1. Introduction

The development of gas turbines has been a significant milestone in the history of engineering, with its roots tracing back to early steam engines and evolving into one of the most critical technologies in modern power generation and aviation. The concept of using compressed air and fuel to generate mechanical work dates back to the 18th century when John Barber patented the first rudimentary gas turbine design in 1791. However, it wasn't until the 20th century that gas turbines became practical for large-scale applications, particularly with the advancements made during World War II for jet propulsion systems [1]. The MIT Gas Turbine Laboratory has played a crucial role in documenting and furthering these developments, providing insights into the technological milestones that have shaped the modern gas turbine industry.

Parallel to the evolution of gas turbines, the development of steam engines in the 18th and 19th centuries laid the groundwork for understanding thermodynamic cycles, which are fundamental to the operation of modern turbines [2]. The steam engine, as documented by Henry Winram Dickinson in his comprehensive history, served as the precursor to many of the principles now applied in gas turbine technology. The transition from steam to gas turbines represented a leap in efficiency and capability, driven by the need for more powerful and reliable engines in both transportation and power generation.

This historical context provides a foundation for understanding the significance of gas turbines in today's energy landscape. From their early conceptual stages to their current state-of-the-art applications, gas turbines have evolved into a cornerstone technology that continues to drive advancements in both efficiency and environmental sustainability. The following sections will delve deeper into the principles behind gas turbines, their modern applications, and the ongoing innovations that promise to shape their future development.

2. Description of engines

Engines, as the heart of mechanical systems, convert various forms of energy into mechanical work [3]. The operation can be broadly classified into two categories: internal combustion (IC) engines and external combustion (EC) engines. Internal combustion engines, as the name suggests, involve the combustion of fuel within the engine itself. This process generates high-pressure gases that move pistons or turbines to produce mechanical work. IC engines are widely used in automobiles, airplanes, and power generation due to their high efficiency and power-to-weight ratio.

Internal combustion engines can be further classified based on their working principles, fuel types, and cycle operations. The two primary types of IC engines are spark-ignition (SI) engines, which typically use gasoline, and compression-ignition (CI) engines, which primarily use diesel. These engines operate on thermodynamic cycles, such as the Otto cycle for SI engines and the Diesel cycle for CI engines, which dictate the energy conversion process and efficiency. The construction of these engines typically involves a cylinder block, pistons, a crankshaft, and a camshaft, among other components, which work in unison to convert chemical energy into mechanical energy.

Gas turbines, another type of IC engine, operate on the Brayton cycle, where air is compressed, mixed with fuel, ignited, and expanded to generate power. Unlike piston engines, gas turbines have fewer moving parts, leading to higher reliability and efficiency at large scales. This makes them ideal for power generation and aviation applications. Gas turbines consist of a compressor, combustion chamber, and turbine, all of which are crucial for the engine's operation.

The classification and understanding of engines are essential for selecting the right type of engine for specific applications, whether it's for transportation, power generation, or industrial use. The ongoing advancements in engine technology continue to enhance efficiency, reduce emissions, and expand their applications across various industries.

3. Principle of gas turbines

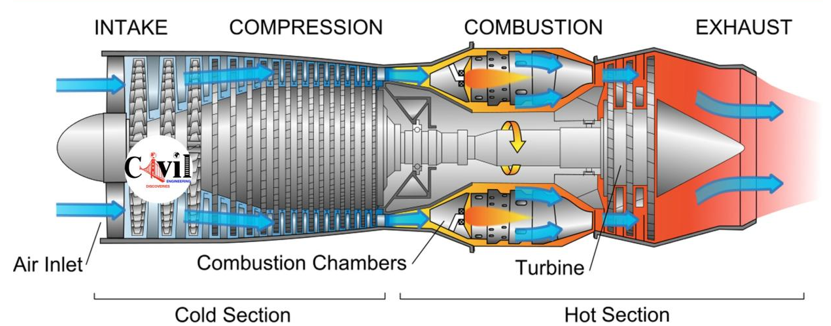

Gas turbines operate on a relatively straightforward yet highly efficient principle, primarily governed by the Brayton cycle, which is a thermodynamic cycle that describes the process of energy conversion within the turbine. The gas turbine's operation can be broken down into several key stages: suction, compression, combustion, expansion, and exhaust [4].

Figure 1. A sketch of gas turbine [5].

Suction process begins with the intake of air through the turbine's inlet. This air is drawn into the compressor section of the turbine, where the first phase of the cycle begins. In the compressor, the incoming air is compressed to a high pressure. This process is critical as it increases the air's density, making it more suitable for efficient combustion. The compression process significantly raises the temperature and pressure of the air before it enters the combustion chamber. During combustion process in the combustion chamber, the compressed air is mixed with fuel and ignited. This process leads to a rapid increase in temperature and pressure, producing high-energy gases. The combustion must be carefully controlled to maintain the turbine's efficiency and prevent damage to the components. During expansion process, the high-energy gases produced during combustion then expand rapidly through the turbine's blades. This expansion drives the turbine, converting the thermal energy of the gases into mechanical energy. The turbine is connected to a shaft, which may be used to drive a generator (in power generation applications) or provide thrust (in aviation applications). Regarding to exhaust process, the spent gases are expelled through the exhaust, often passing through a nozzle that helps to increase their velocity, particularly in jet engines. In power generation, the remaining energy in the exhaust gases can be utilized in a combined cycle setup, further improving the overall efficiency of the system.

The gas turbine's simplicity, combined with its ability to convert a large amount of fuel energy into mechanical energy, makes it a highly effective engine for various applications, from power generation to aviation. As technology continues to improve, the efficiency and environmental performance of gas turbines are expected to advance even further [5]. A typical sketch is shown in Fig. 1.

4. State-of-art facilities

Recent advancements in gas turbine technology have led to the development of highly efficient and environmentally friendly facilities that represent the cutting edge of modern power generation. GE's H-Class Turbines: One of the most notable advancements is GE's development of the 9HA and 7HA series turbines, which are considered among the most efficient gas turbines globally. These turbines are part of the "H-Class" series, achieving efficiency rates of over 61% [6]. This efficiency is primarily due to innovations in turbine cooling technologies, optimal pressure ratios, and the ability to operate at higher firing temperatures. The combination of these factors enables these turbines to convert a significant portion of the energy contained in natural gas into electricity, while also reducing emissions. GE has also focused on enhancing the durability of these turbines, allowing for extended intervals between maintenance, which further improves their operational efficiency [7].

Another exemplary state-of-the-art facility is the Los Esteros Critical Energy Facility in San Jose, California. Originally built as a simple-cycle plant, it was later upgraded to a combined-cycle facility in 2013. This upgrade significantly enhanced the plant's efficiency and flexibility, allowing it to better respond to demand fluctuations. The facility now includes four aero-derivative combustion turbines, four heat recovery steam generators, and a steam turbine. Notably, Los Esteros is equipped with advanced emissions control technology, making it one of the cleanest facilities in California. The use of recycled water for cooling further emphasizes its commitment to sustainability. The improvements made to this facility highlight the ongoing trend of upgrading existing infrastructure to meet modern efficiency and environmental standards [6].

5. Applications of gas turbines

Gas turbines are integral to several industries due to their efficiency, reliability, and adaptability. In recent years, their applications have expanded and evolved, particularly in power generation, the oil and gas industry, and as a complementary technology to renewable energy sources. Gas turbines are a cornerstone of modern electricity generation, especially in regions where rapid power demand growth requires flexible and reliable energy solutions. Large-frame gas turbines are predominantly used in this sector, offering high capacity and efficiency. Models like Mitsubishi Power’s J-series and Siemens Energy’s H-class turbines are notable for their ability to produce more than 500 MW per unit, making them ideal for both base-load and peaking power plants. These turbines are often chosen for new power plants because of their ability to meet stringent environmental regulations by minimizing emissions while maintaining high operational efficiency [8, 9].

The oil and gas sector relies heavily on gas turbines for both power generation and mechanical drive applications. Aeroderivative gas turbines, derived from jet engine technology, are particularly favored in this industry. These turbines are valued for their lightweight, compact design, and the ability to handle rapid start-ups and frequent cycling. The GE LM2500 and LM6000 turbines are popular choices in this sector due to their proven reliability and efficiency. These turbines are often used in offshore platforms and other remote locations where space and weight constraints are critical considerations [10].

As the energy industry shifts towards renewable sources, gas turbines are increasingly used to complement these intermittent power supplies. Their ability to quickly ramp up and down makes them ideal for stabilizing grids that incorporate significant amounts of wind and solar energy. Aeroderivative turbines are particularly useful in this role because of their rapid response times and flexibility. This application is becoming more prevalent as the global energy mix evolves to include more renewable sources, with gas turbines ensuring that energy supply remains stable even when renewable generation is variable [9].

The global market for gas turbines has seen fluctuations, but the overall trend points to a steady demand driven by technological advancements. The market is particularly robust in regions like Asia and the Middle East, where new power generation capacity is urgently needed. In addition, there is growing investment in aftermarket services and maintenance, which underscores the importance of keeping these machines in peak operating condition. This is especially true for sectors like oil and gas, where operational reliability is paramount [10, 11].

6. Limitations and prospects

Despite the numerous advancements in gas turbine technology, several limitations still hinder their performance and broader adoption in some applications. One significant challenge is the efficiency ceiling imposed by current materials and cooling technologies. While modern turbines, especially those in the H-class and J-series, have achieved remarkable efficiency levels, further improvements are increasingly difficult to attain. The high operating temperatures required to push efficiency boundaries place enormous stress on turbine materials, necessitating continuous development in high-temperature alloys and advanced coatings. Even with these innovations, there is a limit to how much the materials can endure before degradation impacts the turbine’s lifespan and reliability [11].

Another limitation is the environmental impact associated with gas turbine operations. Although they are cleaner than many other fossil fuel-based power generation methods, gas turbines still produce significant amounts of carbon dioxide (CO2) and nitrogen oxides (NOx). The ongoing challenge is to further reduce these emissions while maintaining or improving efficiency. Technologies like lean combustion and advanced NOx control systems are being developed, but these solutions often involve trade-offs with other performance metrics, such as startup times or operational flexibility [9].

Looking ahead, the integration of gas turbines with renewable energy sources presents both opportunities and challenges. As the world transitions to a more sustainable energy mix, gas turbines will play a crucial role in balancing the intermittency of renewables like wind and solar power. However, this integration requires turbines to be even more flexible, capable of frequent starts and stops without compromising efficiency or increasing maintenance costs. This need for greater operational flexibility is driving research into hybrid systems that combine gas turbines with battery storage or other forms of energy storage [10].

In the longer term, there is also potential for gas turbines to operate on alternative fuels, such as hydrogen or biofuels. This transition could significantly reduce the carbon footprint of gas turbine operations. However, widespread adoption of such technologies will require substantial modifications to existing infrastructure and further advances in fuel handling and combustion technology. These challenges suggest that while gas turbines will remain a vital component of the global energy landscape, ongoing research and development will be essential to overcoming their current limitations and unlocking their full potential [9, 11].

7. Conclusion

To sum up, this paper has explored the principles of gas turbines, their state-of-the-art facilities, and their wide-ranging applications, emphasizing their critical role in modern energy systems. Gas turbines continue to evolve, with advancements in efficiency, flexibility, and environmental performance, making them indispensable in both power generation and the oil and gas industries. The ongoing integration of gas turbines with renewable energy sources further underscores their importance in achieving a balanced and reliable energy mix. However, despite these advancements, challenges remain, particularly in overcoming material limitations, reducing emissions, and enhancing operational flexibility. The future of gas turbines lies in continued innovation, particularly in developing alternative fuels like hydrogen, which could significantly reduce their carbon footprint. In conclusion, while gas turbines have made significant strides in performance and sustainability, ongoing research and development will be essential in addressing their current limitations and maximizing their potential in the evolving global energy landscape. This study contributes to understanding the current state of gas turbine technology and its future directions, highlighting the need for continued investment in this crucial area of energy research.

References

[1]. Nascimento M A R, Rodrigues L O, Santos E D, Gomes E E B, Dias F L G, Velásques E I G, Carrillo R A M 2013 Micro gas turbine engine: a review Progress in gas turbine performance vol 125 pp 1-14

[2]. Dickinson H W 2022 A short history of the steam engine Routledge

[3]. Van Basshuysen R, Schäfer F 2016 Internal combustion engine handbook SAE International

[4]. Giampaolo T 2020 Gas turbine handbook: principles and practice River Publishers

[5]. Gas Turbine Components and Working Principle Engineering Discoveries 2020 Retrieved from: https://engineeringdiscoveriescom/gas-turbine-components-and-working-principle/

[6]. Spaulding W G, HILL C 2010 Supplement and Amendment to the PRMMP for the Los Esteros Critical Energy Facility.

[7]. A Look at GE’s New State-of-the-Art Gas Turbines. Retrieved from: https://wwwgreentechmediacom/articles/read/ges-new-gas-turbines-are-state-of-the-art-but-are-we-getting-too-cozy-with

[8]. National Academies of Sciences, Division on Engineering, Physical Sciences, Aeronautics, Space Engineering Board, & Committee on Advanced Technologies for Gas Turbines 2020 Advanced technologies for gas turbines. National Academies Press.

[9]. Gas turbine market report. Retrieved from: https://wwwdatamintelligencecom/research-report/gas-turbine-market

[10]. Gas turbine sales surged in 2022 2022 Retrieved from https://wwwturbomachinerymagcom/view/gas-turbine-sales-surged-in-2022

[11]. Biswas S Ramachandra S Hans P & Kumar S S (2022) Materials for gas turbine engines: present status future trends and indigenous efforts Journal of the Indian Institute of Science 102(1) 297-309

Cite this article

Fu,L. (2024). Analysis of the Principle of Gas Turbine and State-of-art Applications. Applied and Computational Engineering,89,14-18.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Nascimento M A R, Rodrigues L O, Santos E D, Gomes E E B, Dias F L G, Velásques E I G, Carrillo R A M 2013 Micro gas turbine engine: a review Progress in gas turbine performance vol 125 pp 1-14

[2]. Dickinson H W 2022 A short history of the steam engine Routledge

[3]. Van Basshuysen R, Schäfer F 2016 Internal combustion engine handbook SAE International

[4]. Giampaolo T 2020 Gas turbine handbook: principles and practice River Publishers

[5]. Gas Turbine Components and Working Principle Engineering Discoveries 2020 Retrieved from: https://engineeringdiscoveriescom/gas-turbine-components-and-working-principle/

[6]. Spaulding W G, HILL C 2010 Supplement and Amendment to the PRMMP for the Los Esteros Critical Energy Facility.

[7]. A Look at GE’s New State-of-the-Art Gas Turbines. Retrieved from: https://wwwgreentechmediacom/articles/read/ges-new-gas-turbines-are-state-of-the-art-but-are-we-getting-too-cozy-with

[8]. National Academies of Sciences, Division on Engineering, Physical Sciences, Aeronautics, Space Engineering Board, & Committee on Advanced Technologies for Gas Turbines 2020 Advanced technologies for gas turbines. National Academies Press.

[9]. Gas turbine market report. Retrieved from: https://wwwdatamintelligencecom/research-report/gas-turbine-market

[10]. Gas turbine sales surged in 2022 2022 Retrieved from https://wwwturbomachinerymagcom/view/gas-turbine-sales-surged-in-2022

[11]. Biswas S Ramachandra S Hans P & Kumar S S (2022) Materials for gas turbine engines: present status future trends and indigenous efforts Journal of the Indian Institute of Science 102(1) 297-309