1. Introduction

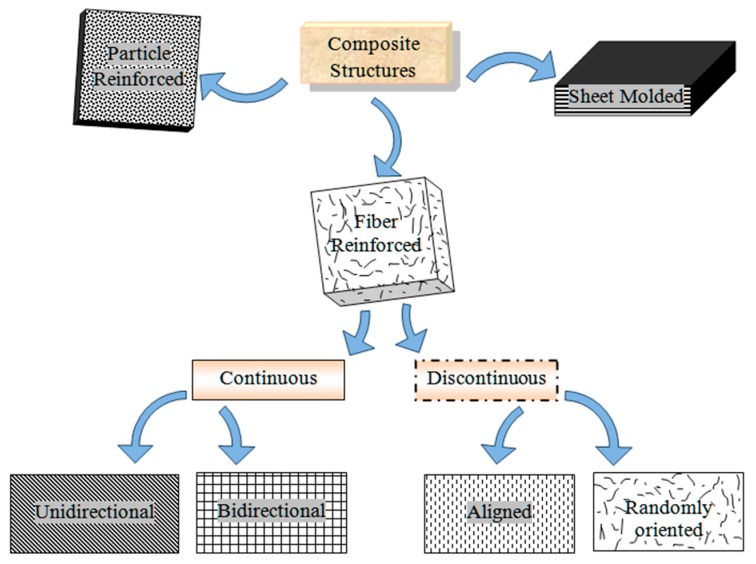

With the rapid development of materials science and technology, the research and application of high-performance composite materials have increasingly become the focus of attention in many fields such as aerospace, transportation, building structure and so on. Among them, fiber-reinforced polymer composites have become an indispensable class of high-performance materials in modern industry because of their unique mechanical properties, light weight and good corrosion resistance. This kind of material not only greatly improves the overall performance of the composite material, but also provides a broad space for material design by combining high-strength and high-modulus fibers with polymer matrix with certain toughness and plasticity. The key concepts in fiber reinforced polymer composites include fiber types (such as carbon fiber, glass fiber, aramid fiber, etc.), matrix polymers (such as epoxy resin, polyimide, polyester, etc.) and their interface interaction. These factors jointly determine the mechanical properties, thermal stability, environmental resistance and other key characteristics of composites. In recent years, with the development of new fibers and resins and the improvement of composite technology, the application scope and properties of fiber reinforced polymer composites have been significantly improved.[1]As shown in Figure1.

Figure 1: Classification of composites.[1]

However, although the research of fiber reinforced polymer composites has made remarkable progress, it still faces many challenges in practical application. For example, the interface compatibility, damage tolerance and thermal expansion coefficient matching of composite materials limit its wide application in some high performance requirements. In addition, the manufacturing cost and efficiency of composite materials are also the key factors restricting its large-scale application. The purpose of this study is to comprehensively review the research progress of fiber reinforced polymer composites in recent years, focus on the analysis of its application status in different fields, and discuss the future research direction and development trend in view of the existing problems and challenges. By deeply understanding the interaction mechanism between fiber and polymer matrix and the design principles of composite materials, it aims to provide theoretical guidance and practical reference for the further research and application of high performance fiber reinforced polymer composites.

2. Structure and characteristics of fiber reinforced polymer composites

2.1. Structure

The structure of fiber reinforced polymer composites can be divided into three levels: microstructure, microstructure and macrostructure. The microstructure includes reinforced fiber, matrix and interface. Reinforcing fibers, such as carbon fiber, glass fiber and aramid fiber, constitute the skeleton of composite materials, and their diameter, length, arrangement and distribution have a significant impact on the properties of materials. Matrix materials, usually polymers such as epoxy resin, polyimide and polyester, surround and fix fibers, transfer stress and protect fibers. Interface is the contact area between fiber and matrix, and its properties are very important to the overall performance. Good interface bonding can effectively transfer stress and prevent fiber from falling off. [2]In the microstructure, the composite material is regarded as an aggregate of multiple single fibers or multiple fiber bundles embedded in the matrix. The microstructure involves the arrangement of fibers, such as unidirectional, braided and random distribution, and the volume fraction of fibers. Macrostructure refers to the overall shape and size of composite materials, which is composed of meso-structure, which is directly related to the engineering application of materials.

2.2. Characteristics

The characteristics of fiber reinforced polymer composites are mainly reflected in mechanical properties, lightweight properties, corrosion resistance, thermal properties, fatigue properties, damage tolerance and designability. In terms of mechanical properties, the composite shows high strength and modulus, and excellent tensile, compressive, bending and shear properties. Due to anisotropy, its properties are significantly different along the fiber direction and perpendicular to the fiber direction, so the material orientation should be considered in design. Light weight makes this kind of materials particularly important in weight-sensitive fields such as aerospace, and its low density provides an ideal material choice for these fields. In terms of corrosion resistance, polymer matrix can protect reinforced fibers from chemical corrosion and ensure the stability of materials in harsh environments. In terms of thermal properties, composites have low thermal expansion coefficient and good thermal stability, but poor thermal conductivity, which depends on the type of matrix and fiber. In terms of fatigue performance, fiber reinforced polymer composites usually have good fatigue resistance and can maintain their performance under cyclic load.[3]

However, the damage tolerance is low, and the composite material is easy to be damaged when it is impacted or overloaded, which limits its application in some applications. Designability is another advantage of composite materials. By changing the fiber type, matrix material, fiber arrangement and volume fraction, the properties that meet the requirements of specific applications can be customized. These structures and characteristics of fiber reinforced polymer composites make them occupy an irreplaceable position in many high-performance applications, and also bring challenges to their design, manufacture and performance evaluation.[4]

3. Applications and Innovations of FRPs

3.1. Wide range of applications for fibre-reinforced polymers

Recent advances in fiber-reinforced polymer composites have opened up new possibilities across many fields. In civil engineering, adding basalt fibers and ethylene-vinyl acetate co-polymer emulsions has improved concrete’s micro structure, boosting its strength by 35-40% and making it last longer in harsh conditions [5]. Also, composites are being used for underwater pile repair and anchor systems, improving durability and offering alternatives to traditional materials [6]. At the same time, research on damping properties has shown how important the interaction between fibers and the matrix is for reducing vibrations. Optimizing these interfaces has cut down vibration levels by 28% in high-stress situations [7].

Not only that, but there are other areas where fiber-reinforced polymer composites come into their own. For example, material recycling, performance prediction, moulding technology and many others. It is believed that this composite material will open up many more applications in the near future.

3.2. MXene materials in fibre reinforced polymers

MXene is a two-dimensional nano-materials, usually in the form of flakes. It can be dispersed as a nanofiller in a polymer matrix or coated on the surface of fibers to improve the properties of composites. In recent years, it has been a popular method to incorporate MXene materials into FRPs to obtain materials with better performance or special functions.

The innovative application of MXene nanosheets has not only enhanced the mechanical strength of the composite material , but also improved its stability in harsh environments, while making breakthroughs in electrical conductivity and thermal stability, opening a new path for the development of multifunctional composites. These interdisciplinary research results not only deepen our understanding of the basic theory of materials, but also provide a solid scientific foundation and technical support for the practical application and industrialization of fiber-reinforced polymer composites, indicating that the field will develop in the direction of higher performance, more functional and more environmentally friendly.

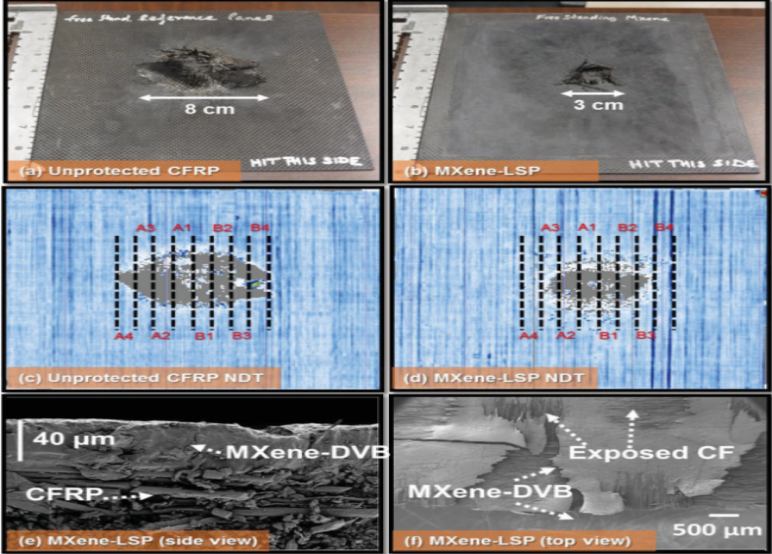

KumarV conducted research on applying MXene-reinforced thermosetting composites to safeguard carbon fiber reinforced polymers against lightning strikes. The study verified that MXene could effectively enhance the electrical conductivity, flexural strength, and modulus of the composite.[8]

Regarding the MXenes-PANI-DVB Composite, 5.0 g of PANI-DBSA was combined with 7.5 g of the MXenes-DVB complex. The subsequent mixing process and composite manufacturing steps paralleled those used in the preparation of the PANI-DVB composite. Table 1 presents a comprehensive overview of the final weight percentages of all components in the fabricated composites.

Table 1: The final weight percentage of all the constituents in the pre-pared composites.

Composite | The final wt%of constituents | ||||

MXene | CNT | PANI | DBSA | DVB | |

PANI-DVB | 0 | 0 | 13.33 | 26.66 | 60 |

CNT-PANI-DVB | 0 | 2 | 13.33 | 26.66 | 58 |

MXenes-PANI-DVB | 2 | 0 | 13.33 | 26.66 | 58 |

Subsequently, in 2023, researchers developed a multifunctional MXene-coated glass fiber to enhance the composite's interface, damage self-monitoring, and self-healing capabilities, highlighting the enhanced interfacial shear strength and the composite's ability to monitor and repair damage[9].

The visual comparison between the unprotected and MXenes-DVB coated CFRP in Figure 2 reveals significant differences in damage area after a lightning strike. The unprotected CFRP experienced damage over 40.61 cm2, whereas the coated CFRP limited damage to 13.29 cm2. The coated CFRP showed a larger smudged area, indicating effective current distribution by the conductive layer, which reduced damage. Despite visible damage, the coated CFRP's protection was attributed to a lower amount of MXenes-DVB (72.66 GSM). Similar damage can occur with state-of-the-art metal-mesh LSP. Future improvements could involve using higher weight loadings of MXenes-DVB and developing a spray coating method for a more uniform and continuous conductive network.

Figure 2: Comparison between the unprotected and MXenes-DVB coated CFRP

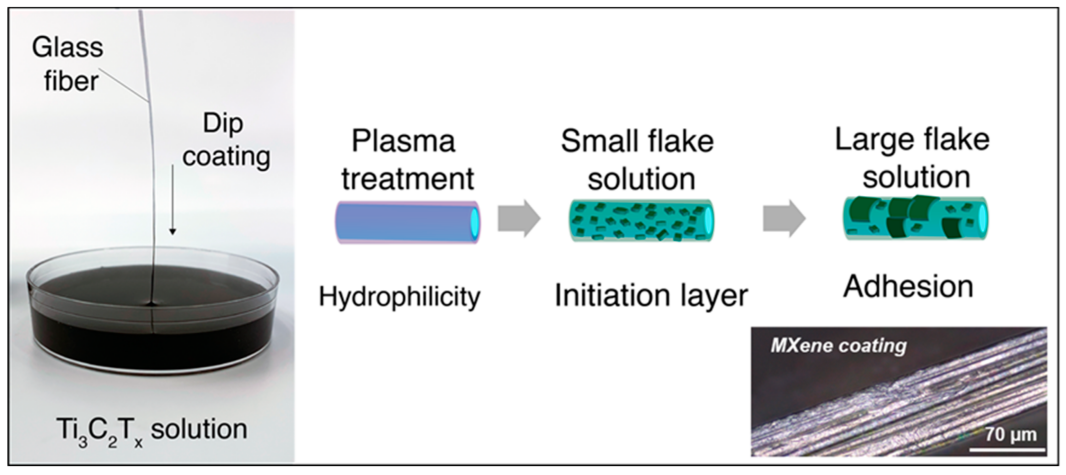

For the method of coating MXene materials, hatter et al. in 2020 have mentioned that. They used oxygen plasma treatment and dip-coating processes to create a hydrophilic surface after removing residual sizing from manufacturing, achieving optimal adhesion. The coating process was repeated until a uniform MXene coating was obtained along the entire length of the fibers. In the SLF coating method, the use of small flakes not only created an initiation layer for larger flakes but also ensured complete coverage of fiber surfaces within dip-coated bundles. Excess water molecules between MXene flakes were removed through simple heating under vacuum. [10]These studies not only deepen our understanding of the basic theories of materials but also provide a solid scientific foundation and technical support for the practical application and industrialization of fiber-reinforced polymer composites, indicating that the field will move towards higher performance, more functionality, and greater environmental sustainability.

Figure 3: Dip-coating process[11]

The dip-coating process for coating Ti3C2Tx MXene(Figure3) onto glass fibers is a crucial step in the fabrication of multifunctional fiber-reinforced composites. The process begins with the preparation of the glass fibers, which are first treated with oxygen plasma to create a hydrophilic layer. This hydrophilic layer enhances the adhesion of the MXene nanosheets to the glass fibers, ensuring a strong bond between the two materials. The MXene solutions, which consist of either large flakes or a combination of small and large flakes, are then prepared separately. The fiber bundles are immersed in these solutions, allowing the MXene nanosheets to adhere to the surface of the glass fibers. Two methods are used for coating the fiber bundles: (1) the use of only large flakes and (2) the alternating small flake-large flake approach. In the first method, the fiber bundles are coated with a solution containing only large MXene flakes. These large flakes cover the surface of the glass fibers, providing a uniform coating. However, this method may result in a thicker coating and a less uniform distribution of the MXene nanosheets. In the second method, the fiber bundles are coated with a solution containing small MXene flakes followed by a solution containing large MXene flakes. This alternating approach allows for a more uniform distribution of the MXene nanosheets on the surface of the glass fibers, resulting in a thinner and more uniform coating.

MXene materials have also made significant breakthroughs in recent years in improving the mechanical properties of FRPs.In 2023, a study investigated the effects of MXene reinforcement on the bending behavior of glass fiber-epoxy laminated composites, showing that MXene significantly improved flexural properties and hardness, further proving its potential as a high-performance reinforcement material [12]. Building on this, 2024 research demonstrated that incorporating MXene and functionalized MXene into these composites not only boosted mechanical strength but also enhanced flame retardancy, setting new performance benchmarks for composite technology [13]. Table 2 summarizes the physical properties of the materials used in these studies, providing a clear overview of how each component contributes to the composite's overall performance.

Table 2: Material properties of the constituent materials.

Constituent materials Density(g/cm³) | Tensile strength (MPa) | Modulus elasticity(GPa) | |

Glass fibre 2.52 | 2500-3450 | 72.5 | |

Epoxy LY 556 | 1.15 | 60-80 | 2.9-3.2 |

MXene | 4.21 | 22,000 | 330 |

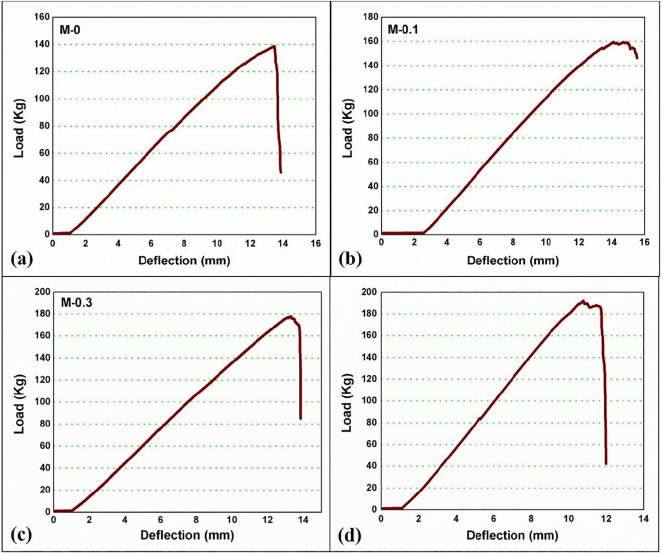

Fig. 4 depicts the load - displacement curve of the prepared samples. It can be noticed that regardless of the samples, the load - deflection curves exhibit similar monotonic characteristics. Moreover, as the content of MXene in the composite rises, the load - carrying capacity of the composite also increases. Correspondingly, with the addition of MXene, the flexural strength of the specimens shows a monotonic upward trend. For example, the flexural strength of the pure composite (without MXene) was 644.33 MPa, but when 0.5 wt% MXene was added, it increased to 883.30 MPa.

The functional groups on the structure of MXene play a role in enabling the reinforcement to disperse uniformly within the matrix. In fact, many researchers have discovered that adding MXene to a polymer matrix leads to a similar trend in property changes.

Figure 4: Load v/s deflection curve generated during the bending test for (a) M 0; (b) M 0.1; (c) M 0.3 and;(d) M 0.5.

Table 3 presents the numerically and experimentally obtained values of the maximum deflection, as well as the experimentally determined flexural strength. From this table, it is evident that there is a high degree of consistency between the numerical and experimental results for the maximum bending deflection. Additionally, with an increase in the MXene loading, the maximum deflection value shows a decreasing trend. This indicates that the addition of MXene contributes to an improvement in the stiffness of the composites.

Table 3: Flexural strength and maximum deflection values of the studied samples.

Sample | Flexural Strength(MPa) | Maximum Deflection (mm) | |

Experimental | Numerical | ||

M-0 | 644.33±16.4 | 13.46 | 14.61 |

M-0.1 | 732.76±19.2 | 13.10 | 14.00 |

M-0.3 | 818.06±21.6 | 12.40 | 12.88 |

M-0.5 | 883.30±19.8 | 11.72 | 11.67 |

In 2021, Liu L, Ying G, Sun C, and other researchers delved into the application of MXene (Ti3C2Tx)-functionalized short carbon fibers (SCFs) as a means of cross-scale mechanical reinforcement in epoxy composites [14]. The surface modification technique, which had previously proven effective in enhancing the interfacial shear strength of polymer matrices, was applied to SCFs in this study. Their findings showed that the MXene-functionalized SCFs could be smoothly incorporated into the epoxy matrix. This integration led to a substantial improvement in the composite's mechanical properties. Specifically, compared with pure epoxy, the tensile strength of the epoxy composites increased by 100%, the flexural strength rose by 67%, and the critical stress intensity factor (KIC) surged by 216%.

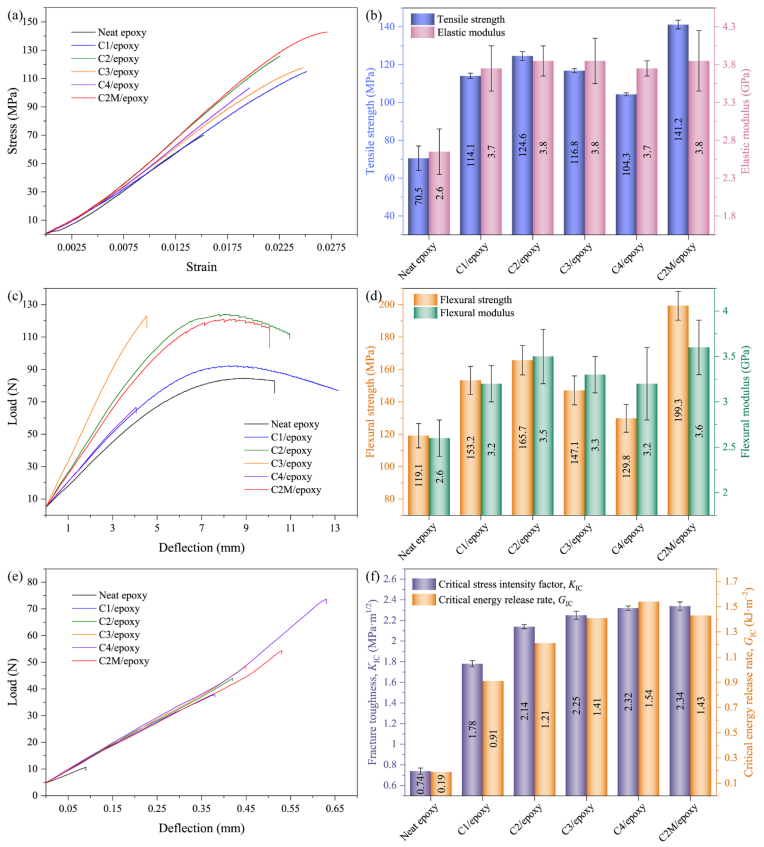

Figure 5: The mechanical performance of neat epoxy[15]

Figure 5 showcases the mechanical properties of pure epoxy, ASCF/epoxy, and MXene-functionalized ASCF/epoxy composites with different filler loadings. As the results indicate, adding ASCFs to the composites leads to an improvement in their mechanical properties compared to pure epoxy. Initially, as the ASCF content increases, the properties of the composites improve, reaching an optimal point at 2 wt.%. Beyond this point, the properties start to decline.

What's more, MXene functionalization further boosts these properties. For example, the C2M/epoxy composites exhibit a 13% increase in tensile strength and a 20% increase in flexural strength when compared to the C2/epoxy composites. In comparison with pure epoxy, the tensile strength and elastic modulus of the MXene-functionalized composites double, while the flexural strength increases by 67% and the flexural modulus by 38%.

4. Conclusion and future prospects

In recent years, research on fibre-reinforced polymer composites (FRPCs) has made great strides, with the main focus being on improving mechanical properties through the incorporation of various types of fibers (e.g. carbon, glass and aramid fibers). Among these, Advanced Short Carbon Fibers (ASCF) and MXene fictionalized composites have shown significant improvements in strength, stiffness and overall performance. These advances are largely due to the unique properties of MXene, a two-dimensional material known for its high electrical conductivity, mechanical strength and surface functionality, which significantly enhances the interfacial adhesion between the fibre and the polymer matrix.

Interfacial engineering plays a key role in optimizing FRPC performance. In particular, the introduction of MXene nanosheets has played an important role in improving the stress transfer efficiency at the fibre-matrix interface. This results in improved mechanical properties including tensile strength, fracture toughness and fatigue resistance. The ability of MXene to form strong interfacial bonds with fibers and polymer matrix makes it a key material for the development of next generation composites.

In addition to mechanical properties, there is a growing trend towards the development of multifunctional composites that integrate additional properties such as electrical conductivity and thermal stability. The incorporation of conductive fillers, such as MXene or carbon nanotubes, gives composites not only excellent mechanical properties but also electrical conductivity, making them suitable for electromagnetic shielding, sensors and flexible electronics. In addition, the thermal stability of these composites has been significantly improved, allowing them to maintain their performance at elevated temperatures, which is critical for applications in the aerospace, automotive and energy sectors.

In conclusion, the field of fiber-reinforced polymer composites is rapidly evolving, driven by advances in materials science, interface engineering and manufacturing technologies. The integration of multifunctional properties, coupled with a focus on sustainability and scalability, will pave the way for the next generation of composites. These materials will not only meet the demanding requirements of modern engineering applications, but will also open up new possibilities in emerging areas such as flexible electronics, wearable technology and renewable energy systems. As research continues, FRPCs will play an increasingly important role in the future development of materials science and engineering.

References

[1]. Rajak, D. K., Pagar, D. D., Menezes, P. L., & Linul, E. (2019). Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers, 11(10), 1667. https://doi.org/10.3390/polym11101667

[2]. Diniță, A., et al. (2023). Advancements in Fiber-Reinforced Polymer Composites: A Comprehensive Analysis. Polymers, 16(1), 2. https://doi.org/10.3390/polym1601002

[3]. Nguyen, K. T. Q., Navaratnam, S., Mendis, P., Zhang, K., Barnett, J., & Wang, H. (2020). Fire safety of composites in prefabricated buildings: From fibre reinforced polymer to textile reinforced concrete. *Composites Part B: Engineering, 187*, 107815. https://doi.org/10.1016/j.compositesb.2020.107815

[4]. Procivilengineer. (n.d.). Introduction of fibre reinforced polymers: Concepts, properties and processes. Pro Civil Engineer. Retrieved February 26, 2025, from https://procivilengineer.com/fibre-reinforced-polymer/

[5]. Ma JH, Wang Q, Jiao HZ, Yang LH, Wang CL, Zhang BY, Chen X. Microstructural characteristics and reinforcement mechanism of flexible fiber polymer concrete [J]. Journal of China University of Mining and Technology

[6]. Luo, J. C. (2024). Application of fiber-reinforced polymer materials in underwater pile repair [J]. Haihe Water Resources, (09), 104-107, 116.

[7]. Wang, T. T., Gao, J. P., Zhang, B. Y., Ma, Z. D., Wang, W. H., & Xu, H. (2024). Research progress on fiber-reinforced polymer damping composites [J]. Materials Engineering, (11), 1-11.

[8]. Kumar V, Yeole P, Majed A, et al. MXene reinforced thermosetting composite for lightning strike protection of carbon fiber reinforced polymer[J]. Advanced Materials Interfaces, 2021, 8(17): 2100803.

[9]. Chen X, Hui Y, Zhang J, et al. Single multifunctional MXene-coated glass fiber for interfacial strengthening, damage self-monitoring, and self-recovery in fiber-reinforced composites[J]. Composites Part B: Engineering, 2023, 259: 110713.

[10]. Hatter C B, Sarycheva A, Levitt A, et al. Electrically conductive MXene-coated glass fibers for damage monitoring in fiber-reinforced composites[J]. C, 2020, 6(4): 64.

[11]. Tang B, Yang Y, Shi Y, et al. Improved mechanical performances of short aramid fiber‐reinforced polypropylene composites by Ti3C2 Mxene nanosheets[J]. Polymer Composites, 2021, 42(4): 2010-2018.

[12]. Bodduru K, Kumar S, Kandpal B C, et al. Effect of MXene reinforcement on bending behavior of glass fiber-epoxy based laminated composites[J]. Materials Today: Proceedings, 2023.

[13]. Yilmaz A N Y, Bedeloglu A C, Yunus D E. Enhancing mechanical and flame retardant characteristics of glass fiber-epoxy laminated composites through MXene and functionalized-MXene integration[J]. Materials Today Communications, 2024, 39: 108745.

[14]. Liu L, Ying G, Sun C, et al. MXene (Ti3C2T x) functionalized short carbon fibers as a cross-scale mechanical reinforcement for epoxy composites[J]. Polymers, 2021, 13(11): 1825.

[15]. Tüfekci, M. (2024). Nonlinear Dynamic Mechanical and Impact Performance Assessment of Epoxy and Microcrystalline Cellulose-Reinforced Epoxy. Polymers, 16(3284), 1-17. https://doi.org/10.3390/polym16233284

Cite this article

Zhang,L. (2025). Research Progress of Fiber Reinforced Polymers. Applied and Computational Engineering,144,1-9.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Rajak, D. K., Pagar, D. D., Menezes, P. L., & Linul, E. (2019). Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers, 11(10), 1667. https://doi.org/10.3390/polym11101667

[2]. Diniță, A., et al. (2023). Advancements in Fiber-Reinforced Polymer Composites: A Comprehensive Analysis. Polymers, 16(1), 2. https://doi.org/10.3390/polym1601002

[3]. Nguyen, K. T. Q., Navaratnam, S., Mendis, P., Zhang, K., Barnett, J., & Wang, H. (2020). Fire safety of composites in prefabricated buildings: From fibre reinforced polymer to textile reinforced concrete. *Composites Part B: Engineering, 187*, 107815. https://doi.org/10.1016/j.compositesb.2020.107815

[4]. Procivilengineer. (n.d.). Introduction of fibre reinforced polymers: Concepts, properties and processes. Pro Civil Engineer. Retrieved February 26, 2025, from https://procivilengineer.com/fibre-reinforced-polymer/

[5]. Ma JH, Wang Q, Jiao HZ, Yang LH, Wang CL, Zhang BY, Chen X. Microstructural characteristics and reinforcement mechanism of flexible fiber polymer concrete [J]. Journal of China University of Mining and Technology

[6]. Luo, J. C. (2024). Application of fiber-reinforced polymer materials in underwater pile repair [J]. Haihe Water Resources, (09), 104-107, 116.

[7]. Wang, T. T., Gao, J. P., Zhang, B. Y., Ma, Z. D., Wang, W. H., & Xu, H. (2024). Research progress on fiber-reinforced polymer damping composites [J]. Materials Engineering, (11), 1-11.

[8]. Kumar V, Yeole P, Majed A, et al. MXene reinforced thermosetting composite for lightning strike protection of carbon fiber reinforced polymer[J]. Advanced Materials Interfaces, 2021, 8(17): 2100803.

[9]. Chen X, Hui Y, Zhang J, et al. Single multifunctional MXene-coated glass fiber for interfacial strengthening, damage self-monitoring, and self-recovery in fiber-reinforced composites[J]. Composites Part B: Engineering, 2023, 259: 110713.

[10]. Hatter C B, Sarycheva A, Levitt A, et al. Electrically conductive MXene-coated glass fibers for damage monitoring in fiber-reinforced composites[J]. C, 2020, 6(4): 64.

[11]. Tang B, Yang Y, Shi Y, et al. Improved mechanical performances of short aramid fiber‐reinforced polypropylene composites by Ti3C2 Mxene nanosheets[J]. Polymer Composites, 2021, 42(4): 2010-2018.

[12]. Bodduru K, Kumar S, Kandpal B C, et al. Effect of MXene reinforcement on bending behavior of glass fiber-epoxy based laminated composites[J]. Materials Today: Proceedings, 2023.

[13]. Yilmaz A N Y, Bedeloglu A C, Yunus D E. Enhancing mechanical and flame retardant characteristics of glass fiber-epoxy laminated composites through MXene and functionalized-MXene integration[J]. Materials Today Communications, 2024, 39: 108745.

[14]. Liu L, Ying G, Sun C, et al. MXene (Ti3C2T x) functionalized short carbon fibers as a cross-scale mechanical reinforcement for epoxy composites[J]. Polymers, 2021, 13(11): 1825.

[15]. Tüfekci, M. (2024). Nonlinear Dynamic Mechanical and Impact Performance Assessment of Epoxy and Microcrystalline Cellulose-Reinforced Epoxy. Polymers, 16(3284), 1-17. https://doi.org/10.3390/polym16233284