1. Introduction

Long-span spatial structures in steel engineering present unique challenges and opportunities, requiring advanced analysis methods and innovative construction techniques to ensure stability, efficiency, and durability. The Direct Analysis Method (DAM) serves as a powerful tool in analyzing the behavior of steel structures, leveraging principles of equilibrium, compatibility, plasticity, and stability to optimize design solutions. Modeling techniques such as Finite Element Analysis (FEA), dynamic analysis, and nonlinear analysis play pivotal roles in predicting structural response under diverse loading conditions, facilitating informed design decisions and enhancing structural performance. Practical considerations in material selection, connection design, and construction are essential for achieving optimal outcomes, with a focus on enhancing performance, durability, and constructability [1]. Prefabrication and modular construction techniques offer significant advantages in terms of schedule acceleration, quality control, and site safety, contributing to the successful delivery of long-span spatial structures in steel engineering. Through a comprehensive exploration of advanced analysis methods and construction techniques, this paper aims to provide valuable insights for engineers and researchers involved in the design and construction of long-span spatial structures in steel engineering.

2. Principles of the Direct Analysis Method (DAM)

2.1. Equilibrium and Compatibility

The Direct Analysis Method (DAM) fundamentally relies on the principles of equilibrium and compatibility to analyze the behavior of steel structures. Equilibrium ensures that the sum of forces acting on the structure is zero in both the linear and angular senses, ensuring overall stability. Compatibility, on the other hand, addresses the deformations and displacements within the structure, ensuring that these deformations are compatible with the structure’s geometry and constraints. Equilibrium is mathematically expressed through the equilibrium equations, which state that the sum of forces in the x, y, and z directions is zero, and the sum of moments about any point is zero:

\( \sum F=0 \ \ \ (1) \)

\( \sum M=0 \ \ \ (2) \)

Where:

• ∑F represents the sum of forces acting on the structure in the x, y, and z directions, ensuring that the structure remains in translational equilibrium.

• ∑M represents the sum of moments about any point, ensuring that the structure remains in rotational equilibrium.

These equations are fundamental in analyzing the external loads acting on the structure and the internal forces developed within the members. Compatibility involves ensuring that the deformations and displacements within the structure satisfy the geometric constraints imposed by the structure’s connections and supports. This requires considering the compatibility of deformations between connected members and ensuring that the structure maintains its intended shape and stiffness under loading conditions [2].

2.2. Plasticity and Stability

The incorporation of plastic behavior into the analysis distinguishes the DAM from traditional elastic analysis methods. Plasticity allows for a more accurate prediction of structural response under extreme loading conditions, where members may undergo significant nonlinear deformation. Plasticity in steel structures occurs when the material undergoes permanent deformation beyond the elastic limit. The DAM accounts for this plastic behavior by considering the redistribution of internal forces and the formation of plastic hinges in structural members. By allowing for plastic deformation, the DAM provides a more realistic representation of structural behavior, particularly in the nonlinear range. Stability considerations are paramount in the design of steel structures to ensure that the structure can resist buckling and maintain its integrity under various loading scenarios. Buckling can occur due to compressive loads acting on slender members, leading to structural instability and potential failure. The DAM addresses stability through proper member sizing, bracing, and connection detailing to prevent buckling and ensure structural safety.

2.3. Load Path and Redundancy

Load path analysis is a critical aspect of the DAM, involving the identification of primary and secondary load paths within the structure. Primary load paths are the main routes through which loads are transferred from the point of application to the supports, while secondary load paths provide redundancy and alternative routes for load transfer. By analyzing load redistribution mechanisms, engineers can optimize the design for efficiency and resilience, ensuring that the structure can withstand localized failures without catastrophic collapse [3]. Redundancy in the structural system enhances robustness and reliability, allowing the structure to maintain functionality even in the event of member failure or extreme loading conditions. The exploitation of redundancy involves designing redundant load paths and connections to distribute loads more evenly throughout the structure. This may include providing redundant bracing systems, alternative load paths for critical members, and redundant connections to ensure structural stability and safety. By leveraging redundancy, engineers can enhance the overall performance and reliability of steel structures, reducing the risk of structural failure and improving long-term durability.

3. Modeling Techniques for Long-Span Spatial Structures

3.1. Finite Element Analysis (FEA)

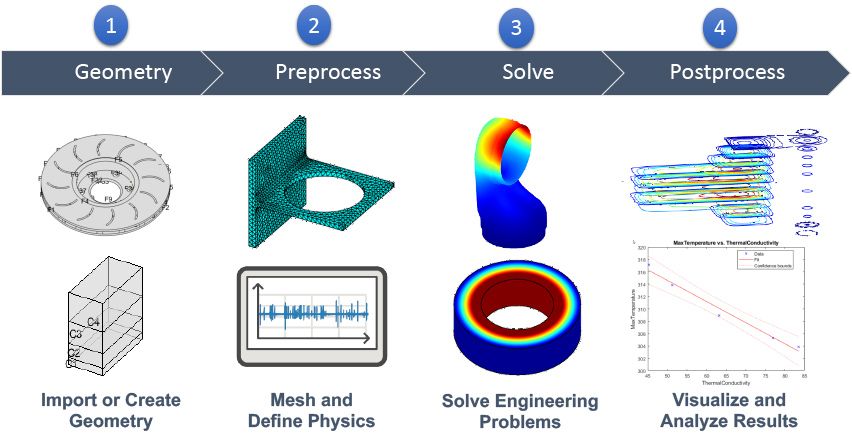

Finite Element Analysis (FEA) stands as a cornerstone in the arsenal of modeling techniques for long-span spatial structures, as shown in Figure 1. It facilitates a comprehensive understanding of structural behavior by discretizing the structure into finite elements and solving for equilibrium within each element.

Figure 1. What Is Finite Element Analysis? (Source: MathWorks)

The process involves representing the complex geometry and loading conditions through a mesh of interconnected elements, where the behavior of each element is governed by mathematical equations derived from structural mechanics principles. FEA enables detailed analysis of various structural components and their interactions, offering insights into stress distribution, deformation patterns, and failure mechanisms. In the context of long-span spatial structures, FEA plays a pivotal role in optimizing design solutions and ensuring structural integrity under diverse loading scenarios. By accurately capturing the behavior of complex geometries, such as curved surfaces and irregular configurations, FEA allows engineers to identify critical regions susceptible to excessive stress concentrations or instability [4]. Additionally, FEA facilitates parametric studies and sensitivity analyses, enabling engineers to evaluate the impact of design parameters, material properties, and boundary conditions on structural performance. The success of FEA hinges on the selection of appropriate element types, mesh densities, and numerical algorithms tailored to the specific characteristics of the structure and loading conditions. Advanced techniques, such as adaptive mesh refinement and substructuring, further enhance the accuracy and efficiency of FEA simulations for long-span spatial structures. Moreover, integration with computational tools for structural optimization and probabilistic analysis enables engineers to systematically explore design alternatives and mitigate uncertainties.

3.2. Dynamic Analysis

Dynamic analysis serves as a crucial tool in assessing the dynamic response of long-span spatial structures to transient loads, including wind, seismic, and human-induced vibrations. Unlike static analysis, which focuses on equilibrium under static loads, dynamic analysis accounts for inertial effects and time-dependent behavior, providing valuable insights into structural stability, comfort criteria, and serviceability limits. Table 1 provides a concise overview of dynamic analysis techniques and their applications in designing and evaluating long-span spatial structures.

Table 1. Overview of Dynamic Analysis Techniques for Long-Span Spatial Structures

Dynamic Analysis Techniques | Description |

Modal Analysis | Modal analysis involves extracting the natural modes of vibration and corresponding frequencies of the structure. This technique helps identify dominant modes and frequencies, assess resonance phenomena, and estimate dynamic amplification factors and modal participation factors. It aids in evaluating structural response under specific loading conditions. |

Time-History Analysis | Time-history analysis simulates the structure’s response over time under prescribed loading histories, such as wind gusts, seismic ground motions, or vehicular traffic. It captures transient effects, providing insights into structural behavior and facilitating the assessment of safety, comfort, and serviceability criteria. |

Strategies for Vibration Mitigation | Dynamic analysis informs the selection and implementation of strategies for vibration mitigation, including tuned mass dampers, passive damping devices, and active control systems. These strategies aim to mitigate excessive vibrations, ensuring occupant comfort and safety. |

Support for Performance-Based Design | Dynamic analysis supports performance-based design approaches, wherein structural response is evaluated against specified performance objectives rather than prescriptive code requirements. It allows for tailored solutions that meet the project’s specific requirements and performance criteria. |

3.3. Nonlinear Analysis

Nonlinear analysis techniques play a pivotal role in capturing the complex behavior of long-span spatial structures under extreme loading conditions, including large deformations, material nonlinearities, and structural instabilities. Unlike linear analysis methods, which assume linear relationships between loads and deformations, nonlinear analysis accounts for nonlinear effects such as geometric imperfections, material yielding, and post-buckling behavior.

Geometric nonlinearities arise from large deformations and displacements, leading to changes in the structural stiffness and redistribution of internal forces. Nonlinear geometric effects become pronounced in long-span spatial structures with slender members and flexible configurations, necessitating their consideration in structural analysis and design. Material nonlinearities, on the other hand, stem from nonlinear stress-strain relationships exhibited by certain materials, such as steel and concrete, under high stress levels or cyclic loading. By incorporating nonlinear material models and plasticity theories, engineers can accurately predict material yielding, plastic deformation, and ultimate failure modes in long-span spatial structures. Structural instabilities, including buckling, snap-through, and limit point phenomena, represent another aspect addressed by nonlinear analysis techniques. These instabilities may arise due to geometric imperfections, initial imperfections, or sudden changes in loading conditions, leading to abrupt changes in structural behavior and collapse mechanisms [5]. Nonlinear analysis facilitates the identification of critical instability modes and the assessment of structural robustness against buckling and post-buckling phenomena. In practice, nonlinear analysis techniques are applied iteratively, starting from simplified linear analyses to establish initial design concepts and gradually refining the model to account for nonlinear effects. Advanced numerical methods, such as nonlinear finite element analysis (NLFEA) and incremental-iterative algorithms, are employed to solve the nonlinear equilibrium equations and trace the structural response under progressively increasing loads. Nonlinear analysis enables engineers to assess the ultimate capacity, ductility, and resilience of long-span spatial structures, guiding design decisions to ensure safety, reliability, and performance under extreme loading conditions. Geometric nonlinearities are mathematically represented by the following equations:

\( {F_{geo}}={K_{geo}}∆u \ \ \ (3) \)

where \( {F_{geo}} \) represents the geometrically nonlinear force, \( {K_{geo}} \) denotes the geometric stiffness matrix, and Δu represents the nodal displacements.

4. Practical Considerations in Design and Construction

4.1. Material Selection and Specification

The selection and specification of materials for long-span spatial structures are crucial determinants of structural performance and longevity. Various factors must be considered in this process, including steel grades, protective coatings, and environmental sustainability.

Steel Grades: The choice of steel grades depends on the specific requirements of the structure, including load-bearing capacity, resistance to corrosion, and environmental conditions. High-strength steels, such as ASTM A992 or EN 10025-2 S355, are often preferred for long-span structures due to their superior strength-to-weight ratio and ductility.

Protective Coatings: Corrosion protection is essential for ensuring the durability of steel structures, especially in harsh environments such as coastal areas or industrial zones. Common coating systems include hot-dip galvanizing, epoxy coatings, and metallic zinc coatings, each offering varying levels of protection against corrosion.

Fire Resistance: Fire protection measures are necessary to safeguard long-span spatial structures against fire hazards. Intumescent coatings, fire-resistant cladding materials, and fireproofing sprays are commonly used to enhance the fire resistance of steel elements, thereby minimizing the risk of structural failure in the event of a fire.

Environmental Sustainability: Sustainable design principles emphasize the use of environmentally friendly materials and practices throughout the lifecycle of a structure. Recycled steel, low-emission coatings, and energy-efficient fabrication techniques contribute to reducing the environmental impact of long-span spatial structures, aligning with green building standards and certifications.

4.2. Connection Design and Detailing

The design and detailing of connections are critical components of long-span spatial structures, as they facilitate load transfer between structural elements and ensure overall stability and performance. Recent advancements in connection design have led to innovative solutions that enhance efficiency and cost-effectiveness.

Moment-Resisting Connections: Moment-resisting connections provide rotational stiffness and strength to resist lateral loads, such as wind or seismic forces. Welded moment connections and bolted end-plate connections are commonly used in long-span structures, offering robustness and ductility under extreme loading conditions.

Bolted Connections: Bolted connections offer versatility and ease of installation, making them popular choices for connecting steel elements in long-span spatial structures. High-strength bolts, along with proper detailing and tightening procedures, ensure reliable and durable connections that can accommodate various design requirements and site conditions [6].

Detailing Considerations: Attention to detail in connection design is essential to minimize stress concentrations, fatigue, and potential failure modes. Proper detailing of welds, bolted connections, and interface details ensures structural integrity and enhances the overall performance of long-span spatial structures, reducing the risk of premature deterioration or structural collapse.

4.3. Constructability and Fabrication

Constructability considerations are paramount in the design of long-span spatial structures, aiming to streamline construction processes, optimize resource utilization, and ensure project success within budget and schedule constraints. Prefabrication and modular construction techniques offer significant advantages in terms of quality control, schedule acceleration, and site safety.

Prefabrication: Prefabrication involves the manufacturing of structural components off-site under controlled conditions, followed by transportation and assembly at the construction site. Prefabricated steel elements, such as beams, columns, and trusses, are fabricated to precise specifications, minimizing onsite labor and construction time while maximizing quality assurance and safety.

Modular Construction: Modular construction entails the assembly of prefabricated modules or units to create larger structural assemblies, such as floors, walls, and roofs. Modular steel construction offers benefits such as rapid deployment, flexibility, and scalability, making it an attractive option for long-span spatial structures with repetitive elements or standardized configurations.

Quality Control: Stringent quality control measures are essential throughout the fabrication and construction process to ensure compliance with design specifications and regulatory requirements. Non-destructive testing techniques, dimensional inspections, and material certifications are employed to verify the quality and integrity of fabricated steel components, mitigating the risk of defects or structural deficiencies.

5. Conclusion

In conclusion, advanced analysis methods and construction techniques play integral roles in the design and construction of long-span spatial structures in steel engineering. The Direct Analysis Method (DAM) offers a robust framework for analyzing complex steel structures, ensuring stability, efficiency, and resilience. Modeling techniques such as Finite Element Analysis (FEA), dynamic analysis, and nonlinear analysis provide valuable insights into structural behavior under diverse loading conditions, informing design decisions and enhancing performance. Practical considerations in material selection, connection design, and construction are essential for optimizing structural performance, durability, and constructability. Prefabrication and modular construction techniques offer effective strategies for accelerating project schedules, improving quality control, and enhancing site safety. By leveraging advanced analysis methods and construction techniques, engineers and researchers can achieve successful outcomes in the design and construction of long-span spatial structures in steel engineering, meeting the evolving demands of the built environment.

References

[1]. Al Khulaifi, Rana Salem, et al. “New method based on the direct analysis in real time coupled with time-of-flight mass spectrometry to investigate the thermal depolymerization of poly (methyl methacrylate).” Polymers 15.3 (2023): 599.

[2]. Imam, Mohamed S., and Maha M. Abdelrahman. “How environmentally friendly is the analytical process? A paradigm overview of ten greenness assessment metric approaches for analytical methods.” Trends in Environmental Analytical Chemistry (2023): e00202.

[3]. Gardner, Leroy. “Metal additive manufacturing in structural engineering–review, advances, opportunities and outlook.” Structures. Vol. 47. Elsevier, 2023.

[4]. Szytula A and Leciejewicz J 1989 Handbook on the Physics and Chemistry of Rare Earths vol 12, ed K A Gschneidner Jr and L Erwin (Amsterdam: Elsevier) p 133

[5]. Csernak, Stephen F., and Jack C. McCormac. Structural steel design. Pearson Education, Incorporated, 2023.

[6]. Gatto, Maria Laura, et al. “On the Biomechanical Performances of Duplex Stainless Steel Graded Scaffolds Produced by Laser Powder Bed Fusion for Tissue Engineering Applications.” Journal of Functional Biomaterials 14.10 (2023): 489.

Cite this article

Xing,J. (2024). Advanced analysis and construction techniques for long-span spatial structures in steel engineering. Applied and Computational Engineering,66,172-177.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Al Khulaifi, Rana Salem, et al. “New method based on the direct analysis in real time coupled with time-of-flight mass spectrometry to investigate the thermal depolymerization of poly (methyl methacrylate).” Polymers 15.3 (2023): 599.

[2]. Imam, Mohamed S., and Maha M. Abdelrahman. “How environmentally friendly is the analytical process? A paradigm overview of ten greenness assessment metric approaches for analytical methods.” Trends in Environmental Analytical Chemistry (2023): e00202.

[3]. Gardner, Leroy. “Metal additive manufacturing in structural engineering–review, advances, opportunities and outlook.” Structures. Vol. 47. Elsevier, 2023.

[4]. Szytula A and Leciejewicz J 1989 Handbook on the Physics and Chemistry of Rare Earths vol 12, ed K A Gschneidner Jr and L Erwin (Amsterdam: Elsevier) p 133

[5]. Csernak, Stephen F., and Jack C. McCormac. Structural steel design. Pearson Education, Incorporated, 2023.

[6]. Gatto, Maria Laura, et al. “On the Biomechanical Performances of Duplex Stainless Steel Graded Scaffolds Produced by Laser Powder Bed Fusion for Tissue Engineering Applications.” Journal of Functional Biomaterials 14.10 (2023): 489.