1. Introduction

The construction industry has become a major source of atmospheric CO2 emissions, playing a substantial role in driving human-induced climate change. As per the International Energy Agency (IEA), in 2018, the building and construction industry accounted for a substantial 36% of the global final energy consumption, which contributed to a notable 39% of all energy and process-related carbon dioxide (CO2) emissions worldwide. Within this context, it’s important to highlight that a significant portion, amounting to 11%, of these emissions was directly attributable to the manufacturing of various key materials in construction and building industries such as steel, cement, and glass production [1].

Heightening population density, expanding urbanization and land shortage has increase the need of high-rise building. Estimates suggest that by the year 2050, around 70% of the world’s population will reside in urban region, with trends of population increase and urban migration, leading to an expansion of vertical housing [2].

Furthermore, The Intergovernmental Panel on Climate Change (IPCC) has verified that in 2010, buildings constituted 35% of the world’s overall energy consumption and were responsible for 19% of energy-related greenhouse gas emissions [3]. If we continue with the current practices to meet our needs, this energy consumption and associated emissions may increase twofold or even threefold by 2050 [3]. The reduction of energy consumption and the mitigation of climate change effects from buildings are regarded as a vital step in mitigating climate changes by IPCC [3]. To achieve carbon neutrality by the year 2050, it is essential to ensure that every newly constructed building, as well as a substantial portion, specifically 20%, of the existing building infrastructure, achieves zero-carbon status by the year 2030. This ambitious objective demands a significant transformation in contemporary construction methods and the retrofitting of a considerable segment of current structures to meet rigorous zero-carbon criteria within the next decade [4].

Timber, as a construction material, offers distinct advantages over conventional high-rise building construction materials such as steel and reinforced concrete (RC). Research revealed that augmenting timber consumption by 17% can lead to an impressive decrease of carbon emissions by 20% from construction materials [5]. Timber is renewable and boasts a naturally low carbon footprint, contributing minimally to greenhouse gas emissions during its production and utilization. This stands in contrast to steel and RC, which are associated with higher carbon emissions due to their energy-intensive manufacturing processes [6].

This study presents a thorough review, comparison, and analysis of the structural components required for the construction of high-rise buildings of various heights, focusing on the use of both RC and timber as primary materials. A detailed Life Cycle Assessment (LCA) of each material is conducted to ascertain their environmental impacts. The assessment is designed to highlight the comparative environmental and practical advantages of timber against the traditional RC approach, thus guiding the choice of structural materials towards sustainable urban development.

The paper supplements its analysis by acknowledging the global discrepancies in defining what constitutes a high-rise or tall building, based either on the structure’s height in meters or its number of floors. For this discussion, the definition of a high-rise aligns with the guidelines set by The Council on Tall Buildings and Urban Habitat (CTBUH), which identifies high-rises as buildings measuring 35 to 100 meters in height, typically equating to about 12 to 40 stories [7]. This uniform definition guarantees that the investigation of structural materials remains pertinent and applicable across the international landscape of high-rise architecture. In line with these standards, the research benchmarks a spectrum of buildings ranging from 12 to 21 stories.

2. Life Cycle Assessment

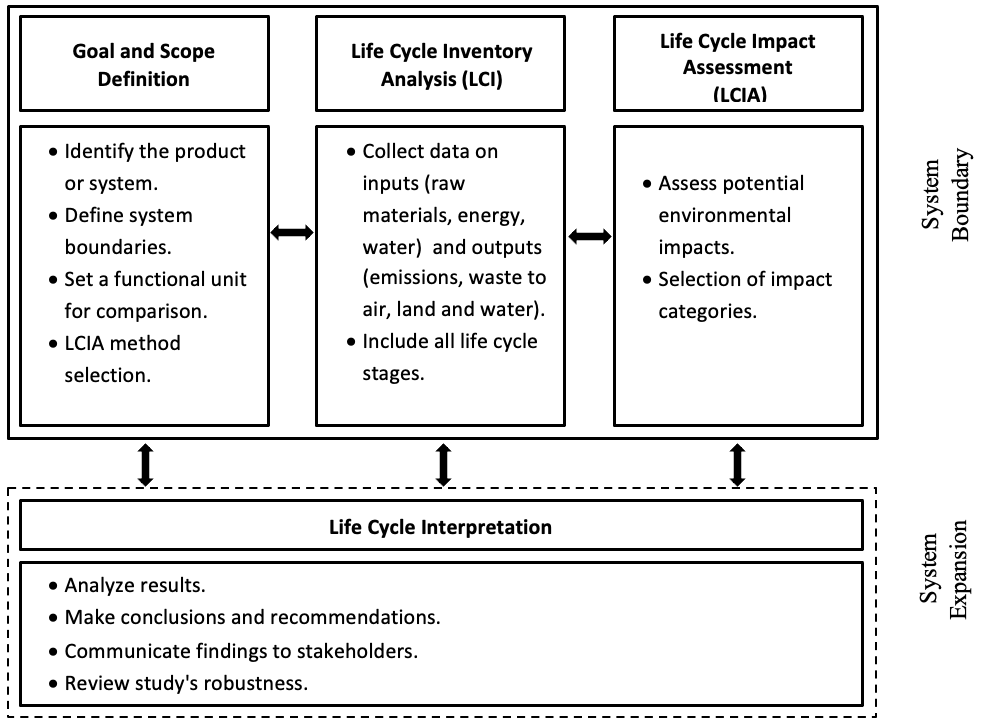

LCA is a methodical approach for evaluating the ecological effects associated with each phase in the lifespan of a product, from the initial gathering of its foundational components to its ultimate termination — a concept often termed as cradle to grave. This approach, established as a standard by the International Organization for Standardization in ISO 14040 [8], provides a consistent framework for assessment, as depicted in figure 1, which ensures methodological consistency and comparability across studies.

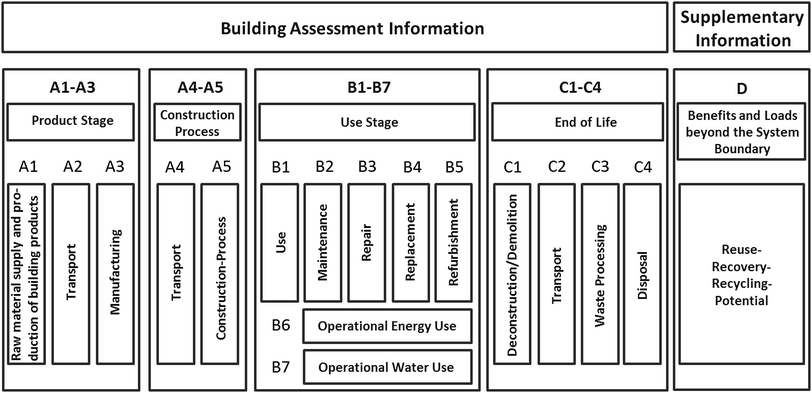

Figure 2 illustrates the four separate phases constituting life span of a building, from which environmental effects originate. These phases include material production (A1-A3) and construction (A4-A5), the operational lifespan (B1-B7), end of life (C1-C4), and potential advantages and loads that extend beyond the system boundary (D), as per the European Standard EN 15978 [9]. Through the examination of this assessment, we can comprehend and minimize the environmental impacts that span the entire lifecycle of construction materials—including manufacturing, transportation, construction, operation, maintenance, and the final demolition and waste management of the building etc.

In the quest to reduce the environmental footprint of the construction industry, LCA is becoming an indispensable tool. Recognized increasingly for its importance in evaluating and mitigating the ecological impacts of construction materials and methods, LCA is gaining traction across the sector. It encompasses a building’s journey from inception to demolition, offering a comprehensive and systematic approach. This method not only provides a wide-ranging perspective but also ensures a thorough consideration of every aspect. By offering an integrated evaluation of a building’s environmental impact, LCA stands as a key concept in modern green building research and assessment, emphasizing the significance of sustainable practices in construction [10].

Figure 1. LCA Framework based on ISO 14040 [8].

Figure 2. LCA modules for comprehensive building evaluation from inception to end-of-life as per the EN 15978 standard [9].

3. Mass Timber vs. Reinforced Concrete Building

Puettmann et al. [11] explored the environmental advantages of using mass timber (MT) for building projects, in contrast to the environmental impacts of conventional concrete structures, with a focus on the release of greenhouse gases from the start of the material life cycle to the construction phase. This evaluation included resource extraction (A1), transportation to the manufacturing site (A2), the manufacturing process (A3), delivery to the building location (A4), and the energy consumption during construction (A5).

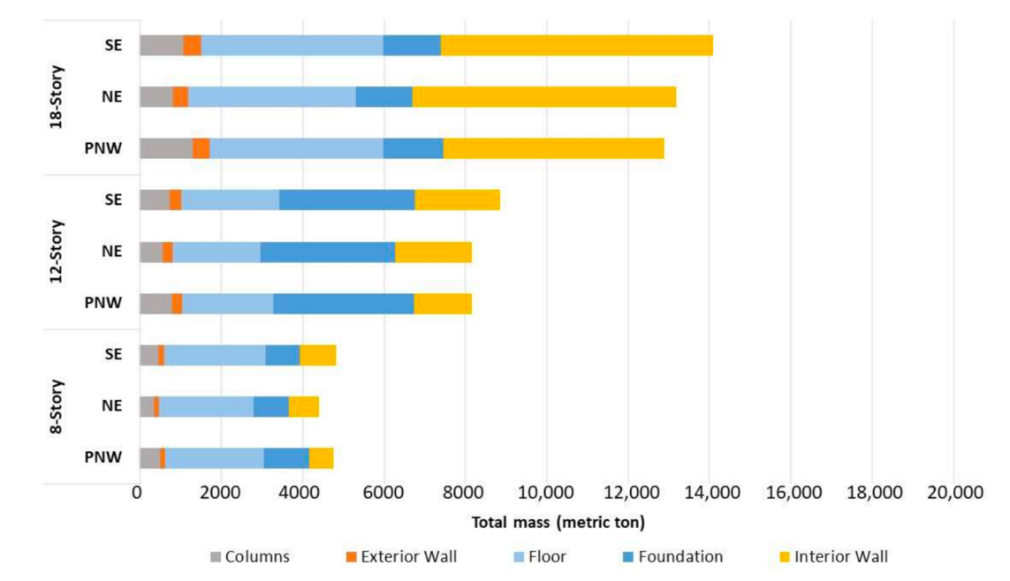

The study highlighted that implementing MT in the construction of buildings of various heights, particularly 8, 12, and 18 stories, in distinct United States locations—Seattle, Boston, and Atlanta—required certain assumptions about soil analysis for bearing capacity. The outcomes for the 12 and 18-story buildings, as documented by Puettmann et al., were of particular interest [11].

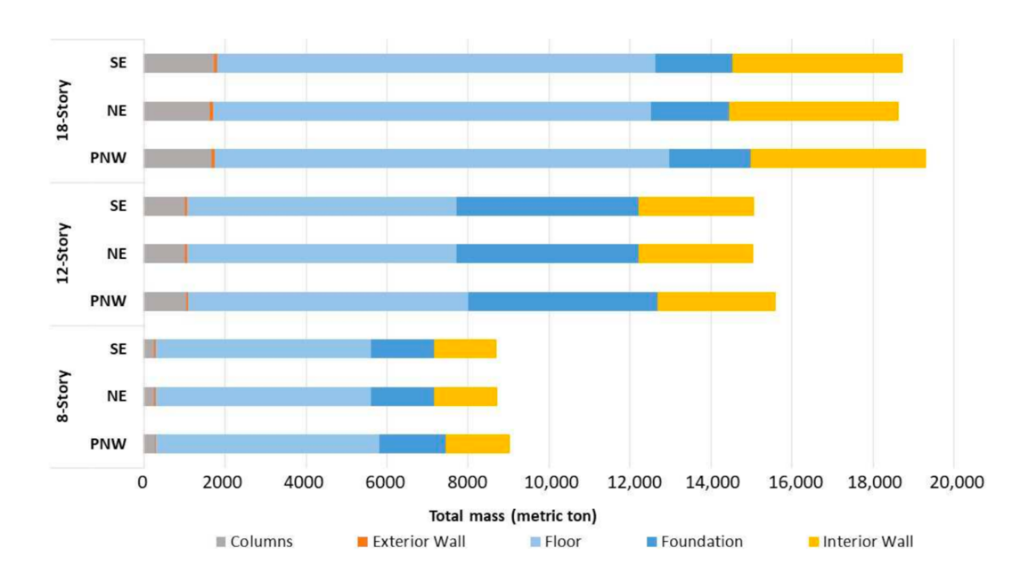

The research highlighted a notable reduction in the mass of buildings constructed with MT; specifically, a 12-story MT building weighs almost half as much as a RC structure. For buildings reaching 18 stories, MT structures are lighter by an estimated 2,500 metric tons, as shown in figure 3 [11]. The weight of high-rise buildings can negatively impact the environment; the greater the mass of the building, the more substantial the force exerted on the soil below. Constructing high-rises, particularly in regions with soft soil, may result in land subsidence—a scenario where the soil compacts and settles, causing the ground level to drop under the weight of large structures [12]. Additionally, large and heavy buildings necessitate deep and extensive foundations, potentially disrupting the land’s natural state, altering underground water tables, and changing the natural flow of groundwater [13].

Regarding the total embodied carbon from life cycle stages A1-A5, a 12-story wooden building emits 55-62% of the embodied carbon of an RC building. An 18-story MT structure emits 69-78% of that of an RC building, as shown in table 1, with variations primarily due to differences in transportation distances during the product stage (A2) [11].

(a) Mass of materials in mass timber buildings

(b) Mass of materials in concrete buildings

Figure 3. The mass of materials utilized in (a) mass timber and (b) concrete buildings with 8, 12, and 18 stories, situated in the Pacific Northwest (PNW), Northeast (NE), and Southeast (SE) areas of the U.S. [11].

Table 1. Embodied carbon totals across life cycle stages (A1–A5) for buildings made of mass timber and concrete. [11].

PNW Embodied Carbon kg CO2 e/m2 | |||||||||

Building System | A1-A3 | A4 | A5 | Total | |||||

12-story | Mass timber building | 139.2 | 88.5% | 12.8 | 8.1% | 5.3 | 3.4% | 157.3 | 100.0% |

Concrete building | 264.5 | 94.0% | 6.3 | 2.2% | 10.7 | 3.8% | 281.4 | 100.0% | |

18-story | Mass timber building | 146.1 | 87.3% | 14.8 | 8.8% | 6.5 | 3.9% | 167.3 | 100.0% |

Concrete building | 223.4 | 93.5% | 5.3 | 2.2% | 10.1 | 4.2% | 238.9 | 100.0% | |

NE Embodied Carbon kg CO2e /m2 | |||||||||

A1-A3 | A4 | A5 | Total | ||||||

12-story | Mass timber building | 121.4 | 86.1% | 14.2 | 10.1% | 5.3 | 3.8% | 141.0 | 100.0% |

Concrete building | 254.0 | 95.1% | 3.1 | 1.2% | 9.9 | 3.7% | 267.0 | 100.0% | |

18-story | Mass timber building | 130.0 | 87.2% | 13.0 | 8.7% | 6.1 | 4.1% | 149.1 | 100.0% |

Concrete building | 196.3 | 94.6% | 2.6 | 1.2% | 8.6 | 4.1% | 207.4 | 100.0% | |

SE Embodied Carbon kg CO2e/m2 | |||||||||

A1-A3 | A4 | A5 | Total | ||||||

12-story | Mass timber building | 144.0 | 90.8% | 8.76 | 5.5% | 5.81 | 3.7% | 158.6 | 100.0% |

Concrete building | 242.6 | 95.7% | 1.12 | 0.4% | 9.86 | 3.9% | 253.5 | 100.0% | |

18-story | Mass timber building | 157.2 | 91.4% | 7.68 | 4.5% | 7.09 | 4.1% | 172.0 | 100.0% |

Concrete building | 210.5 | 95.3% | 0.96 | 0.4% | 9.43 | 4.3% | 220.9 | 100.0% | |

The study by Skullestad et al [3]. investigated reducing greenhouse gas (GHG) emissions in multi-storey structures by replacing steel and concrete with timber. the study omitted buildings of 3, 7, 12, and 21 storeys. This paper will concentrate on high-rise buildings; hence 3 and 7 storeys buildings are out of the scope of this paper. The comparison was based on identical load-bearing capacity, location, and wind speed, considering only materials required for the load-bearing structure and foundations.

The system boundaries were established from cradle-to-gate (A1-A3), including an analysis of advantages and burdens extending past the system boundary (D). Three distinct calculation approaches were used to assess LCA, Approach 1 involved calculating and multiplying material emission factors by the corresponding material quantities. Approach 2 added the Global Warming Potential of biogenic CO2 (GWPbio) factors and considered concrete carbonation over the building’s lifetime. Approach 3 took a consequential perspective, looking at impacts from reuse, recycling, and concrete carbonation after the end of life [3].

The study revealed that timber structures exhibit a substantially reduced impact on climate change and GHG emissions than RC structures. Timber buildings caused approximately 30-85% less climate change impact (CC) than RC buildings, a variance influenced by building heights and methodological approaches. When 90% of timber by-products and waste underwent incineration with heat recapture, GHG emissions reduction potentials increased. Consequential analysis showed that timber structures could result in negative CC, reducing CO2-equivalent emissions by -140 to -235 kg per square meter depending on building height. This underscores timber buildings as a more sustainable construction option, especially for climate change mitigation [3].

4. Conclusion

In conclusion, the analysis reveals that mass timber structures significantly reduce the structural weight of high-rise buildings, offering an eco-friendlier alternative by halving the load exerted on the land compared to traditional reinforced concrete buildings. This weight reduction is vital in the burgeoning construction of high-rises and the consequent environmental burden.

Although the CC impact may vary with the height of the building, mass timber consistently results in less CC impact than reinforced concrete in every method analyzed. This finding underscores the potential of mass timber as a more sustainable building material in terms of reducing CC impact, regardless of the building’s height.

The study’s limitations might include variations in regional factors that affect energy usage. In the cited research, thorough comparisons between buildings made of mass timber and those of reinforced concrete were carried out, ensuring these assessments were performed in identical geographical regions to keep the analysis consistent. Nonetheless, it’s crucial to understand that the energy consumed in manufacturing and moving construction materials may vary across different areas. This variation results from differences in transportation distances and methods, implying that LCA for buildings might yield different outcomes depending on their specific locations.

Different soil conditions and geological characteristics can lead to variations in foundation requirements and the quantity of materials used. Geographic locations with erosive elements, such as maritime winds, may influence the durability of mass timber versus reinforced concrete. Therefore, further research into their respective life spans under varying environmental stressors is warranted. This additional research could provide more comprehensive insights into the long-term sustainability and resilience of these building materials in different geographical settings. Replacing reinforced concrete with timber in high-rise buildings is undeniably beneficial for the environment. This substitution significantly reduces the structural pressure on the land and greatly lowers carbon emissions. Nonetheless, the development of timber structures might be limited due to a lack of comprehensive legal and standard support. In many countries, existing building regulations may not adequately recognize the characteristics and advantages of timber, highlighting the need for further legislative and regulatory advancements to encourage the innovation and application of timber construction techniques. Consequently, it is essential for policymakers, architects, and engineers to collaborate in creating suitable building standards and norms for timber structures to facilitate the adoption and growth of this environmentally friendly building material.

References

[1]. Abergel T, Dulac J, Hamilton I et al. 2019 Global Status Report for Buildings and Construction The APPEA Journal

[2]. Ritchie H and Roser M Urbanization 2018 Retrieved on 11.20.2023. Retrieved from: https://ourworldindata.org/urbanization

[3]. Skullestad J L, Bohne R A and Lohne J 2016 High-rise Timber Buildings as a Climate Change Mitigation Measure – A Comparative LCA of Structural System, Alternatives Energy Procedia 96 112-123

[4]. Duan Z, Huang Q and Zhang Q 2022 Life cycle assessment of mass timber construction: A review. Building and Environment 221

[5]. Buchanan A H and Levine S B 1999 Wood-based building materials and atmospheric carbon emissions Environmental Science & Policy

[6]. Tsai Y S 2017 Estimation for the Feasibility of High-rise Timber Buildings in Taiwan by Means of Life Cycle Assessment-Comparative Environment Evaluation about Timber and RC Housing National Cheng Kung University

[7]. CTBUH Council on Tall Buildings and Urban Habitat 2023 Retrieved on 11.20.2023. Retrieved from: https://www.ctbuh.org/resource/height

[8]. ISO 14040, 2006 Environmental Management - Life Cycle Assessment - Principles and Framework, second ed., International Organization for Standardization, Geneva, Switzerland, Retrieved on 11.18.2023. Retrieved from: https://www.iso.org/standard/37456.html

[9]. EN C 15978 2011 Sustainability of Construction Works - Assessment of Environmental Performance of Buildings - Calculation Method European Standards: Brussels, Belgium

[10]. Chang Y-S. 2002 Life cycle assessment on the reduction of carbon dioxide emission of buildings National Cheng Kung University.

[11]. Puettmann M, Pierobon F, Ganguly I et al. 2021 Comparative LCAs of Conventional and Mass Timber Buildings in Regions with Potential for Mass Timber Penetration Sustainability 13 4-19

[12]. Cui Z D, Yang J Q and Yuan L 2015 Land subsidence caused by the interaction of high-rise buildings in soft soil areas Nat Hazards 79 1199-1217

[13]. Ireland H O, Varnes D J and Kiersch G 1969 Reviews in Engineering Geology Geological Society of America

Cite this article

Chan,Y. (2024). Comparison of mass timber structure and RC structure with regard to sustainability by life cycle assessment. Applied and Computational Engineering,61,255-261.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Abergel T, Dulac J, Hamilton I et al. 2019 Global Status Report for Buildings and Construction The APPEA Journal

[2]. Ritchie H and Roser M Urbanization 2018 Retrieved on 11.20.2023. Retrieved from: https://ourworldindata.org/urbanization

[3]. Skullestad J L, Bohne R A and Lohne J 2016 High-rise Timber Buildings as a Climate Change Mitigation Measure – A Comparative LCA of Structural System, Alternatives Energy Procedia 96 112-123

[4]. Duan Z, Huang Q and Zhang Q 2022 Life cycle assessment of mass timber construction: A review. Building and Environment 221

[5]. Buchanan A H and Levine S B 1999 Wood-based building materials and atmospheric carbon emissions Environmental Science & Policy

[6]. Tsai Y S 2017 Estimation for the Feasibility of High-rise Timber Buildings in Taiwan by Means of Life Cycle Assessment-Comparative Environment Evaluation about Timber and RC Housing National Cheng Kung University

[7]. CTBUH Council on Tall Buildings and Urban Habitat 2023 Retrieved on 11.20.2023. Retrieved from: https://www.ctbuh.org/resource/height

[8]. ISO 14040, 2006 Environmental Management - Life Cycle Assessment - Principles and Framework, second ed., International Organization for Standardization, Geneva, Switzerland, Retrieved on 11.18.2023. Retrieved from: https://www.iso.org/standard/37456.html

[9]. EN C 15978 2011 Sustainability of Construction Works - Assessment of Environmental Performance of Buildings - Calculation Method European Standards: Brussels, Belgium

[10]. Chang Y-S. 2002 Life cycle assessment on the reduction of carbon dioxide emission of buildings National Cheng Kung University.

[11]. Puettmann M, Pierobon F, Ganguly I et al. 2021 Comparative LCAs of Conventional and Mass Timber Buildings in Regions with Potential for Mass Timber Penetration Sustainability 13 4-19

[12]. Cui Z D, Yang J Q and Yuan L 2015 Land subsidence caused by the interaction of high-rise buildings in soft soil areas Nat Hazards 79 1199-1217

[13]. Ireland H O, Varnes D J and Kiersch G 1969 Reviews in Engineering Geology Geological Society of America