1. Introduction

In recent years, the scale of highway construction has continued to expand, and numerous highway bridges have been put into operation. The maintenance and repair of highway bridges have become increasingly important, with particular emphasis on the treatment of crack diseases. When carrying out maintenance and repair work on highway bridges, it is important to conduct a comprehensive and objective analysis of the cracks’ causes and develop targeted treatment strategies to prevent potential safety hazards. Although previous studies, such as the work by Houlong Bao in “Analysis and Treatment Measures for the Causes of Bridge Cracks in Highway Bridge Maintenance and Repair,” [1] have provided a comprehensive summary of bridge cracks, they have overlooked preventive maintenance. Similarly, Weifurong’s work on “Discussion of Common Diseases and Crack Treatment Techniques in Continuous Rigid Bridges” [2] focuses only on rigid bridges. Additionally, Wu Penglai and Li Peng have analyzed and summarized cracks in masonry arch bridges [3] and girder bridges [4], respectively, but their studies are limited to specific types of bridges. Considering the current research status in China, there is still a lack of comprehensive summaries on the causes and preventive maintenance measures for bridge cracks. Therefore, this paper aims to provide a systematic summary of the causes and preventive maintenance measures for bridge cracks using an inductive approach.

2. Causes of Bridge Cracks

2.1. Temperature

Temperature has a significant impact on cracks, including thermal expansion and contraction, annual temperature difference, daily temperature difference, temperature-induced stress, and hydration heat [1]. Non-structural cracks [4], which are frequent in most concrete bridges, especially in girder bridges, are often caused by temperature variations. Temperature cracks can be further classified as uniform temperature difference cracks, internal and external temperature difference cracks, and upper and lower temperature difference cracks, based on the temperature field, temperature deformation, and temperature stress of the concrete structure. Non-structural cracks are primarily caused by concrete deformation and are influenced by factors such as concrete pouring methods, curing conditions, material composition, temperature differences, daily temperature variations, and solar radiation.

2.2. Uneven Shrinkage

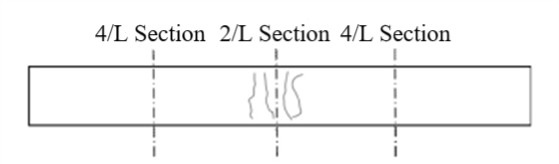

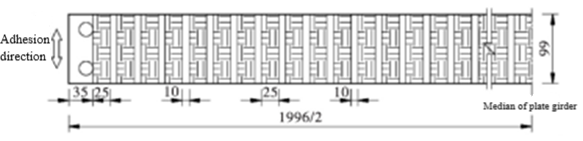

There are various reasons for the occurrence of cracks in bridge structures, with cracks caused by local compression and material shrinkage deformation referred to as shrinkage cracks [5]. The main causes of shrinkage cracks are uneven local compression leading to material shrinkage deformation and tensile strength being less than the tensile force resulting in structural deformation (discussed here only during the operational phase). Shrinkage cracks can be further classified into plastic shrinkage cracks and drying shrinkage cracks, based on their mechanisms. Generally, external constraints and the delayed deformation of the structure itself contribute to the formation and propagation of cracks to some extent. In continuous rigid bridges, transverse cracks are more likely to occur near the mid-span of the beam, around 1/4L to 3/4L [2]. The width of transverse cracks can reach approximately 0.2mm, and these cracks often form in the tensile zone of the beam’s side face and gradually extend in the direction perpendicular to the main reinforcement. If multiple transverse cracks exist in the same area of the beam, these cracks tend to converge and can pose significant structural safety issues. The distribution of transverse cracks in the bottom plate, web plate, and wing plate is also different, with transverse cracks primarily appearing in the bottom plate, as shown in Figure 1.

Figure 1. Schematic diagram of horizontal crack distribution

2.3. Reinforcement Corrosion

The insufficient thickness of the concrete protective layer leads to the corrosion of reinforcement, causing longitudinal and transverse cracks in the overall structure along the direction of the reinforcement. A typical example is the exposure of reinforcement due to concrete damage. For ordinary bridges, the main diseases that affect their durability and service life include concrete damage, reinforcement corrosion and exposure of reinforcement. This also applies to continuous rigid-frame bridges. When concrete is damaged, the reinforcement is easily exposed to external rainwater, and the obvious characteristic of reinforcement corrosion is the appearance of longitudinal cracks parallel to the reinforcement in the direction of traffic flow. As the cracks expand and the concrete gradually flakes off, the reinforcement will eventually be exposed to the air. Concrete damage leading to reinforcement exposure and corrosion directly causes stress concentration, resulting in a decrease in the load-bearing capacity of the bridge. In severe cases, it can lead to increased brittleness and fracture failure of the bridge [2].

2.4. Structural Overload

Bridges in operation are subjected to long-term effects of vehicle loads, which can make their structures unstable. For steel bridges, prolonged exposure to heavy loads can cause significant cracks in the steel plate structure of the bridge deck. The rigidity of the bridge deck steel plate is insufficient to support the vehicle load [6], and under high traffic pressure, the steel plate is prone to deformation. Long-term deformation will reduce the performance of the pavement materials and pose a risk of crack diseases. For girder bridges, long-term exposure to high-intensity loads can generate structural cracks [4] (load-induced cracks). There are generally two forms of cracks depending on their location: vertical cracks occurring in areas subjected to large bending moments are called flexural cracks, and diagonal cracks occurring on both sides of the web plate due to shear or combined shear and bending moments are called shear cracks. Such cracks are common on bridges with long service periods and high traffic volume, and they require careful treatment. In addition, due to excessive local stress, splitting cracks may occur in the prestressed anchorage zone. Longitudinal cracks may appear on concrete piers due to excessive longitudinal pressure. Insufficient protective layer thickness in the main girder can cause longitudinal cracks along the direction of the prestressed ducts. For arch bridges, excessive vehicle loads on the bridge deck can cause excessive lateral pressure on the side walls, leading to cracking of the side walls [3].

2.5. Missing Drainage System

In the later stages of operation, settlement cracks occur in the foundation and pier abutments due to differential settlement and inadequate drainage facilities, allowing water to enter. Taking arch bridges as an example, the lack of a drainage system can cause cracking and damage to the bridge deck. The damage to the bridge deck pavement not only increases the impact pressure from passing vehicles but also allows more water to infiltrate the interior of the arch bridge, endangering the side walls and arch rings. When cracks and damage appear on the bridge deck pavement, repairs should be carried out promptly. Moreover, water seepage occurs in the arch rings and side walls, where alkaline crystals can precipitate, leading to cracks [3], as shown in Figure 2.

Figure 2. Whitening of the side walls of an arch bridge due to deep water immersion.

2.6. Structural Aging and Excessive Service Life

For arch bridges, excessive service life will first cause natural weathering of the stone materials. Exposed to the air for a long time, the stone materials and mortar joints undergo erosion from wind and water, resulting in natural weathering and joint damage, which affects the structural safety to some extent. Secondly, it may also cause cracking of the arch ring. Cracking of the arch ring is one of the most serious diseases in stone arch bridge structures. Common arch ring cracking usually starts horizontally from the top of the arch ring and follows the mortar joints. In severe cases, it can penetrate the entire width of the arch ring at the bottom. If cracks in the arch ring are not repaired and strengthened in a timely manner, and they are allowed to develop freely to a certain extent, the bending moment resistance of the arch bottom will significantly decrease, causing changes in the original design structural system of the bridge and altering the internal forces, leading to instability of the arch bridge [3]. In addition, for most bridges, the aging and cracking of bearings are also common diseases. The main reason is that over time, under the long-term action of external live loads, the bearings age and deteriorate, leading to cracking. Of course, part of the reason can also be attributed to issues with the quality of the bearings themselves.

3. Treatment methods for maintenance and repair of cracks in concrete structures

3.1. Surface sealing method

For non-structural cracks with a width <0.15mm, crack sealant can be directly applied to the surface [7]. The first step is to locally repair the surface. For example, if there is local damage or weathering on the arch surface, the damaged area should be chiseled, cleaned, and then M10 cement mortar should be layered and sprayed to the required thickness. If the damage is deep, the spraying should be done in multiple layers with a one to two-day interval between each layer. If the damage is severe, to enhance the strength of the repaired area, a layer of steel wire mesh can be arranged during the mortar spraying. If the joint mortar has come off, it should be repaired and rejointed in a timely manner. If there is weed growth in the joint, the weed and roots inside the joint must be removed, and the affected joint should be removed and rejoined. The joint should be filled as much as possible. The second step is to use crack repair technology to repair the cracks. Crack repair technology is used for cracked slab beams. The repair adhesive is injected into the cracks under pressure to seal them and restore the working performance of the slab beam. The cracks are repaired by injecting a proportionally mixed grout into the longitudinal cracks under a certain pressure. The grout solidifies over time, providing adhesion and recombining the cracked concrete components into a cohesive whole.

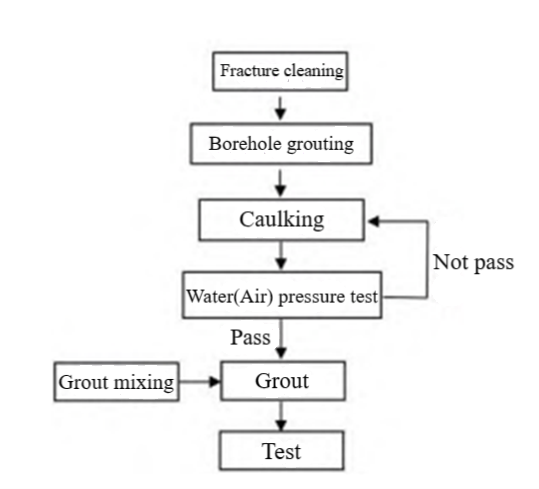

3.2. Low-pressure grouting method

For bridge cracks with a width ≥0.15mm, the low-pressure grouting method is generally used for repair and treatment to restore the integrity of the concrete at the crack location [8]. The first method is direct grouting repair at the crack location. For example, once cracking occurs in an arch bridge, it usually develops rapidly and affects the stability of the bridge. To repair this damage, cement mortar or other chemical grouts can be injected into the cracks. The process flowchart for grouting repair of arch bridges is shown in Figure 3.

Figure 3. Process flowchart for grouting repair of arch bridges

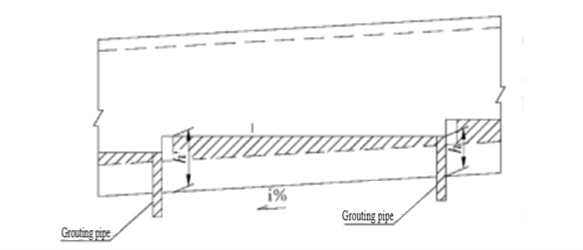

The second method is the use of bottom plate grouting technology [9] for crack repair. Bottom plate grouting technology mainly involves opening holes at the bottom of the beam slab and injecting flowable polymer cement grout material into the voids of the slab beam under external pressure, as shown in the Figure 4 below.

Figure 4. Schematic diagram of bottom plate grouting

3.3. Treatment of cracks using carbon fiber cloth bonding

For bridge cracks with a large range of fine cracks and irregular distribution on the surface of the beam, the cracks can be treated first and then carbon fiber cloth can be bonded. This method not only meets the requirements for strengthening and repairing cracks but also improves the local bearing capacity of the bridge [10]. Two techniques are mainly used: transverse carbon fiber bonding technique and external transverse prestressing technique. In the first technique, after repairing the cracks, adhesive is applied transversely to bond the carbon fiber and restore the working performance of the slab beam. The carbon fiber bonding method is widely used in bridge strengthening practice and, like the bottom plate grouting method, belongs to passive reinforcement. The bonded carbon fiber only bears the subsequent live load. The bonding effect is shown in Figure 5.

Figure 5. Schematic diagram of transverse carbon fiber bonding (cm)

The second technique, the external transverse prestressing technique [2], involves bonding and anchoring steel plates on the side of the beam after repairing the cracks, and then applying transverse prestressing force externally to the beam slab, generating transverse pre-compression stress on the bottom plate of the beam, preventing re-cracking of the bottom plate.

4. Measures for Proactive Prevention of Bridge Cracks

4.1. Ensuring the thickness of the concrete cover for beam reinforcement.

During the maintenance and operation stage of the bridge, regular inspections of the thickness of the protective layer of the beam should be conducted, especially for beams with carbonation on the surface of the concrete. First, taking the masonry arch bridge as an example, the cross-section of the main arch ring can be reinforced, mainly targeting the main arch ring. When it is not possible to add a new arch ring below the original arch ring, the construction of a new arch ring on the original arch ring can be considered [3]. However, this method is more complex and requires closing the traffic, demolishing part of the old bridge arch, and arranging steel mesh for cast-in-place concrete. Secondly, for most bridges, protection against scouring can be applied to pier and abutment foundations, with the use of perimeter stone concrete reinforcement for individual or fewer piers and abutments.

4.2. Regular inspections of critical parts of the bridge

Especially for critical load-bearing and force-transmitting structures such as main beams and transverse diaphragms. First, measures should be taken to reduce temperature difference cracks, such as proper positioning of ventilation holes and drainage outlets during maintenance and repair, in cooperation with the design unit to supplement ventilation openings, drainage systems, etc. Secondly, improving the bridge deck drainage equipment is also essential. During bridge maintenance, the blockage in the drainage pipes should be cleared promptly to ensure smooth drainage. At the same time, for some bridges with short drainage pipe lengths, wind can cause scouring of the side walls during the drainage process. In such cases, the drainage pipes can be replaced with longer and downward-bent pipes to prevent side wall scouring.

4.3. Strengthening operational management

Preventing excessive overloading of the bridge. If overloaded vehicles must pass, the bridge should be strengthened with protective and reinforcement measures. During maintenance and repair, other bridge diseases, such as uneven settlement of foundations and sinking of bearings, should be promptly treated.

4.4. Surface appearance enhancement protection

Taking the masonry arch bridge as an example, to prevent weathering and water erosion of the masonry arch bridge structure, surface coating protection materials can be used to enhance durability. Examples of protective materials include stone protection agents, waterproof and salt-resistant agents, and real stone paint. On the basis of improving the surface’s abilities to resist water, corrosion, and salt, it can also enhance the aesthetic perception of the bridge, as shown in Figure 6.

Figure 6. Masonry arch bridge with stone protection agent coating

5. Conclusion

From the start of bridge operation, it enters the maintenance stage, and the most important task during this stage is to identify and address bridge diseases. Before addressing these diseases, it is necessary to analyze their causes in order to handle them specifically and prevent them from happening. Based on a large amount of practical experience in highway bridge maintenance and repair in recent years, cracks in bridge structures are very common and can be considered inevitable. This paper analyzes the causes of bridge cracks and proposes a series of treatment methods and preventive maintenance measures, enabling bridge maintenance and repair personnel to better differentiate the causes of various types of cracks and promptly take remedial measures. At the same time, proactive prevention measures should be taken during the daily maintenance of bridges to ensure effective control of concrete cracks in the early stages, limiting their degree of harm and preventing further development, thus reducing safety hazards during the operation of bridges.

References

[1]. Hou, L. B. (2022). Analysis of the causes of cracks in highway bridge maintenance and repair and their treatment measures. Science, Technology and Innovation, (24), 109-112.

[2]. Wei, F. R. (2019). Discussion on common diseases and crack treatment techniques of continuous rigid frame bridges. Western China Science and Technology, (09), 107-110. DOI:10.13282/j.cnki.wccst.2019.09.031.

[3]. Wu, P. L. (2022). Exploration of maintenance and repair of masonry arch bridges. China Highways, (11), 162-164. doi:10.13468/j.cnki.chw.2022.11.035.

[4]. Li, P. (2019). Summary of common diseases and causes of beam bridges during operation. Sichuan Cement, (06), 25.

[5]. Wang, T. M. (2017). Crack Control of Engineering Structures (2nd ed.). Beijing: China Architecture & Building Press.

[6]. Yu, Y. F., & Wang, Y. (2022). Analysis of causes and preventive measures for pavement diseases in bridge maintenance. Journal of New Industrialization, 12(08), 138-141. DOI:10.19335/j.cnki.2095-6649.2022.8.034.

[7]. He, R. X. (2020). Analysis of causes and control measures of concrete bridge cracks. China High-Tech, (10), 119-120.

[8]. Wu, Y. Y., Li, Y. L., & Niu, G. (2010). Research on crack treatment methods during bridge operation. Journal of Guizhou University (Natural Sciences), 27(01), 119-120.

[9]. Sun, J. B. (2020). Research on the causes and treatment measures of longitudinal cracks in the bottom plate of hollow slab bridges. Construction and Design, (05), 74-76. DOI:10.13616/j.cnki.gcjsysj.2020.03.026.

[10]. Chen, K. (2021). Application of carbon fiber cloth pasting reinforcement method in maintenance and reinforcement of highway bridges. Transportation World, (36), 61-62+79. DOI:10.16248/j.cnki.11-3723/u.2021.36.058.

Cite this article

Zhang,Z. (2024). Causes and treatment of bridge cracks. Applied and Computational Engineering,63,181-187.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Hou, L. B. (2022). Analysis of the causes of cracks in highway bridge maintenance and repair and their treatment measures. Science, Technology and Innovation, (24), 109-112.

[2]. Wei, F. R. (2019). Discussion on common diseases and crack treatment techniques of continuous rigid frame bridges. Western China Science and Technology, (09), 107-110. DOI:10.13282/j.cnki.wccst.2019.09.031.

[3]. Wu, P. L. (2022). Exploration of maintenance and repair of masonry arch bridges. China Highways, (11), 162-164. doi:10.13468/j.cnki.chw.2022.11.035.

[4]. Li, P. (2019). Summary of common diseases and causes of beam bridges during operation. Sichuan Cement, (06), 25.

[5]. Wang, T. M. (2017). Crack Control of Engineering Structures (2nd ed.). Beijing: China Architecture & Building Press.

[6]. Yu, Y. F., & Wang, Y. (2022). Analysis of causes and preventive measures for pavement diseases in bridge maintenance. Journal of New Industrialization, 12(08), 138-141. DOI:10.19335/j.cnki.2095-6649.2022.8.034.

[7]. He, R. X. (2020). Analysis of causes and control measures of concrete bridge cracks. China High-Tech, (10), 119-120.

[8]. Wu, Y. Y., Li, Y. L., & Niu, G. (2010). Research on crack treatment methods during bridge operation. Journal of Guizhou University (Natural Sciences), 27(01), 119-120.

[9]. Sun, J. B. (2020). Research on the causes and treatment measures of longitudinal cracks in the bottom plate of hollow slab bridges. Construction and Design, (05), 74-76. DOI:10.13616/j.cnki.gcjsysj.2020.03.026.

[10]. Chen, K. (2021). Application of carbon fiber cloth pasting reinforcement method in maintenance and reinforcement of highway bridges. Transportation World, (36), 61-62+79. DOI:10.16248/j.cnki.11-3723/u.2021.36.058.