1. Introduction

The unique capabilities of smart materials have enabled aerospace technology, such as adaptive systems that can respond dynamically to environmental changes [1]. Whereas traditional materials maintain their static properties regardless of external conditions, smart materials can reversibly change their shape, size, or stiffness with temperature, stress, or electric fields [2]. This has enabled the translation of capabilities that have transformed aerospace engineering into ways that make systems lighter, more efficient, and capable of operating autonomously [3].

The most promising smart materials for aerospace applications include shape-memory alloys, piezoelectric materials, and electroactive polymers [1]. Examples of SMAs are Nitinol, used in morphing wings and deployable structures, where shape recovery improves aerodynamic efficiency by reducing drag [2]. Piezoelectric materials, which generate electrical energy from mechanical stress, play an important role in structural health monitoring and vibration control to ensure aircraft reliability and safety [4]. EAPs are known for their lightweight and large deformation capabilities, thus enabling adaptive control of surfaces and soft actuators for advanced aerospace applications such as spacecraft maneuvering and biomimetic mechanisms [5].

Despite these promising outlooks, certain drawbacks regarding temperature sensitivity, fatigue, and high-voltage requirements pose challenges for smart materials in the aerospace industry [2]. This paper discusses in detail the mechanism, advantages, and disadvantages, together with their applications, emphasizing their metamorphosing role in aerospace engineering [1]. As ongoing research overcomes these deficiencies, smart materials will redefine the future of flight and space exploration [6].

2. Smart Materials

This section provides an in-depth analysis of three prominent types of smart materials: Piezoelectric Materials, Shape Memory Alloys (SMAs), and Electroactive Polymers (EAPs). The mechanisms will be explored behind each material type, their strengths and weaknesses, and their various applications.

2.1. Piezoelectric materials

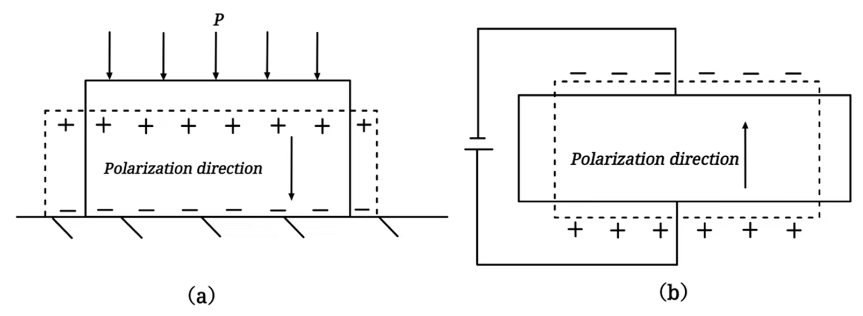

Piezoelectric materials develop a charge owing to the mechanically applied stress caused by their anisotropic crystal lattice structure [4]. In Figure 1, atom charges balance under non-electrically stressed conditions but are internally shifted in the event of deformation, such as compression, tension, or shear, thereby creating an electric dipole and, hence, a measurable voltage [7]. Conversely, the application of an electric field results in mechanical deformation, commonly called the inverse piezoelectric effect [5]. It is this possibility for duality of operation that makes such materials highly suitable for sensing and actuation applications [3].

The most commonly used piezoelectric materials are lead zirconate titanate (PZT), polyvinylidene fluoride (PVDF), and quartz, because they are widely used in many aerospace applications owing to their high electromechanical coupling efficiency. The piezoelectric properties depend on the composition and crystalline orientation, which are characterized by piezoelectric coefficients. Their performance enables them to serve as sensors, actuators, and energy harvesters for vibration in general aerospace applications, such as structural health monitoring, vibration suppression, and energy harvesting for autonomous sensing systems.

|

|

(a) Direct piezoelectric effect [3]. | (b) Inverse piezoelectric effect [3]. |

Figure 1: Direct and inverse piezoelectric effect [3].

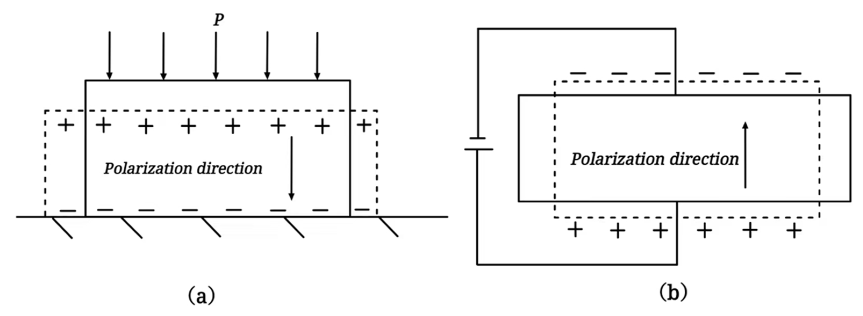

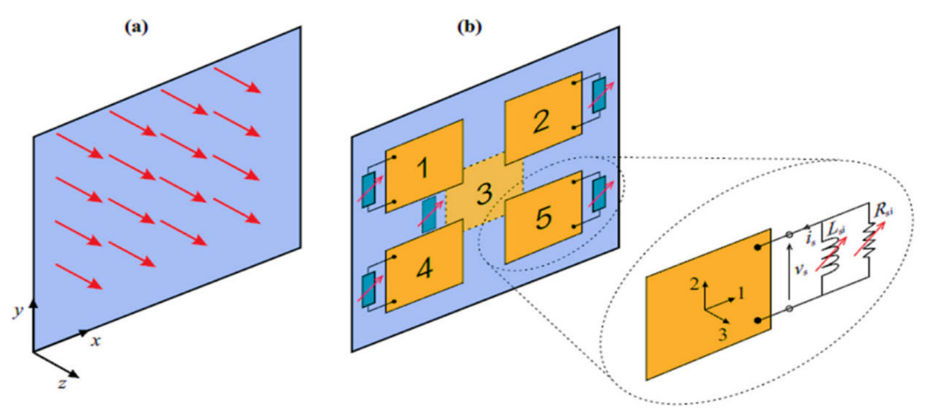

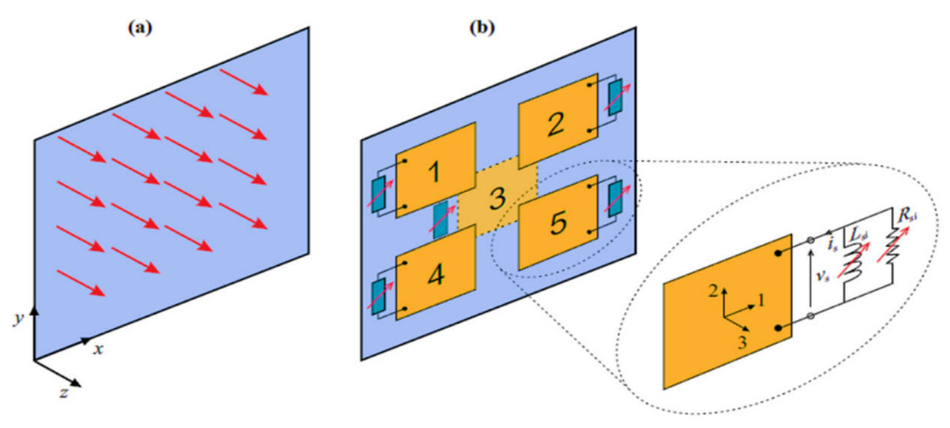

Piezoelectric materials have important advantages for aerospace applications. They are highly sensitive to mechanical stress, which makes them suitable for structural health monitoring by detecting microscopic deformations and fatigue in aircraft components. They are also widely used in vibration control systems that were shown in Figure 2, where they actively dampen oscillations in aircraft fuselages and wings, thereby improving stability and reducing structural wear, where they actively dampen oscillations in aircraft fuselages and wings, thereby improving stability and reducing structural wear. Piezoelectric energy harvesting is a fast-growing, sustainable solution for self-powered sensors that minimize dependency on any external power source in advanced aircraft. However, these materials present several challenges. Brittleness, especially in ceramic-based piezoelectric materials such as PZT, makes them prone to fracture under extreme mechanical stress conditions, which limits their application in high-vibrational environments. Other major disadvantages involve temperature dependence, because piezoelectric properties degrade under extreme conditions, reducing their reliability in high-altitude or space environments [2]. Additionally, the response of piezoelectric materials to stress is nonlinear, as represented by hysteresis [8]. This would also lead to inaccuracies in applications that involve very high precision, such as aerospace control systems [9]. The output strain is only 0.1–0.2% of the original length of the actuator; thus, amplification mechanisms should be used to realize large-scale actuation.

|

|

(a) Stress generated by structural vibration [3]. | (b) Multiple piezoelectric patches integrated with microcircuits [3]. |

Figure 2: Vibration-Induced Stress and Multiple Piezoelectric Energy Harvesting System.

2.2. Shape Memory Alloys (SMAs)

Shape memory alloys possess the peculiar capability of "remembering" their original shape and returning to it under a specific change in either temperature or stress [2]. This capability is based on the phase transformation between two crystal structures: a martensite-low-temperature flexible phase and an austenite-high-temperature rigid phase [3]. At lower temperatures, SMAs are in the martensitic phase, where the atoms adopt a disordered structure such that the material can be deformed by the action of an external stress. Upon heating at a critical temperature, the material transforms into an austenitic phase, in which the atoms are aligned in an ordered structure; the material returns to its original, pre-deformed shape [6]. Most such phase changes are reversible and depend on either the induced temperature or mechanical stress.

Another important aspect of the working mechanism of SMA is their super-elastic characteristics. The deformed SMA displays super-elasticity above the phase transformation threshold temperatures, showing super-large deformability and returning completely to its as-processed initial shape without the need for further thermal activation; this is good for applications requiring high flexibility [5]. The phase transformation is realized by the martensite-austenite phase transition in the crystalline atomic structure. Therefore, the temperature and mechanical properties of SMAs strongly depend on the temperature and stress. SMAs can release substantial amounts of energy stored within them during the transformation from martensite to austenite. Thus, they can be used as highly effective actuators and energy storage devices [9].

Figure 3: Boeing variable chevron [2].

Nitinol is a shape memory alloy (SMAs) with outstanding properties, such as shape recovery, super elasticity, and high energy density. These properties make them highly advantageous in applications where adaptive behavior and compact lightweight actuation systems are of prime concern. In the aerospace industry, such as Figure 3, the main uses of SMAs involve deployable structures, such as solar panels, antennae, and morphing wings and structures, owing to temperature variations. With the ability to return to a predefined shape through heating, SMAs have extensive applications as actuators in systems where minimum mechanical complexity is required. However, the use of SMAs has several serious drawbacks. The major drawbacks include temperature sensitivity, because a very accurate temperature range should be maintained to work effectively. This is problematic in situations such as high-altitude aircraft or space missions with fluctuating temperature conditions. Second, fatigue is an issue; the material degradation of repeated phase transformation cycles between martensite and austenite results in poor performance in long-term, high-cycle applications. In addition, the high material costs of Nitinol and the difficulty in manufacturing make SMAs relatively expensive compared to conventional materials, which limit their use in cost-sensitive industries.

2.3. Electroactive Polymers (EAPs)

Electroactive Polymers (EAPs) are a class of materials that can exhibit large deformations when subjected to an electric field [5, 10]. Their mode of operation relies on the interactions between the polymer molecular structure and the applied electric field, which creates mechanical responses in the material. EAPs can be broadly divided into two classes: ionic EAPs and electronic EAPs, each with a different type of actuation process [3].

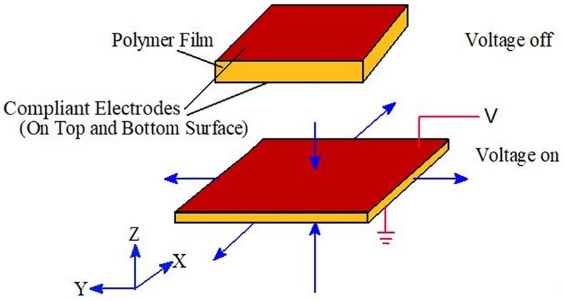

The working principle of ionic EAPs allows ions to migrate within a polymer matrix under the application of an electric field. These migrations result in volumetric expansion or contraction, thereby allowing for large deformations under low voltages. Typical examples are ionomeric polymer-metal composites and ionic gels, which are widely used in low-energy applications owing to their efficiency. However, because they depend on electrolytes, their application under dry conditions is extremely limited to one of the major factors for aerospace applications. In Figure 4, Electronic EAPs, including dielectric elastomers, deform because of the electrostatic forces generated by the application of an electric field. The applied voltage causes mechanical strain owing to the attraction or repulsion of charges within the polymer. Such materials respond faster than ionic EAPs, and thus can be driven in an aerospace environment under dry conditions. However, high voltages must be applied to actuate the electronic EAPs, which can be hazardous and inefficient for energy applications.

Figure 4: Schematic representation of DE actuation [10].

The major advantages of EAPs in aerospace applications include their light weight and large deformation. Indeed, no other material can provide strains larger than 300%, making it highly suitable for adaptive structures such as morphing wings, which may change shape during flight to optimize aerodynamic performance. Another advantage of Ionic EAPs is that they require low voltages, which helps minimize power consumption in energy-sensitive aerospace systems. Although they have relatively fast response time, electronic EAPs are more applicable in aerospace because of their operational stability without the use of electrolytes and fast response times.

Despite these challenges, EAPs face various challenges in their widespread utilization in aerospace applications. First, the relatively low force output of EAPs makes them less suitable for tasks requiring high mechanical strength, such as the actuation of heavy control surfaces. Very efficient at very low voltages, ionic EAPs depend greatly on wet or humid conditions, which probably limits their use under dry conditions at high altitudes in the aerospace industry. In addition, electronic EAPs must be driven with very high voltages, which can raise significant safety and operational concerns. Long-term durability remains problematic for both types of EAPs because ionic EAPs are degraded with ion migration under operation, and electronic EAPs might easily suffer electrical breakdown under continued high-voltage operation. These shortcomings pose a real challenge to finding applications requiring safety-critical aerospace systems.

3. Discussion

Aerospace engineering smart material applications have significantly developed the state of concerned adaptive structures, vibration control, and energy-efficient actuation systems. Each material has certain advantages and specific challenges that limit its applicability in aerospace applications. It is very important to derive the most effective applications to realize the differences between these materials in terms of actuation mechanisms, durability, and aerospace performance.

3.1. Actuation Mechanism and Energy Efficiency

SMAs work on the principle of thermal phase transformation between the martensite and austenite phases, which enables them to recover a preprogrammed shape upon heating [2]. This unique property of this category of materials makes them suitable for deployable structures and morphing wing applications where high force and compact actuation are required. However, temperature changes govern SMAs by introducing thermal lag and slow response times into real-time control systems [6]. In contrast, piezoelectric materials act through the conversion of mechanical stress to electrical energy, and vice versa, and hence exhibit fast and precise actuation [4]. Owing to their bidirectional electromechanical coupling, they find applications in vibration damping, energy harvesting, and precision motion control in aerospace. However, compared to SMA materials, piezoelectric materials do not exhibit thermal delays but suffer from a low strain output, which restricts the generation of large displacements [5]. EAPs have a biomimetic approach that involves large deformations when excited with an electric field. This characteristic enables the application of EAPs to soft actuators, adaptive surfaces, and lightweight aerospace mechanisms. Although EAPs provide high flexibility and adaptiveness compared to SMAs and piezoelectric, the force output is very low, and the requirement of high operational voltage eliminates their use for heavy-load applications in aerospace.

3.2. Structural Durability and Environmental Adaptability

Durability and adaptability to the environment are crucial for selecting smart materials for aerospace applications [2, 3]. SMAs face fatigue after multiple thermal cycles; despite their very high actuation force and high energy efficiency, they can affect material degradation after a period [6]. The development of high-temperature SMAs and composites of SMA structures aims to improve the fatigue resistance and operational lifetime, making it more feasible for long-term use in aerospace applications. Piezoelectric materials, particularly ceramic-based materials such as PZT, possess a very high stiffness with a fast response to actuation [4].

However, their brittleness and sensitivity to temperature may not be favorable in high-stress environments. On the other hand, polymer-based piezoelectric materials, such as PVDF, are more flexible and resilient; however, their lower piezoelectric efficiency restricts their extensive application in aerospace actuation [5]. EAPs are recognized by their light, flexible structure and have the potential for great performance in deployable components and adaptive morphing surfaces. However, ionic EAPs require an electrolyte medium and thus cannot be used under vacuum conditions in space. However, electronic EAPs operating in dry conditions require high voltages with the growth of power consumption and system complexity. In this process, hybrid EAP material development combines the ionic and electronic properties to enhance the mechanical resilience and energy efficiency.

3.3. Aerospace Applications and Performance Considerations

Each SMAs is dedicated to its usage in specific aeronautics applications [2]. Although SMAs play a critical role in morphing wings, deployable mechanisms, and adaptive control surfaces in applications requiring high compact power in actuation, their sensitivity to temperature changes does not suit systems that demand responsiveness in real time [6]. Along with fast response and duality in sensing and actuation, piezoelectric materials are considered an indispensable enabling technology for vibration control, structural health monitoring, and energy harvesting in both aircraft and spacecraft applications [4]. This property makes them especially valuable in self-sustaining sensor networks on satellites and high-altitude aircraft [5]. Low-strain output and material fragility are important for wider applications in aerospace actuation. Owing to their high flexibility and large deformation capability, EAPs are in high demand for use in biomimetic actuators, adaptive wing structures, and deployable space components. Being soft and light, they should be suitable for mechanisms in space that require controlled changes in shape. Low force generation and high voltage demands pose serious obstacles to the use of EAPs in high-performance aerospace systems despite their enormous potential [10].

3.4. Smart Material Integration and Hybrid Systems

The future of smart materials in aerospace will be connected to the use and integration of various types of materials to take full advantage of their complementary capabilities [2, 4]. Hybrid SMA-piezoelectric actuators combine shape memory from SMAs with the fast response and sensing provided by the piezoelectric material. In contrast, EAP-piezoelectric composites optimize actuation performance, energy efficiency, and adaptability [5]. State-of-the-art nanotechnology, combined with advanced additive manufacturing techniques, offers new possibilities for smart material design. Such self-sensing and self-healing material systems can open the path to autonomous aircraft structures with capabilities for real-time detection and self-repair of structural damage [3, 10]. As the demand for more electric and energy-efficient aircraft is increasing daily, the synergistic application of SMAs, piezoelectric materials, and EAPs will contribute significantly to shaping next-generation aerospace systems. Their complete realization demands continuous research and technological development in the evolution of adaptive, self-sustaining, and high-performance aerospace engineering.

4. Conclusion

In aerospace engineering, smart materials are often employed to develop systems that are adaptive and can respond to their environment in real time [1, 2]. Materials such as Shape Memory Alloys (SMAs), Piezoelectric Materials, and Electroactive Polymers (EAPs) are revolutionizing the design of birds, spacecraft, and satellites to boost aerodynamics and reduce vibrations, as well as to adapt the structural design of the airframe [5]. From morphing wings and deployable mechanisms to energy-harvesting systems, they redefine the foundations of current aerospace technologies [4]. In another sense, smart materials are unique. SMAs have shape-recovery properties that can be helpful in deployable structures, and piezoelectric materials are employed in vibration damping and energy generation.

However, these materials face challenges associated with temperature sensitivity, fatigue resistance, and operational limitations in extreme aerospace environments [3]. To mitigate these barriers, current research is trying to boost durability, force output, and energy efficiency, while also reducing costs. Hybrid systems that integrate several smart materials can provide higher efficiencies [10]. As developments in this area continue, these smart materials will undoubtedly be at the forefront of the field of aerospace engineering, pushing the forward through a diverse range to include this adaptive technology, ensuring that flaps and dealing with origin for the future will be sustainable and efficient.

References

[1]. Susmita Kamila (2013). Introduction, Classification and Applications of Smart Materials: An Overview. Retrieved from https://thescipub.com/abstract/ajassp.2013.876.880

[2]. Costanza, G., & Tata, M. E. (2020). Shape Memory Alloys for Aerospace, Recent Developments, and New Applications: A Short Review. Materials. Retrieved from https://www.mdpi.com/1996-1944/13/8/1856

[3]. Wang, W., Xiang, Y., Yu, J., & Yang, L. (2023). Development and Prospect of Smart Materials and Structures for Aerospace Sensing Systems and Applications. Sensors. Retrieved from https://www.mdpi.com/1424-8220/23/3/1545

[4]. Vo, T. V. K., Lubecki, T. M., Chow, W. T., Gupta, A., & Li, K. H. H. (2021). Large-Scale Piezoelectric-Based Systems for More Electric Aircraft Applications. Micromachines. Retrieved from https://www.mdpi.com/2072-666X/12/2/140

[5]. Komal Powar, Prasad Vengurlekar (2018) APPLICATIONS OF ELECTROACTIVE POLYMER IN ELECTRONICS AND MECHATRONICS. Retrieved from https://www.ijser.org/researchpaper/APPLICATIONS-OF-ELECTROACTIVE-POLYMER-IN-ELECTRONICS-AND-MECHATRONICS.pdf

[6]. M Balasubramanian, R Srimath, L Vignesh and S Rajesh (2021) Application of shape memory alloys in engineering – A review. Retrieved from https://iopscience.iop.org/article/10.1088/1742-6596/2054/1/012078

[7]. Rocha, Helena & Semprimoschnig, Christopher & Nunes, J.P. (2021). Sensors for process and structural health monitoring of aerospace composites: A review. Engineering Structures. Retrieved from https://www.researchgate.net/publication/350624256_Sensors_for_process_and_structural_health_monitoring_of_aerospace_composites_A_review

[8]. S. E. Prasad, D. F. Waechter, R. G. Blacow, H. W. King, and Y. Yaman (2005). Application of Piezoelectrics to Smart Structures. Retrieved from Application of Piezoelectrics to Smart Structures

[9]. Mehaan Mehra (2024). Smart Materials And Their Applications In Aerospace Engineering. Retrieved from https://www.iosrjournals.org/iosr-jmce/papers/vol21-issue6/Ser-1/D2106012426.pdf

[10]. Bashir, Musavir & Rajendran, Parvathy. (2018). A review on electroactive polymers development for aerospace applications. Journal of Intelligent Material Systems and Structures. Retrieved from https://www.researchgate.net/publication/326734422_A_review_on_electroactive_polymers_development_for_aerospace_applications

Cite this article

Gu,L. (2025). Advancements and Challenges of Smart Materials in Aerospace: Applications, Mechanisms, and Future Prospects. Applied and Computational Engineering,147,7-13.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Mechatronics and Smart Systems

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Susmita Kamila (2013). Introduction, Classification and Applications of Smart Materials: An Overview. Retrieved from https://thescipub.com/abstract/ajassp.2013.876.880

[2]. Costanza, G., & Tata, M. E. (2020). Shape Memory Alloys for Aerospace, Recent Developments, and New Applications: A Short Review. Materials. Retrieved from https://www.mdpi.com/1996-1944/13/8/1856

[3]. Wang, W., Xiang, Y., Yu, J., & Yang, L. (2023). Development and Prospect of Smart Materials and Structures for Aerospace Sensing Systems and Applications. Sensors. Retrieved from https://www.mdpi.com/1424-8220/23/3/1545

[4]. Vo, T. V. K., Lubecki, T. M., Chow, W. T., Gupta, A., & Li, K. H. H. (2021). Large-Scale Piezoelectric-Based Systems for More Electric Aircraft Applications. Micromachines. Retrieved from https://www.mdpi.com/2072-666X/12/2/140

[5]. Komal Powar, Prasad Vengurlekar (2018) APPLICATIONS OF ELECTROACTIVE POLYMER IN ELECTRONICS AND MECHATRONICS. Retrieved from https://www.ijser.org/researchpaper/APPLICATIONS-OF-ELECTROACTIVE-POLYMER-IN-ELECTRONICS-AND-MECHATRONICS.pdf

[6]. M Balasubramanian, R Srimath, L Vignesh and S Rajesh (2021) Application of shape memory alloys in engineering – A review. Retrieved from https://iopscience.iop.org/article/10.1088/1742-6596/2054/1/012078

[7]. Rocha, Helena & Semprimoschnig, Christopher & Nunes, J.P. (2021). Sensors for process and structural health monitoring of aerospace composites: A review. Engineering Structures. Retrieved from https://www.researchgate.net/publication/350624256_Sensors_for_process_and_structural_health_monitoring_of_aerospace_composites_A_review

[8]. S. E. Prasad, D. F. Waechter, R. G. Blacow, H. W. King, and Y. Yaman (2005). Application of Piezoelectrics to Smart Structures. Retrieved from Application of Piezoelectrics to Smart Structures

[9]. Mehaan Mehra (2024). Smart Materials And Their Applications In Aerospace Engineering. Retrieved from https://www.iosrjournals.org/iosr-jmce/papers/vol21-issue6/Ser-1/D2106012426.pdf

[10]. Bashir, Musavir & Rajendran, Parvathy. (2018). A review on electroactive polymers development for aerospace applications. Journal of Intelligent Material Systems and Structures. Retrieved from https://www.researchgate.net/publication/326734422_A_review_on_electroactive_polymers_development_for_aerospace_applications