1. Introduction

The convergence of AI and IoT technologies has catalyzed significant developments in wearable electronics, encompassing flexible conductors, sensing devices, and transistor systems. This technological evolution drives innovations across multiple domains, including intelligent health monitoring systems, artificial intelligence applications, and advanced prosthetic developments. Among these components, flexible pressure sensors play a fundamental role in wearable technology integration. Their malleable nature enables seamless conformity to human skin and complex geometries, transforming mechanical deformation into measurable electrical outputs.

Contemporary applications demand sensing systems combining multiple performance metrics: enhanced sensitivity, mechanical flexibility, rapid response characteristics, durability, and cost-effective production methods. Traditional pressure sensors often struggle to accommodate the full spectrum of human motion-induced pressures, ranging from subtle forces (0-10kPa) to significant pressures (100-300kPa), limiting their practical utility in integrated sensing applications. While existing microstructural substrate-based resistive sensors demonstrate remarkable sensitivity and response characteristics, they face challenges including hysteresis effects and reproducibility issues. Cost-effective piezoresistive solutions remain relatively unexplored. This research introduces an innovative sandwich-structured transparent sensor incorporating highly purified (99%) metallic CNTs combined with PDMS composite films. The device demonstrates exceptional surface adaptability across biological interfaces while maintaining consistent contact integrity. Notable features include an expanded detection range (0-30 kPa), extended operational lifespan (∼10000 cycles), and zero standby power consumption, representing significant advances in energy-efficient sensing technology.

2. Application of flexible pressure sensors in wearable devices

2.1. Sensors based on CNT and PDMS

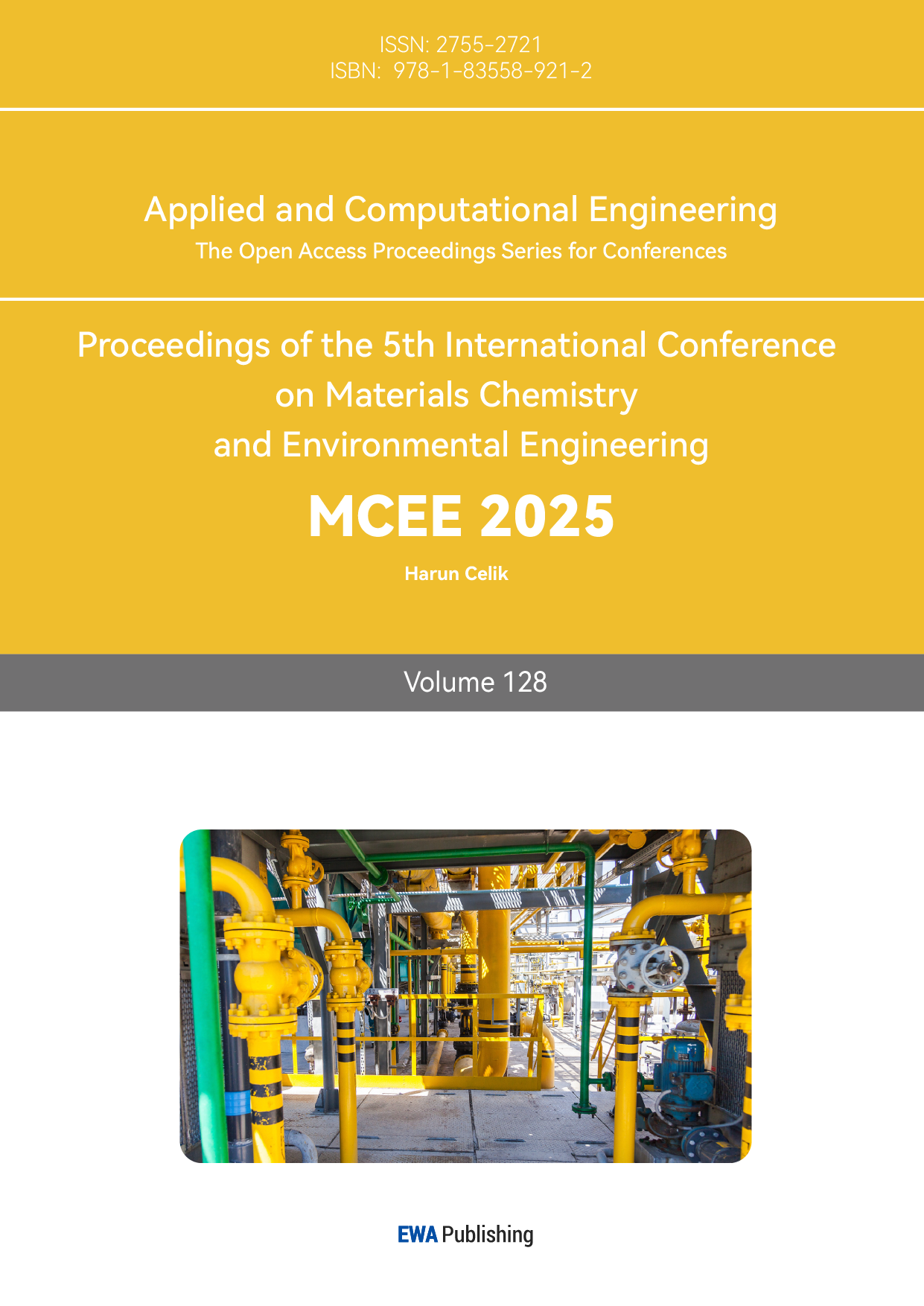

Contemporary flexible pressure sensing technology predominantly utilizes CNT and PDMS combinations. Several notable implementations demonstrate promising potential for widespread application. A pioneering transparent sensor featuring a sandwich-like architecture has been developed [1]. As illustrated in Figure 1(a), this device integrates highly refined (99% purity) solution-processed metallic CNTs with PDMS composite films. This configuration yields robust mechanical properties while maintaining manufacturing simplicity. The sensor exhibits exceptional optical characteristics, achieving over 92% transparency across visible wavelengths, while delivering optimal sensing performance metrics including minimal drift, enhanced sensitivity, reduced hysteresis, and linear response patterns, as demonstrated in Figure 1(b).

Sensitivity and linearity characteristics can be precisely controlled through CNT spray density modulation, enabling application-specific optimization. The technology shows particular promise for integration with flexible displays and photovoltaic systems, while maintaining wrinkle-free conformity when applied to biological surfaces. The implementation of density-gradient ultracentrifugation (DGU) processing enables selective elimination of semiconducting CNTs and carbonaceous impurities, resulting in enhanced optical transparency through optimized metallic CNT network formation.

Performance analysis focused on electromechanical characteristics of the metallic CNT percolation networks within the composite structure. The research demonstrated that CNT spray density serves as a critical parameter for performance optimization. Lower CNT densities prove advantageous for detecting subtle strain variations, while higher densities enable broader strain measurement ranges. The sandwich configuration effectively minimizes hysteresis effects, contributing to enhanced measurement stability.

Figure 1: Schematic illustration and Image of the fabricated transparent strain sensor. (a) Schematic illustration of the transparent CNT-PDMS composite strain sensor in the form of a sandwich structure. (b) Image of the fabricated transparent CNT-PDMS strain sensor when it was bent, stretched, and twisted [1]

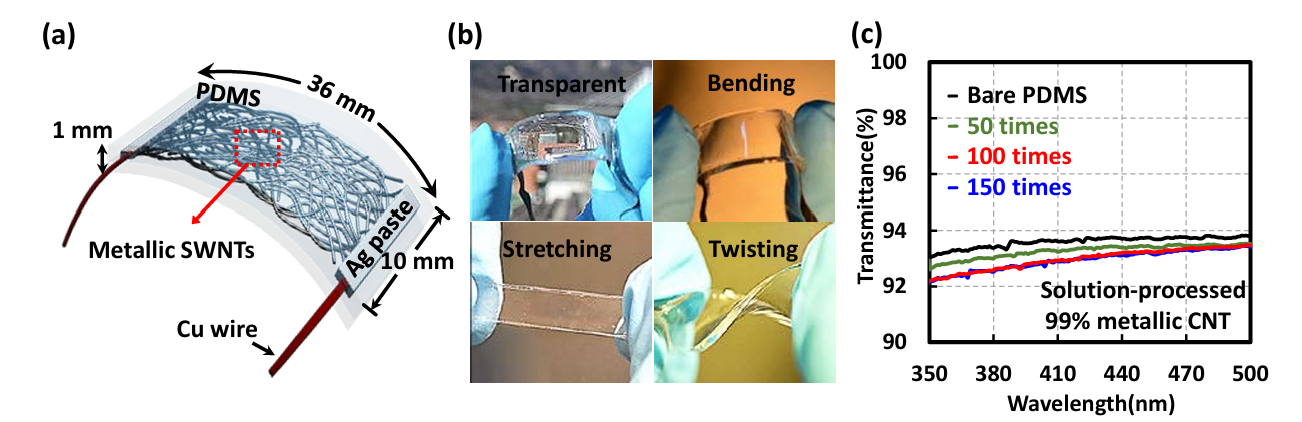

The second sensor with CNT-wrapped PDMS MSs shows potential for integration into wearable electronics for real-timely monitoring the physiological signals [2]. When external forces are applied, the spaces between constructed CNT-wrapped PDMS MSs can allow for structural deformations, changing the contact area between MSs and flat electrodes. The preparation method for PDMS MS is simple, scalable, and environmentally friendly, in contrast to lithography. The sensitivity of the CNT-wrapped PDMS MS-based device is fifteen times more than that of the flat one, with a detection limit of 0.02 kPa. The device's response time is 200 ms, while its relaxation time is 150 ms. Furthermore, dynamic cycling tests demonstrated the device's strong resilience. The CNT-wrapped PDMS MS-based sensor exhibits a variety of tactile sensing capabilities, such as the capacity to transmit Morse codes, detect pulsations, and perceive eye movements. The sensors with CNT-wrapped PDMS MSs are able to detect real-time pulses, muscle movements, and eye blinking, with target of monitoring the human physiological signals, as shown in Figure 2.

Figure 2: Comparison study on the R/R0 of the device and the real-time variation in the R/R0 based on CNT-wrapped PDMS MSs [2]

In next work, the author introduces a new technique for creating a flexible, sensitive, and affordable pressure sensor that uses polydimethylsiloxane (PDMS) sheets and modified multi-walled carbon nanotube (m-MWNT)/polyurethane (PU) composites. To decorate the MWNTs, two modifiers were used: sodium dodecyl benzene sulfonate (SDBS) and γ-aminopropyl-triethoxy silane (KH550). To create the m-MWNT/PU composite films, the m-MWNTs were then dissolved in polyurethane and N, N-dimethylformamide (DMF) solution. In order to investigate the impact of MWNT surface modification on the electrical and piezoresistive characteristics of the composites, the raw MWNT/PU was also synthesized under comparable circumstances. Additionally, m-MWNT/PU's piezoresistive response was more stable than that of raw MWNT/PU composites.

Using melt or solution mixing techniques, CNTs are distributed throughout the polymer matrix as conductive fillers. Electrical signals can be generated from external stress by the resulting piezoresistive conductive composites. After applied stress, the electrical conductivity of CNT-filled polymeric composites will vary in two ways. One is a change in tunneling resistance brought on by the distance between CNTs, and the other is a change in CNT intrinsic resistance brought on by the deformation of the composite [3].

2.2. Other sensors

Various sensing technologies have emerged recently, with this research presenting an innovative capacitive pressure sensor characterized by structural simplicity, flexibility, and economic efficiency [4]. The design incorporates an ionically charged CFM functioning as the dielectric component, with its straightforward manufacturing process making it suitable for mass production applications. The exceptional properties of CFMs - including skin adaptability, biocompatibility, and inherent elasticity - position them as prime candidates for wearable sensing applications. While current triboelectric nanogenerator developments offer promising solutions for self-powered sensor systems, challenges remain in optimizing wearability, signal processing, and power management for capacitive sensors.

The technology demonstrates particular promise in medical monitoring and diagnostic applications, attributed to its efficient fabrication process, cost-effectiveness, biological compatibility, and mechanical adaptability. These sensors enable quantitative mechanical measurements that surpass traditional experience-based assessment methods in therapeutic settings. The potential applications extend to specialized medical devices, such as enhanced collagen fiber pads for managing various podiatric conditions, including diabetic complications and plantar ulcers. The technology also enables development of customized orthotic solutions, including precision-engineered insoles, designed to address and mitigate pathological pressure conditions in affected individuals.

An innovative pressure sensing system has been developed through the incorporation of magnetic CIP/silicone resin within CS structure [5]. The magnetorheological properties enable remarkable pressure detection capabilities, with sensitivity ranging from 70 Pa without magnetic field application to an enhanced upper limit of 330 kPa (increased from 180 kPa) under magnetic field exposure at 0.01-5 Hz. This comprehensive detection range enables monitoring of diverse human activities, from subtle respiratory movements to high-pressure physical actions like gripping and lifting. Unlike conventional polymer matrices with fixed mechanical characteristics post-fabrication, this system exploits magnetic particle chain formation under field exposure. The implementation of sub-1T static magnetic fields ensures human safety while significantly enhancing the pressure detection threshold through increased CS/CIP/silicone composite modulus under magnetic influence.

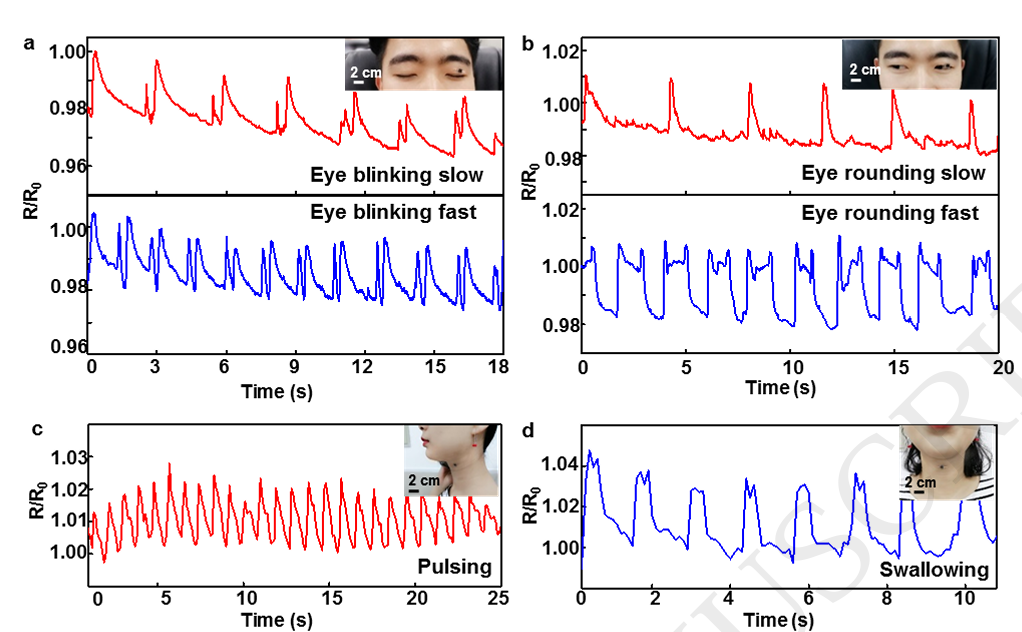

Additionally, this research presents a sensor incorporating microscopic surface texturing, utilizing MoSe2/MWNTs as the active sensing component on sandpaper-textured PDMS substrate, as depicted in Figure 3 [6]. This configuration demonstrates exceptional versatility in motion detection, capturing both major physical activities and subtle physiological movements. While microstructural substrate-based resistive pressure sensors have shown enhanced sensitivity and responsiveness, cost-effective piezoresistive solutions remain limited. The current approach employs sandpaper-textured PDMS substrates, creating strategic gaps between sensor layers to optimize sensitivity ranges. The integration of MoSe2-modified MWNTs demonstrates marked performance improvements compared to conventional MWNT-PDMS configurations, offering substantial advantages in sensing capabilities.

Figure 3: The whole production process of the sensor [6]

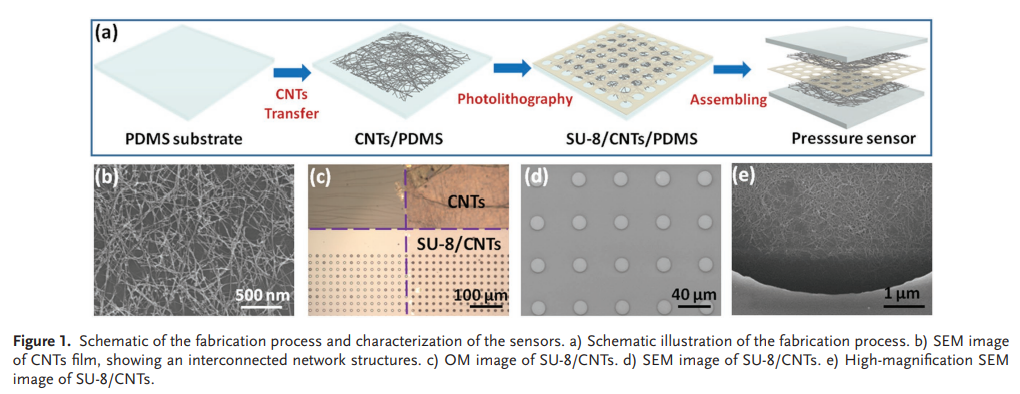

A novel piezoresistive sensing platform has been engineered featuring a CNTs/SU-8/CNTs layered architecture, delivering transparency, heightened sensitivity, and energy efficiency [7]. The design leverages rapid contact resistance changes while minimizing initial resistance. Sensitivity parameters can be precisely tuned through modifications to the intermediate porous SU-8 dielectric layer. The fabrication methodology aligns with established semiconductor processing techniques, enabling scalable production.

The manufacturing sequence, illustrated in Figure 4, employs photolithographic techniques - the preferred approach for mass production of porous insulating CNT electrode structures. The process begins with direct deposition of 20nm CNT films onto PDMS substrates using copper foil, facilitated by PMMA-assisted transfer methods commonly utilized in CVD graphene production. Following photoresist application, conventional photolithography creates uniform micro-hole patterns, maintaining surface smoothness within 15nm variation. The structure is completed by applying a matching CNT electrode layer.

Operational mechanics involve pressure-induced deformation of CNT electrodes into SU-8 cavities, while the rigid SU-8 layer maintains structural integrity against the more flexible PDMS substrate. Current flow initiates at a threshold pressure (P0) when electrodes establish contact, with increasing pressure expanding the contact area and enhancing conductivity. The system demonstrates zero standby power consumption, as current ceases entirely without applied pressure - a significant advancement over conventional conductive network or microstructure-based sensors [8].

Figure 4: The fabrication procedures of the sensors [7]

3. Conclusion

This paper presents a comprehensive review of advanced pressure sensors, highlighting their breakthroughs in sensitivity, stretchability, response time, stability, and cost-effectiveness. In that way, they are more relevant to a broader range of scenarios. Simultaneously, owing to the low production costs, they can be effectively marketed and widely adopted. In addition, the sensors can detect various human motions from low to high stimuli, thus have the power to support integrated design of sensing system. Innovations in wearable sensors have brought about changes in the way health is monitored. They are playing an increasingly important role in preventive care. Wearable devices provide quantified movement data and various physiological data to enable accurate diagnosis. And the self-powered system and the integration of sensing system will be in use, in order to supply electricity, further increase sensitivity and expand instant and wider monitoring in people’s body dimensions. With the widespread adoption of smartphones, these sensors can be integrated with mobile applications to provide real-time physiological data, keeping pace with the current technological trends. When detecting abnormal physical indicators, they can raise the alarm and offer constructive suggestions according to this in a prompt time. IoT compatible and wearable sensors are booming in health applications. Sensors help with geriatric care monitoring, having evolved into a variety of medical applications, with artificial intelligence, DNA testing, 3D printed organs, and IoT digital platforms changing existing health prevention models. They can also achieve the function in features such as remote patient access interface and updatability. In conclusion, these advanced sensors are paving the way for digitally intelligent healthcare systems, promising not only smarter and more comfortable daily lives but also revolutionizing preventive care and personalized medicine.

References

[1]. Lee, J., Lim, M., Yoon, J., Kim, M. S., Choi, B., Kim, D. M., Kim, D. H., Park, I., & Choi, S. J. (2017). Transparent, flexible strain sensor based on a solution-processed carbon nanotube network. ACS Applied Materials & Interfaces, 9(31), 26279-26285. https://doi.org/10.1021/acsami.7b03184

[2]. Xu, M., Gao, Y., Yu, G., Lu, C., Tan, J., & Xuan, F. (2018). Flexible pressure sensor using carbon nanotube-wrapped polydimethylsiloxane microspheres for tactile sensing. Sensors and Actuators A: Physical, 284, 260-265. https://doi.org/10.1016/j.sna.2018.10.040

[3]. He, Y., Ming, Y., Li, W., Li, Y., Wu, M., Song, J., Li, X., & Liu, H. (2018). Highly stable and flexible pressure sensors with modified multi-walled carbon nanotube/polymer composites for human monitoring. Sensors, 18(5), 1338. https://doi.org/10.3390/s18051338

[4]. Peng, Z., Zheng, S., Zhang, X., Yang, J., Wu, S., Ding, C., Lei, L., Chen, L., & Feng, G. (2022). Flexible wearable pressure sensor based on collagen fiber material. Micromachines, 13(5), 694. https://doi.org/10.3390/mi13050694

[5]. Yang, G., Tian, M. Z., Huang, P., Fu, Y. F., Li, Y. Q., Fu, Y. Q., Wang, X. Q., Li, Y., Hu, N., & Fu, S. Y. (2020). Flexible pressure sensor with a tunable pressure-detecting range for various human motions. Carbon, 173, 736-743. https://doi.org/10.1016/j.carbon.2020.11.066

[6]. Guan, J., Zhang, D., & Li, T. (2021). Flexible pressure sensor based on molybdenum diselide/multi-walled carbon nanotubes for human motion detection. IEEE Sensors Journal, 21(9), 10491-10497. https://doi.org/10.1109/JSEN.2021.3060425

[7]. Liang, B., Chen, W., He, Z., Yang, R., Lin, Z., Du, H., Shang, Y., Cao, A., Tang, Z., & Gui, X. (2017). Highly sensitive, flexible MEMS based pressure sensor with photoresist insulation layer. Small, 13(44), 1702422. https://doi.org/10.1002/smll.201702422

[8]. Jung, Y., Kim, J., Lee, H., Park, S., & Kim, T. (2021). Flexible and highly sensitive three-axis pressure sensors based on carbon nanotube/polydimethylsiloxane composite pyramid arrays. Sensors and Actuators A: Physical, 331, 113034. https://doi.org/10.1109/ENBENG.2015.7088850

Cite this article

Qiao,Y. (2025). Research on the Application of Flexible Pressure Sensors in Wearable Devices. Applied and Computational Engineering,128,59-65.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 5th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Lee, J., Lim, M., Yoon, J., Kim, M. S., Choi, B., Kim, D. M., Kim, D. H., Park, I., & Choi, S. J. (2017). Transparent, flexible strain sensor based on a solution-processed carbon nanotube network. ACS Applied Materials & Interfaces, 9(31), 26279-26285. https://doi.org/10.1021/acsami.7b03184

[2]. Xu, M., Gao, Y., Yu, G., Lu, C., Tan, J., & Xuan, F. (2018). Flexible pressure sensor using carbon nanotube-wrapped polydimethylsiloxane microspheres for tactile sensing. Sensors and Actuators A: Physical, 284, 260-265. https://doi.org/10.1016/j.sna.2018.10.040

[3]. He, Y., Ming, Y., Li, W., Li, Y., Wu, M., Song, J., Li, X., & Liu, H. (2018). Highly stable and flexible pressure sensors with modified multi-walled carbon nanotube/polymer composites for human monitoring. Sensors, 18(5), 1338. https://doi.org/10.3390/s18051338

[4]. Peng, Z., Zheng, S., Zhang, X., Yang, J., Wu, S., Ding, C., Lei, L., Chen, L., & Feng, G. (2022). Flexible wearable pressure sensor based on collagen fiber material. Micromachines, 13(5), 694. https://doi.org/10.3390/mi13050694

[5]. Yang, G., Tian, M. Z., Huang, P., Fu, Y. F., Li, Y. Q., Fu, Y. Q., Wang, X. Q., Li, Y., Hu, N., & Fu, S. Y. (2020). Flexible pressure sensor with a tunable pressure-detecting range for various human motions. Carbon, 173, 736-743. https://doi.org/10.1016/j.carbon.2020.11.066

[6]. Guan, J., Zhang, D., & Li, T. (2021). Flexible pressure sensor based on molybdenum diselide/multi-walled carbon nanotubes for human motion detection. IEEE Sensors Journal, 21(9), 10491-10497. https://doi.org/10.1109/JSEN.2021.3060425

[7]. Liang, B., Chen, W., He, Z., Yang, R., Lin, Z., Du, H., Shang, Y., Cao, A., Tang, Z., & Gui, X. (2017). Highly sensitive, flexible MEMS based pressure sensor with photoresist insulation layer. Small, 13(44), 1702422. https://doi.org/10.1002/smll.201702422

[8]. Jung, Y., Kim, J., Lee, H., Park, S., & Kim, T. (2021). Flexible and highly sensitive three-axis pressure sensors based on carbon nanotube/polydimethylsiloxane composite pyramid arrays. Sensors and Actuators A: Physical, 331, 113034. https://doi.org/10.1109/ENBENG.2015.7088850