1. Introduction

Basketball is a globally popular sport with numerous benefits, such as fostering teamwork and physical fitness. Basketball shoes play a pivotal role in ensuring the safety of basketball players, with the performance of the shoe soles affecting the stress on lower limb joints [1]. With the advancements in materials science, various high-performance materials, including air cushions and EVA foam [2][3], have been employed in basketball shoe manufacturing. Among these, thermoplastic polyurethane elastomer (TPU) materials, known for their excellent elasticity, are widely used in basketball shoe sole production. Traditional EVA (ethylene-vinyl acetate copolymer) shoe soles suffer from drawbacks like wrinkling and hardening. In contrast, E-TPU materials, a new type of TPU foam material with high rebound foam particles achieved through structural rearrangement, exhibit exceptional resilience. E-TPU materials can be classified into aliphatic and aromatic categories, with the latter having a popcorn-like structure when molded. Adidas employs boost technology, which uses aromatic E-TPU material, in the Harden signature basketball shoes [4]. This technology is manufactured through foam molding processes, resulting in excellent cushioning and rebound properties. Furthermore, physical foam molding can achieve a “zero” pollution effect. Nevertheless, aromatic E-TPU is prone to oxidation and yellowing, leading to the prevalent use of aliphatic E-TPU for basketball shoe soles. For instance, ANTA Nitro Technology utilizes supercritical foaming of sub-embryos and in-mold foaming technology, with energy return rates of up to 86.8%, a 30% improvement in durability, and a density of only 0.09 g/cm3. This material is known for its outstanding rebound, lightweight properties, and durability [5].

Despite the widespread use of E-TPU materials in basketball shoe soles, there are still challenges in their preparation methods, relevant theories, and application extensions. Issues such as poor breathability, sensitivity to temperature variations, and subpar weather resistance persist [6]. Poor breathability and temperature sensitivity are attributed to the flexibility and elasticity of TPU materials. Certain shoe models may exhibit reduced breathability, leading to issues like sweating, odors, and discomfort. While some advanced E-TPU materials offer decent weather resistance, overall, these materials still face issues like color fading, aging, and embrittlement when exposed to sunlight, rain, and humidity. This presents room for further research in their new applications and future investigations in this field [7].

This paper aims to introduce the development history, preparation methods, and factors influencing the performance of TPU materials used in basketball shoe soles. Furthermore, it proposes performance control methods based on this foundation. Through this research, a better understanding of the performance and application potential of TPU materials can be achieved, offering new perspectives and approaches for basketball shoe design and materials. Additionally, the study of this material will contribute to technological advancements in related fields, ultimately making a valuable contribution to the development of the sport of basketball.

2. Research Progress on E-TPU Materials

2.1. TPU Research Progress

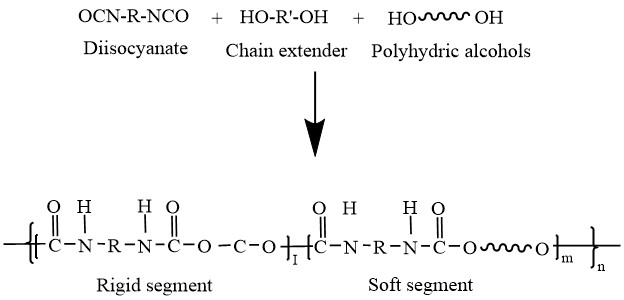

The fundamental material for the innovative high rebound foam particle-based E-TPU foam material is TPU (Thermoplastic Polyurethane) material. TPU is the world’s first thermoplastic elastomer, and it is currently one of the fastest-growing thermoplastic elastomer materials on the market. TPU is a segmented copolymer composed of diisocyanates, polyether or polyester oligomeric diols, and small-molecule chain extenders. As shown in Figure 1, the hard segments are typically formed by diisocyanates and chain extenders, while the flexible long chains are composed of oligomeric diols, making up the repeating structural units of TPU [8].

Figure 1. Reaction for TPU synthesis and basic structure of TPU materials.

TPU is a synthetic polymer material that combines the high elasticity of rubber with the high strength and hardness of plastics. It can be processed using various conventional methods such as extrusion, calendering, and injection molding. Notably, TPU materials automatically degrade into water and carbon dioxide when discarded, making them environmentally friendly. Furthermore, TPU material properties, such as strength, cold resistance, wear resistance, sound insulation, water resistance, oil resistance, mold resistance, aging resistance, shock absorption, and hardness, can be adjusted from both physical and chemical perspectives by modifying TPU molecule structures and through material blending [8].

In 1937, Professor Bayer from Germany first synthesized polyurethane fibers known as “perlon”. Subsequently, research by DuPont in the United States and Imperial Chemical Industries in the United Kingdom led to the discovery of the elastomeric properties of polyurethane, although its unstable nature prevented practical use. In 1942, Hanford synthesized segmented copolymers of the (AB)n type using diisocyanates and dihydroxyl polymers. In 1966, Copper compared the performance of TPU and Styrene-Butadiene-Styrene (SBS) segmented copolymers and found that the thermoplastic elastomeric properties of TPU resulted from phase separation between the soft and hard segments, rather than hydrogen bonding. With the establishment of production facilities in Japan, the UK, Germany, and other countries, the thermoplastic polyurethane elastomer rapidly developed. Leading foreign TPU manufacturers were primarily located in the United States, Japan, and Europe, with over 30 companies producing TPU materials. Prominent global TPU material manufacturers included Lubrizol from the United States, BASF from Germany, Covestro from Germany, and Huntsman from the United States. As of 2017, the global TPU material production capacity was approximately 2 million tons, with these companies accounting for approximately 40% of the TPU material market share.

China initiated its independent research on TPU materials in 1973 at the Shanxi Provincial Institute of Chemical Industry. In the late 1980s and 1990s, domestic development of TPU materials began, with the Tianjin Polyurethane Plastic Products Factory being one of the first entities to develop TPU materials. Subsequently, institutions such as the Li Ming Institute of Chemical Industry, Yantai Wanhua Co., and others introduced multiple TPU material production lines and employed domestically developed production equipment for TPU material preparation. These materials found applications primarily in the manufacturing of shoes, gaskets, and sealing rubbers.

2.2. Expanded-Thermoplastic Polyurethanes

TPU materials exhibit numerous excellent properties, making them widely used in fields such as national defense, electronics, petrochemicals, and medical devices. Additionally, with the rising popularity of basketball, more high-performance TPU materials have been invented, including the aforementioned supercritical foaming E-TPU. Due to its low density, high elasticity, and high toughness, it has found application in basketball shoe soles.

In 1993, BASF’s Fischer disclosed a method for preparing ETPU particles using a high-pressure vessel for foaming [9]. In 2006, Prissok and others used polyether-based TPUs with hardness ranging from 44 to 84 and supercritical CO2 as a foaming agent to produce microcellular foaming TPU particles. These foaming particles, when filled into molds and subjected to injection of high-temperature steam, resulted in foamed TPU materials with mold shapes. The development of steam-forming technology made it commercially viable for supercritical foaming ETPU particles.

In 2012, German company Adidas, in collaboration with BASF, developed the Boost running shoe brand, which used foamed TPU as the midsole material. Using polyether-based TPU with a hardness of 80-85 as the base material, the foamed TPU midsole retains excellent elasticity and flexibility even at temperatures below 0 °C, compared to the common EVA midsole. This greatly improved wearing comfort, making the running shoes immensely popular among sports enthusiasts worldwide.

Researchers such as Zhu Peijin from China have studied the impact of water and CO2 as co-blowing agents on TPU foaming [10]. Without adding water, the internal pores of TPU foaming particles exhibit characteristics of smaller edge pore diameters and larger central pore diameters, with an unfoamed edge layer near the edges of the particles. Increasing the water content significantly reduces the thickness of the edge layer of TPU particles, increases the overall pore diameter, reduces pore wall thickness, and increases the expansion ratio. However, excessive water addition can lead to pore collapse and merging.

Subsequently, Zhu Tongyu researched the influence of supercritical CO2 and N2 as mixed blowing agents on TPU foaming [11]. When the CO2 proportion increases, the temperature required for material foaming decreases. The pore size of ETPU significantly becomes smaller, more uniform, with thinner pore walls, and a higher pore density. Simultaneously, the melting point of ETPU decreases, the melting range widens, and the enthalpy of fusion slightly increases, resulting in better bonding quality in steam-forming. The tensile strength, tear strength, and peel tear strength of the molded ETPU material saw a significant improvement.

As the proportion of nitrogen gas in the foaming gas increases, the dimensional stability of ETPU during maturation improves, and the shrinkage rate decreases. The compression permanent deformation rate of the product gradually decreases as well. Additionally, under the same conditions, using mixed gases such as oxygen and nitrogen in a 1:1 or 1:3 ratio as foaming agents results in ETPU materials with lower density.

3. Preparation and Factors Influencing the Performance of E-TPU Materials

3.1. E-TPU Material Preparation Methods

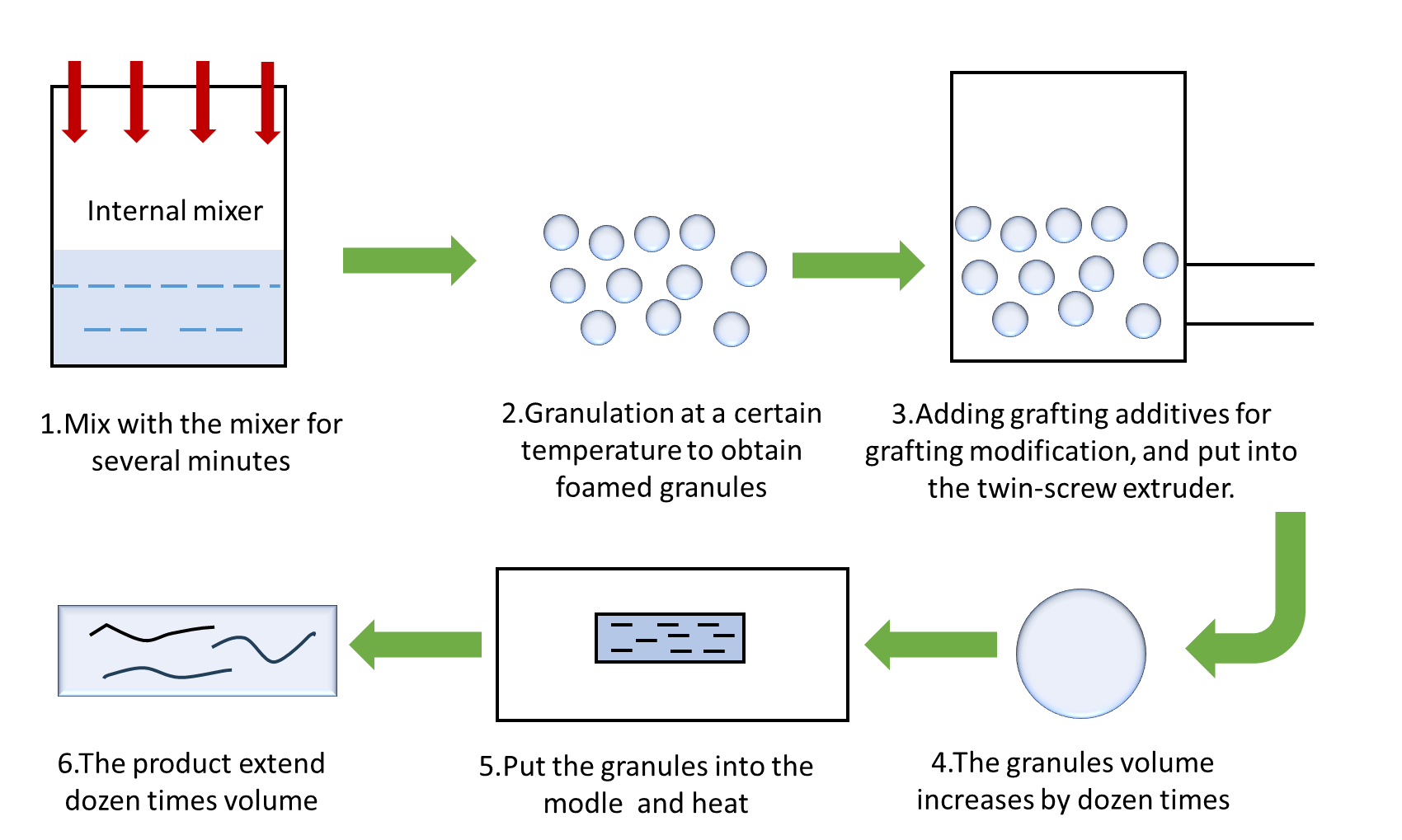

E-TPU material is based on TPU (Thermoplastic Polyurethane) material and is shaped through physical foaming. The preparation process is illustrated in Figure 2. E-TPU materials can be prepared through three main methods: high-pressure autoclave foaming, continuous extrusion foaming, and injection foaming. The most commonly used foaming method is the high-pressure autoclave foaming process, which is an intermittent process. In this method, TPU and foaming agents are placed in a high-pressure autoclave, allowing the foaming agent to saturate the TPU. Then, a rapid depressurization or a rapid temperature increase is employed to induce a thermodynamic imbalance in the homogeneous system of TPU and gas. This results in phase separation, nucleation, and growth of bubbles, followed by cooling for solidification [12]. Unlike melt extrusion foaming and injection foaming, the high-pressure autoclave foaming of polymers occurs in a highly elastic state. During foaming, polymer chains can move to allow cell nucleation and growth, but they cannot flow to avoid uneven deformation of the foamed material [13].

Figure 2. E-TPU Preparation Principle.

3.2. Factors Influencing E-TPU Material Performance

3.2.1. Factors in the E-TPU material synthesis process. E-TPU exhibits high flexibility and, during synthesis, its performance can be altered by modifying various variables, including:

1. Polyurethane Formulation: The performance of E-TPU materials is related to their polyurethane formulation, which includes the ratio and selection of polyether or polyester polyols, diisocyanates, chain extenders, and crosslinkers. Different formulations can yield varying properties such as hardness, strength, elastic modulus, and wear resistance. For example, the hardness of E-TPU materials can be controlled by adjusting the ratio of polyols and diisocyanates in the polyurethane formulation. A higher polyol content leads to lower material hardness, while a higher diisocyanate content results in higher hardness.

2. Molecular Weight: The molecular weight of E-TPU materials significantly influences their performance. Higher molecular weight typically enhances material strength and toughness but may reduce melt flowability.

3. Degree of Polymerization: The degree of polymerization in E-TPU materials refers to the number of alcohol and diisocyanate groups in the polyurethane molecule. A higher degree of polymerization can enhance material strength and wear resistance but may lead to increased hardness.

4. Additives: Specific properties of E-TPU materials can be improved by incorporating various additives such as fillers, plasticizers, stabilizers, and pigments. For instance, adding fiber reinforcement can enhance material strength and rigidity.

5. Processing Conditions: The processing conditions for E-TPU materials can also impact their performance. Variations in processing parameters such as temperature, pressure, and cooling rate can affect the crystallinity, crystal size, and microstructure of the material, influencing its mechanical and thermal properties.

3.2.2. Factors in the E-TPU material shaping process. As previously mentioned, the current commercialized supercritical foaming E-TPU primarily employs the high-pressure autoclave foaming process. Factors influencing the effectiveness of high-pressure autoclave foaming can be categorized into four main aspects: foaming agents, foaming temperature, supercritical fluid pressure, and physical properties such as TPU type, melting point, and hardness.

Fang Yang and colleagues proposed a method involving an endothermic foaming agent mixed with a small amount of supercritical N2 through a single-screw extrusion. The resulting self-skinning TPU foaming particles exhibited strong adhesion during steam forming, resulting in improved mechanical performance.

Zhang Xianghan and others [14] connected a supercritical foaming system to an injection molding machine. They introduced supercritical N2 into the molten TPU during the injection process and foaming shaping, which led to a decrease in material density from 1.189 g/cm3 to 0.396 g/cm3. This resulted in reduced hardness, elongation at break, and Young’s modulus. The rebound rate increased from 25% to 38%.

3.2.3. Factors influencing TPU material performance during use. The mechanical performance of TPU materials may deteriorate over time due to aging, with factors such as the storage environment playing a significant role. To maintain the elasticity of TPU basketball shoes or running shoes with TPU midsoles, it’s essential to store them in a cool, dry, and well-ventilated place. Moist environments can lead to material degradation, causing loss of elasticity.

Additionally, polyesters, polyamides, and polyurethanes may experience chain breakage due to hydrolysis, leading to degradation. Prolonged exposure to sunlight can cause TPU materials to oxidize and yellow, while internal polymer chains may experience oxidation, chain scission, or cross-linking reactions. All these factors can influence the mechanical performance of TPU materials.

4. Discussion on the Mechanisms for Enhancing E-TPU Performance

Due to its high resilience, low density, and excellent toughness, E-TPU material has become the mainstream choice for basketball shoe midsoles and holds promise for future materials. With technological advancements and societal development, there is a growing demand for E-TPU materials with even higher resilience, lower density, and enhanced toughness to meet the evolving needs of society.

As mentioned above, various factors influence the performance of E-TPU materials during their synthesis, shaping, and use in basketball shoe midsoles. During the synthesis process, improvements in hardness and toughness can be achieved by controlling the polyurethane formulation, the molecular weight, degree of polymerization, additives, and synthesis conditions of E-TPU materials. In the shaping process, mainstream manufacturing techniques such as high-pressure autoclave foaming and continuous extrusion processes, coupled with the appropriate introduction of supercritical N2, can be employed to reduce the density of TPU materials. To prevent performance degradation during use, the addition of protective materials, such as a film-like material on the outer side of the midsole, can be considered. These materials can shield or reduce exposure to ultraviolet radiation from the sun, as well as minimize contact with water and air.

5. Conclusion

This paper primarily investigates the research history, preparation methods, and factors influencing the performance of TPU materials and E-TPU materials. It also presents mechanisms for enhancing the performance of E-TPU materials. By controlling factors like polyurethane formulation, molecular weight, degree of polymerization, additives, and synthesis conditions, the performance of E-TPU materials can be improved. Additionally, the choice of shaping processes, such as high-pressure autoclave foaming and continuous extrusion processes, along with the appropriate introduction of supercritical N2, can reduce the density of TPU materials and enhance their performance.

In the future, as technology advances and society develop, the demand for E-TPU materials for basketball shoe midsole applications is expected to grow. Therefore, researching the factors influencing their performance and the mechanisms for performance enhancement is crucial. This study provides new insights and approaches for enhancing the performance of basketball shoe midsoles.

References

[1]. Xiang-Lin W , Feng Q U , University B S .Influence of Shoe Midsole Bending Stiffness on Comfort and Sprinting Performance[J].China Sport Science, 2013.

[2]. Lin Y S , Wu T T , Wan H Y .Enhanced adhesion of EVA and NBR soles with polyurethane adhesives by cold atmospheric pressure plasmas[J].Journal of Adhesion Science and Technology, 2023, 37(10):1625-1648.DOI:10.1080/01694243.2022.2084272.

[3]. Yamaguchi T , Pathomchat P , Shibata K ,et al.Effects of Porosity and SEBS Fraction on Dry Sliding Friction of EVA Foams for Sports Shoe Sole Applications[J].Tribology Transactions, 2020:1-15.DOI:10.1080/10402004.2020.1789797.

[4]. Hui Pao. Supercritical foaming material has become the mainstream midsole technology: Which brand of running shoes has better shock resilience? [EB/OL].10-17-2023. new.qq.com/rain/a/20220317A091R100.html.

[5]. Anta. Big data, nitrogen technology, top slow - a brief review after creating 2.0pro62km[EB/OL].10-17-2023.post.smzdm.com/p/am8gv834/.

[6]. Arifvianto B , Iman T N , Prayoga B T ,et al.Tensile properties of the FFF-processed thermoplastic polyurethane (TPU) elastomer[J]. 2021.DOI:10.21203/rs.3.rs-299979/v1.

[7]. Yang, W., & Qin, X. (2015). Research and Applications of Thermoplastic Polyurethane Elastomers (TPU). Plastic Manufacturing, 2015(07), 70-77. DOI:10.16587/j.cnki.issn1727-2890.2015.07.030.

[8]. Xiao, H., Ding, S., & Li, K. (2011). Synthesis of Polyether-based Thermoplastic Polyurethane Elastomer (TPU). Plastic Industry, 39(09), 13-15.

[9]. BASF Research on Thermoplastic Polyurethane Elastomers. Fiberglass/Composite Materials, 2014(10), 126.

[10]. Zhu, P., & Wang, J. (2021). Preparation of TPU Foam Particles by Water-Assisted Supercritical Carbon Dioxide. Engineering Plastics Application, 49(02), 50-54.

[11]. Zhu, T. (2021). Preparation and Performance Study of Thermoplastic Polyurethane Foam Materials (Doctoral dissertation). Qingdao University of Science and Technology. DOI:10.27264/d.cnki.gqdhc.2020.000455.

[12]. Jiang J , Liu F , Yang X ,et al.Evolution of ordered structure of TPU in high-elastic state and their influences on the autoclave foaming of TPU and inter-bead bonding of expanded TPU beads[J].Polymer: The International Journal for the Science and Technology of Polymers, 2021.

[13]. Lu, H., & Wang, J. (2020). Research on High-Pressure Vessel Foaming Process of Thermoplastic Polyurethane. Plastic Industry, 48(05), 49-52+149.

[14]. Zhang, X., Zhong, X., Luo, S., et al. (2020). Preparation of Thermoplastic Polyurethane Foam Materials and Their Properties Using Supercritical Nitrogen. Synthetic Rubber Industry, 43(05), 402-406.

Cite this article

Yao,R. (2024). Preparation and performance characteristics study of thermoplastic polyurethane elastomer (TPU) for basketball shoe soles. Applied and Computational Engineering,61,137-143.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Xiang-Lin W , Feng Q U , University B S .Influence of Shoe Midsole Bending Stiffness on Comfort and Sprinting Performance[J].China Sport Science, 2013.

[2]. Lin Y S , Wu T T , Wan H Y .Enhanced adhesion of EVA and NBR soles with polyurethane adhesives by cold atmospheric pressure plasmas[J].Journal of Adhesion Science and Technology, 2023, 37(10):1625-1648.DOI:10.1080/01694243.2022.2084272.

[3]. Yamaguchi T , Pathomchat P , Shibata K ,et al.Effects of Porosity and SEBS Fraction on Dry Sliding Friction of EVA Foams for Sports Shoe Sole Applications[J].Tribology Transactions, 2020:1-15.DOI:10.1080/10402004.2020.1789797.

[4]. Hui Pao. Supercritical foaming material has become the mainstream midsole technology: Which brand of running shoes has better shock resilience? [EB/OL].10-17-2023. new.qq.com/rain/a/20220317A091R100.html.

[5]. Anta. Big data, nitrogen technology, top slow - a brief review after creating 2.0pro62km[EB/OL].10-17-2023.post.smzdm.com/p/am8gv834/.

[6]. Arifvianto B , Iman T N , Prayoga B T ,et al.Tensile properties of the FFF-processed thermoplastic polyurethane (TPU) elastomer[J]. 2021.DOI:10.21203/rs.3.rs-299979/v1.

[7]. Yang, W., & Qin, X. (2015). Research and Applications of Thermoplastic Polyurethane Elastomers (TPU). Plastic Manufacturing, 2015(07), 70-77. DOI:10.16587/j.cnki.issn1727-2890.2015.07.030.

[8]. Xiao, H., Ding, S., & Li, K. (2011). Synthesis of Polyether-based Thermoplastic Polyurethane Elastomer (TPU). Plastic Industry, 39(09), 13-15.

[9]. BASF Research on Thermoplastic Polyurethane Elastomers. Fiberglass/Composite Materials, 2014(10), 126.

[10]. Zhu, P., & Wang, J. (2021). Preparation of TPU Foam Particles by Water-Assisted Supercritical Carbon Dioxide. Engineering Plastics Application, 49(02), 50-54.

[11]. Zhu, T. (2021). Preparation and Performance Study of Thermoplastic Polyurethane Foam Materials (Doctoral dissertation). Qingdao University of Science and Technology. DOI:10.27264/d.cnki.gqdhc.2020.000455.

[12]. Jiang J , Liu F , Yang X ,et al.Evolution of ordered structure of TPU in high-elastic state and their influences on the autoclave foaming of TPU and inter-bead bonding of expanded TPU beads[J].Polymer: The International Journal for the Science and Technology of Polymers, 2021.

[13]. Lu, H., & Wang, J. (2020). Research on High-Pressure Vessel Foaming Process of Thermoplastic Polyurethane. Plastic Industry, 48(05), 49-52+149.

[14]. Zhang, X., Zhong, X., Luo, S., et al. (2020). Preparation of Thermoplastic Polyurethane Foam Materials and Their Properties Using Supercritical Nitrogen. Synthetic Rubber Industry, 43(05), 402-406.