1. Introduction

With the rapid advancement of technology, human-machine interfaces (HMIs) are transitioning from conventional input devices such as keyboards and mice toward more natural, intuitive, and intelligent modalities. By leveraging their distinctive physical and chemical properties, flexible sensors can conform seamlessly to human body surfaces or object interfaces, enabling high-sensitivity detection and feedback for diverse physical signals including pressure and humidity. These capabilities significantly expand the potential for developing next-generation HMIs characterized by enhanced efficiency, convenience, and human-centric design [1].

Flexible sensors are defined as sensing devices fabricated using flexible substrates, exhibiting superior mechanical properties that permit free bending or folding while maintaining a variety of structural configuration [2]. In contrast to them, traditional rigid sensors lack mechanical compliance and cannot adequately conform to measured surfaces. When subjected to bending, stretching, or other complex measurement scenarios requiring curved surface integration, conventional semiconductor and metal-based sensors are prone to irreversible deformation, leading to degraded sensing performance [3]. HMIs constitute operational paradigms for human-machine interaction, specifically referring to the bidirectional information exchange pathways between users and systems [4]. As electronic technologies continue to evolve and intelligent systems proliferate, flexible sensors are increasingly adopted in HMIs, demonstrating expanding application prospects [5].

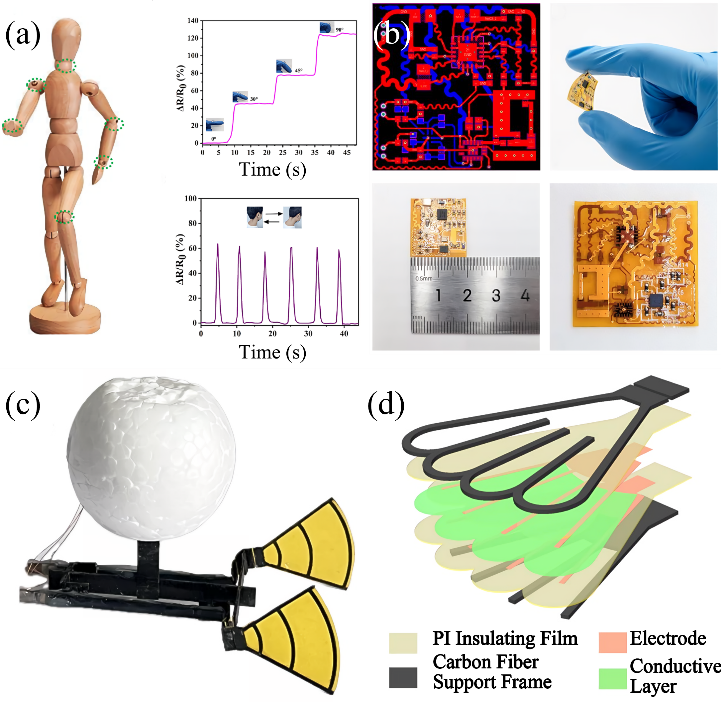

Figure 1: (a) Wearable strain sensors for human motion detection, attached to fingers and cervical joints. (b) Flexible sensor sensing node data acquisition, transmission/reception, and power management circuits. (c) Physical prototype of dual-caudal-fin biomimetic robotic fish. (d) Piezoresistive-type caudal fin sensing structure

Fang et al. developed a novel flexible strain sensor based on ionic hydrogels. When test subjects flexed their fingers at varying angles, the sensor demonstrated corresponding deformation gradients, enabling precise monitoring of diverse human activities through strategic placement on different joints (Figure 1a). Zhang et al. investigated a resistive flexible pressure sensor with a mechanically graded structure that simultaneously achieved wide measurement range and high sensitivity. By integrating radiofrequency energy harvesting, low-power Bluetooth communication, and flexible printed circuit technologies, they fabricated a non-invasive pressure monitoring system for long-term bedridden patient care. This system exhibited high sensitivity (0.34 kPa⁻¹) within the 0–5 kPa pressure range while implementing functions including pressure ulcer prevention, posture recognition, and fall detection (Figure 1b). Wang et al. designed a piezoresistive caudal fin-integrated strain sensor using a three-dimensional conductive carbon-loaded polyolefin film (Velostat) combined with polyvinylidene fluoride (PVDF) coating. This innovation enabled robotic fish caudal fins to simultaneously achieve aquatic propulsion through undulatory motion and hydrodynamic force sensing under varying oscillation frequencies and amplitudes (Figure 1c,d).

2. Classification and technical principles of flexible sensors

The working principle of flexible sensors lies in the fact that, upon receiving external stimuli, changes occur in their internal structure and material properties. These changes lead to variations in electrical or optical properties, which are then converted into electronic or output forms to monitor environmental or physiological parameters [6]. Depending on the type of stimulus, flexible sensors can be categorized into stress-strain sensors, humidity sensors and pH sensors among others. [7].

2.1. Stress and strain sensors

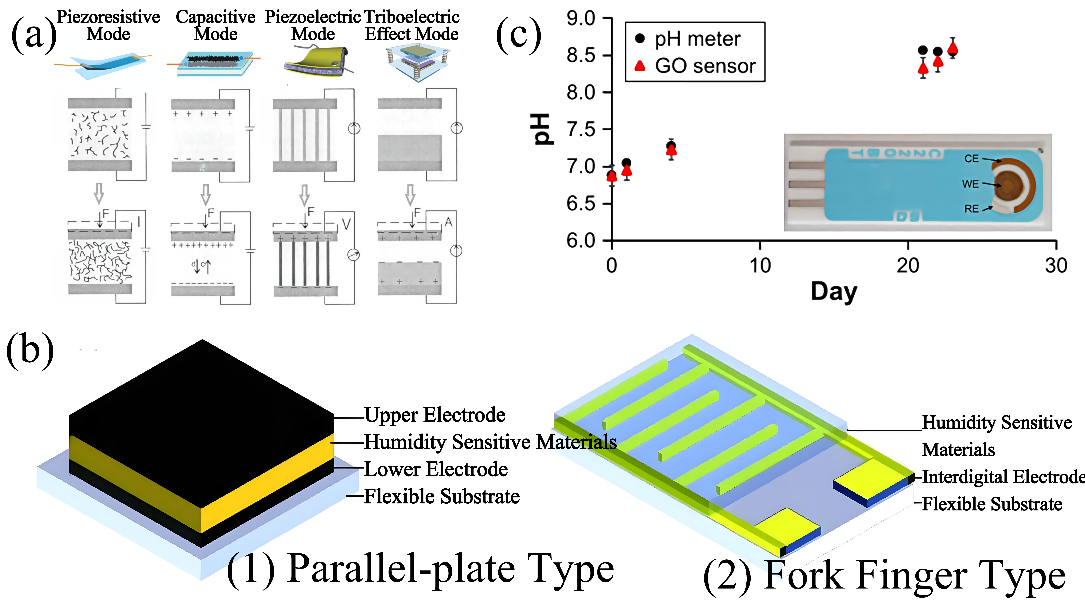

Flexible stress-strain sensors can convert minor deformations caused by external stress or strain into resistance, capacitance, or voltage changes in conductive materials. By monitoring these electrical signal variations, the magnitude and distribution of external loads or strains can be determined. To convert detected physical stimuli into easily output and recordable electrical signals, stress-strain sensors can generally be categorized into four types based on signal transduction mechanisms: piezoresistive, capacitive, piezoelectric, and triboelectric effect types (Figure 2a). Flexible stress-strain sensors are generally composed of sensing materials and elastic substrates. Sensing materials perceive external stimuli and convert stress/strain into electrical signals [8].

2.2. Humidity sensors

Humidity not only affects human health and living comfort but also profoundly impacts the economic benefits of various industrial productions. Flexible humidity sensors mainly consist of sensitive materials and flexible substrate interdigitated electrodes (Figure 2b). The working principle of flexible humidity sensors is that the electrical properties of the sensitive material change after adsorbing water molecules, and humidity detection is achieved by collecting and analyzing these electrical property changes of the sensor [9].

2.3. pH sensors

pH value serves as a crucial monitoring indicator not only in environmental, industrial, and food fields but also as an important measure of human physiological status. Traditional industrial production and research experiments rely on pH meters equipped with glass electrodes to provide reliable detection. However, in practical applications, these pH meters exhibit drawbacks such as fragility, hysteresis, large size, and difficulty in testing on curved surfaces. Consequently, the fabrication and application of flexible pH sensors have garnered attention from researchers [10]. Conventional flexible pH sensors predominantly employ electrochemical mechanisms. When their sensing materials interface with aqueous solutions, the electrochemical properties of these materials undergo characteristic alterations, thereby enabling the determination of hydrogen ion concentration through established signal-concentration correlations (Figure 2c) [11].

Figure 2: (a) Schematic diagram of four working principles of flexible stress and strain sensors. (b) Two different structures of flexible humidity sensors. (c) Comparison between the test results of pH sensor based on graphene oxide (GO) and pH meter

3. Key materials and manufacturing technologies for flexible sensors

Special materials and fabrication technologies are the core elements enabling the superior performance of flexible sensors. This section focuses on conductive materials, humidity-sensitive materials, pH-sensitive materials, as well as micro-nano structuring techniques and printing technologies, exploring their roles and advantages in flexible sensors.

3.1. Key materials

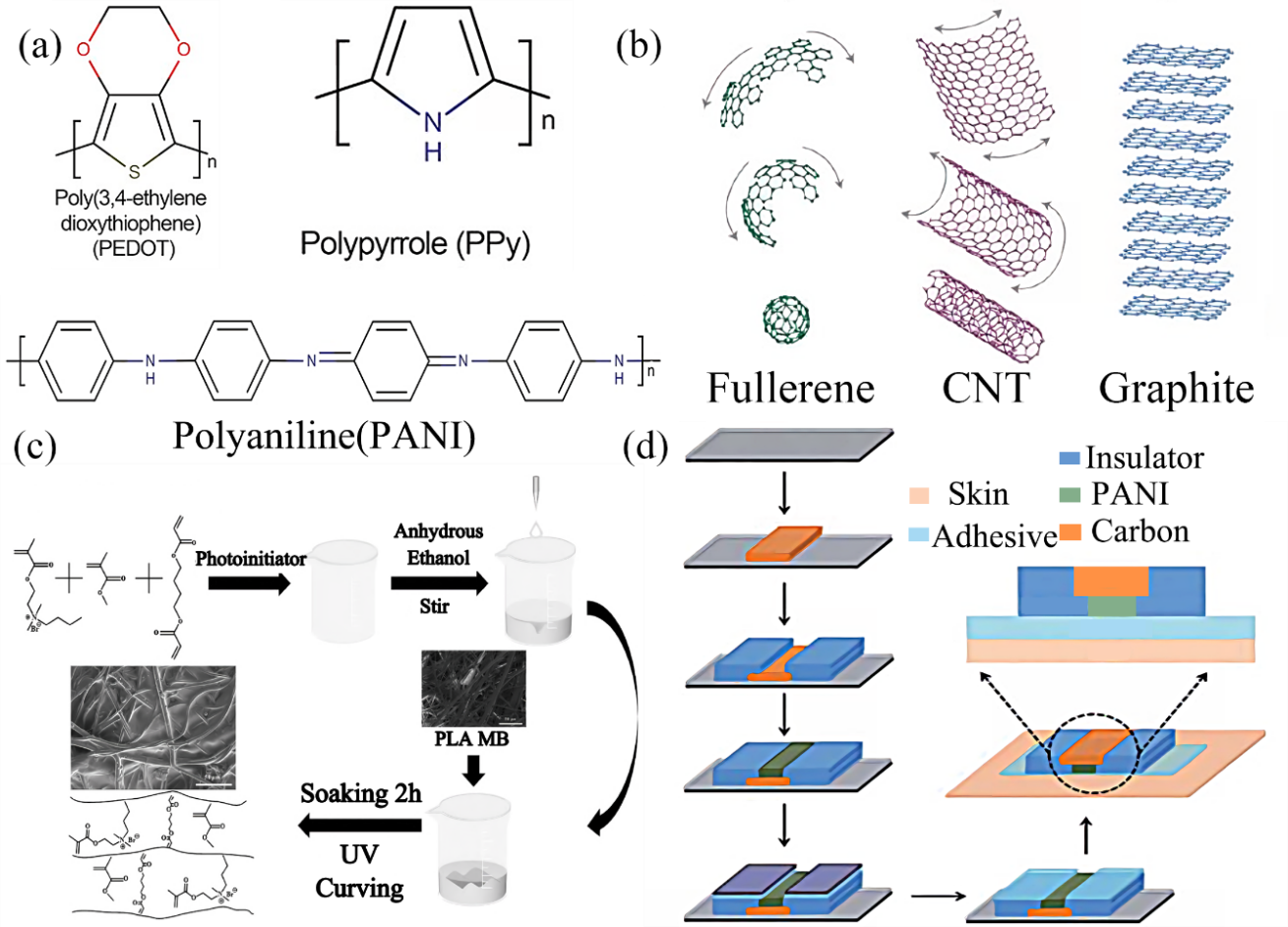

Flexible stress-strain sensors are typically composed of a flexible substrate, a sensitive layer, and electrodes. Polymer materials are usually the primary choice for flexible substrates, while the sensitive layer mainly consists of conductive materials. Conductive materials are the core of flexible sensors, determining the sensor's performance and serving as the foundation of intelligent sensing systems [12]. Common conductive materials include one-dimensional nanomaterials (metal nanowires (NW), carbon nanotubes (CNT), and ceramic nanofibers (CNF), etc.), two-dimensional layered materials (boron nitride (BN), tungsten disulfide (WS₂), and MXene, etc.), conductive polymers (poly(3,4-ethylenedioxythiophene) (PEDOT), polypyrrole (PPy), etc.), liquid metals (LM), ionic liquids (IL), and polyionic liquids (PIL), etc. [13]. Yang et al. [14] developed a flexible composite material based on PEDOT by incorporating sodium polystyrene sulfonate (PSS) through a single-step immersion process, which achieved structurally homogeneous morphology and stable electrical conductivity. The flexible sensor fabricated from this composite material exhibited remarkable characteristics, including high sensitivity (GF = 10.65), broad strain detection range (0% to 100%), excellent local linearity (98.8%), and superior operational stability.

Figure 3: (a) Chemical structures of commonly used π-conjugated polymers. (b) Structural diagram of graphene composites. (c) Fabrication process flowchart of flexible humidity sensors. (d) Fabrication process flowchart of flexible pH sensors

Unlike stress-strain sensors, humidity sensors primarily rely on humidity-sensitive materials, which are considered the core of humidity sensors. In recent years, inorganic materials have stood out among sensing materials due to their high specific surface area and hydrophilicity. Additionally, hygroscopic polymer materials have received widespread attention in humidity sensors due to their biocompatibility and degradability [15]. Currently, humide-sensitive materials for resistive humidity sensors can be categorized into polymers (PEDOT, PPy, and polyaniline (PANI)), ceramics (tin dioxide (SnO2), titanium dioxide (TiO2), zinc oxide (ZnO), iron oxide (Fe2O3), spinel oxides, etc.), and nanomaterials (TiO2 nanoparticles, ZnO nanorods, silica (SiO2) nanospheres), etc. [16]. Yu et al. developed a novel flexible humidity sensor based on a cross-linking method, using polylactic acid meltblown nonwoven material (PLA MB) as the substrate, 2-(dimethylamino)ethyl methacrylate quaternary ammonium salt (DEB) as the humidity-sensitive monomer, and 1,6-hexanediol diacrylate (HDDA) as the cross-linking agent. By UV-curing DEB with hydrophobic methyl methacrylate (MMA), a polyelectrolyte humidity-sensitive coating with a cross-linked network structure was formed on the surface of PLA MB. This sensor exhibited a fast response time (10 s) and stable dynamic and static cycle performance in high humidity environments (Figure 3c).

Compared to stress-strain sensors and humidity sensors, flexible pH sensors require sensitive materials with pH-responsive properties to observe pH changes. Currently, PANI is the most widely used pH-responsive material. It has a porous structure, is sensitive to environmental pH, easy to synthesize, and its structure and properties can be controlled by adjusting synthesis conditions and methods. It is often combined with other conductive polymers, CNT, and other functional coatings to design flexible sensors [17]. Rahimi et al. [18] developed a low-cost flexible pH sensor array based on a commercial paper substrate coated with a polymer coating, using PANI as the pH-sensitive material, paired with silver and silver chloride (Ag/AgCl) reference electrodes and carbon electrodes. Through laser micromachining, screen printing, and lamination techniques, they successfully created a sensor with linear response (R² = 0.9734), high sensitivity (-50 mV/pH), fast response time (rise time 12 s, fall time 36 s), and good biocompatibility (Figure 3d).

3.2. Manufacturing technologies

Manufacturing processes form the foundation of flexible sensor research and applications, not only determining the sensing performance of the sensors but also significantly influencing their production costs and practical application prospects. The fabrication of flexible sensors requires processes that meet high precision, reproducibility, low cost, and environmental friendliness. Common manufacturing methods for flexible sensors are mainly categorized into micro-nano structuring techniques and printing technologies [19].

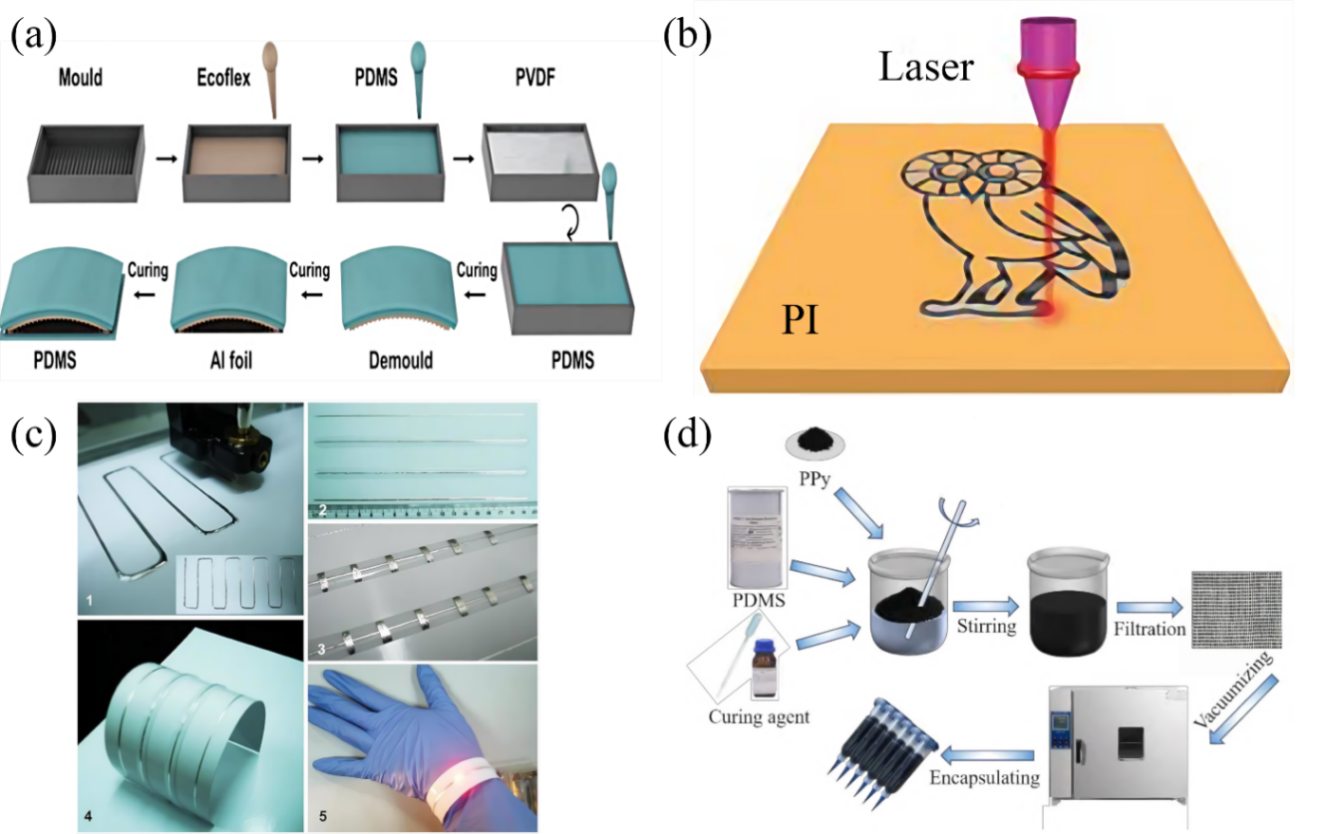

Micro-nano fabrication technology, which involves transferring micro/nanostructures from templates to target materials through photoresist-assisted processes, demonstrates significant advantages including high manufacturing precision, strong scalability, and broad material compatibility. With rapid advancements in this technology, researchers have developed diverse manufacturing processes for micro-array structures, such as template-based methods and etching techniques, which further enhance sensor performance (Figure 4a) [20]. Xiang et al. created a dual-level microstructured ionic-electroactive supercapacitive flexible tactile sensor by employing laser-induced graphene as electrodes and ionogel as the dielectric layer (Figure 4b). Experimental validation of its static and dynamic characteristics confirmed superior attributes including high sensitivity, wide measurement range, structural simplicity, and low fabrication cost.

Unlike micro-nano fabrication techniques that control microscopic morphology, printing technologies enhance flexible sensor performance by optimizing electrodes, materials, and overall architectures. Among printing technologies, 3D printing has emerged as the most promising approach. As a novel additive manufacturing technology, it demonstrates distinct advantages over traditional mold-casting processes, including design flexibility, rapid manufacturing, and superior production predictability. Through computer-controlled precision, this technique enables the fabrication of complex structures with high spatial freedom in three-dimensional configurations (Figure 4c,d) [21]. Jain et al. [22] prepared composite inks using CNT and polydimethylsiloxane (PDMS), printing them onto pre-prepared PDMS substrates using a 3D printer to obtain flexible piezoresistive sensors. Their research showed significant performance improvements with increasing CNT concentration: the 2wt% CNT sensor exhibited a 57% higher fracture strength than the 1wt% CNT sensor; its contact angle reached 105°, 15° larger than the 0.5wt% CNT sensor; at 15% strain, the relative current of the 1wt% CNT sensor was three times that of the 0.5wt% CNT sensor; and at 50% strain, the 2wt% CNT sensor achieved maximum relative current, 2.5 times that of the 0.5wt% CNT sensor. The sensor also successfully tracked finger movements at various angles, suitable for biomedical and industrial applications.

Figure 4: (a) Flexible strain sensor with micro-corrugated structure fabricated by template method. (b) Laser-scribed polyimide (PI) film induced graphene. (c) Manufacturing process of printed electronics. (d) Preparation process of composite printing inks

4. Application scenarios of HMIs

4.1. Medical monitoring

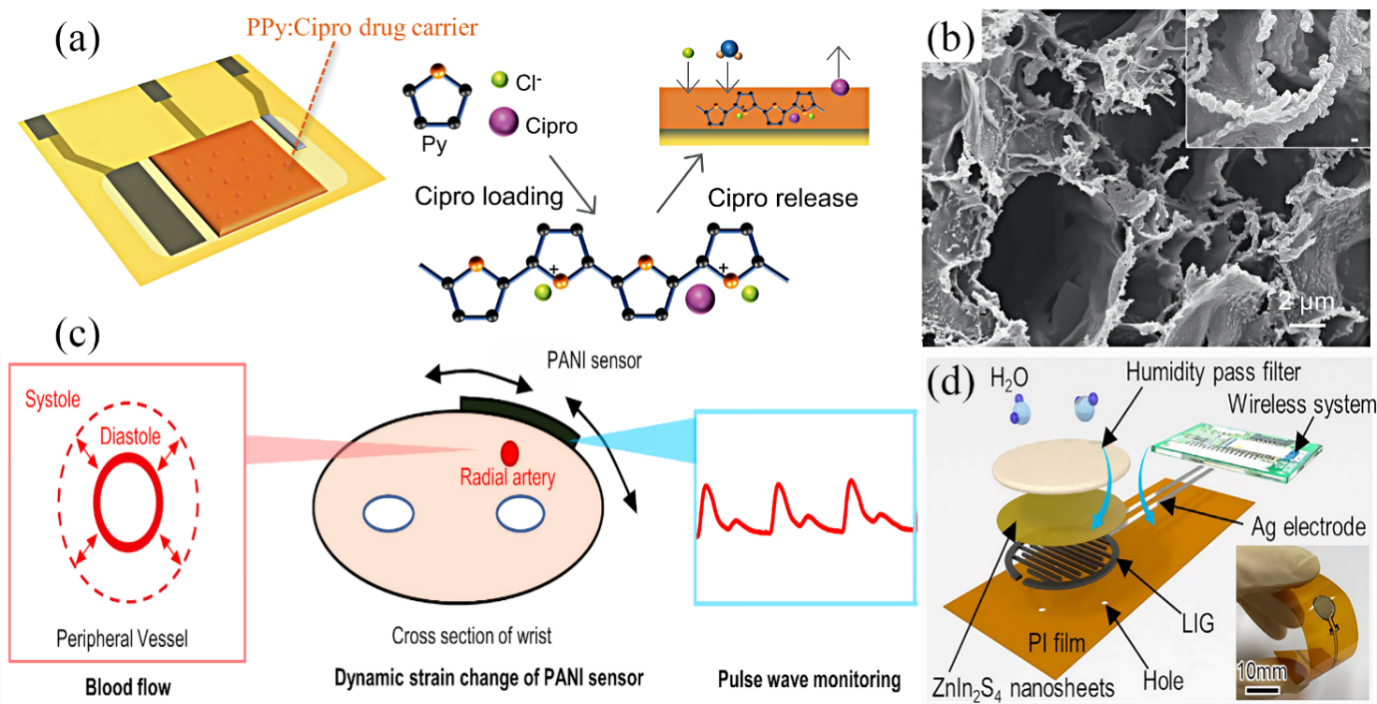

Traditional health monitoring methods rely on bulky medical equipment and limited data acquisition frequencies, which significantly restrict the real-time performance and convenience of monitoring. Flexible sensors can collect physiological data in milliseconds by adhering to the skin or being implanted in the body, and combined with AI algorithms, they can realize personalized health management solutions throughout the entire process from diagnosis, treatment to rehabilitation, promoting the development of precision medicine. Meng et al. [23] developed a multifunctional conductive polymer (CPs)-based multiplexed sensor and drug delivery array, which integrates pH sensing, pH-compensated uric acid biosensing, and on-demand antibiotic release using different conductive polymers. This array was assembled into a three-dimensional patch, connected to a flexible printed circuit board, and further integrated into a smart bandage, showing promise for wound biomarker detection, controlled drug delivery, and wirelessly connected wound management, thereby achieving intelligent wound treatment and diagnosis (Figure 5a, b). Kang et al. [24] proposed a patch-type pulse wave sensor using the conductive polymer PANI based on the electrodeposition method. This sensor utilizes the piezoresistive properties of PANI to detect dynamic volume changes in blood vessels caused by pulse waves. Experiments demonstrated that the fabricated sensor has high sensitivity (GF = 74.28) and linearity (R2 = 0.99), comparable to commercially available photoplethysmography (PPG) sensor results, with deviations and confidence intervals below 0.1% and 3%, respectively (Figure 5c). Honda et al. [25] used all-thioindium zinc sulfide (ZnIn2S4) nanosheets as humidity-sensitive materials to construct a mask-mounted resistive flexible humidity sensor based on a PI film, laser-induced graphene (LIG) electrodes, ZnIn2S4 stacked layers, and a humidity pass filter for long-term wireless respiratory monitoring during sleep to identify sleep apnea symptoms in wearers, featuring high sensitivity (RH70%) and stability, capable of continuous monitoring for over 150 hours. This research opens up new possibilities for home health management and healthcare delivery (Figure 5d).

Figure 5: (a) Schematic diagram of drug loading and release in sensor electrodes. (b) Scanning electron microscope (SEM) image of sensor electrodes, with an inset scale bar of 200 nm. (c) Schematic diagram of the pulse wave monitoring process using a PANI sensor. (d) Schematic diagram and photograph of the flexible humidity sensor

4.2. Intelligent interaction

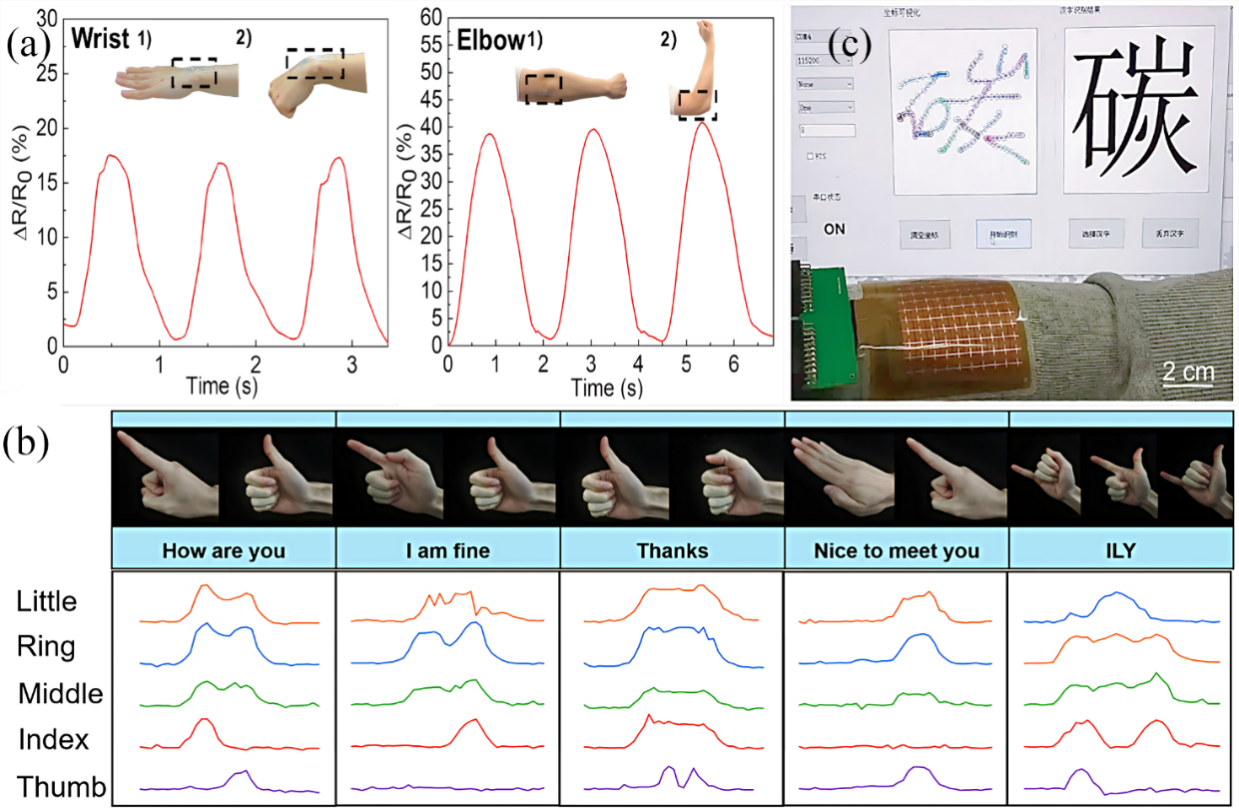

In human-computer interaction, flexible sensors can provide precise feedback, enabling seamless interaction between humans and smart devices. Meanwhile, by integrating sensors with advanced software and hardware, the development of flexible electronics technology is further promoted, facilitating the realization of concepts such as electronic skin, smart gloves, and brain-computer interfaces, and achieving a transition from mechanical operations to emotional resonance. Zhang et al. [26] developed a multi-channel strain sensor based on liquid metal with added nickel powder particles and used machine learning methods to classify sign language gestures. By integrating multiple strain sensors into a smart glove to monitor 14 joints of the human hand (including 5 metacarpophalangeal joints, 5 proximal interphalangeal joints, and 4 distal interphalangeal joints), it can recognize 10 sign language gestures, with a gesture recognition accuracy of up to 99% under the EGBoost model (Figure 6a). Zhou et al. [27] prepared a poly(acrylic acid-co-acrylamide) hydrogel cross-linked by silica nanoparticles based on photopolymerization and the salting-out of hydrophilic ions for strain sensors, featuring low electrical hysteresis (1.6%), low mechanical hysteresis (<7%), high cycle stability (410,000 cycles), high durability, water retention, and antifreeze capabilities. A sign language translation system developed with the assistance of machine learning achieved a recognition rate of over 98% for 15 different sign languages (Figure 6b). Zhang et al. [28] fabricated a capacitive touch sensor using graphene-metal nanofilm (GMNFs), carbon, and copper based on the mixed coordination electron trapping effect, manufactured by an electron cyclotron resonance system. The flexible touch screen equipped with this sensor has a signal-to-noise ratio of 41.16 dB and a resolution of up to 650 dpi, achieving a handwriting Chinese character recognition accuracy of 94.82%. Moreover, after 3,000 bending cycles, the screen can still maintain high sensitivity, demonstrating the promise of flexible touch-sensitive screens (Figure 6c).

Figure 6: (a) Liquid metal strain sensors used for detecting different human wrist and elbow movements. (b) Gesture photographs of five complex sign languages and their corresponding sensing signal curves. (c) Result of the touch screen successfully recognizing the handwritten Chinese character which means carbon

5. Conclusion

Despite the fruitful research achievements of flexible sensing technology in HMIs, large-scale applications still face several critical challenges.

(1) Balancing sensitivity and strain range: While many flexible sensors can maintain a certain sensitivity over a wide strain range, tailoring their performance to suit diverse environmental conditions remains a key consideration. Similar to sensors that monitor human joints, flexible sensors have significant energy dissipation during the sensing process, which imposes high requirements on their mechanical properties. They must achieve high sensitivity under small strains to accurately capture subtle changes, enabling effective signal transduction. Therefore, selecting and designing suitable materials to strike a balance between strain range and sensitivity remains a major challenge.

(2) Signal crosstalk: During the application of flexible sensors, the issue of signal crosstalk cannot be ignored. This is particularly evident in complex environments such as medical monitoring systems, where sensors must simultaneously detect multiple physiological signals—including heart rate, respiration, and muscle activity. However. these signals may interfere with each other, leading to inaccurate data. Additionally, environmental factors such as temperature and humidity changes can also affect the sensor's signals. Addressing signal crosstalk requires a multi-faceted involving from material selection, structural design, and signal processing. On the one hand, materials with selective responses can be used to make sensors more sensitive to target signals while being insensitive to other interfering signals. On the other hand, optimizing the sensor's structural design, such as adding isolation layers or using micro-nano structures, can reduce mutual interference between different sensors. In addition, utilizing advanced signal processing algorithms, such as filtering and noise reduction techniques, can also effectively improve signal quality and reliability.

(3) Energy conservation and environmental protection: As technology continues to advance, research on flexible sensors is expanding in new directions that prioritize ecological sustainability. Among them, self-powered sensors are an important research area. By integrating energy harvesting technologies—such as solar energy and kinetic energy—these sensors can operate autonomously without external power sources. This not only enhances their portability and flexibility but also reduces maintenance costs. For example, in wearable devices, mechanical energy generated by human movement can be harvested to provide continuous power support for sensors. Additionally, biodegradable sensors are an emerging research direction. These sensors can degrade on their own in natural environments after completing monitoring tasks, reducing environmental pollution. This is particularly significant for disposable medical or environmental monitoring sensors.

Future progress in flexible sensors will focus on achieving high integration, performance and multifunctionality. With sustained innovation and interdisciplinary efforts, these challenges are expected to be resolved, advancing their use in next-generation HMIs.

References

[1]. Han, S.T., Peng, H., Sun, Q., Venkatesh, S., Chung, K.S., Lau, S.C., Zhou, Y., and Roy, V.A.L. (2017) An Overview of the Development of Flexible Sensors. Advanced Materials, 29, 1700375-1700396.

[2]. Liu, E., Cai, Z., Ye, Y., Zhou, M., Liao, H., and Yi, Y. (2023) An Overview of Flexible Sensors: Development, Application, and Challenges. Sensors, 23, 817-834.

[3]. Nguyen, T., Dinh, T., Phan, H.-P., Pham, T.A., Dau, V.T., Nguyen, N.-T., and Dao, D.V. (2021) Advances in ultrasensitive piezoresistive sensors: from conventional to flexible and stretchable applications. Materials Horizons, 8, 2123-2150.

[4]. Singh, H.P. and Kumar, P. (2021) Developments in the human machine interface technologies and their applications: a review. Journal of Medical Engineering & Technology, 45, 552-573.

[5]. He, F., You, X., Wang, W., Bai, T., Xue, G., and Ye, M. (2021) Recent Progress in Flexible Microstructural Pressure Sensors toward Human–Machine Interaction and Healthcare Applications. Small Methods, 5, 2001041-2001071.

[6]. Seesaard, T. and Wongchoosuk, C. (2023) Flexible and Stretchable Pressure Sensors: From Basic Principles to State-of-the-Art Applications. Micromachines, 14, 1638-1672.

[7]. Liu, H., Zhang, Z., Ge, J., Lin, X., Ni, X., Yang, H., and Yang, L. (2019) A flexible conductive hybrid elastomer for high-precision stress/strain and humidity detection. Journal of Materials Science & Technology, 35, 176-180.

[8]. Liu, H., Zhang, H., Han, W., Lin, H., Li, R., Zhu, J., and Huang, W. (2021) 3D Printed Flexible Strain Sensors: From Printing to Devices and Signals. Advanced Materials, 33, 2004782-2004800.

[9]. Delipinar, T., Shafique, A., Gohar, M.S., and Yapici, M.K. (2021) Fabrication and Materials Integration of Flexible Humidity Sensors for Emerging Applications. ACS Omega, 6, 8744-8753.

[10]. Zhao, M., Wang, J., Lei, Z., Lu, L., Wang, S., Zhang, H., Li, B., and Zhang, F. (2021) NIR‐II pH Sensor with a FRET Adjustable Transition Point for In Situ Dynamic Tumor Microenvironment Visualization. Angewandte Chemie International Edition, 60, 5091-5095.

[11]. Neupane, S., Subedi, V., Thapa, K.K., Yadav, R.J., Nakarmi, K.B., Gupta, D.K., and Yadav, A.P. (2021) An alternative pH sensor: graphene oxide-based electrochemical sensor. Emergent Materials, 5, 509-517.

[12]. Costa, J.C., Spina, F., Lugoda, P., Garcia-Garcia, L., Roggen, D., and Münzenrieder, N. (2019) Flexible Sensors—From Materials to Applications. Technologies, 7, 35-115.

[13]. Zazoum, B., Batoo, K.M., and Khan, M.A.A. (2022) Recent Advances in Flexible Sensors and Their Applications. Sensors, 22,

[14]. Yang, P., Xiang, S., Li, R., Ruan, H., Chen, D., Zhou, Z., Huang, X., and Liu, Z. (2022) Highly Stretchable and Sensitive Flexible Strain Sensor Based on Fe NWs/Graphene/PEDOT:PSS with a Porous Structure. International Journal of Molecular Sciences, 23, 8895-8909.

[15]. Ma, L., Wu, R., Patil, A., Zhu, S., Meng, Z., Meng, H., Hou, C., Zhang, Y., Liu, Q., Yu, R., Wang, J., Lin, N., and Liu, X.Y. (2019) Full‐Textile Wireless Flexible Humidity Sensor for Human Physiological Monitoring. Advanced Functional Materials, 29, 190549-190557.

[16]. Arman Kuzubasoglu, B. (2022) Recent Studies on the Humidity Sensor: A Mini Review. ACS Applied Electronic Materials, 4, 4797-4807.

[17]. Manjakkal, L., Dervin, S., and Dahiya, R. (2020) Flexible potentiometric pH sensors for wearable systems. RSC Advances, 10, 8594-8617.

[18]. Rahimi, R., Ochoa, M., Parupudi, T., Zhao, X., Yazdi, I.K., Dokmeci, M.R., Tamayol, A., Khademhosseini, A., and Ziaie, B. (2016) A low-cost flexible pH sensor array for wound assessment. Sensors and Actuators B: Chemical, 229, 609-617.

[19]. Nyabadza, A., Vázquez, M., Coyle, S., Fitzpatrick, B., and Brabazon, D. (2021) Review of Materials and Fabrication Methods for Flexible Nano and Micro-Scale Physical and Chemical Property Sensors. Applied Sciences, 11, 8563-8591.

[20]. Niu, H., Zhang, H., Yue, W., Gao, S., Kan, H., Zhang, C., Zhang, C., Pang, J., Lou, Z., Wang, L., Li, Y., Liu, H., and Shen, G. (2021) Micro‐Nano Processing of Active Layers in Flexible Tactile Sensors via Template Methods: A Review. Small, 17, 2100804-2100833.

[21]. Khan, S., Lorenzelli, L., and Dahiya, R.S. (2015) Technologies for Printing Sensors and Electronics Over Large Flexible Substrates: A Review. IEEE Sensors Journal, 15, 3164-3185.

[22]. Jain, B., Phand, K., Jain, V., Lahiri, I., and Lahiri, D. (2024) 3D Printed Carbon Nanotubes Reinforced Polydimethylsiloxane Flexible Sensors for Tactile Sensing. ECS Sensors Plus, 3, 020606-020613.

[23]. Meng, L., Liu, S., Borsa, B.A., Eriksson, M., and Mak, W.C. (2024) A conducting polymer-based array with multiplex sensing and drug delivery capabilities for smart bandages. Communications Materials, 5, 28-37.

[24]. Kang, S., Pradana Rachim, V., Baek, J.-H., Lee, S.Y., and Park, S.-M. (2020) A Flexible Patch-Type Strain Sensor Based on Polyaniline for Continuous Monitoring of Pulse Waves. IEEE Access, 8, 152105-152115.

[25]. Honda, S., Hara, H., Arie, T., Akita, S., and Takei, K. (2022) A wearable, flexible sensor for real-time, home monitoring of sleep apnea. iScience, 25, 104163-104172.

[26]. Zhang, J., Zou, X., Li, Z., Chan, C.P.Y., and Lai, K.W.C. (2025) Liquid-Metal-Based Multichannel Strain Sensor for Sign Language Gesture Classification Using Machine Learning. ACS Applied Materials & Interfaces, 17, 6957-6968.

[27]. Zhou, L., Zhao, B., Liang, J., Lu, F., Yang, W., Xu, J., Zheng, J., Liu, Y., Wang, R., and Liu, Z. (2024) Low hysteresis, water retention, anti-freeze multifunctional hydrogel strain sensor for human–machine interfacing and real-time sign language translation. Materials Horizons, 11, 3856-3866.

[28]. Zhang, X., Ma, J., Deng, H., Zhong, J., Xu, K., Wu, Q., Wen, B., and Diao, D. (2024) A mixed-coordination electron trapping-enabled high-precision touch-sensitive screen for wearable devices. Bio-Design and Manufacturing, 7, 413-427.

Cite this article

Yuan,Z. (2025). Application and Prospect of Flexible Sensors in Human-machine Interfaces. Applied and Computational Engineering,162,11-20.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-FMCE 2025 Symposium: Semantic Communication for Media Compression and Transmission

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Han, S.T., Peng, H., Sun, Q., Venkatesh, S., Chung, K.S., Lau, S.C., Zhou, Y., and Roy, V.A.L. (2017) An Overview of the Development of Flexible Sensors. Advanced Materials, 29, 1700375-1700396.

[2]. Liu, E., Cai, Z., Ye, Y., Zhou, M., Liao, H., and Yi, Y. (2023) An Overview of Flexible Sensors: Development, Application, and Challenges. Sensors, 23, 817-834.

[3]. Nguyen, T., Dinh, T., Phan, H.-P., Pham, T.A., Dau, V.T., Nguyen, N.-T., and Dao, D.V. (2021) Advances in ultrasensitive piezoresistive sensors: from conventional to flexible and stretchable applications. Materials Horizons, 8, 2123-2150.

[4]. Singh, H.P. and Kumar, P. (2021) Developments in the human machine interface technologies and their applications: a review. Journal of Medical Engineering & Technology, 45, 552-573.

[5]. He, F., You, X., Wang, W., Bai, T., Xue, G., and Ye, M. (2021) Recent Progress in Flexible Microstructural Pressure Sensors toward Human–Machine Interaction and Healthcare Applications. Small Methods, 5, 2001041-2001071.

[6]. Seesaard, T. and Wongchoosuk, C. (2023) Flexible and Stretchable Pressure Sensors: From Basic Principles to State-of-the-Art Applications. Micromachines, 14, 1638-1672.

[7]. Liu, H., Zhang, Z., Ge, J., Lin, X., Ni, X., Yang, H., and Yang, L. (2019) A flexible conductive hybrid elastomer for high-precision stress/strain and humidity detection. Journal of Materials Science & Technology, 35, 176-180.

[8]. Liu, H., Zhang, H., Han, W., Lin, H., Li, R., Zhu, J., and Huang, W. (2021) 3D Printed Flexible Strain Sensors: From Printing to Devices and Signals. Advanced Materials, 33, 2004782-2004800.

[9]. Delipinar, T., Shafique, A., Gohar, M.S., and Yapici, M.K. (2021) Fabrication and Materials Integration of Flexible Humidity Sensors for Emerging Applications. ACS Omega, 6, 8744-8753.

[10]. Zhao, M., Wang, J., Lei, Z., Lu, L., Wang, S., Zhang, H., Li, B., and Zhang, F. (2021) NIR‐II pH Sensor with a FRET Adjustable Transition Point for In Situ Dynamic Tumor Microenvironment Visualization. Angewandte Chemie International Edition, 60, 5091-5095.

[11]. Neupane, S., Subedi, V., Thapa, K.K., Yadav, R.J., Nakarmi, K.B., Gupta, D.K., and Yadav, A.P. (2021) An alternative pH sensor: graphene oxide-based electrochemical sensor. Emergent Materials, 5, 509-517.

[12]. Costa, J.C., Spina, F., Lugoda, P., Garcia-Garcia, L., Roggen, D., and Münzenrieder, N. (2019) Flexible Sensors—From Materials to Applications. Technologies, 7, 35-115.

[13]. Zazoum, B., Batoo, K.M., and Khan, M.A.A. (2022) Recent Advances in Flexible Sensors and Their Applications. Sensors, 22,

[14]. Yang, P., Xiang, S., Li, R., Ruan, H., Chen, D., Zhou, Z., Huang, X., and Liu, Z. (2022) Highly Stretchable and Sensitive Flexible Strain Sensor Based on Fe NWs/Graphene/PEDOT:PSS with a Porous Structure. International Journal of Molecular Sciences, 23, 8895-8909.

[15]. Ma, L., Wu, R., Patil, A., Zhu, S., Meng, Z., Meng, H., Hou, C., Zhang, Y., Liu, Q., Yu, R., Wang, J., Lin, N., and Liu, X.Y. (2019) Full‐Textile Wireless Flexible Humidity Sensor for Human Physiological Monitoring. Advanced Functional Materials, 29, 190549-190557.

[16]. Arman Kuzubasoglu, B. (2022) Recent Studies on the Humidity Sensor: A Mini Review. ACS Applied Electronic Materials, 4, 4797-4807.

[17]. Manjakkal, L., Dervin, S., and Dahiya, R. (2020) Flexible potentiometric pH sensors for wearable systems. RSC Advances, 10, 8594-8617.

[18]. Rahimi, R., Ochoa, M., Parupudi, T., Zhao, X., Yazdi, I.K., Dokmeci, M.R., Tamayol, A., Khademhosseini, A., and Ziaie, B. (2016) A low-cost flexible pH sensor array for wound assessment. Sensors and Actuators B: Chemical, 229, 609-617.

[19]. Nyabadza, A., Vázquez, M., Coyle, S., Fitzpatrick, B., and Brabazon, D. (2021) Review of Materials and Fabrication Methods for Flexible Nano and Micro-Scale Physical and Chemical Property Sensors. Applied Sciences, 11, 8563-8591.

[20]. Niu, H., Zhang, H., Yue, W., Gao, S., Kan, H., Zhang, C., Zhang, C., Pang, J., Lou, Z., Wang, L., Li, Y., Liu, H., and Shen, G. (2021) Micro‐Nano Processing of Active Layers in Flexible Tactile Sensors via Template Methods: A Review. Small, 17, 2100804-2100833.

[21]. Khan, S., Lorenzelli, L., and Dahiya, R.S. (2015) Technologies for Printing Sensors and Electronics Over Large Flexible Substrates: A Review. IEEE Sensors Journal, 15, 3164-3185.

[22]. Jain, B., Phand, K., Jain, V., Lahiri, I., and Lahiri, D. (2024) 3D Printed Carbon Nanotubes Reinforced Polydimethylsiloxane Flexible Sensors for Tactile Sensing. ECS Sensors Plus, 3, 020606-020613.

[23]. Meng, L., Liu, S., Borsa, B.A., Eriksson, M., and Mak, W.C. (2024) A conducting polymer-based array with multiplex sensing and drug delivery capabilities for smart bandages. Communications Materials, 5, 28-37.

[24]. Kang, S., Pradana Rachim, V., Baek, J.-H., Lee, S.Y., and Park, S.-M. (2020) A Flexible Patch-Type Strain Sensor Based on Polyaniline for Continuous Monitoring of Pulse Waves. IEEE Access, 8, 152105-152115.

[25]. Honda, S., Hara, H., Arie, T., Akita, S., and Takei, K. (2022) A wearable, flexible sensor for real-time, home monitoring of sleep apnea. iScience, 25, 104163-104172.

[26]. Zhang, J., Zou, X., Li, Z., Chan, C.P.Y., and Lai, K.W.C. (2025) Liquid-Metal-Based Multichannel Strain Sensor for Sign Language Gesture Classification Using Machine Learning. ACS Applied Materials & Interfaces, 17, 6957-6968.

[27]. Zhou, L., Zhao, B., Liang, J., Lu, F., Yang, W., Xu, J., Zheng, J., Liu, Y., Wang, R., and Liu, Z. (2024) Low hysteresis, water retention, anti-freeze multifunctional hydrogel strain sensor for human–machine interfacing and real-time sign language translation. Materials Horizons, 11, 3856-3866.

[28]. Zhang, X., Ma, J., Deng, H., Zhong, J., Xu, K., Wu, Q., Wen, B., and Diao, D. (2024) A mixed-coordination electron trapping-enabled high-precision touch-sensitive screen for wearable devices. Bio-Design and Manufacturing, 7, 413-427.