1. Introduction

With the implementation of increasingly strict policies aimed at reducing carbon footprints and the global efforts to combat climate change intensifing, reducing carbon footprints and transitioning to clean energy sources have become pressing priorities. Electric vehicles (EVs) have garnered significant attention in this context, serving as a critical tool to lower greenhouse gas emissions and reduce reliance on fossil fuels. Current research highlights the multifaceted challenges and innovations associated with EV development, with a particular focus on advancing technologies to enhance energy efficiency and sustainability. One area receiving increasing attention is lightweight vehicle design, which is crucial for improving EV efficiency, range, and overall performance. For instance, research has demonstrated the potential of advanced materials like aluminum and carbon fiber in reducing vehicle weight and enhancing efficiency[1]. Another study explored the trade-offs between cost, safety, and performance in lightweight designs and proposed strategies for optimization[2]. While these studies provide valuable insights, they often address isolated aspects of lightweight design, such as materials or manufacturing methods, without fully considering their integration into comprehensive EV systems. This essay builds on prior research by taking a holistic approach to lightweight EV design. It examines not only the materials and technologies being adopted by leading manufacturers such as Tesla, BMW, and Lucid Motors but also the innovative solutions used to address the challenges of balancing weight reduction with cost, safety, and performance requirements. By doing so, it aims to provide a comprehensive understanding of how lightweight design contributes to the advancement of EVs and offers insights for future researchers and investors.

2. The Importance of Lightweight Design in Electric Vehicles

Lightweight design is the strategic use of specific materials and engineering to decrease the vehicle's overall weight while maintaining safety, reliability, and performance. When applied to EVs, the objective is to increase the vehicle’s efficiency and range by decreasing the amount of energy imputed. In Eq. 1, KE is the kinetic energy that the battery has to provide, m is the weight, and v is the velocity. According to basic kinetic energy theories in Eq. 1, weight reduction would reduce the energy required to accelerate and decelerate the vehicle[3].

\( KE=\frac{1}{2}m{v^{2}} \) (1)

In addition, lightweight design improves the vehicle's maneuverability and performance, which are also significant factors consumers consider when purchasing a car. Overall, lightweight design is a critical factor in the evolution of EVs, as it directly contributes to the enhanced performance, sustainability, and practicality of these vehicles in the rapidly growing electric vehicle market.

3. Difficulties of Performing Lightweight Design in EVs

3.1. Tesla’s Solution for a Better Battery

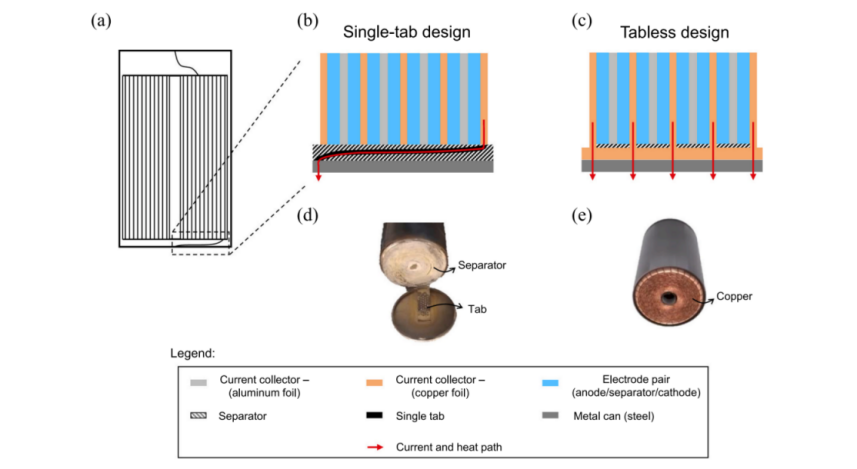

To further reduce the weight while increasing performance, Tesla introduced their new battery design. The new “tabless” 4680 batteries announced at the company’s Battery Day event are the perfect demonstration of increasing power density. As Figure 1(b) and (d) show, a traditional lithium-ion(Li) battery has a tab that connects the negative side to the external circuit[4]. This conventional type of battery is relatively simple and traditional, so it is relatively easy and cheap to manufacture. However, it has two significant disadvantages: internal resistance and cooling. Although highly conductive, the singular tab still has a slight resistance. This resistance would result in energy dissipation as heat, leading to energy loss and thermal management issues. The supplementary thermal insulation of the tab exacerbates the cooling problem[5].

Figure 1: Cell diagram for the two cylindrical cell designs. (a) Cross section of cylindrical cell with single-tab design. The geometry details between jellyroll and metal can are zoomed in for (b) single-tab design and (c) tabless (or continuous-tab) design. The negative side for (d) an opened 2170 LG M50T cell, obtained experimentally, and (e) a 4680 Tesla tabless cell jellyroll[4]

Engineers at Tesla were tasked with designing a better battery that would hold more energy with reduced size and better cooling ability. The first thing they decided to deal with was that resistance. As Eq. 2 shows, resistors of the same resistance would have less resistance when paralleled than a singular resistor’s resistance[6]. Concerning the tabless batteries, increased contact between the current collector and the exterior circuit results in reduced internal resistance. Theoretically, the internal resistance should tend toward zero with an infinite number of contacts. This is where Tesla’s tabless battery comes into play. As shown in Figures 1(c) and (e), the new battery design removed the singular connection and the tab, replacing them with a brush-like end. This structure would ensure the maximum contact between the battery and the external circuit, reducing the resistance to a minimum. Since resistance is reduced, the energy efficiency of the tabless batteries is significantly better. In addition to that, the tabless design also ensures the heat generated is evenly spread to the bottom side of the battery, making cooling measurements much more effective. Less heat generated also significantly increases the safety of these batteries.

\( {R_{Parallel}}=(\sum _{i=1}^{N}\frac{1}{{R_{i}}}{)^{-1}} \) (2)

For now, the only downsides are the cost and difficulty of production. This is primarily caused by the size of the battery; it is hard to maintain a high pass rate at quality control. However, once production ramps up and new methods are discovered, these downsides should be overcome shortly. Tesla’s revolutionary battery design is an excellent engineering breakthrough in the field of Lithium-ion batteries, and it will continue to inspire many other manufacturers.

3.2. BMW’s Approach to Chassis Design

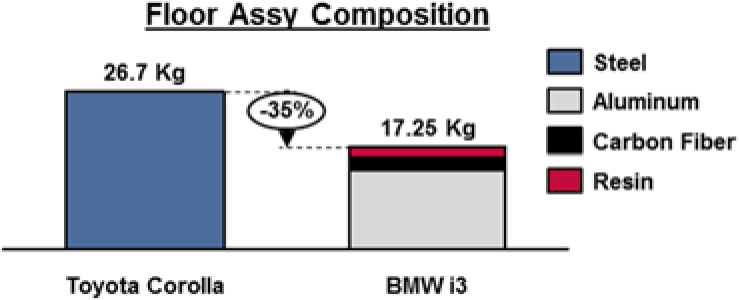

When it comes to chassis design, the material used is vital. Engineers have to consider the properties of each material and decide where and how to use them. Three primary considerations to consider when selecting a material are strength, weight, and cost. Lightweight materials such as aluminum and carbon fiber are progressively employed to diminish the overall weight of the chassis, hence enhancing energy efficiency and prolonging the vehicle's range. The traditional German car manufacturer BMW is well known for its lineup of luxury sedans and SUVs featuring Internal Combustion Engines(ICE). In recent years, BMW has realized the exponentially growing market for electric vehicles. Most of the EVs the company builds share the same chassis design as the ICE vehicles. However, there is one special exception: the BMW i3. Although carbon fiber is already widely used in aircraft and race cars to reduce weight, it is too expensive to be commonly implemented in the chassis of consumer-grade vehicles. The engineers at BMW decided that should not be the case anymore. The chassis of the i3 utilized a material called carbon fiber-reinforced plastic (CFRP), a type of composite that uses aluminum, resin, and carbon fiber. As Figure 2 shows, when compared to a traditional gas-powered sedan of similar size, the BMW i3 reduces the weight of the floor by 35 percent, an exceptional amount[7].

Figure 2: Toyota Corolla and BMW i3 floor assembly composition[7]

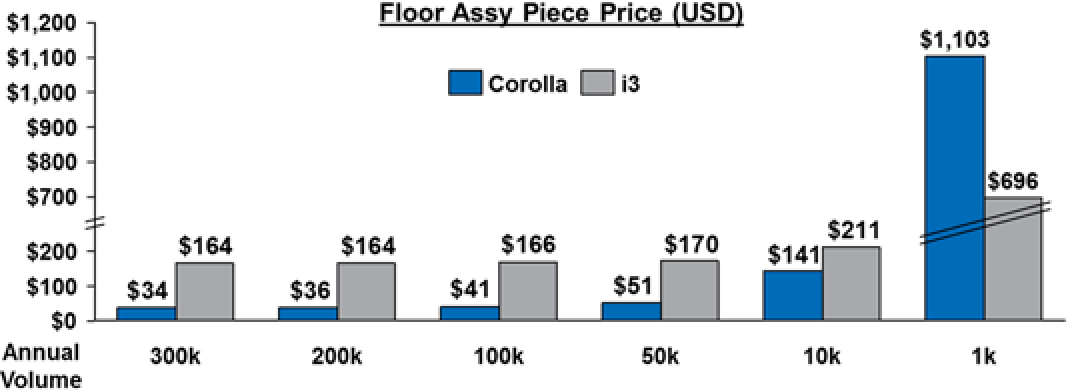

Unfortunately, although CFRP is much cheaper than pure carbon fiber, it is still considerably more expensive than traditional materials such as steel. This price difference primarily comes down to the material cost instead of the processing. Traditional steel is the opposite: production is a lot cheaper when mass-produced. In Figure 3, the price of the floor assembly of the i3 starts with an advantage when the production is only 1000 units; it is about $400 cheaper for each piece of the floor assembly. But it quickly gets overtaken when the production exceeds 10k[7]. After 10k, there is no significant decrease in price for the i3 in comparison to the Corolla, the price of the i3’s floor assembly stays around $165.

Figure 3: Calculated floor assembly piece price for Toyota Corolla and BMW i3 at production volumes ranging from 300,000-1,000 parts/year[8]

At the end of 2021, only around 250,000 BMW i3s were produced in the nine years since the start of production, further proving the bottleneck of mass producibility of the i3. Even though flawed, the BMW i3 is still an engineering precedent that successfully integrated CFRP in a small personal vehicle[8]. It is reasonable to anticipate that with additional time and investigation, material costs may diminish, so propelling chassis design into a new era.

3.3. Lucid’s Permanent Magnet Motor

The electric motor is another vital part of an electric vehicle that could benefit from a lightweight design. It is the component that transfers the energy stored in the battery directly into the kinetic energy that achieves the fundamental function of a vehicle: moving from point A to point B. The design and construction of the motor are essential for the vehicle's energy economy and driving performance. Consequently, motor technology has consistently been crucial to manufacturers' research and development efforts.

The EV manufacturer Lucid released its first entry into the EV industry in 2021, the Lucid Air. The top model of the luxury sedan was able to achieve 60 miles per hour from zero in 2.5 seconds and drive 512 miles without charging[9]. These are industry-leading stats even compared to competitors such as Tesla. However, unlike Tesla, Lucid took a very different approach to motor design.

Lucid put interior permanent magnet synchronous motors (IPMSM) in their first entry, the Lucid Air. Although IPMSM is not a new technology in the EV industry, Tesla uses it to power most of its vehicles; Lucid stood out by only using IPMSM with no auxiliary induction motor.

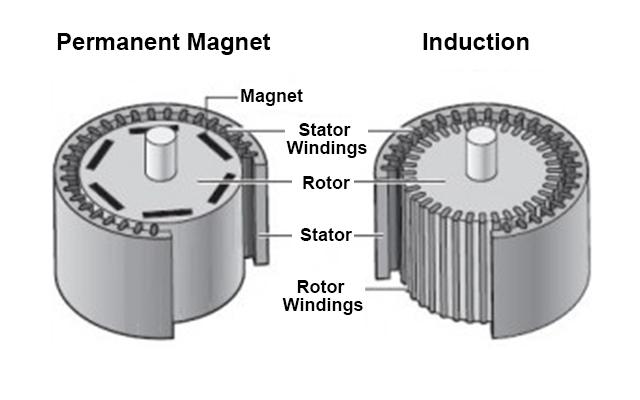

Figure 4: Comparison of Permanent Magnet Motor and Induction Motor[10]

As Figure 4 suggests, the magnetic source of the rotor is the primary difference between IPMSM and IM. The induction motor is one of the oldest types in motor history. It is known for its reliable nature and high performance. It uses electromagnetic induction to magnify the rotor and stator. This makes their peak performance more significant[11]. However, heaving more winding not only means more power consumption but also more weight. Conversely, as indicated by its nomenclature, the permanent magnet motor employs rare earth magnets to interact with the stator's magnetic field, rather than utilizing windings. Natural magnets enhance efficiency by substituting a portion of the electrical windings, particularly at reduced speeds. In addition to that, it is significantly lighter than the induction motor. This difference could be observed in Table 1 as well[9].

Table 1: Specifications of Motor Topologies[12]

Parameter | 48/8 IPMSM | 12/8 IPMSM | 48/36 IM | 12/8 SRM |

Maximum dc-link voltage (V) | 500 | 500 | 500 | 500 |

Peak power (kW) | 50 | 50 | 50 | 50 |

Maximum rotational speed (rpm) | 6000 | 6000 | 6000 | 6000 |

Peak torque (Nm) | 300 | 300 | 300 | 300 |

Designed torque (Nm)* | 100 | 120 | 90 | 100 |

Rated operating speed (rpm)* | 3000 | 2500 | 3300 | 3000 |

Pole pairs | 4 | 4 | 2 | - |

Stator outer diameter (mm) | 269 | 269 | 269 | 269 |

Stator inner diameter (mm) | 161.9 | 166 | 177.9 | 172 |

Rotor inner diameter (mm) | 110 | 100 | 104 | 90 |

Stack length (mm) | 83.82 | 83.82 | 108 | 105 |

Air gap length (mm) | 0.73 | 0.7 | 0.45 | 0.8 |

Rotor inertial moment (kg·m²) | 0.042 | 0.047 | 0.051 | 0.069 |

Armature core weight (kg) | 17.3 | 13.75 | 17.25 | 17.83 |

Armature copper weight (kg) | 5.9 | 8.13 | 13.05 | 15.39 |

Rotor core steel weight (kg) | 5.37 | 6.7 | 10.06 | 9.24 |

Magnet weight (kg) | 1.23 | 1.3 | - | - |

Rotor bar and ring (kg) | - | - | 8.43 | - |

Total weight (kg) | 29.8 | 30.3 | 48.8 | 42.5 |

Magnet type | N36Z_20 | N36Z_20 | - | NA |

Magnet size (mm) | 18.9*6. | 19.1*6. | - | NA |

Characteristic current (A) | 105 | 98 | - | - |

Steel lamination | M19-29G | M19-29G | M19-29G | M19-29G |

*Estimated value. |

Researchers from the Illinois Institute of Technology were tasked with finding the differences between different electric motors under different power setups. When providing the same power, IPMSMs are more potent in terms of torque, 120 Nm versus 90 Nm of IM in 12/8 format. On top of that, it is also 18.8 kilograms lighter than the induction motor. IPMSM only loses its edge when compared in speed, only 2500 rpm versus the 3300 rpm for IM[11]. Although much superior to IM in many ways, IPMSM still faces challenges. Despite the lack of high speed, IPMSM is also more costly due to the usage of rear earth magnets. These challenges have limited the use of IPMSM to only less powerful and more expensive vehicles. However, Lucid, with their lightning-fast Lucid Air top model, proves that pure highspeed IPMSM is not a distant dream, thanks to the numerous improvements to the material and geometry design.

4. Conclusion

Lightweight design is a crucial element in the evolution and success of electric vehicles. As the automotive industry increasingly focuses on sustainability, reducing vehicle weight through innovative designs and advanced materials has become essential. Tesla's groundbreaking tabless battery design is a prime example of how engineering ingenuity can lead to more efficient, powerful, and safer batteries, addressing one of the most significant challenges in EV development. Similarly, BMW's use of carbon fiber-reinforced plastic in the i3’s chassis demonstrates the potential of lightweight materials to reduce vehicle weight while maintaining strength and safety. Lastly, the giant leap in motor technology done by Lucid also shows a clear future for lighter and more efficient motors. This essay has highlighted only a few examples of lightweight design innovations within the automotive industry, with a focus on specific advancements by Tesla, BMW, and Lucid Motors. A limitation of this research is its reliance on a select range of case studies, which may not fully capture the breadth of ongoing innovations in this field. Future studies could expand the scope to include a broader range of manufacturers and explore the integration of lightweight materials across different vehicle components.

References

[1]. Börner, M. F., Mohsseni, A. M., et al. (2024). Manufacturing cost comparison of tabless vs. standard electrodes for cylindrical lithium-ion batteries. Journal of Energy Storage, 77, 109941.

[2]. Yegireddy, N. K. (2021). Sustainability meets performance: Eco-friendly materials for lightweight EV structures. NeuroQuantology, 19(6), 283–291. https://doi.org/10.48047/nq.2021.19.6.nq21100

[3]. Pili, U. B. (2020). Expressing Newton’s second law of motion as Fnet= 2ma and kinetic energy as KE= mv 2. Physics Education, 55(5), 053003.

[4]. Li, S., Marzook, M. W., Zhang, C., Offer, G. J., & Marinescu, M. (2023). How to enable large format 4680 cylindrical lithium-ion batteries. Applied Energy, 349, 121548. https://doi.org/10.1016/j.apenergy.2023.121548

[5]. Li, M., Lu, J., Chen, Z., & Amine, K. (2018). 30 years of lithium‐Ion Batteries. Advanced Materials, 30(33). https://doi.org/10.1002/adma.201800561

[6]. Smith, Joshua & Vianelli, Edoardo. (2015). Series and Parallel Resistors. 10.13140/RG.2.2.31199.71843.

[7]. Bubna, P., & Wiseman, M. (2016). Impact of light-weight design on manufacturing cost-a review of BMW i3 and Toyota corolla body components.

[8]. Official: BMW i3 electric car production to end in July. Drive. (n.d.). https://www.drive.com.au/news/official-bmw-i3-electric-car-production-to-end-in-july/

[9]. Detloff, C. (2023, January 16). AC Induction Motors vs. Permanent Magnet Synchronous Motors. Empowering Pumps and Equipment. https://empoweringpumps.com/ac-induction-motors-versus-permanent-magnet-synchronous-motors-fuji/

[10]. Lucid’s world-leading electric powertrain technology propels Aston Martin to a bold electric future. Lucid’s World-Leading Electric Powertrain Technology Propels Aston Martin to a Bold Electric Future. (n.d.). https://lucidmotors.com/stories/lucid-powertrain-technology-aston-martin

[11]. Electrical4U, Nageshnags, Electrical4U, Sharma, B., Alex, A. G., Ndeulita, J., Shivani, Billaiya, A., Behera, B., Riyanston, & Anand. (2024, April 22). Induction Motor: How Does It Work? (basics & types). Electrical4U. https://www.electrical4u.com/induction-motor-types-of-induction-motor/

[12]. Yang, Z., Shang, F., Brown, I. P., & Krishnamurthy, M. (2015). Comparative study of interior permanent magnet, induction, and switched reluctance motor drives for EV and HEV applications. IEEE Transactions on Transportation Electrification, 1(3), 245-254.

Cite this article

Wang,G. (2025). The Crucial Role of Lightweight Design in the Evolution of Electric Vehicles. Applied and Computational Engineering,129,144-149.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 5th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Börner, M. F., Mohsseni, A. M., et al. (2024). Manufacturing cost comparison of tabless vs. standard electrodes for cylindrical lithium-ion batteries. Journal of Energy Storage, 77, 109941.

[2]. Yegireddy, N. K. (2021). Sustainability meets performance: Eco-friendly materials for lightweight EV structures. NeuroQuantology, 19(6), 283–291. https://doi.org/10.48047/nq.2021.19.6.nq21100

[3]. Pili, U. B. (2020). Expressing Newton’s second law of motion as Fnet= 2ma and kinetic energy as KE= mv 2. Physics Education, 55(5), 053003.

[4]. Li, S., Marzook, M. W., Zhang, C., Offer, G. J., & Marinescu, M. (2023). How to enable large format 4680 cylindrical lithium-ion batteries. Applied Energy, 349, 121548. https://doi.org/10.1016/j.apenergy.2023.121548

[5]. Li, M., Lu, J., Chen, Z., & Amine, K. (2018). 30 years of lithium‐Ion Batteries. Advanced Materials, 30(33). https://doi.org/10.1002/adma.201800561

[6]. Smith, Joshua & Vianelli, Edoardo. (2015). Series and Parallel Resistors. 10.13140/RG.2.2.31199.71843.

[7]. Bubna, P., & Wiseman, M. (2016). Impact of light-weight design on manufacturing cost-a review of BMW i3 and Toyota corolla body components.

[8]. Official: BMW i3 electric car production to end in July. Drive. (n.d.). https://www.drive.com.au/news/official-bmw-i3-electric-car-production-to-end-in-july/

[9]. Detloff, C. (2023, January 16). AC Induction Motors vs. Permanent Magnet Synchronous Motors. Empowering Pumps and Equipment. https://empoweringpumps.com/ac-induction-motors-versus-permanent-magnet-synchronous-motors-fuji/

[10]. Lucid’s world-leading electric powertrain technology propels Aston Martin to a bold electric future. Lucid’s World-Leading Electric Powertrain Technology Propels Aston Martin to a Bold Electric Future. (n.d.). https://lucidmotors.com/stories/lucid-powertrain-technology-aston-martin

[11]. Electrical4U, Nageshnags, Electrical4U, Sharma, B., Alex, A. G., Ndeulita, J., Shivani, Billaiya, A., Behera, B., Riyanston, & Anand. (2024, April 22). Induction Motor: How Does It Work? (basics & types). Electrical4U. https://www.electrical4u.com/induction-motor-types-of-induction-motor/

[12]. Yang, Z., Shang, F., Brown, I. P., & Krishnamurthy, M. (2015). Comparative study of interior permanent magnet, induction, and switched reluctance motor drives for EV and HEV applications. IEEE Transactions on Transportation Electrification, 1(3), 245-254.