1.Introduction

At present, industrial robots have become an irreplaceable part of production automation, greatly promoting industrial automation and efficiency, and in many areas have replaced the physical exertion of human beings engaged in highly repetitive tasks. Traditional industrial robots often use a pre-programmed program for the robot needs to reach the position of the control, such as a control method to adapt to a single working environment, such as automotive manufacturing, palletizing and handling, etc. However, in many industrial assembly scenarios, the products are usually not in batches and the assembly conditions are not repetitive. If the traditional position control is still adopted, the pre-planned path action is no longer adapted to complex tasks, and the contact force of the mounting interface and the precision of the mounting cannot be guaranteed during the assembly process. Therefore, the problem of adapting robot actions to changes in external conditions needs to be solved urgently.

Various sensor schemes have been proposed to solve the problem of robot interaction with the outside world, including visual sensing, force sensing and collision detectors [1]. In assembly scenarios, force sensing schemes and flexible control techniques have been widely studied [2]. For example, Wu Binglong [3] et al. addressed the jamming phenomenon in the final loading stage during high-precision assembly due to the deviation in the alignment stage. Although, the research results are relatively abundant, most of them focus on the application of specific methods and lack systematic summarization and analysis.

By systematically combing and analyzing the existing literature, this paper will outline the concepts, classifications, and development history of force-aware and flexible control technologies, analyze the applications of these technologies in assembly scenarios as well as their strengths and weaknesses, and present the shortcomings of the current research and the directions for future research. This paper hopes to provide a clear framework and direction to promote the further development and application of flexible control technologies in assembly scenarios.

2.Overview of flexible control technology

2.1.The development process of flexible control technology

The earliest research in force sensing dates back to the 1950s and focused on addressing the need for force feedback for specific tasks. A typical example is Goertz's proposal to install a force feedback device on a robotic arm to sense the contact forces between the manipulator and the environment, in the face of the challenges of a harsh environment in a radioactive experimental workshop. Since the 1970s, the force control of robots has changed radically with the development of robotics. In 1985, Hogan proposed impedance control, which equates a robot to a “mass-spring-damping” system. Impedance control regulates how a robot interacts with its environment by controlling the relationship between force and position. Unlike traditional force or position control, impedance control emphasizes the dynamic relationship between force and displacement.

The development of impedance control has led to a gradual shift in robotics research towards active flexible control techniques. Flexible control techniques require the robot to adjust its state in response to the forces applied by the environment to produce a predetermined force perception, also known as force perception control. The purpose of flexible control techniques is to avoid excessive contact forces in contact with the environment, which can lead to rigid collisions between the robot and the environment and damage the robot or the workpiece.

In summary, from the force sensing research in the 1950s to the force control changes in the 1970s, to the proposal and development of impedance control and active flexible control technology in the 1980s, force sensing and control technology is continuously progressing, which provides an important support for the application of robotics.

2.2.Classification of flexible control technology and its characteristics

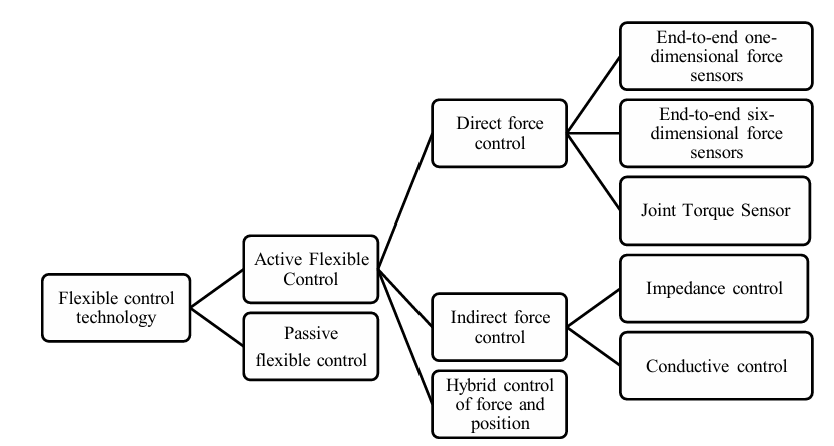

Currently used flexible control technology can be categorized as passive flexible control technology and active flexible control technology, active flexible control technology can be categorized according to the presence or absence of force sensors as direct force control, indirect force control (including impedance control, conductive control), as shown in Figure 1. Passive flexible control technology installs a mechanical elastic structure at the end of the robotic arm to realize the force control function through the elasticity of the robotic arm, which is inexpensive, but the accuracy of the force control can not be guaranteed, so it is seldom studied. In active flexible control technology, direct force control controls both force and position in different directions in an independent form. Indirect force control controls both force and position relative to each other, using software algorithms to realize the flexible structure. These control schemes for force are combined with position control to arrive at a hybrid control of force and position according to specific scenarios and needs. Currently, those that have been widely studied and discussed include the conductive and impedance control in indirect force control, as well as the hybrid control of force and position [4].

Figure 1: Classification of flexible control technology

3.Optimized assembly process with flexible control technology

The role of flexible control technology is to monitor and adjust the motion trajectory and apply force to cope with small deformations and assembly errors that may be present in the actual assembly. In assembly scenarios, the pin-in-hole pattern is more susceptible to small deformations that can lead to damage and waste of shaft-hole components. The introduction of flexible control technology can ensure that the pins can be inserted into the holes safely and accurately, which improves the success rate and efficiency of the shaft hole assembly process.

The study of technical problems in shaft hole assembly is typical and representative, which can effectively promote the development of the whole robot assembly technology and solve the common problems in other similar assembly tasks.

The process of shaft hole assembly can be divided into four stages, search stage, alignment stage, loading stage and interface separation stage [5]. This paper will summarize the two phases of alignment and loading, as well as the gravity compensation algorithm.

3.1.The alignment phase

The alignment phase, also known as calibration or alignment, is designed to ensure that the individual components are precisely aligned, and refers to the process of accurately positioning different parts or components during the assembly process so that they conform to the relative positions required by the design.

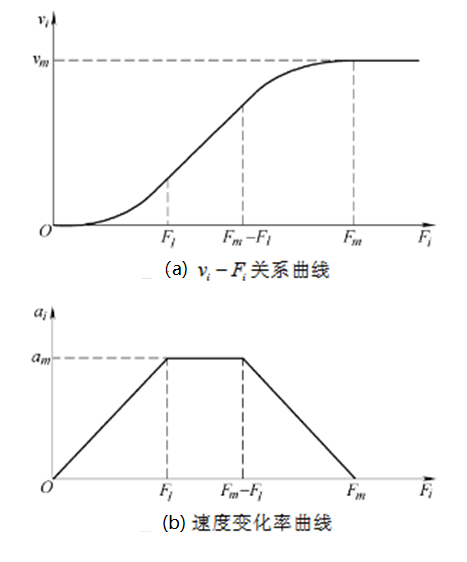

Hu Ruiqin et al [6] based on the direction of the assembly interface force and the direction of the robot tool coordinate system, give a set of robots based on the force-position hybrid control of the smooth assembly program, to avoid the force control process of the robot jitter, the design of the machine manpower and speed of the “S” curve relationship, as shown in Figure 2.

Figure 2: Velocity versus force curves [8].

Some researchers have also introduced intelligent control principles, for example, Song [2] et al. combined imitation learning with model-based control by using Gaussian mixture models and regression methods to fit the data, and experimented with inaccuracies in the geometrical contour parameters of the assemblies and the elasticity parameters of the materials with a tolerance of 0.18 mm, with a success rate of 100%.

In conclusion, in the close alignment stage, some researchers have improved the traditional force-position hybrid control scheme, and there are also references to intelligent control principles, such as the imitation learning approach, to make the shaft hole alignment scheme more widely adaptable.

3.2.The mounting phase

The mounting phase is the step in the assembly process where the pre-aligned component is mounted in its final position and secured.

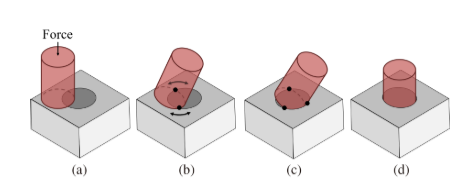

Some researchers are trying to find active flexure solutions that do not require force feedback systems. For example, Park H et al [7] proposed an inexpensive peg-hole assembly method that does not require force feedback or a passive flexure mechanism, which analyzes the contact state between the pile and the hole and proposes a strategy to overcome the unavoidable uncertainty of the hole position during the recognition process. Four basic motions, as shown in Figure 3, are designed and modelled after the human assembly process. After the axial “push” motion, the shaft contacts the hole; after the axial spiral “kneading” motion, the end of the shaft enters the hole; after the axial “pendulum” motion centred on the end of the shaft, the front of the shaft enters the hole; after the axial spiral “kneading” motion, the front of the shaft enters the hole; after the axial spiral “kneading” motion, the front of the shaft enters the hole; after the axial spiral “kneading” motion, the front of the shaft enters the hole. The front part of the shaft enters the hole through a “swinging” motion centred on the end of the shaft in a variable axial direction; the shaft is loaded into the hole through a “spinning” motion rotating in an axial direction.

Figure 3: Four basic motions (push, knead, swing, and spin) of the robot assembly process [7]

Dynamic movement primitives (DMP) are widely used in imitation learning and have been improved in recent years. Xu et al [8] investigated a robot multi-pin assembly task and proposed a model-driven deep deterministic policy gradient (MDDPG) algorithm, which learns the contact state without analyzing the contact state by the strategies to accomplish the assembly task without analyzing the contact state, and a fuzzy reward system is used for the complex assembly process. The decision-making efficiency in the robot assembly process is greatly improved.

Beltran-Hernandez et al [9] at Osaka University proposed a learning-based approach to solving the pinning hole task with hole position uncertainty using a non-strategic, model-free reinforcement learning method. The learning method can be generalized directly from single-axis hole learning to many socket scenarios with success rates between 55% and 80%, providing relatively good flexibility.

In summary, in the loading phase of shaft hole assembly, there are multi-directional studies on sensorless, reinforcement learning and its combination with traditional force-position hybrid control to jointly explore how to ensure assembly accuracy and avoid workpiece damage.

3.3.Gravity Compensation

During the assembly of heavy components, gravity compensation algorithms are used in the robotic arm to calculate and apply appropriate compensating forces to counteract torque due to gravity, thus improving the accuracy and stability of the robotic arm.

Duan Yufei et al [10], for the scenario of high load gravity during spacecraft assembly, based on the calculation method of load weight and centre of gravity position in the case of slow and smooth movement of the workpiece, studied the force-displacement moment-rotation control function in detail, converted the force into displacement step, improved the efficiency of the algorithm, and realized fast gravity compensation.

4.Application status of flexible control technology

In the conventional lightweight assembly market, robot models developed by KUKA Germany, such as the LBR IIWA lightweight assembly robot, demonstrate the promise of flexible control technology.KUKA realizes flexible control technology through the use of articulated torque sensors, a technological option that is cheaper in terms of cost than the end-to-end six-dimensional sensors, guaranteeing controllable costs. In addition, KUKA has a mature force control process package, which has been used in some applications in areas such as grinding and assembly, demonstrating its effectiveness in real industrial scenarios.

However, despite the maturity of these technologies and process packages, there is a lack of applications for flexible control technologies. This is because despite the relatively low cost of joint torque sensors, the overall system cost is still high, market acceptance is still low due to cost and price considerations, and it takes a process for users to trust and rely on the new technology. Future applications should focus on reducing cost, simplifying the system, improving user-friendliness, and providing more technical support and training to promote the use of force perception control technology in a wider range of industrial assembly applications.

5.Problems

The current research and application of flexible control technology in robot assembly scenarios still has problems in several areas, including how to obtain the interaction force between the robot and the outside world, the problem of data bandwidth, and how to unify the control system.

First and foremost, the most difficult part is still to accurately acquire the robot's interaction with the outside world. Force control techniques are crucial in many scenarios, but most of them rely on force sensors. Existing industrial robots, however, usually acquire the interaction force through a current loop. The accuracy of this approach is poor, making it difficult to meet the demands of high-precision assembly. Adding higher precision force detection equipment to existing robots would significantly increase costs. For example, the price of a high-quality six-axis force sensor may exceed the price of the robot itself.

Second, because of the lack of data bandwidth, high-precision force sensors are not compatible with many existing robot models. This limits the ability to transmit and process sensor data in real-time. Although there are some indirect force control methods, e.g., estimation or modelling to derive the interaction force, the parameter establishment of these methods still requires the support of force sensors. In the absence of direct force measurements, the accuracy of indirect force control can be relatively low.

Finally, another important challenge is how to solve the frequent switching between force control and position control. Force control and position control are two basic modes in robot operation, but their control principles and requirements differ greatly, and the robot needs to switch frequently between these two control modes. However, realizing this seamless switching is a complex problem, and if the switching is not smooth, it may lead to unstable control and affect the accuracy and safety of assembly.

6.Future outlook

Assembly technology occupies an important position in modern manufacturing, and its future development requires, first and foremost, a higher degree of flexibility. At present, the flexibility of flexible control technology is not yet sufficient to cope with different types of complex assembly tasks and still needs to be specifically analyzed and adjusted for specific situations. To improve the adaptability of the system, the future research direction is to combine with artificial intelligence, and machine learning, and quickly respond to the needs of different assembly tasks, to improve assembly efficiency and accuracy.

Secondly, the development of large component assembly technology cannot be separated from extensive practical application. In the application process, through continuous practice and feedback, problems in the technology can be found and solved promptly. This kind of improvement based on practical application helps to promote the iterative upgrading of the technology and ensures that the assembly system can respond to the ever-changing production environment and demands. Therefore, expanding the scope of technology application, penetrating all kinds of assembly scenarios, and continuously accumulating experience are the key paths to improving the assembly technology of large parts.

Finally, the underlying hardware issues are central to the development of robotic assembly technology. Existing force sensors have significant room for improvement in terms of accuracy and cost. The development of more accurate and less costly force sensors is key to improving the performance of assembly systems.

In summary, the future development of industrial robot assembly technology will continue to advance the manufacturing industry in the direction of intelligence and refinement by improving system flexibility, expanding the range of applications and optimizing the underlying hardware in these three areas of effort.

7.Conclusion

This paper summarizes and analyzes the current status of research and application of flex-control technology in assembly scenarios from the concept and classification of flex-control technology by systematically combing and analyzing the existing literature.

This paper analyzes the alignment and loading phases of shaft hole assembly scenarios in depth. It analyzes some practical cases in which traditional force-position hybrid control schemes, intelligent control principles, and various techniques such as imitation learning have been used to improve assembly efficiency and success rate. In particular, the researchers have explored the sensorless active flexible control technology and the combination of intelligent algorithms and traditional control methods, demonstrating the wide adaptability of flexible control technology in complex work scenarios.

Flexible control technology still has great potential in the field of robot assembly. Future research should be devoted to enhancing system flexibility, expanding application scope and optimizing hardware, enabling the system to respond quickly to different assembly tasks by combining artificial intelligence and machine learning technologies to improve adaptability and efficiency. In practical applications, optimize technical solutions through practice and feedback to ensure that the system responds to changing production environments. At the same time, more accurate and lower-cost force sensors are developed, and data transmission and processing technologies are improved to solve the problems of insufficient sensor accuracy and bandwidth. In summary, flexible control technology will play an important role in promoting the intelligent and refined development of the manufacturing industry in the future.

References

[1]. Zhu, B. W., Ma, L., Chen, W. N., & et al. (2019). Current status and key technology of automatic shaft hole assembly system. Modern Manufacturing Engineering, (5), 156-161.

[2]. Song, J. Z., Chen, Q. L., & Li, Z. D. (2021). A peg-in-hole robot assembly system based on Gauss mixture model. Robotics and Computer-Integrated Manufacturing, 67, 101996.

[3]. Wu, B. L., Qu, D. K., & Xu, F. (2018). Precision shaft hole assembly of industrial robot based on force/position hybrid control. Journal of Zhejiang University (Engineering Edition), 52(2), 379-386.

[4]. Wang, J. P., Xie, Y. Q., Song, T., & et al. (2019). Precision position control technology of robotic arm with force sensing interaction control. Mechanical Design and Research, 35(4), 47-52.

[5]. Jiang, J. G., Huang, Z. Y., Bi, Z. M., & et al. (2020). State-of-the-art control strategies for robotic PiH assembly. Robotics and Computer-Integrated Manufacturing, 65, 101894.

[6]. Hu, R. Q., Zhang, L. J., Meng, S. H., & et al. (2018). Robotic assembly technology of spacecraft large parts based on flexible control technology. Journal of Mechanical Engineering, 6.

[7]. Park, H., Park, J., Lee, D. -H., & et al. (2017). Compliance-based robotic peg-in-hole assembly strategy without force feedback. IEEE Transactions on Industrial Electronics, 64(8), 6299-6309.

[8]. Xu, J., Hou, Z., Wang, W., & et al. (2019). Feedback deep deterministic policy gradient with fuzzy reward for robotic multiple peg-in-hole assembly tasks. IEEE Transactions on Industrial Electronics, 15(3), 1658-1667.

[9]. Beltran-Hernandez, C. C., Petit, D., Ramirez-Alpizar, G. I., & et al. (2020). Variable compliance control for robotic peg-in-hole assembly: A deep-reinforcement-learning approach. Applied Sciences-Basel, 10(19), 6923.

[10]. Duan, Y., Mo, W., Liu, S., & et al. (2022). Research on assisted assembly strategy of heavy-duty robot based on force sensing control with fast gravity compensation. Mechanical Design and Research, 6.

Cite this article

Liu,B. (2025). Research on Assembly Robots Based on Flexible Control Technology. Applied and Computational Engineering,125,8-14.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Mechatronics and Smart Systems

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Zhu, B. W., Ma, L., Chen, W. N., & et al. (2019). Current status and key technology of automatic shaft hole assembly system. Modern Manufacturing Engineering, (5), 156-161.

[2]. Song, J. Z., Chen, Q. L., & Li, Z. D. (2021). A peg-in-hole robot assembly system based on Gauss mixture model. Robotics and Computer-Integrated Manufacturing, 67, 101996.

[3]. Wu, B. L., Qu, D. K., & Xu, F. (2018). Precision shaft hole assembly of industrial robot based on force/position hybrid control. Journal of Zhejiang University (Engineering Edition), 52(2), 379-386.

[4]. Wang, J. P., Xie, Y. Q., Song, T., & et al. (2019). Precision position control technology of robotic arm with force sensing interaction control. Mechanical Design and Research, 35(4), 47-52.

[5]. Jiang, J. G., Huang, Z. Y., Bi, Z. M., & et al. (2020). State-of-the-art control strategies for robotic PiH assembly. Robotics and Computer-Integrated Manufacturing, 65, 101894.

[6]. Hu, R. Q., Zhang, L. J., Meng, S. H., & et al. (2018). Robotic assembly technology of spacecraft large parts based on flexible control technology. Journal of Mechanical Engineering, 6.

[7]. Park, H., Park, J., Lee, D. -H., & et al. (2017). Compliance-based robotic peg-in-hole assembly strategy without force feedback. IEEE Transactions on Industrial Electronics, 64(8), 6299-6309.

[8]. Xu, J., Hou, Z., Wang, W., & et al. (2019). Feedback deep deterministic policy gradient with fuzzy reward for robotic multiple peg-in-hole assembly tasks. IEEE Transactions on Industrial Electronics, 15(3), 1658-1667.

[9]. Beltran-Hernandez, C. C., Petit, D., Ramirez-Alpizar, G. I., & et al. (2020). Variable compliance control for robotic peg-in-hole assembly: A deep-reinforcement-learning approach. Applied Sciences-Basel, 10(19), 6923.

[10]. Duan, Y., Mo, W., Liu, S., & et al. (2022). Research on assisted assembly strategy of heavy-duty robot based on force sensing control with fast gravity compensation. Mechanical Design and Research, 6.