, through which a clearer understanding can emerge, contributing to a better selection of actuating methods for future related researches aiming at different application scenarios.

2. Literature review

2.1. Tendon-driven actuators

Tendons connect muscles (power source) and bones (effector) in human bodies. With such inspiration, tendon-driven method is employed in robotic hands, and the word “tendon” is used to indicate a linear object that connects a power source to a moving structure.

Tendon-driven underactuating has been widely applied in robotic hands, which uses several tendons (usually cables) to control the entire hand with a multi degree of freedom. In traditional rigid robotic hands, tendon-driven has been very well employed [7] [8]. Robotic hands using tendon-driven actuators traditionally consist of rigid links and joints with different numbers of tendons. Claudio Melchiorri et al. mentioned that limitations of current technology (materials, sensors, motors’ dimensions and power, etc.) have occurred and a potential improvement is to seek surface compliance through applying soft structures [9]. Therefore, tendon-driven actuation is applied in soft robotic hands aiming for better compliance.

While in rigid robotic hands tendon-driven requires rigid joints to mimic the structure of human knuckles, in a soft robotic hand such structures are improved and optimized by employing soft materials, combining the function of joints and bones. Elastomers are used to replace both the articulated segments and the joints, enabling the integration of finger structures. As the power source shortens the tendon, the distance between the fixed points at both ends is reduced, so the elastomers will be pulled by force at both ends which makes the finger to bend. This control method is an effective underactuation which reduces difficulty in controlling.

2.2. Soft pneumatic actuators

Soft pneumatic actuators (also called fluidic elastomer actuators) are a type of adaptable and low-power requiring soft actuators. In soft robotic hands, soft pneumatic actuators work similar with muscles in human bodies: its deformation actuates its own movements. Soft pneumatic actuators consist of elastomers that are deformed by chambers inside an elastic housing and a strain-limited layer (also called stiff constraint layer) [10]. Most elastomers are not anisotropic, so a strain-limited layer is necessary in order for the chamber expansion to produce deformation in a certain direction. This layer is made of soft composite materials made up of silicone polymers and elastomers [11], embedded with paper or cloth to withstand large stresses during deformation.

The fluid (liquid or gas) is filled into the extended elastomeric chambers with reinforcing fibers and layers on the other side to operate the actuator. The pressure generated by the fluid acts on the elastomers, resulting in their deformation (expanding) while the strain-limited layer has a smaller deformation. The difference in this deformation eventually leads to a bending of the whole actuator.

The grasp performance of soft robotic hands is mainly associated with the expansion of the chamber. Different chamber designs can result in different movements such as bending, rotating and even more complicated bidirectional movements [12]. Pneumatic networks are a popular design that feature numerous channels lined up in a row to allow the elastomer to deform as much as possible [13]. Besides the maximum deformation, reaction speed is also an important aspect to estimate the motion performance of soft pneumatic actuators. Weiping Hu et al. proposed an improvement method to increase the actuating speed by optimizing pneumatic network structure design [14].

3. Method

To compare the characteristics of the two actuation methods more intuitively, in this part two different designs will be introduced as examples

3.1. Twisted string actuators in tendon-driven soft robotic hand

Revanth Konda et al. used twisted string actuators (TSAs) to realize tendon-driven in soft robotic hand [15]. TSA is an efficient way to realize tendon-driven, in which a motor twists the strings to reduce their length and hoist the attached load linearly. Compared with traditional SMTAs (i.e., spooled motor tendon actuators), TSAs can provide larger input torque while reducing the size. In this design, each finger has two tendons. The frontal tendon is used to achieve the bending of the fingers, while the extra rear tendon was applied in this design to gain adjustable stiffness by counteracting frontal tendon’s actuation.

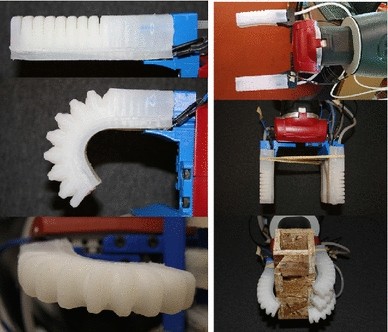

The soft robotic hand consists of a monolithic soft palm which has four fingers, another monolithic thumb attachment and a rigid base which is used to hold the motors and limit the position of the strings based on the position of the fingers (shown in center-top figure in figure 1). There is a 10-degree angle between each finger (left-top figure in figure1), which enables the soft hand to replicate the position of the fingers in a human hand when resting. This enables the hand to emulate the natural open position of a human hand. All the fingers have almost an identical structure design which enables all the fingers to have a same actuation mode. The thumb attachment has an extra roll joint, also actuated by TSA (right-bottom figure in figure 1). Installed to an extra jointed section in the palm, the thumb’s maximum bending angle is 90∘ theoretically. This enables the soft hand to complete complicated grasp strategies.

|

Figure 1. Detailed model with main components including hand, actuators and base [16]. |

There are three 90∘ triangular cuts in each finger, parallel to the primary bending axis (right-top figure in figure 1), functioning as the joints. This design can reduces bending resistance and thus reduces the required external forces, enabling the elastomer to behave more like a real human finger. Inside each fingers there are two channels parallel to its length, which are used to place the two tendons. Similarly, the palm has continuous tendon channels aligned with the tendon channels of each finger. This allows the tendons to pass within the palms of the hands and into the base where they connect to the motor. Polytetrafluoroethylene (PTFE) tubes are equipped in the channels in the fingers and the palm. These tubes not only reduce the frictional force between the soft structures and the tendons but also reinforce the soft structures of the fingers and palms. The tendons are 0.7-mm diameter strings which are made of ultrahigh-molecular-weight polyethylene (UHMWPE). Such selection is because UHMWPE has a low frictional coefficient with PTFE (0.04–0.06 as previously reported).

Acrylonitrile butadiene styrene plastic is used to 3-D print the reusable molds for four fingers, the palm and thumb attachment, The fingers and palm were cast from silicone rubber (Dragon Skin 20) and then silicone rubber adhesive (SIL-Poxy) was used to stick fingers and the palm together. The base was made up of a holder piece which fixed the hand in place, a collar in order to install the TSA motors and a sorter mechanism that constrained strings’ twisting (left-bottom figure in figure 1). The sorter mechanism separated the two strings in each pair of TSA by threading the two strings through two different channels within in order to sort different pair of strings. Separating the twisted and untwisted regions ensured that the strings would not twist within the hand. Steel sticks support the collar up away from the sorter, extending the twisting length to provide greater actuating force. The motor collar had points to install the 11 motors for TSAs. Overall, the soft robotic hand had a total length of 295mm, with a footprint of 106 × 106 mm.

3.2. Fast pneu-net structures in soft pneumatic robotic hand

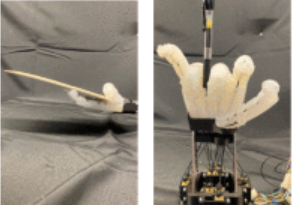

Homberg et al. introduced a four fingers pneumatic soft robotic hand[16], which is based on their previous work on a type of modular, easily adapted pneumatic finger in 2015[17]. The soft hand has three fingers on one side of the palm and the thumb on the other, making a total of four identical fingers constitute the main functional structure (entire hand shown in the right figure in figure 2). The fingers are all hollow rubber elastomers. Distributed in the direction of finger’s length, the chambers of the bending function section use fast pneu-net structure [15]. In such structure, the inside walls between each chamber are thinner than the top walls. If fluid is injected, inside walls will expand preferentially, making the extensible layer preferentially elongated with only minor changes in the height of the layer. Traditional pneu-net structure has thinner top walls. When pressurized, chambers preferentially extends the top walls and stretches the inside walls (side views of an individual finger before and after inflation). This structure not only responds slowly, but also causes greater stress on the walls of the air chamber. The use of the fast pneu-net solves these problems very well, and can additionally reduce the volume and increase the service life.

Each finger has small holes at one end for connecting pneumatic pistons via a tube which inject gas into the chamber The pneumatic piston is actuated by a linear actuator which is controlled by motor controllers, enabling the fingers to execute accurate movements. The connection part between the tube and the finger can also attach the finger to an existing robot structure. The connection parts are 3D printed, making it easy for the finger to attach and detach while maintaining sealing. The fingers have three layers, which are the first layer (medium-soft rubber Dragonskin 20A), the constraint layer (thin Delrin) and the second layer (Dragonskin 10A). The three layers are cast in batches in the mold by the lost wax method, making it possible to add sensors internally during the constraint layer fabrication process. They applied two sensors: the Flexi-force force sensor and the Bendshort-2.0 flex sensor. The two sensors are glued to two points, one at the circuitry base and one along the length of the sensor, keeping the sensors in place during deformation. Both sensors react to the bending, enabling the control system have a better assessment of the bending state of the fingers. Based on past research, a finger facing the thumb has been added to the design. The extra finger is directly opposite the thumb of the hand. It can increase load capability while enabling the robot to complete additional gripping options, such as pinching small objects.

|

Figure 2. Side view of an individual finger (left) and the entire hand (right) [17]. |

4. Experiments and results

Depending on the characteristics of different soft robotic hands, different experiments have been performed to evaluate gripping performance, which will be presented separately in the following sections

4.1. Twisted string actuators in tendon-driven soft robotic hand

4.1.1. Thumb dexterity

The Kapandji test was used to estimate the dexterity of the thumb [18]. In the Kapandji test the thumb tip had to reach 10 different points located on the other four fingers and the palm. From zero to ten, a higher score indicates a better anthropomorphic dexterity. The thumb shown in this case gets 6 in total, unable to reach the points on the little finger except the tip. This problem was caused by decreased mobility at the end of the rolling actuation. But the dexterity of the thumb mainly influenced the gripping performance and the little finger didn’t play an important in gripping, so such score of 6 is enough for the soft robotic hand to perform basic grasp.

4.1.2. Grasping performance

The basic gripping ability of the robot hand is evaluated by verifying whether the robot can replicate the anthropomorphic grip according to the Feix GRASP taxonomy [19], which has been introduced to illustrate the dexterity of grippers. The tendon-driven soft robotic hand was capable of achieving 31 of 33 grasps presented in the Feix GRASP taxonomy. The hand failed to achieve the parallel extension grasp and the adduction grip, with the best trials presented in the figure 3.

To achieve the parallel extension grasp, the fingers (including the thumb) should be actuated from the base while maintaining the extension. However, because of the soft pseudo joints in the finger structure, the bending is evenly distributed over the entire finger, which causes unexpected bending of the part near the base of the finger. Such problem can be solved by adding a second DOF (degree of freedom) to the finger in order to separately control the different part of a finger. For the adduction grip, the hand can not hold the object with a controllable DOF. This problem is caused by the single DOF along the length of a finger and can be solved by adding extra DOFs in the palm.

The soft robotic hand successfully completes different grasp strategies on a flat surface like a human hand through open-loop control. For the top grasping, the fingers first touched the surface which then guided the actuators until the hand achieve the grasp. For the flip grasp, the fingers flipped the object with the support of the thumb before completing the grasp. For the edge grasp, the fingers slid the object to the edge of the surface until the thumb could hold the bottom side and achieve the grasp. The completion of these three strategies reflects the good adaptability of the soft robotic hand to the grasping scenarios of various objects.

|

Figure 3. Best efforts for failed grasps: parallel extension grasp (left) and adduction grip (right) [16]. |

4.2. Fast pneu-net structures in soft pneumatic robotic hand

4.2.1. Grasping capability

To estimate the ability of the soft robotic hand to have a basic gripping posture, two different types of grasping were tested: enveloping grasp and pinch grasp. In order to efficiently complete the verification of the basic grasp, the soft robotic hand was simplified. The number of fingers was reduced to three (the little finger and ring finger, which play a minor role in basic grabbing, are omitted).

To complete an enveloping grasp, the hand had to contain the entire object within the fingers. The object is in close contact with the inside of the fingers to ensure a firm grasp between the fingers and the compliant palm. To test this type of grasp, the hand was required to grasp a cylindrical container, an empty coffee cup, a tennis ball, an egg, and a lemonade bottle. The hand was able to hold various objects firmly. Two examples are shown in the figure.

For a pinch grasp, the hand had to grip the object using the tips of the fingers. In the test the hand successfully grasped a cylindrical container, a tennis ball, an empty lemonade bottle, an empty coffee cup, and a pen. Moreover, the grasp can be achieved through multiple orientations, proving the possibility of multiple gripping positions. Examples are presented in the figure.

4.2.2. Grasping performance

In order to obtain more detailed grasping characteristics close to the application scenario, the hand was tested with 100 different objects of various shape and material, placed in various poses. For different objects, different grasping strategies were applied (including enveloping grasps, side grasps, pinch grasps, and top grasps). The soft hand successfully picked up 94 of 100 objects and demonstrated strong stability. Except for enveloping grasp and pinch grasp, the hand also managed to complete more complicated grasp modes like edge grasp. In an edge grasp, the hand slid the object with its index finger until the thumb can support the object on the other side. Such grasp strategy is extremely efficient for grasping flake objects such as disc and paper. The robotic hand also showed good compliance, having a good performance while grasping compliant objects. Specifically, the soft hand successfully grasped an empty soft paper cup without crushing it for many times.

However, the soft hand was unable to grasp 6 of the 100 objects (shown in figure 4). Except for the screw which is too small for grasp, the hand also can’t grasp long flake objects like a spoon, because it is difficult for the thumb to support the object if using edge grasp and the object was too flat to use top grasp. Moreover, the hand was unable to pick amorphous object (a bag). Regardless of the grasping modes, the object would deform and slip out of the fingers. This problem also occurred on soft objects with uneven mass distribution (a fish tail).

|

Figure 4. Objects that the soft pneumatic hand were unable to grasp. From left to right are a fish tail, a screw, a spoon, a pair of scissors, a propeller and a bag [17]. |

5. Discussion

The two different soft robotic hands both showed good compliance and have good grasp performance. Both soft hands can complete anthropomorphic gripping strategies and are able to grasp various objects, some of which are extremely difficult for traditional rigid robotic hands to grasp.

Although both soft hands can pick up most daily objects, there is still difference between the grasping strength. According to Jun Shintake, the lifting ratio (object mass / gripper mass, including actuators) of soft hands which have passive structure with external motors is 4.549-16.346 while the ratio of soft pneumatic actuators is 24–6877[7]. Such data proves that soft pneumatic actuators have significantly better ability to grip heavy objects than tendon-driven actuators. The advantages of grasping heavier objects make soft pneumatic actuators have good applications in work scenarios that require gripping strength, such as industrial production. By contrast, the tendon-driven hand doesn’t have same grasp strength, but it can still handle most daily objects grasping task.

In terms of the grasp performance, both hands have several cases where they failed to complete the grasp. The tendon-driven hand failed to complete two specific gripping strategies. The failed cases are not caused by the features of the objects, such as shape and mass distribution. Instead, it was caused by the lack of DOF of the fingers’ more precise manipulation. This problem can be solved by adding more DOFs to the hand. But the failed cases of the soft pneumatic hand are caused by the features of the objects. In this case, because the strain-limited layer in the fingers of the pneumatic hand defines the direction of deformation, the finger movement is relatively single and difficult to improve through structural design, which makes the finger unable to complete more delicate operations. Because of the simultaneous increase of pressure inside the chambers, it is difficult to realize different deformations in different section. This means that it is difficult to simulate the distribution of joints in the human hand with pneumatic fingers, which reduces the degree of freedom of the fingers. At the same time, soft pneumatic actuators rely on special chamber designs, while tendon-driven actuators only require an increase in the number of tendons, which makes it extremely difficult to increase the degree of freedom of the pneumatic fingers. This means that the soft pneumatic hand is not suitable for gripping objects requiring precise manipulation, which makes pneumatic hands less versatile.

According to the grasp performance experiments, the soft pneumatic hand was more capable of enveloping grasp than other more anthropomorphic gripping strategies. Such feature is mainly due to the great grasp strength and compliance of pneumatic hand, which make the fingers hold the objects firmly. However, the tendon-driven hand does not show significant differences in performance in different gripping strategies. Such difference between the two soft robotic hands is mainly due to the distribution of the fingers. Fingers in the tendon-driven hand have a similar distribution like a human hand. Although fingers can’t change the angle between each other, the tendon-driven hand still showed good manipulation capability. In the tendon-driven hand, thumb is connected to the palm differently from the other fingers. It has an extra rolling joint section, ensuring the capability of the thumb to move across the palm. This design enables the thumb to have a better dexterity, and behave more like a human thumb. On the contrary, the thumb in the soft pneumatic hand is the same as other fingers. The soft pneumatic hand have a lower similarity to human hand: fingers and palm are almost vertical. Distribution of fingers can be optimized but the requirement of the chambers makes it difficult to make the thumb have same dexterity like the tendon-driven hand. Despite this design sacrifices the dexterity of the thumb, it increases the stability of the enveloping grasp, resulting in different completion of different grasp strategies.

Therefore, tendon-driven hands are more capable of situations in which dexterity is necessary. The less load capability makes it not suitable for industrial use which usually requires grasping heavy objects. High similarity to human hands allows tendon-driven hands to be applied in more areas requiring high interaction with people like medical rehabilitation. Soft pneumatic hands have stronger load capability which makes it suitable for industrial use. But soft pneumatic hands have less dexterity. Key to solve the problem is optimizing chamber design, which is a promising area of research to improve the performance of soft pneumatic hands.

6. Conclusion

In this article, advantages and disadvantages of tendon-driven actuators and soft pneumatic actuators are discussed through the comparison of two specific designs of soft robotic hands. By analyzing the principles of the two actuating methods and comparing the dexterity and grasp performance of the two soft robotic hands, conclusion is drawn that tendon-driven actuators have more dexterous bionic functions but less load capacity, while soft pneumatic actuators have more load capacity and stability of the basic grasp strategies but less completion of complex bionic grasps. Concluding features of the two actuating methods, this article is intended to help researchers have a better understanding of tendon-driven actuators and soft pneumatic actuators before structure designing. Expected functions can be better achieved if a more suitable actuating method can be chosen according to specific task requirements. Additionally, this article provides inspiration for new applications of the two different types of soft robotic hands according to the summarized characteristics, such as production and transportation of soft objects and bionic soft prosthetic hands.

References

[1]. Yang J, Kim M, Kim D and Yun D 2021 Protrusion type slip detection soft sensor and application to anthropomorphic robot hand 24th Int. Conf. on Mechatronics Technology (ICMT) 2021 Singapore pp 1-5

[2]. Jeong H and Cheong J 2011 Design of hybrid type robotic hand : The KU hybrid hand 11th International Conference on Control, Automation and Systems 2011 Gyeonggi-do pp 1113-1116

[3]. Zhou J, Chen X, Chang U, Lu J, Leung C, Chen Y, Hu Y and Wang Z 2019 A soft-robotic approach to anthropomorphic robotic hand dexterity IEEE Access 7 101483-95

[4]. Heung K, Tang Z, Ho L, Tung M, Li Z and Tong R 2019 Design of a 3D printed soft robotic hand for stroke rehabilitation and daily activities assistance IEEE 16th Int. Conf. on Rehabilitation Robotics (ICORR) 2019 Toronto pp 65-70

[5]. Laliberte T, Birglen L, Gosselin C. 2002 Underactuation in robotic grasping hands[J]. Machine Intelligence & Robotic Control 4(3) 1-11

[6]. Shintake J, Cacucciolo V, Floreano D and Shea H 2018 Soft robotic grippers Adv. Mater. 30(29) 1707035

[7]. Jung S, Kang S, Lee M and Moon I 2007 Design of robotic hand with tendon-driven three fingers Int. Conf. on Control, Automation and Systems 2007 Seoul pp 83-86

[8]. Wen L, Li Y, Cong M, Lang H and Du Y 2017 Design and optimization of a tendon-driven robotic hand IEEE Int. Conf. on Industrial Technology (ICIT) 2017 Toronto pp 767-772

[9]. Melchiorri C, Palli G, Berselli G and Vassura G 2013 Development of the UB hand IV: overview of design solutions and enabling technologies," IEEE Robotics & Automation Magazine 20(3) 72-81

[10]. Rus D and Tolley M 2015 Design, fabrication and control of soft robots Nature 521 467–75

[11]. Robert F, Filip I, Choi W, Stephen A, Adam A, Aaron D, Chen X, Wang M and George M 2011 Multigait soft robot Proc. Natl Acad. Sci. 108 20400–3

[12]. Scharff R, Doubrovski E, Poelman W, Poelman W, Jonker P, Wang C and Geraedts J 2016 Towards behavior design of a 3D-printed soft robotic hand Soft Robotics: Trends, Applications and Challenges: Proc. of the Soft Robotics Week April 25-30, 2016 Livorno (New York: Springer International Publishing) pp 23-29

[13]. Hu W, Mutlu R. Li W and Alici G 2018 A structural optimisation method for a aoft pneumatic actuator Robotics 7 24

[14]. Mosadegh B, Polygerinos P, Keplinger C, Wennstedt S, Shepherd R, Gupta U, Shim J, Bertoldi K, Walsh C and Whitesides G 2014 Pneumatic networks for soft robotics that actuate rapidly Adv. Funct. Mater.24 2163-70

[15]. Konda R, Bombara D, Swanbeck S and Zhang J 2023 Anthropomorphic twisted string-actuated soft robotic gripper with tendon-based stiffening IEEE Transactions on Robotics 39(2) 1178-95

[16]. Homberg B, Katzschmann R, Dogar M and Rus D 2019 Robust proprioceptive grasping with a soft robot hand Auton Robot 43 681–96

[17]. Homberg B, Katzschmann R, Dogar M and Rus D 2015 Haptic identification of objects using a modular soft robotic gripper IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS) 2015 Hamburg pp 1698-705

[18]. Kapandji A 1986 Clinical test of apposition and counter-apposition of the thumb Annales de Chirurgie de la Main 5(1) 67-73

[19]. Feix T, Romero J, Schmiedmayer H, Dollar A and Kragic D 2016 The GRASP taxonomy of human grasp types IEEE Trans. Human-Mach. Syst. 46(1) 66-77

Cite this article

Ye,Q. (2024). Comparison between tendon-driven and soft pneumatic actuators in soft robotic hands. Applied and Computational Engineering,52,123-131.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Signal Processing and Machine Learning

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Yang J, Kim M, Kim D and Yun D 2021 Protrusion type slip detection soft sensor and application to anthropomorphic robot hand 24th Int. Conf. on Mechatronics Technology (ICMT) 2021 Singapore pp 1-5

[2]. Jeong H and Cheong J 2011 Design of hybrid type robotic hand : The KU hybrid hand 11th International Conference on Control, Automation and Systems 2011 Gyeonggi-do pp 1113-1116

[3]. Zhou J, Chen X, Chang U, Lu J, Leung C, Chen Y, Hu Y and Wang Z 2019 A soft-robotic approach to anthropomorphic robotic hand dexterity IEEE Access 7 101483-95

[4]. Heung K, Tang Z, Ho L, Tung M, Li Z and Tong R 2019 Design of a 3D printed soft robotic hand for stroke rehabilitation and daily activities assistance IEEE 16th Int. Conf. on Rehabilitation Robotics (ICORR) 2019 Toronto pp 65-70

[5]. Laliberte T, Birglen L, Gosselin C. 2002 Underactuation in robotic grasping hands[J]. Machine Intelligence & Robotic Control 4(3) 1-11

[6]. Shintake J, Cacucciolo V, Floreano D and Shea H 2018 Soft robotic grippers Adv. Mater. 30(29) 1707035

[7]. Jung S, Kang S, Lee M and Moon I 2007 Design of robotic hand with tendon-driven three fingers Int. Conf. on Control, Automation and Systems 2007 Seoul pp 83-86

[8]. Wen L, Li Y, Cong M, Lang H and Du Y 2017 Design and optimization of a tendon-driven robotic hand IEEE Int. Conf. on Industrial Technology (ICIT) 2017 Toronto pp 767-772

[9]. Melchiorri C, Palli G, Berselli G and Vassura G 2013 Development of the UB hand IV: overview of design solutions and enabling technologies," IEEE Robotics & Automation Magazine 20(3) 72-81

[10]. Rus D and Tolley M 2015 Design, fabrication and control of soft robots Nature 521 467–75

[11]. Robert F, Filip I, Choi W, Stephen A, Adam A, Aaron D, Chen X, Wang M and George M 2011 Multigait soft robot Proc. Natl Acad. Sci. 108 20400–3

[12]. Scharff R, Doubrovski E, Poelman W, Poelman W, Jonker P, Wang C and Geraedts J 2016 Towards behavior design of a 3D-printed soft robotic hand Soft Robotics: Trends, Applications and Challenges: Proc. of the Soft Robotics Week April 25-30, 2016 Livorno (New York: Springer International Publishing) pp 23-29

[13]. Hu W, Mutlu R. Li W and Alici G 2018 A structural optimisation method for a aoft pneumatic actuator Robotics 7 24

[14]. Mosadegh B, Polygerinos P, Keplinger C, Wennstedt S, Shepherd R, Gupta U, Shim J, Bertoldi K, Walsh C and Whitesides G 2014 Pneumatic networks for soft robotics that actuate rapidly Adv. Funct. Mater.24 2163-70

[15]. Konda R, Bombara D, Swanbeck S and Zhang J 2023 Anthropomorphic twisted string-actuated soft robotic gripper with tendon-based stiffening IEEE Transactions on Robotics 39(2) 1178-95

[16]. Homberg B, Katzschmann R, Dogar M and Rus D 2019 Robust proprioceptive grasping with a soft robot hand Auton Robot 43 681–96

[17]. Homberg B, Katzschmann R, Dogar M and Rus D 2015 Haptic identification of objects using a modular soft robotic gripper IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS) 2015 Hamburg pp 1698-705

[18]. Kapandji A 1986 Clinical test of apposition and counter-apposition of the thumb Annales de Chirurgie de la Main 5(1) 67-73

[19]. Feix T, Romero J, Schmiedmayer H, Dollar A and Kragic D 2016 The GRASP taxonomy of human grasp types IEEE Trans. Human-Mach. Syst. 46(1) 66-77