1. Introduction

Since the emergence of nanotechnology in the 1980s, microelectronic processing has continually advanced towards smaller sizes and more complex structures, somehow driving the revolution in information technology. Manufacturing electronic devices at micrometer and nanometer scales using microelectronic processing necessitates sophisticated mechanical components to support the production process. Moreover, mechanical design has been integrated with microelectronics to achieve more compact functional integration and ultra-high performance. The intersection of mechanical design and integrated circuits is occurring more and more frequently and is a guarantee of high performance and diversity in the field of mechanical engineering today.

The application of integrated circuits in mechanical design is mainly reflected in the control system and sensor technology. With the development of information engineering technology, integrated circuits are also often used in communication interfaces to enhance the intelligence of mechanical equipment. For instance, the application of integrated circuits in Micro Electro Mechanical System (MEMS) demonstrates the potential of this kind of micro-device integrating nanoscale integrated circuits and micro-machinery in the integration of medical engineering, aerospace, and industrial machinery, and the application of integrated circuits makes MEMS more powerful and superior [1]. While stimulating the market demand and technological innovation, the increasingly mature microelectronic process has brought about the growth of product yield, process stability, product reliability and other aspects, which is mainly reflected in the demand for high-performance, low-power and miniaturized products [2, 3]. The consumer demand for integrated circuits and semiconductors continues to grow with developments in areas such as the Internet of Things (IoT) and artificial intelligence. In addition, with advances in mechanical engineering, materials science, and other fields, users are looking for higher processing speeds and more automated manipulation. These factors have in turn driven continuous innovation and upgrading of microelectronic processes.

In this paper, we will use the literature review to examine the application of microelectronics in different areas of mechanical design, such as control systems, precision sensors, etc., all of which are intended to provide recommendations for improving system intelligence and reliability, as well as to provide examples of industry standards and best practices of microelectronics in the field of mechanical engineering, thereby showing the key role it has played in driving industrial progress and technological convergence.

2. Literature Review

2.1. Automation Control

The application of microelectronics technology in automation control system can significantly improve the working performance and operational efficiency of the control systems. Accompanied by the progress of the times, the demand for automation control technology is also growing, leading to the inability for the ordinary single-closed control system to meet the growing diversity and complexity of the demand. As a result, the automation control system began to develop in the direction of intelligence [4]. From the viewpoint of the essential characteristics of the automation system, its diversified and comprehensive nature makes it in electronic technology and computer technology have a close relationship. The use of a large number of automation technologies in production activities, will greatly enhance production efficiency and reduce operating costs. At the same time, automation technology can effectively improve the information feedback rate and accelerate the development of production to a large extent in the context of today's increasing degree of informatization.

In microelectronic automation systems, the use of microelectronic controllers and their automatic operation has always been a top priority in this field. First of all, the ability to quickly collect and process sensor data for real-time monitoring of the state of the entire system, such as a shunt piezoelectric transducer that is self-tuning through a digitally programmable inductor to enhance system compatibility and impedance management [5]. In the field of mechanical design, automated control systems often utilize sensors to continuously collect data for high-speed sampling, and then deliver the information to microelectronic controllers, which then quickly analyze this data to improve equipment accuracy and responsiveness. Additionally, the system can immediately make decisions and adjust errors according to the analysis results, to achieve closed-loop control, and ensure the efficiency and stability of the system operation, thus supporting the intelligent automatic operation.

Secondly, another important manifestation of microelectronics in the field of automation is its flexible programming, which allows users to adjust the control strategy according to their needs to meet different production needs. Before the application of microelectronics technology to automation control technology, if you want to add new control strategies to the automation system, you have to add new hardware facilities, which will inevitably bring about an increase in operating and time costs, but also add to the complexity of the work. However, after the application of microelectronics technology to the automation system, the system can complete the control of the automation system as long as a few integrated chips, and no matter how large-scale integrated circuits can be efficient and comprehensive monitoring and control in the chip [6]. And when the automation control system is faced with the growth of the control strategy, it is only necessary to utilize the programming of the computer, and it can be very convenient to achieve its purpose.

2.2. Sensors

Sensors play a crucial role in machinery design as they can monitor the status of the whole system by real-time monitoring. In general, the sensors are mainly able to detect temperature, pressure, vibration and other parameters to provide users with critical data to help them identify and solve potential problems in time to achieve the purpose of improving safety and performance. In addition, the combination of sensors and control systems makes intelligent regulation possible, making mechanical equipment more automated and conveniently adapting to more complex working environments. In addition, the use of sensors also allows equipment to perform autonomous fault diagnosis and repair, thereby reducing maintenance costs and extending equipment life. In short, the application of sensors promotes the automation and intelligence of mechanical design and improves the overall performance of the equipment.

Microelectronics enables sensors to integrate more functions in a smaller volume, and one of the main goals of intelligence is to integrate sensors and actuators into passive structural components in the manufacturing process to save space and enhance performance [7]. In this way, integration can result in significant space and cost savings, greatly reducing material and production costs, as well as simplifying the system architecture, enhancing performance, and improving data accuracy. Furthermore, integrated sensors can also share signal processing resources more easily. By sharing signal processing resources, integrated sensors are able to achieve faster response times, making them suitable for more complex application scenarios and meeting the multiple demands for information in complex systems [8]. The multi-threaded operation capability of integrated sensors also enhances the system's environment sensing capability, enabling the system to better respond to dynamic changes. At the same time, integrated sensors provide fast signal processing and real-time feedback, disguised to support the application of intelligent algorithms, to enhance the level of intelligence of the system, and these features have led to integrated sensors becoming an important solution to deal with the complexity of the use of the scene [9].

2.3. Embedded Systems

Embedded systems, most of which refer to computer systems embedded in mechanical or electrical systems with specific functions and real-time computing performance, are often embedded systems with mechanical components and hardware devices. Unlike general-purpose computers, embedded systems are usually used to carry out some kind of computation exclusively, rather than a diverse range of computing situations. In the field of mechanical design, embedded systems are often used in automated production lines and human-computer interaction. In today's general environment of mechanical automation, some embedded automation instruments are rapidly developing to cope with the growing requirements of industrial production for the intelligence and networking of electromechanical components. Embedded systems not only have a very good compatibility with today's intelligent megatrend, but another of their characteristics is the in-depth and comprehensive production process, so that a malfunction can be quickly and accurately identified. Nowadays, embedded systems are used in automated instrumentation, image processing, etc. [10, 11]. Also, the development and manufacturing of embedded systems, including high-density layouts and multilayer board designs [12], are advancing. Besides, interconnections between systems can be realized by embedded systems through IoT technology. In this way, each device on the production line can share data and work together, achieving the purpose of further optimizing resource management and configuration.

The integration of computer hardware and software in embedded systems requires them to have a close and complementary relationship with microelectronics technology and integrated circuits. This primarily manifests in microprocessor manufacturing processes, the integration of multiple functions and modules, and power consumption and thermal management [13]. Microelectronics technology integrates multiple functional circuits onto a single chip, improving system compatibility and enabling embedded systems to be used in various fields such as home appliances, automobiles, and industrial robots.

With the development of mobile devices, battery life has always been a focus of user attention. Another critical aspect of the connection between microelectronics technology and embedded systems is power consumption management. Innovations in microelectronics technology have reduced power consumption and heat generation, facilitating efficient power and thermal management for embedded systems, enabling them to operate efficiently with limited power.

3. Application Analysis

3.1. Application of Small-scale Integrated Circuits in Mechanical Design

3.1.1. Smart Sensors

The integration of microcircuits makes machinery and equipment more intelligent, convenient, and efficient, driving innovation and development in many industries. Microcircuits play a crucial role in sensor applications, often used to detect the external environment, such as air humidity, temperature, and brightness, and then use this information for environmental change detection, air pollution monitoring, or automatic adjustment of lighting and temperature in smart homes, as well as detecting the surrounding environment in unmanned or autonomous vehicles to enable automatic cruise and collision warning functions. Another application track is using sensors in medical equipment and industrial automation to monitor equipment status and provide real-time data. For example, wearable medical devices use sensors to detect heart rate, blood sugar levels, and other indicators. In industrial production, smart sensors are also used to monitor equipment production status, aging, and faults to optimize production processes.

3.1.2. Micro Electro Mechanical System (MEMS)

Another significant achievement of small-scale integrated circuits in the field of mechanical design is Micro Electro Mechanical System (MEMS). MEMS is a system that combines microelectronics and mechanical engineering, typically consisting of micro-sensors, controllers, and electronic components. It is also utilized in various products such as electronics, automobiles, and aerospace. In our everyday smartphones, MEMS essentially integrates instruments like accelerometers, gyroscopes, and pressure sensors to support functions such as screen rotation, activity monitoring, and altitude detection. In the automotive industry, MEMS is used to deploy accelerometers to monitor the instant of collision and accelerate the rapid deployment of airbags. In the aerospace field, MEMS serves as gyroscopes, accelerometers, and other devices to detect changes in the spacecraft's position, direction, and attitude, ensuring flight stability. Additionally, it undertakes responsibilities for navigation, data collection, and human-computer interaction.

3.2. Applications of Large-scale Integrated Circuits in Mechanical Design

3.2.1. Robotics

Compared with small-scale integrated circuits, large-scale integrated circuits have shown strong vitality in robotics. In addition to some normal sensor input, actuator output and other operations, with the deepening of the degree of information technology, these large-scale integrated circuits are also commonly used to connect a variety of sensors, such as cameras, infrared cameras, LIDAR, etc., to transmit the collected images or data to the processing unit, to help the robots recognize objects and environments. Even tactile sensors have emerged so that robots can sense pressure. Meanwhile, with the advancement of energy technology, large-scale integrated circuits are often used to undertake the work of power distribution and energy consumption optimization of robots to ensure the long-lasting and stable operation of robots in complex working environments.

3.2.2. Testing and Measurement Equipment

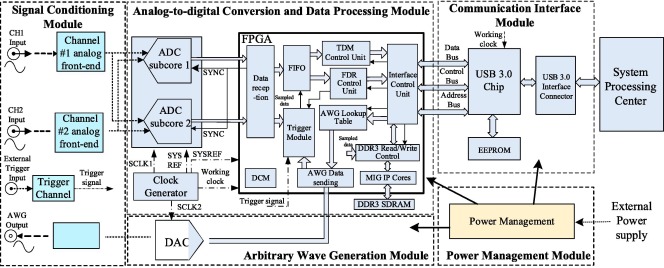

In the application of testing and measurement equipment, conventional instruments such as oscilloscopes and multi-meters are first used to monitor and analyze electrical signals, assisting users in debugging and optimizing circuit designs. Secondly, they are used for real-time data acquisition from multiple sensors, integrating different types of data to analyze the working state of the equipment. Simultaneously, filtering techniques are utilized to reduce noise impact and improve data quality, thereby obtaining more accurate data types. Large-scale ICs are also used in mechanical performance testing to evaluate the material, structure, vibration, and load characteristics of components, identifying potential faults and ensuring that the equipment meets performance and safety standards.

Figure 1: Schematic Diagram of a High-Speed Oscilloscope Structure [14]

4. Discussion

This paper argues that the rapid development of microelectronics technology and ICs in the field of mechanical design is not only due to their significant ability to enhance automation and intelligence levels in the field of mechanical engineering. At the same time, the cost reduction brought about by advancements in microelectronics technology itself cannot be ignored. With the continuous progress of semiconductor manufacturing technology, the production efficiency and yield of chips have been significantly improved. The expansion of market demand for large-scale production has gradually reduced the cost of microelectronic components, allowing more products to enter the market at lower prices. As integration density increases, users can achieve more functions on a single chip, further reducing the number of chips required and lowering costs.

Along with lower costs, more and more businesses and consumers are beginning to be able to afford these components, and with that comes the establishment of standardization, accelerating the spread of technology within the industry. In recent years, advances in software development and programming languages have also made it easier for developers to write efficient control programs for them, making the application of diverse functions more efficient and greatly accelerating their development in the field of mechanical design.

At the same time, some areas of mechanical design have also begun to follow the trend of miniaturization in microelectronics technology.

5. Conclusion

The emergence and development of microelectronic processes, as well as the application in the field of mechanical design, have not only accelerated the development and innovation within the machinery industry but also brought great convenience to people's production and life. With its wide application in various fields, it has also met the market's growing demand for intelligent and automated products. This paper takes the study of microelectronic processes in the microelectronic process as an example, and reveals the microelectronic process and integrated circuit in today's degree of informatization, the application of microelectronic processes and integrated circuits in the field of microelectronics, which not only improve the operational accuracy and automation level of mechanical equipment but also mark the strong momentum of traditional machinery manufacturing transitioning to intelligence.

Nevertheless, this paper still has many deficiencies. For example, although it covers advancements in microelectronics technology and the impact of nanotechnology, it fails to delve deeply into the application of cutting-edge technologies such as the IoT and 5G technology in mechanical equipment, making the technological vision somewhat limited. At the same time, there is a lack of in-depth analysis of the context of how industry standards are formed and how the market is changing, and there is insufficient analysis of the specific cost-effectiveness and economic returns, thus failing to provide readers with a deeper understanding.

In summary, the application of microelectronic processes not only speeds up the advancement of the machinery industry but also fulfills the escalating market demand for intelligent and automated products. It is anticipated that, with the ongoing evolution of scientific and technological advancements, microelectronic processes will find even broader applications in the future, ultimately generating even greater value.

References

[1]. Yong J, Kang Z Y & Yin C S. (2024). Research on lithography simulation technology based on microelectromechanical system machining. Modern Manufacturing Technology and Equipment,7: 18-20.

[2]. Ji X., Li Y. & Peng T.(2016). Research on microelectronic integration technology based on Si-Al alloy. Electronic Process Technology, 02: 74-76+84.

[3]. Zhang X., Shang Z, & Yu J. (2017). Vacuum baking process of sealed microelectronic devices. Electronics and Packaging, 01: 6-9.

[4]. Yan W. & Li H.(2021). Research and Application of Microelectronics Design automation technology. Electronic Test, 18: 117-118+100.

[5]. Ma S., Zhang Y., Zhuang X., Wang D., Chen S., Liu H. (2024).Frequency tuning and automatic frequency tracking of shunted piezoelectric transducers. Ultrasonics, 141.

[6]. Xue Y. (2022). On the application of microelectronics technology in automatic control. Digital Technology and Application, 07: 15-17.

[7]. Stein, S., Wedler, J., Rhein, S., Schmidt, M., Körner, C., Michaelis, A., & Gebhardt, S. (2017). A process chain for integrating piezoelectric transducers into aluminum die castings to generate smart lightweight structures. Results in physics, 7, 2534-2539.

[8]. Huang C J, Mao H Y.(2024). Progress has been made in the study of flexible humidity sensor in nanoforest in the Institute of Microelectronics. Sensor World, 04: 40.

[9]. Shi L J. (2024). Research on Wireless sensor network technology in computer and communication integrated system. China New Communications, 17: 10-12.

[10]. Bansal, T., Talakokula, V., & Saravanan, T. J. (2022). Monitoring of prestressed concrete beam under corrosion using embedded piezo sensor based on electro-mechanical impedance technique. Science Talks, 4, 100095.

[11]. Liu Y L. (2024). Research on application of embedded image processing technology in industrial automation. Paper making equipment and Materials, 03: 50-52.

[12]. Zhang Q.(2024). EDA automation process optimization for PCB design in embedded systems. Automation Applications, 08: 259-261+264.

[13]. Morchid, A., Jebabra, R., Ismail, A., Khalid, H. M., El Alami, R., Qjidaa, H., & Jamil, M. O. (2024). IoT-enabled fire detection for sustainable agriculture: A real-time system using flask and embedded technologies. Results in Engineering, 23, 102705..

[14]. Huang W, Chen A, Pan Z, Zhang S, Yang K, Qiu D, Ye P, Tian S, Wang H. (2023). Design of portable high-speed oscilloscope analyzer for multifunctional integrated signal testing. Measurement, 209, 112490.

Cite this article

Zheng,H. (2025). The Application Potential of Microelectronic Processing and Integrated Circuit in Mechanical Design. Applied and Computational Engineering,117,93-99.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Mechatronics and Smart Systems

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Yong J, Kang Z Y & Yin C S. (2024). Research on lithography simulation technology based on microelectromechanical system machining. Modern Manufacturing Technology and Equipment,7: 18-20.

[2]. Ji X., Li Y. & Peng T.(2016). Research on microelectronic integration technology based on Si-Al alloy. Electronic Process Technology, 02: 74-76+84.

[3]. Zhang X., Shang Z, & Yu J. (2017). Vacuum baking process of sealed microelectronic devices. Electronics and Packaging, 01: 6-9.

[4]. Yan W. & Li H.(2021). Research and Application of Microelectronics Design automation technology. Electronic Test, 18: 117-118+100.

[5]. Ma S., Zhang Y., Zhuang X., Wang D., Chen S., Liu H. (2024).Frequency tuning and automatic frequency tracking of shunted piezoelectric transducers. Ultrasonics, 141.

[6]. Xue Y. (2022). On the application of microelectronics technology in automatic control. Digital Technology and Application, 07: 15-17.

[7]. Stein, S., Wedler, J., Rhein, S., Schmidt, M., Körner, C., Michaelis, A., & Gebhardt, S. (2017). A process chain for integrating piezoelectric transducers into aluminum die castings to generate smart lightweight structures. Results in physics, 7, 2534-2539.

[8]. Huang C J, Mao H Y.(2024). Progress has been made in the study of flexible humidity sensor in nanoforest in the Institute of Microelectronics. Sensor World, 04: 40.

[9]. Shi L J. (2024). Research on Wireless sensor network technology in computer and communication integrated system. China New Communications, 17: 10-12.

[10]. Bansal, T., Talakokula, V., & Saravanan, T. J. (2022). Monitoring of prestressed concrete beam under corrosion using embedded piezo sensor based on electro-mechanical impedance technique. Science Talks, 4, 100095.

[11]. Liu Y L. (2024). Research on application of embedded image processing technology in industrial automation. Paper making equipment and Materials, 03: 50-52.

[12]. Zhang Q.(2024). EDA automation process optimization for PCB design in embedded systems. Automation Applications, 08: 259-261+264.

[13]. Morchid, A., Jebabra, R., Ismail, A., Khalid, H. M., El Alami, R., Qjidaa, H., & Jamil, M. O. (2024). IoT-enabled fire detection for sustainable agriculture: A real-time system using flask and embedded technologies. Results in Engineering, 23, 102705..

[14]. Huang W, Chen A, Pan Z, Zhang S, Yang K, Qiu D, Ye P, Tian S, Wang H. (2023). Design of portable high-speed oscilloscope analyzer for multifunctional integrated signal testing. Measurement, 209, 112490.