1. Introduction

The need for a more efficient and cost-effective manufacturing industry is increasing because of the fast speed of urbanization and consumerism. That’s why Industry 4.0 is underway. And it stands out by these main advancements, such as safety, flexibility, cost efficiency, and efficiency. Finally, a new era of industry mass production is been revealed. In smart factories, the combination of sensors and AI provides autonomous decision-making capabilities, creating a new paradigm in industrial automation.

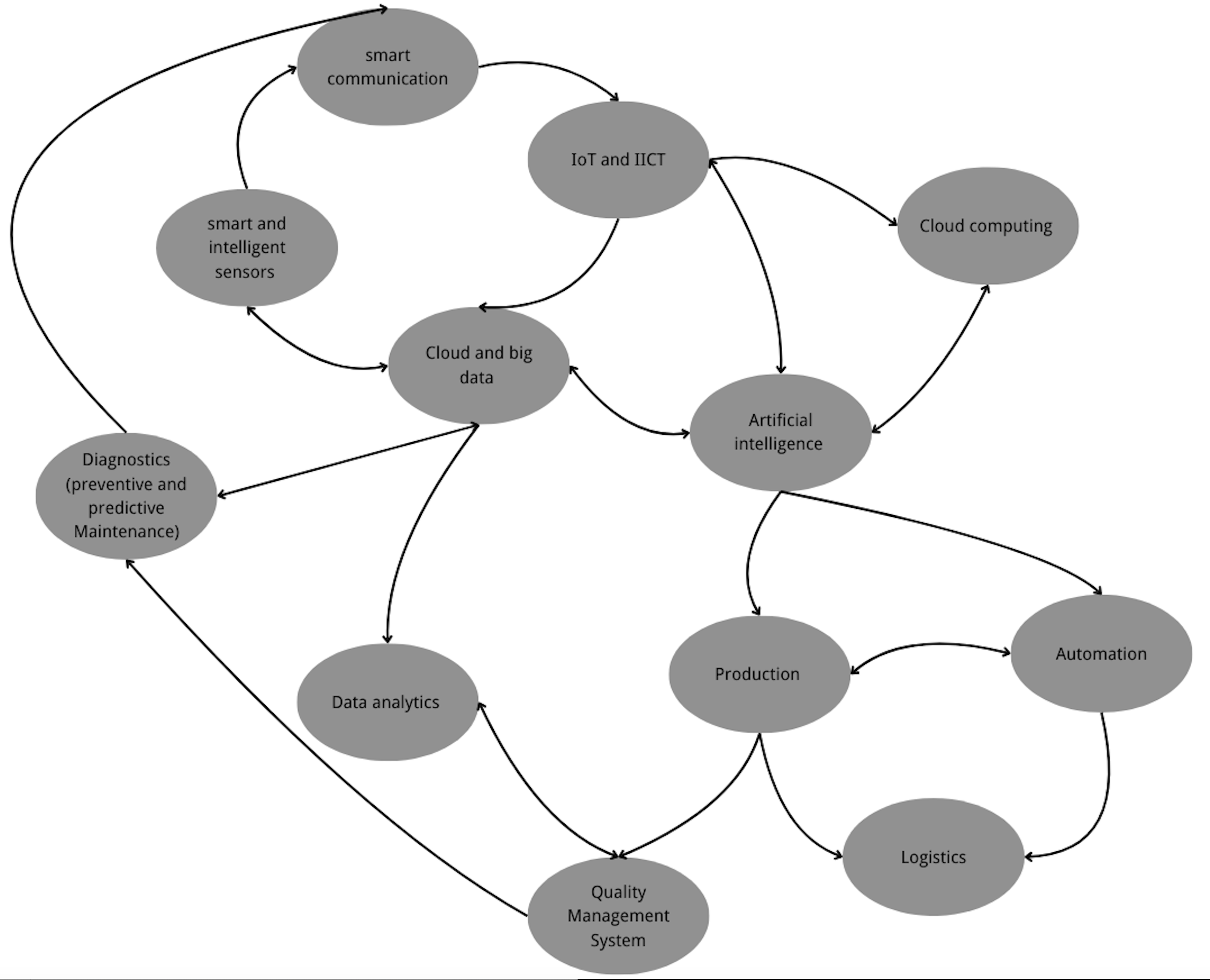

Sensors play a vital role in these systems by providing real-time data essential for automated control, predictive maintenance, and safety assurance, as shown in Figure 1. The combination of AI and sensors offers more than traditional data collection. It enables autonomous decision-making and improves overall performance. AI-driven sensors can analyze vast amounts of data, detect anomalies, and trigger responses, revolutionizing industrial automation [1].

Figure 1. AI-driven sensors’ application in Industry 4.0.

The significance of AI-powered sensors within industrial systems lies in their ability to continuously monitor environmental parameters and machine conditions. Compared to traditional types of sensors, AI-integrated sensors can process data in real time, enabling autonomous systems to make predictive adjustments and enhance system performance [2].

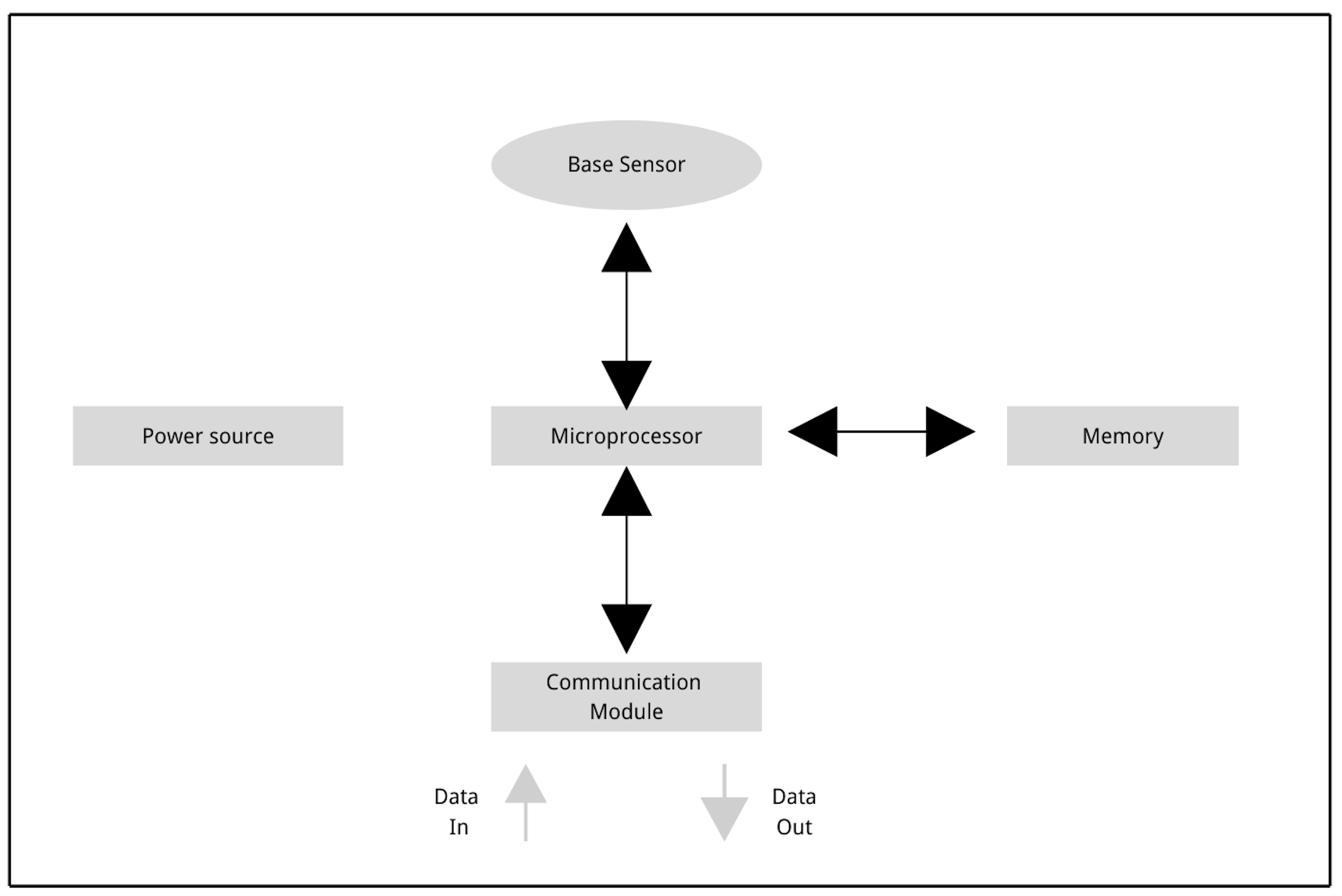

Figure 2. AI-driven sensor system.

Moreover, one of the primary advantages of AI-driven sensors is their ability to anticipate possible equipment failures. In the environment of Industry 4.0 and the Internet of Things, many different production processes need to communicate with each other to form a large network, as shown in Figure 2, even one liability might cause a failure within the whole system, causing downtime which can result in substantial financial losses. However, the development of AI-enabled sensors not only collects vast amounts of data but also analyzes it to detect patterns and anomalies that signal potential issues. For example, vibration sensors embedded in rotating machinery can detect minute changes in operational conditions, allowing AI systems to predict when components are likely to fail, thereby facilitating proactive maintenance and reducing unplanned downtime [3].

For wearable equipment, for example, the mining helmet usually has a smart sensor that can perceive the existence of dangerous gas in the mining tunnel, and alert the workers to evacuate. Thanks to the development of fast communication and wireless technologies such as 5G, and Wi-Fi 7, sensors can chat over a larger distance and feed real-time data to control systems. This helps in automating complex operations with minimal human intervention so that the accuracy and speed are also increased [4].

This paper will focus on the integration of AI with various types of sensors, emphasizing their roles in autonomous industrial production. The research focuses on autonomous decision-making, predictive maintenance, safety enhancements, and improvements in efficiency. By examining different types of sensors, this paper outlines how each of them contributes to industrial automation and safety.

In order to explain the process of the integration of artificial intelligence and various types of sensors, this study will utilize two primary methods: a comprehensive literature review and case study analysis. The literature review will involve an examination of existing academic papers, articles, and reports related to the integration of AI and sensor systems, with a main focus on areas such as autonomous production lines, predictive decision-making and maintenance, and safety.

Additionally, the research will include case studies from industries that have experience in using AI-integrated sensors and smart network systems. In the manufacturing aspect, the focus would be on how the combination of smart sensors and powerful AI features can have effects on product quality, efficiency, safety, and cost. For the energy sector, this study will concentrate on how AI-driven sensors improve the monitoring of energy consumption and generation, in order to achieve optimal results [5].

In the context of this research, the primary objective is to explore how the integration of artificial intelligence with smart sensor systems enhances industrial automation, operational efficiency, and safety. This study will focus on:

• Research the role of AI in processing the data collected by sensors

• The impact of AI-powered predictive maintenance systems

• The impact of AI-powered sensors on safety

• Evaluate efficiency improvements driven by AI-sensor networks

• Analyze case studies from industries such as manufacturing and energy

2. Types of sensors and their roles in AI-enhanced industrial systems

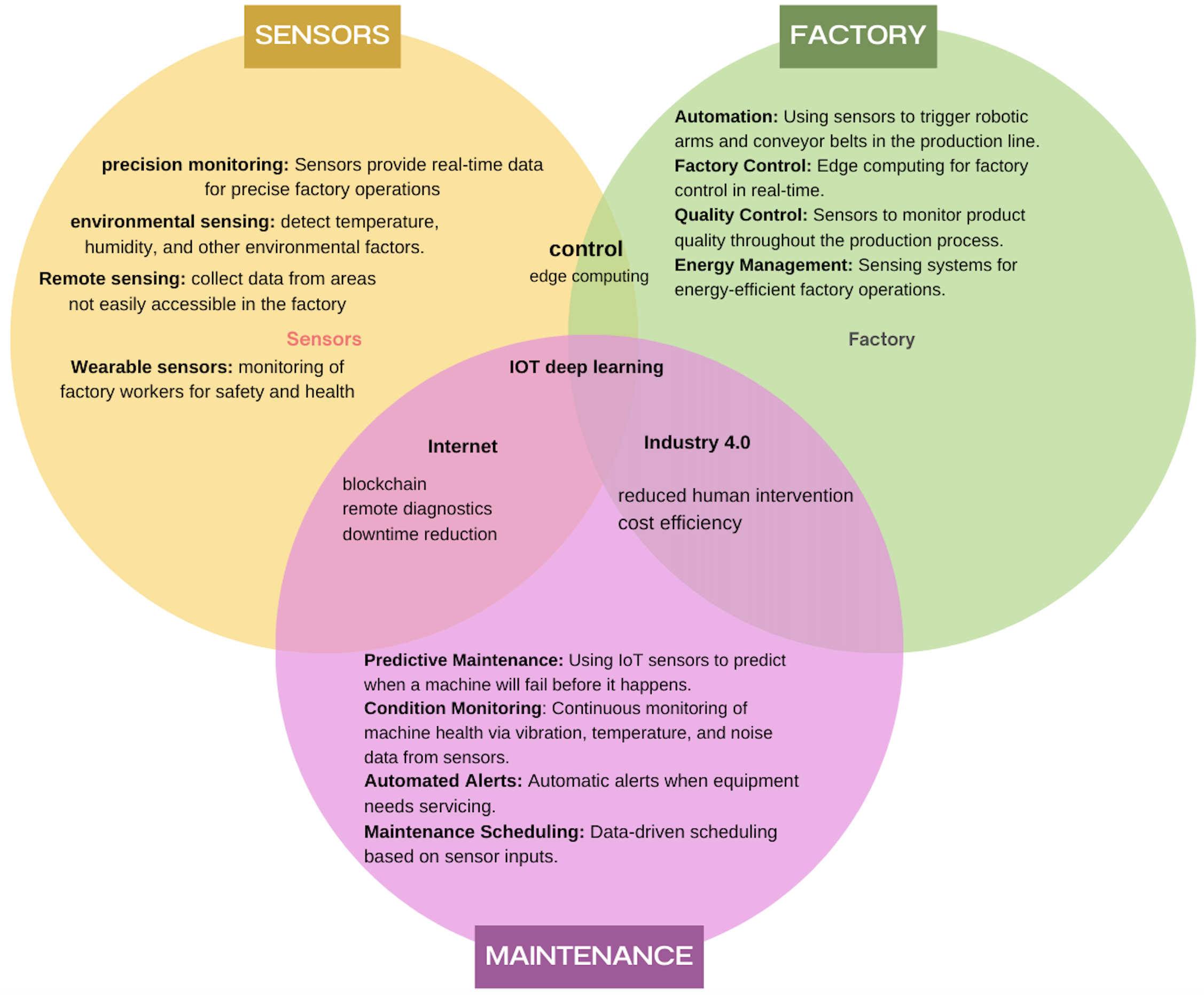

In the context of Industry 4.0, there are various types of sensors playing critical roles in maintaining operational efficiency, safety, and predictive maintenance, and details can be seen in Figure 3. Following up this study will introduce temperature sensors, pressure sensors, infrared sensors, and optical sensors, each contributing to different aspects of industrial automation.

Figure 3. Sensor maintenance in the factory.

2.1. Types of sensors

2.1.1. Temperature sensors. Temperature sensors are widely used in the industry field to monitor the temperature of equipment and the environment, ensuring the working temperature of different equipment within safe and optimal parameters [2].

2.1.2. Pressure sensors. These sensors are crucial in industries like oil and gas, where maintaining pressure levels within pipelines is vital to prevent leaks or explosions. AI-enhanced pressure sensors can predict abnormal patterns, preventing catastrophic failures before they happen [6].

2.1.3. Infrared sensors. Infrared sensors are commonly used in safety applications, providing heat signature detection, which can send equipment signals about overheating or hazardous conditions. They can also provide object movement checking and safety-enhancing in factory settings in robotics and automated systems [7].

2.1.4. Optical Sensors. These sensors are essential for quality control, especially in assembly lines. They deliver exact dimensions, there now is a product that is to code and catch defects sooner in the production cycle [8].

2.2. Roles of sensors

2.2.1. Monitoring and control. Sensors play a crucial role in real-time monitoring and control of industrial systems. An example of this is AI-enhanced temperature and pressure sensors being used in high-stakes environments like chemical plants or refineries to keep track of conditions at all times. By feeding real-time data into AI systems, these sensors allow automated adjustments to processes, ensuring that machinery operates within optimal parameters without requiring human intervention. This not only boosts operational efficiency but also mitigates the risk of manual errors [9].

2.2.2. Safety applications. In hazardous environments like mining, manufacturing, or chemical processing, AI-powered sensors enhance safety measures by detecting dangerous conditions before they become critical. For instance, infrared and gas sensors can identify high-temperature hotspots or the presence of hazardous gases in confined spaces. When paired with AI, these sensors can trigger automated shutdowns or alarms, ensuring quick responses to potential safety threats and safeguarding workers from life-threatening situations [10].

2.2.3. Data collection for predictive maintenance. One of the most impactful uses of sensors in industrial systems is in predictive maintenance. Sensors, such as vibration and pressure sensors, continuously collect data about machine performance. By analyzing this data, AI is able to spot patterns that indicate when a part will fail and maintenance can be scheduled before breakdown of the machine. With this proactive method, more costly downtime is reduced and the expected life of the equipment is extended. For example, an AI system might analyze data from pressure sensors in a hydraulic system and predict when parts will wear out, allowing timely replacements before system failure [11].

2.2.4. AI-driven predictive maintenance in wind farms. The wind energy sector is one of the best applications for AI-enhanced sensors. It is one of the most successful. Wind turbines are embedded with multiple types of sensors (vibration and temperature sensors, etc.) to read the turbine components' health status in real-time. By integrating AI models, companies can predict potential failures before they occur, thus optimizing maintenance schedules. A study conducted by Zerbo et al. in the wind energy sector showed that AI-driven predictive maintenance systems reduced turbine downtime by 30%, significantly decreasing the operational costs of wind farms [1]. The sensors continuously feed data into machine learning models, which identify patterns that specify the patterns of impending problems, such as blade fatigue or generator overheating, long before they become catastrophic failures.

2.2.5. Temperature and humidity sensors in semiconductor manufacturing. In semiconductor fabrication, precision is key, as even small deviations in environmental conditions can ruin entire batches of products. Temperature and humidity sensors with AI capabilities can be very practical in order to keep the perfect environment for semiconductor manufacturing. A recent case study by Feki et al. highlighted how factories, particularly in South Korea, implemented AI-powered environmental monitoring systems to control temperature and humidity levels in clean rooms [6]. These sensors, paired with AI, these sensors will automatically control the HVAC systems on a real-time basis to assure adherence to precision environmental specifications and minimize semiconductor production defects. This lowered yield losses from environmental factors by 20%, emphasising the role of AI-integrated sensors in technology-driven sectors.

2.2.6. AI-enhanced vibration sensors in aerospace manufacturing. In aerospace manufacturing, precision and safety are paramount. Aircraft components, such as engines and turbines, are exposed to extreme operational conditions. Vibration sensors are critical for monitoring the condition of rotating parts. In a recent collaboration between Rolls-Royce and Siemens, AI-enhanced vibration sensors were implemented to monitor the health of aircraft engines in real-time. The AI system used machine learning algorithms to analyze vibration data, detecting subtle shifts that could signal wear or impending failure. By predicting failures early, Rolls-Royce was able to reduce unscheduled maintenance events by 15%, improving operational safety and reducing costly downtime. This also led to an optimized inventory system for spare parts, as predictive maintenance helped align supply with actual maintenance needs.

3. Challenges and solutions in sensor integration

3.1. Interoperability

One of the major challenges associated with sensor integration is that sensors come in various types and are installed on different systems, utilizing differing communication protocols. Industrial environments often involve multiple devices and platforms, making seamless data exchange difficult. As sensor networks expand, this issue becomes more significant. AI-driven systems need to effectively communicate and understand data coming from various sensors, which may follow different standards or formats. For example, sensors deployed in wireless sensor networks (WSNs) often suffer from data collection, routing, and dissemination issues, which hinder integration across multiple platforms [10].

Developing standardized architectures that facilitate cross-platform communication is crucial. Emerging Internet of Things (IoT) platforms aim to address this by using common communication protocols and data exchange standards, such as MQTT or CoAP. Additionally, edge computing frameworks allow real-time data processing at the network edge, improving integration across diverse sensors Edge computing also reduces latency and helps process data locally, reducing the demand for cloud bandwidth and ensuring real-time responses [11].

3.2. Data management

As the number of sensors grows, so does the data. As such data can be a problem to manage, especially in real-time. This further obfuscates API calls that retrieve data from disparate sources, with varied degrees of quality and consistency, typically sensor and temperature data. A very critical issue in this case arises when it comes to systems like Wireless Sensor Networks, where the resource constraints (such as battery life or communication bandwidth) need to be balanced against the continuous data transmission need [6].

AI techniques can help by optimizing data aggregation and dissemination processes. For example, data-centric routing protocols can reduce redundant data transmissions, conserving power and improving system efficiency. AI-powered algorithms can also compress or filter unnecessary data before transmission, reducing network load. Moreover, utilizing distributed edge computing frameworks minimizes data management issues, as AI processes data closer to the sensors, allowing for efficient data storage and bandwidth usage [5].

3.3. Security and privacy

As AI sensors handle sensitive industrial data, security vulnerabilities emerge, particularly in environments involving critical infrastructure like energy or healthcare. Unauthorized access or tampering with sensor networks can lead to significant disruptions, making cybersecurity a paramount concern [7].

AI and machine learning models can be employed to detect anomalies or breaches in real-time, identifying suspicious behavior in the network. Advanced encryption methods are also being developed to secure sensor data during transmission. Blockchain technology is also being explored to add a layer of decentralized security, ensuring the authenticity and integrity of sensor data [4].

3.4. Power consumption

Energy consumption constraints are among the most important issues of sensors in general, and industrial applications, particularly in a wireless sensor network an important issue as most of these sensors must be powered with batteries. Artificial intelligence AI-based sensors, on the other hand, constantly process data and this results in rapid depletion of energy sources [10].

Energy-efficient routing protocols, along with AI techniques such as machine learning, can optimize data transmission routes to reduce power consumption. These protocols intelligently manage when and how often data is transmitted, focusing on only essential information. Edge computing frameworks also reduce energy use by processing data locally, minimizing the need for continuous communication with centralized servers [11].

3.5. Other challenges

3.5.1. Challenges in sensor technologies. Smart sensors are gaining more and more importance in achieving highly accurate data, especially under harsh environmental conditions such as biomedical applications, space missions, and meteorological observations. Nevertheless, wireless sensor networks (WSNs) pose several challenges which are deployment, tracking and communication reliability issues. Signal latencies and coverage issues plague sensors in harsh environments, which deteriorate the whole network performance. Significant challenges for WSNs are to pick up the proper hardware units, synchronize sensors and optimize network calibration in terms of protocols and computing algorithms in order to provide robust data collection reliable enough for Industry 4.0 applications [12].

3.5.2. Challenges in wireless communication. Wireless communication is fundamental to Industry 4.0, yet it faces security risks like denial of service (DoS) attacks and wormholes, where attackers manipulate sensor network routes. Reliable, low-latency, and energy-efficient communication is essential for machine-to-machine interactions. Although 5G addresses some of these needs, issues like resource allocation and network traffic congestion remain. High sensor density in industrial environments can lead to data loss, requiring efficient retransmission protocols and signal separation methods, such as those utilizing convolutional and federated learning techniques [12].

3.5.3. Challenges of digitalization. While Industry 4.0 offers many benefits, the shift toward digitalization brings concerns about data sharing and privacy. Many companies fear they might lose the competitive edge or have sensitive information exposed by sharing data [13]. Moreover, the security of cloud services is a significant concern, and many industries lack the skilled personnel to handle these challenges. Businesses are confronting other challenges as well, such as resistance to change, an absence of skilled professionals and financial constraints that must be battled on multiple fronts so the enterprise can manage this transition [14].

4. Conclusion

In conclusion, the integration of AI and sensors is bringing a revolutionary change to modern industry production and automation by providing unprecedented levels of efficiency, safety, and predictive maintenance. The common use of smart sensors and AI sensors is enabling industries to transition from reactive to proactive operations. Furthermore, the convenience of real-time data collection and autonomous decision-making are reducing downtime, improving product quality, and enhancing worker safety. From predictive maintenance for minimal operational disruptions to real-time hazardous environment detection and resource management optimization, cases across manufacturing, energy, agriculture and construction are showing the largest value of AI-powered sensors.

References

[1]. Zerbo, E., Sacile, R., Trinchero, D., & Fossa, M. (2024). Smart Sensors and Smart Data for Precision Agriculture: A Review. Sensors, 24(8), 2647. https://doi.org/10.3390/s24082647

[2]. De Vaulx, C. (2023). Trends and Challenges in AIoT/IIoT/IoT Implementation. Sensors, 23(11), 5074. https://doi.org/10.3390/s23115074

[3]. Hossain, M. S., & Muhammad, G. (2019). Cloud-assisted Industrial Internet of Things (IIoT)-Enabled Framework for Healthcare Monitoring. IEEE Internet of Things Journal, 6(5), 9095-9103.https://doi.org/10.1109/JIOT.2019.2922403

[4]. Van der Waal, M., Romijn, H. A., & Herder, P. M. (2020). The Role of Sensing Technologies in the Industrial Internet of Things (IIoT). IEEE Internet of Things Journal, 7(5), 3999-4010.https://doi.org/10.1109/JIOT.2020.2995251

[5]. Osamy, W., Khedr, A. M., Salim, A., & El-Sawy, A. A. (2022). Recent Studies Utilizing Artificial Intelligence Techniques for Solving Data Collection, Aggregation and Dissemination Challenges in Wireless Sensor Networks: A Review. Sensors, 11(3), 313.https://doi.org/10.3390/electronics11030313

[6]. Feki, M. A., Kawsar, F., Boussard, M., & Trappeniers, L. (2010). The Internet of Things: The Next Technological Revolution. Future Internet, 2(2), 96-114.https://doi.org/10.3390/fi2020096

[7]. Morrison, R. (2007). Wireless Sensor Network Design for Industrial Automation. IEEE Sensors Applications Symposium, 457-462.https://doi.org/10.1109/SAS.2007.4349161

[8]. Zhang, Y., & Dai, H. (2023). Real-Time Monitoring in Industrial Wireless Sensor Networks. IEEE Transactions on Industrial Informatics, 19(6), 1234-1242.https://doi.org/10.1109/TII.2023.10122774

[9]. Jovanović, Z. (2010). Sensor Systems for Environmental Monitoring: Sensors and Applications. In Advanced Knowledge Application in Practice (pp. 267-288). IntechOpen.https://doi.org/10.5772/10846

[10]. Ramamurthy, A., & Jain, P. (2012). Security Challenges in Industrial Wireless Sensor Networks. IEEE Communications Magazine, 50(6), 134-142.https://doi.org/10.1109/MCOM.2012.6165193

[11]. Krotofil, M., & Gollmann, D. (2006). Industrial Control Systems: Security and Sensor Deployment. Sensors and Actuators A: Physical, 126(2), 245-255.https://doi.org/10.1016/j.sna.2005.09.043

[12]. Nimbalkar, N., Zareie, S., Dehghani, M., Gonzalez-Aguirre, J., & Lee, Y. C. (2021). Smart sensors and IoT in smart cities: Challenges and future directions. Sensors, 21(5), 1595. https://doi.org/10.3390/s21051595

[13]. Kumar, S., Singh, A., Singh, R. P., & Pandey, R. (2021). An overview on Industry 4.0: Transformation of cyber-physical system with AI, Big Data, and IoT. Sensors, 21(9), 3031. https://doi.org/10.3390/s21093031

[14]. Singh, R. P., Javaid, M., Haleem, A., & Suman, R. (2021). Internet of things (IoT) applications to fight against COVID-19 pandemic. Diabetes & Metabolic Syndrome: Clinical Research & Reviews, 15(2), 521–524. https://doi.org/10.1016/j.dsx.2021.02.019

Cite this article

Qi,M. (2024). Enhancing Industrial Automation Through AI-driven Sensors: A Comprehensive Study on Efficiency, Safety, and Predictive Maintenance. Applied and Computational Engineering,80,188-195.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-MLA Workshop: Mastering the Art of GANs: Unleashing Creativity with Generative Adversarial Networks

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Zerbo, E., Sacile, R., Trinchero, D., & Fossa, M. (2024). Smart Sensors and Smart Data for Precision Agriculture: A Review. Sensors, 24(8), 2647. https://doi.org/10.3390/s24082647

[2]. De Vaulx, C. (2023). Trends and Challenges in AIoT/IIoT/IoT Implementation. Sensors, 23(11), 5074. https://doi.org/10.3390/s23115074

[3]. Hossain, M. S., & Muhammad, G. (2019). Cloud-assisted Industrial Internet of Things (IIoT)-Enabled Framework for Healthcare Monitoring. IEEE Internet of Things Journal, 6(5), 9095-9103.https://doi.org/10.1109/JIOT.2019.2922403

[4]. Van der Waal, M., Romijn, H. A., & Herder, P. M. (2020). The Role of Sensing Technologies in the Industrial Internet of Things (IIoT). IEEE Internet of Things Journal, 7(5), 3999-4010.https://doi.org/10.1109/JIOT.2020.2995251

[5]. Osamy, W., Khedr, A. M., Salim, A., & El-Sawy, A. A. (2022). Recent Studies Utilizing Artificial Intelligence Techniques for Solving Data Collection, Aggregation and Dissemination Challenges in Wireless Sensor Networks: A Review. Sensors, 11(3), 313.https://doi.org/10.3390/electronics11030313

[6]. Feki, M. A., Kawsar, F., Boussard, M., & Trappeniers, L. (2010). The Internet of Things: The Next Technological Revolution. Future Internet, 2(2), 96-114.https://doi.org/10.3390/fi2020096

[7]. Morrison, R. (2007). Wireless Sensor Network Design for Industrial Automation. IEEE Sensors Applications Symposium, 457-462.https://doi.org/10.1109/SAS.2007.4349161

[8]. Zhang, Y., & Dai, H. (2023). Real-Time Monitoring in Industrial Wireless Sensor Networks. IEEE Transactions on Industrial Informatics, 19(6), 1234-1242.https://doi.org/10.1109/TII.2023.10122774

[9]. Jovanović, Z. (2010). Sensor Systems for Environmental Monitoring: Sensors and Applications. In Advanced Knowledge Application in Practice (pp. 267-288). IntechOpen.https://doi.org/10.5772/10846

[10]. Ramamurthy, A., & Jain, P. (2012). Security Challenges in Industrial Wireless Sensor Networks. IEEE Communications Magazine, 50(6), 134-142.https://doi.org/10.1109/MCOM.2012.6165193

[11]. Krotofil, M., & Gollmann, D. (2006). Industrial Control Systems: Security and Sensor Deployment. Sensors and Actuators A: Physical, 126(2), 245-255.https://doi.org/10.1016/j.sna.2005.09.043

[12]. Nimbalkar, N., Zareie, S., Dehghani, M., Gonzalez-Aguirre, J., & Lee, Y. C. (2021). Smart sensors and IoT in smart cities: Challenges and future directions. Sensors, 21(5), 1595. https://doi.org/10.3390/s21051595

[13]. Kumar, S., Singh, A., Singh, R. P., & Pandey, R. (2021). An overview on Industry 4.0: Transformation of cyber-physical system with AI, Big Data, and IoT. Sensors, 21(9), 3031. https://doi.org/10.3390/s21093031

[14]. Singh, R. P., Javaid, M., Haleem, A., & Suman, R. (2021). Internet of things (IoT) applications to fight against COVID-19 pandemic. Diabetes & Metabolic Syndrome: Clinical Research & Reviews, 15(2), 521–524. https://doi.org/10.1016/j.dsx.2021.02.019