1. Introduction

With the rapid development of modern electronic devices, their power density has continually increased, leading to increasingly prominent heat dissipation problems. An efficient thermal management system is crucial for ensuring the stability of equipment and extending its lifespan. As a highly efficient microscale heat dissipation technology, microchannel heat sinks (MCHS) have gained significant attention due to their high surface area-to-volume ratio, low fluid requirements, and excellent heat transfer performance [1,2]. However, in practical applications, MCHS still face challenges such as high flow resistance and limited heat transfer efficiency. Therefore, optimizing the flow and heat transfer performance of MCHS to improve their heat dissipation efficiency is one of the current research hotspots.

In recent years, researchers have explored various aspects, including microchannel structural design, material selection, and working fluids. This study will focus on summarizing and analyzing research on channel structural design and its impact on microchannel heat sink performance. For example, methods such as adopting channels with different cross-sectional shapes can significantly enhance the fluid mixing and disrupt the thermal boundary layer, thereby improving heat transfer efficiency. Among these methods, non-rectangular and wavy channel designs are the most commonly used [3-10]. Additionally, fractal-inspired designs, which draw inspiration from nature, have shown great potential in reducing pressure drop and improving thermal performance [11-15].

This study aims to explore the optimization of the flow and heat transfer performance of MCHS in depth. By reviewing the literature and summarizing existing methodologies, the study systematically analyzes the influence of different structural parameters and fluid characteristics on microchannel heat sink performance. Based on this, and in conjunction with the latest research findings, a series of innovative design strategies and optimization schemes are proposed. These strategies aim to effectively improve the heat dissipation efficiency of MCHS without significantly increasing flow resistance, thereby providing theoretical guidance for thermal management in high-performance electronic devices.

2. Basic principles of MCHS

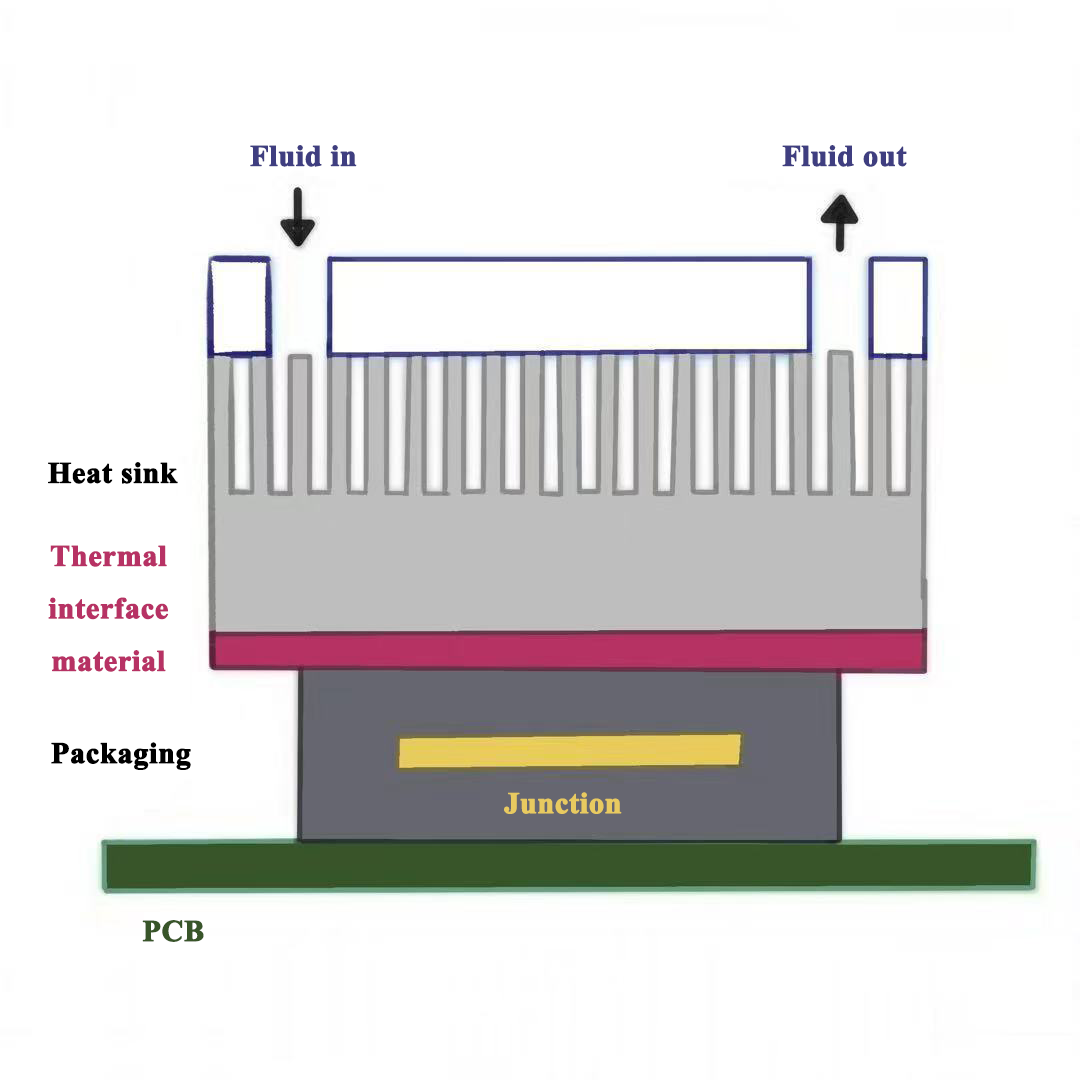

MCHS primarily utilize two modes of heat transfer: thermal conduction and thermal convection. They are an improvement upon the heat exchange of small tube coils and offer superior heat dissipation, especially for applications with high heat flux densities. The device typically consists of a series of tiny channels arranged inside the heat sink, through which the cooling fluid can directly contact the surface that generates heat, thereby rapidly carrying away the heat.

The heat dissipation principle of MCHS mainly relies on their ability to provide a large surface area-to-volume ratio and efficient thermal pathways [1,2]. As the cooling fluid flows through these tiny channels, the small size effect allows the fluid to absorb heat more quickly and efficiently carry it away. Additionally, since the fluid directly contacts the heat source surface, the process of heat transfer through the cooling base, common in traditional heat dissipation methods, is omitted, greatly reducing thermal resistance and improving heat dissipation efficiency.

Research on MCHS often focuses on optimizing the microchannel structure, such as adopting multilayer microchannel configurations, gradually expanding microchannel designs, and arranging concave and convex ribs. These designs enhance flow stability and effectively improve heat transfer performance. For example, dual-layer MCHS, by designing different channel structures in the upper and lower layers, can significantly enhance heat transfer efficiency and reduce bottom surface temperatures. Furthermore, using high-performance cooling media, such as nanofluids, is another important method to improve the heat dissipation performance of MCHS.

In addition to structural optimization and the use of high-performance coolant, the heat transfer performance of MCHS is also influenced by external factors such as magnetic field intensity and fin height. The inlet and outlet pressure drops increase with Reynolds number, and the increase in pressure drop becomes more pronounced with higher magnetic field intensity. The heat transfer performance of MCHS initially increases and then decreases as the magnetic field intensity increases. Increasing the fin height can effectively enhance the heat transfer performance of the heat sink.

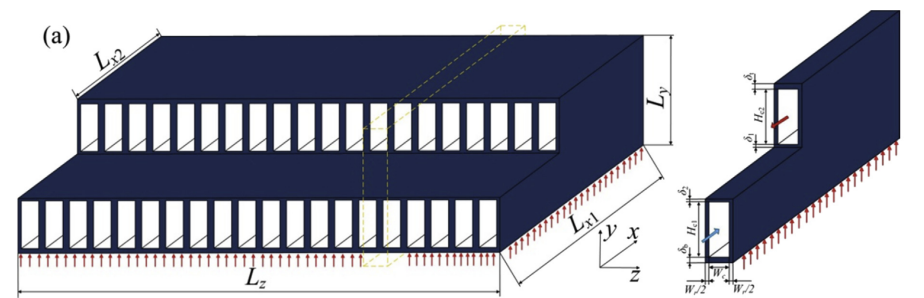

Figure 1: Schematic diagram of liquid-cooled transistor model

3. Latest advances in geometric optimization

3.1. Channel cross-section

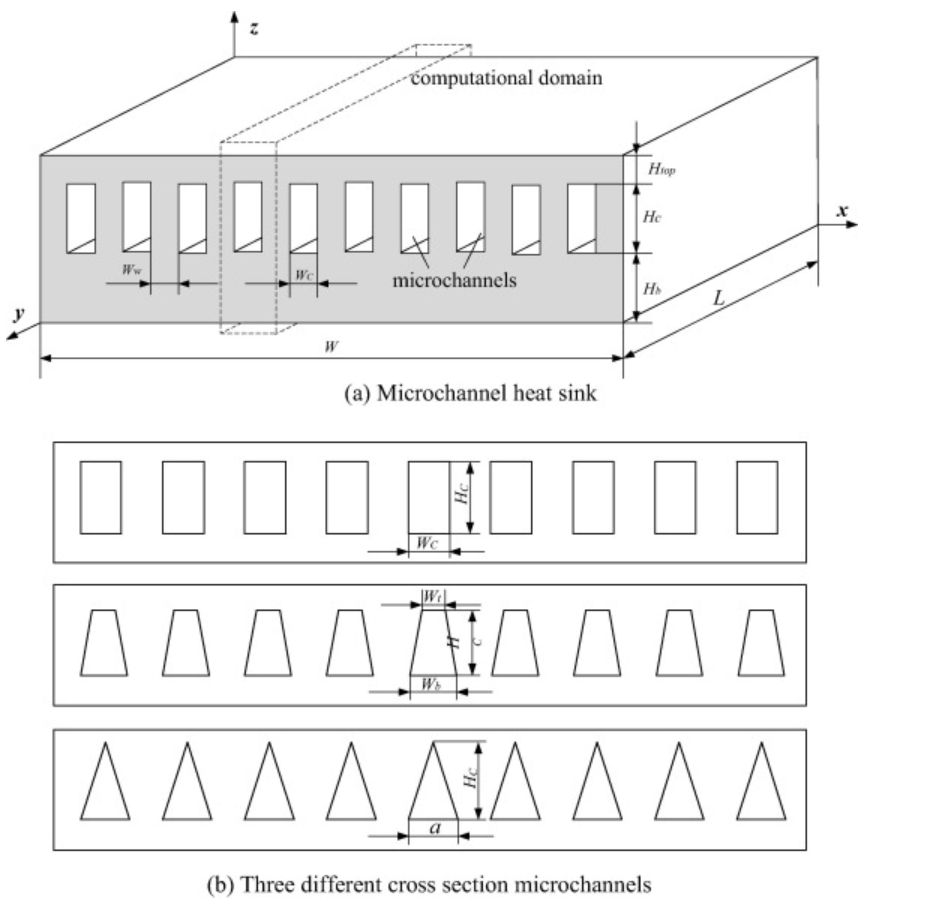

In the geometric optimization of MCHS, the shape of the channel cross-section significantly impacts heat transfer and pressure drop characteristics. Traditional MCHS typically use rectangular cross-sectional channels. However, with advancements in technology and the increasing demand for high-performance heat dissipation, researchers have begun exploring non-rectangular channel designs in an effort to optimize the heat sink’s performance by altering the cross-sectional shape.

(1) Non-rectangular Channels - Non-rectangular cross-sections influence heat transfer efficiency and pressure drop by providing different flow paths and surface areas. Research has shown that an appropriate cross-sectional design can significantly enhance the heat sink’s thermal performance while maintaining an acceptable level of pressure drop. However, manufacturing these non-rectangular geometries, due to their specialized processes and technologies, increases production complexity and cost [3-5].

Trapezoidal and triangular cross-sectional channels are two common non-traditional types used in microchannel heat sink design. These shapes optimize the flow and heat transfer characteristics of the heat sink by altering the channel cross-section. The trapezoidal cross-section, due to its unique structure, increases the contact area between the fluid and the channel, thereby improving the convective heat transfer performance. This design is particularly suitable for cooling applications involving phase change, as it can more effectively manage the formation and movement of bubbles. The main advantage of triangular cross-sectional channels lies in their higher surface area-to-volume ratio, meaning that for the same volume, they provide a larger heat exchange area. This is particularly beneficial for high-density integrated microsystems that require efficient heat dissipation.

Figure 2: (a) Microchannel radiator geometry; (b) Cross sections and dimensions of different microchannels [6]

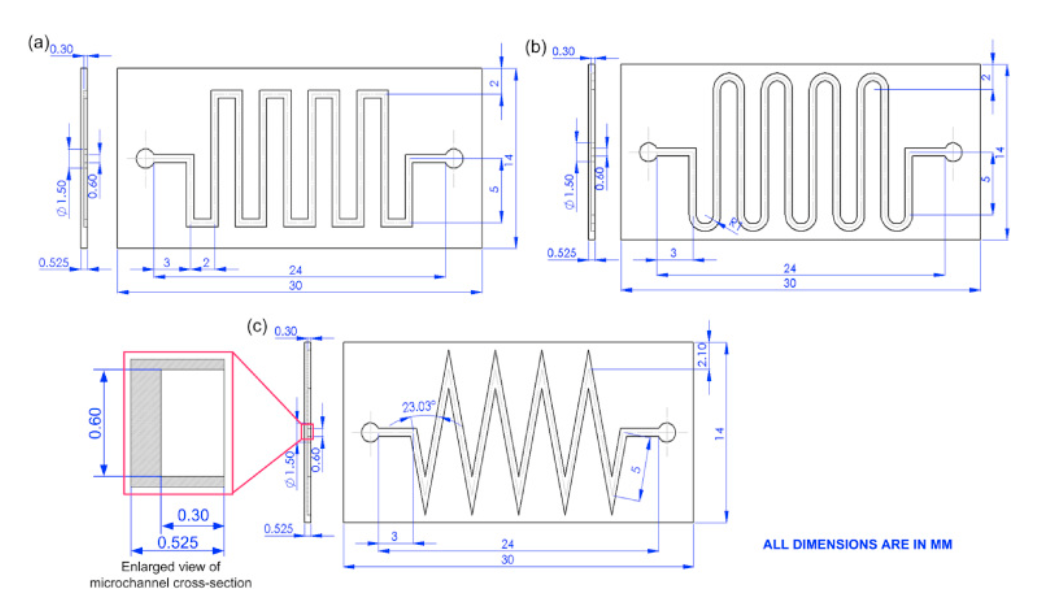

(2) Curved and Wavy Channels - Compared to straight or other simple geometric channels, sinusoidal and serpentine channels can achieve longer effective flow paths within a shorter space. This design introduces curves and bends to promote flow mixing and boundary layer disruption, thus increasing the heat dissipation area and facilitating more heat exchange and fluid dynamics interactions. As a result, sinusoidal and serpentine channels not only help to improve heat transfer efficiency but also reduce localized thermal concentration, thereby improving the uniformity of the temperature distribution. This is particularly important for high-power-density integrated micro-electro-mechanical Systems, as uneven temperature distribution may lead to reduced device performance or even failure. However, these designs typically result in increased pressure drop, requiring a balance between heat transfer enhancement and pressure drop increase [7-9].

The sinusoidal channel design promotes boundary layer disruption and fluid mixing by introducing curves and flow detours, thereby improving heat transfer efficiency. This design is especially suitable for applications that require low pumping power, as it can achieve higher heat dissipation efficiency while maintaining lower pressure drops. Serpentine channels, through their winding paths, increase the flow distance and residence time of the fluid within the heat sink, thus improving heat transfer performance. This design is particularly effective for applications dealing with high heat flux densities, especially in space-constrained environments.

Figure 3: Schematic diagram of different curved and wavy channel structures: (a) Rectangular serpentine; (b) U-shaped serpentine; (c) V-shaped microchannel [10]

(3) Stepped Channels - The stepped design involves sudden changes in channel size, which can effectively reduce overall thermal resistance and uneven temperature distribution, resulting in higher heat transfer coefficients in localized regions. This design may also introduce additional pressure drop, so its impact needs to be carefully evaluated in practical applications. The design and manufacture of stepped channels are also challenging, but they provide an effective way to improve the performance of heat sinks [16-19].

As shown in Fig. 4, Leng et al. [20] proposed a DL-MCHS (truncated top channel) design, in which the top channel is truncated to reduce the heating effect of the upper coolant on the lower coolant, thereby lowering overall thermal resistance and reducing uneven temperature distribution on the bottom surface, thus improving cooling efficiency. Compared to the traditional single-layer MCHS, the counter-flow DL-MCHS demonstrates better thermal performance. However, the DL-MCHS structure is more complex and requires more coolant to maintain the cooling system cycle.

Figure 4: DL-MCHS with truncated top channel [20]

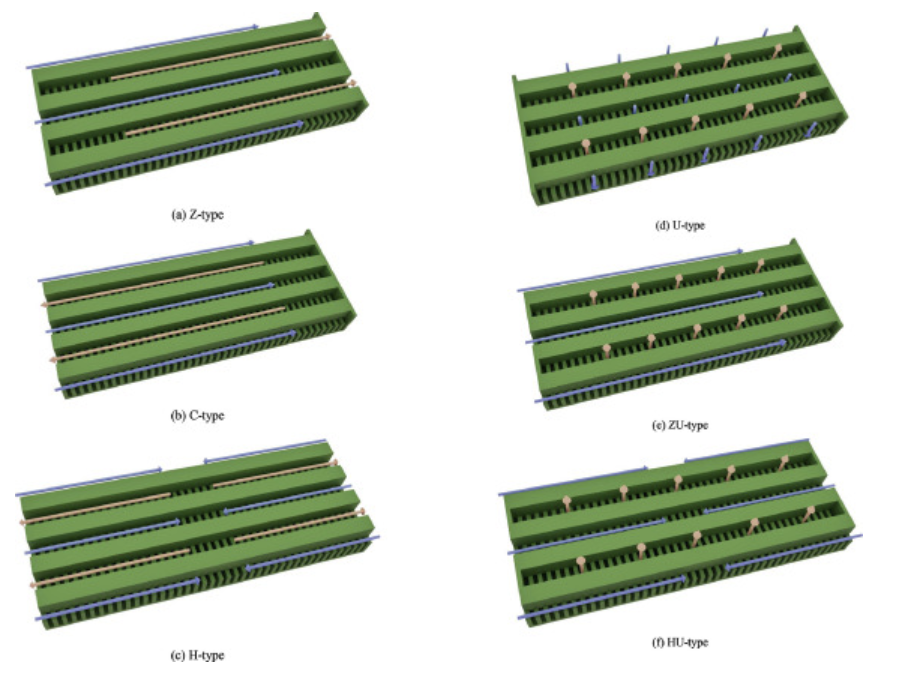

3.2. Manifold design

Manifold design in MCHS is one of the key optimization directions, as it involves the distribution and flow path of the fluid within the heat sink. The quality of manifold design directly affects the heat dissipation efficiency and pressure drop of the heat sink.

(1) Bifurcated Manifold - The application of bifurcated manifolds in MCHS aims to optimize fluid distribution by mimicking the tree-like structures found in nature. This design divides the main flow path into multiple branches, forming a layered, progressively finer flow network, thus achieving more uniform flow distribution and more efficient heat exchange [21-23].

A significant advantage of bifurcated manifold design is its ability to reduce uneven flow distribution. In traditional parallel channel designs, fluid tends to concentrate in paths with lower resistance, leading to excessive flow in some channels while others receive insufficient flow, thus affecting the overall performance of the heat sink. The bifurcated manifold, through its unique structure, can more effectively balance the flow between channels, ensuring that each channel participates in the heat exchange process.

However, scalability and manufacturing challenges are issues that bifurcated manifold designs must address. As the number of branches increases, the complexity of the design and manufacturing process also rises. Producing such complex manifold structures requires high-precision manufacturing techniques, which may increase production costs and difficulties. Additionally, to ensure the performance of the manifold structure, precise control over the dimensions and shapes of the channels is required, placing higher demands on the manufacturing process.

Figure 5: Various manifold types and flow paths [24]

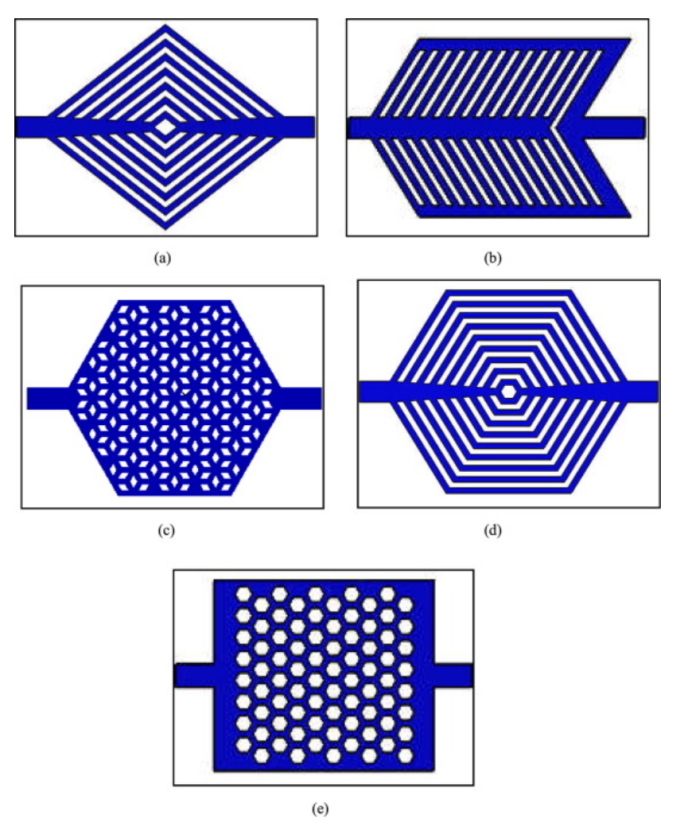

(2) Fractal-Inspired Manifold - Fractal-inspired manifold design is based on the ubiquitous fractal structures found in nature, such as the veins of leaves and the branching of rivers. These natural structures have evolved over time to form highly efficient fluid transport and heat exchange systems. Based on these natural models, fractal-inspired manifold design optimizes fluid flow paths through recursively replicated branching patterns, thus improving the heat dissipation efficiency and fluid dynamics performance of the microchannel heat sink [11-15].

Fractal-inspired manifolds show great potential in reducing pressure drop and improving thermal performance. The fractal structure provides a larger surface-area-to-volume ratio, which means that more heat can be effectively transferred and dissipated within a limited space in a shorter time. Meanwhile, the recursive branching design of the fractal manifold optimizes flow paths, effectively reducing fluid flow resistance and thereby lowering the overall pressure drop. This is crucial for energy conservation and reducing pumping power requirements.

Figure 6: Five microchannel models: (a) Three veins; (b) Leaf veins; (c) Snowflake shape; (d) Spider webs; (e) Honeycomb [14]

4. Challenges and prospects

As an efficient heat dissipation solution, MCHS have promising potential in thermal management of high-power density electronic devices. However, with the continuously increasing of power and reduced device volume, there are great challenge and design strategies in optimizing the flow and heat transfer performance in MCHS [25,26].

4.1. Stacked design

The stacked manifold design is a major optimization direction for the flow heat transfer performance of MCHS [27]. However, we still face a series of challenges and opportunities. First, integrating manifold MCHS into electronic chips and conducting thermal-electrical-mechanical coupling tests and characterization is crucial for enhancing the cooling capabilities of high-power electronic devices. Yet, this significantly increases the difficulty of structural design, material selection, and system integration. In terms of structural optimization, especially the optimization of the microchannel layers, this has become a hot research topic. However, optimization efforts must be based on achievable technical foundations while establishing relevant optimization design guidelines. Additionally, strengthening the fundamental research on manifold MCHS, particularly regarding the collective dimensionless parameters of their structures and the interactions and synergistic effects between them, is vital for advancing the field. Furthermore, research should not be limited to the structure of the manifold microchannel itself, but should expand to the system level, developing a comprehensive thermal management system based on practical applications. This requires a deep understanding of the heat dissipation needs of high-power electronic devices and their clusters, as well as designing corresponding heat dissipation solutions. Finally, research on non-uniform heat flux and “hotspots” may become a new focus in future manifold microchannel studies. To address this challenge, we need to work towards obtaining the basic heat generation characteristics of real chips, such as the relationship between peak heat flux and general heat flux, the relationship between hotspot heat flux and background heat flux, and common hotspot areas. These studies will provide strong support for optimizing the flow heat transfer performance of manifold MCHS.

4.2. Biomimicry

By drawing inspiration from the fine structures and mechanisms that have evolved over millions of years in nature, biomimicry offers a fresh perspective and method for optimizing the performance of MCHS. In current research, efforts have been made to imitate natural structures with efficient heat transfer characteristics, such as the venation of leaves and insect wings, in designing novel microchannel networks. These structures often have complex branching and interwoven patterns, which maximize the heat transfer area within a limited space while promoting fluid mixing and disturbance, significantly enhancing heat exchange efficiency [28]. Meanwhile, inspired by the opening and closing of plant leaves and the body temperature regulation mechanisms of animals, the development of dynamically adjustable structures also shows great research potential. These structures can automatically adjust porosity or thermal conductivity in response to environmental changes such as temperature and pH, thus enabling self-adaptive regulation of the microchannel heat sink’s performance. In the future, various organisms with unique textural patterns, such as tree leaves, spider silk, or shark skin, may be used as natural templates. By replicating their surface structures and unique materials, (MCHS) materials with excellent heat transfer properties could be fabricated. By mimicking nature’s fine structures and mechanisms, combined with novel high-performance materials and innovative manufacturing processes, it is expected that breakthroughs in traditional designs can be achieved. This will lead to the development of more efficient, intelligent, and reliable MCHS systems to meet the demands of future technological advancements.

4.3. Self-similarity

In the field of flow heat transfer performance optimization for MCHS, research on the self-similarity approach has also shown tremendous potential. By transforming the inlet bifurcation channel from its original constant cross-sectional structure into a gradually narrowing ramp-like structure, we can effectively alleviate the issue of uneven flow distribution and reduce the phenomenon of uneven heat transfer between overflow channels [29]. This innovative design not only improves the flow heat transfer efficiency of MCHS but also provides a more reliable and efficient solution for cooling high-power electronic devices. Looking ahead, with the in-depth study and widespread application of self-similarity theory, we can expect further breakthroughs in the design and optimization of MCHS. Through continuous exploration of new structures and materials, combined with advanced manufacturing processes, we can further enhance the performance of MCHS to meet the growing heat dissipation demands of high-power electronic devices.

4.4. Manufacturing technology

In the future, precision manufacturing technology will be the key method for advancing the development of microchannel heat sink structures. In current research, 3D printing technology has been used to precisely replicate the fine structures found in nature, enabling customized design and rapid prototyping of MCHS, which reduces development cycles and costs. For more complex structural designs and stricter precision requirements, it is possible to utilize the multi-photon absorption effect to trigger photopolymerization reactions, directly constructing three-dimensional micro-nano structures suitable for rapid prototyping of MCHS. From breakthroughs in high-precision manufacturing technology to innovative applications in material science and advancements in design and simulation technologies, the integrated development of these fields will propel microchannel heat sink technology toward greater efficiency and intelligence.

5. Conclusion

In this study, we have thoroughly explored various optimization approaches in the field of flow heat transfer performance for MCHS. Through the design and optimization of microchannel structures, we have summarized a variety of solutions that effectively enhance the heat transfer efficiency of the heat sink while reducing flow resistance. We have discussed improvements to the performance of MCHS from several perspectives, including non-rectangular cross-sections, wavy channels, stepped channels, bifurcated flow patterns, and fractal-inspired flow patterns. For example, the stepped design, by introducing sudden changes in channel size, effectively reduces overall thermal resistance and uneven temperature distribution, producing higher heat transfer coefficients in localized areas. Such innovations are of significant importance for improving the heat dissipation performance of electronic devices. Fractal-inspired flow patterns, which draw design inspiration from nature, also show immense potential in reducing pressure drop and improving thermal performance. This study provides valuable insights for optimizing the flow heat transfer performance of MCHS. Building on this, we have looked ahead to future developments from the perspectives of stacked designs, biomimicry, self-similarity, and manufacturing technologies. In summary, as the performance of electronic devices continues to improve and their heat dissipation demands increase, research into MCHS will become more in-depth and widespread. We believe that through continuous effort and innovation, we will be able to develop more efficient and reliable heat dissipation solutions, providing strong support for the advancement of electronic devices.

References

[1]. Zhang, X., Ji, Z., Wang, J., & Lv, X. (2023). Research progress on structural optimization design of MCHS applied to electronic devices. Applied Thermal Engineering, 235, 121294.

[2]. He, Z., Yan, Y., & Zhang, Z. (2021). Thermal management and temperature uniformity enhancement of electronic devices by micro heat sinks: A review. Energy, 216, 119223.

[3]. Wang, Y., Shin, J.-H., Woodcock, C., et al. (2018). Experimental and numerical study about local heat transfer in a microchannel with a pin fin. International Journal of Heat and Mass Transfer, 121, 534-546.

[4]. Sajedi, R., Osanloo, B., Talati, F., et al. (2016). Splitter plate application on the circular and square pin fin heat sinks. Microelectronics Reliability, 62, 91-101.

[5]. Tullius, J. F., Tullius, T. K., & Bayazitoglu, Y. (2012). Optimization of short micro pin fins in minichannels. International Journal of Heat and Mass Transfer, 55, 3921-3932.

[6]. Wang, H., Chen, Z., & Gao, J. (2016). Influence of geometric parameters on flow and heat transfer performance of micro-channel heat sinks. Applied Thermal Engineering, 107, 870-879.

[7]. Mohammed, H. A., Gunnasegaran, P., & Shuaib, N. H. (2011). Numerical simulation of heat transfer enhancement in wavy microchannel heat sink. International Communications in Heat and Mass Transfer, 38, 63-68.

[8]. Yuan, D., Zhou, W., Fu, T., & Liu, C. (2020). Experimental and numerical investigation of heat and mass transfer in non-uniform wavy microchannels. International Journal of Thermal Sciences, 152, 106320.

[9]. Lin, L., Zhao, J., Lu, G., Wang, X.-D., & Yan, W.-M. (2017). Heat transfer enhancement in microchannel heat sink by wavy channel with changing wavelength/amplitude. International Journal of Thermal Sciences, 118, 423-434.

[10]. Sreehari, D., & Sharma, A. K. (2019). On thermal performance of serpentine silicon microchannels. International Journal of Thermal Sciences, 146, 106067.

[11]. He, Z., Yan, Y., Zhao, T., Zhang, L., & Zhang, Z. (2021). Multi-objective optimization and multi-factors analysis of the thermal/hydraulic performance of the bionic Y-shaped fractal heat sink. Applied Thermal Engineering, 195, 117157.

[12]. Fan, Y., Wang, Z., Fu, T., & Wu, H. (2022). Numerical investigation on lithium-ion battery thermal management utilizing a novel tree-like channel liquid cooling plate exchanger. International Journal of Heat and Mass Transfer, 183, 122143.

[13]. Huang, P., Dong, G., Zhong, X., & Pan, M. (2020). Numerical investigation of the fluid flow and heat transfer characteristics of tree-shaped microchannel heat sink with variable cross-section. Chemical Engineering and Processing: Process Intensification, 147, 107769.

[14]. Tan, H., Wu, L., Wang, M., Yang, Z., & Du, P. (2019). Heat transfer improvement in microchannel heat sink by topology design and optimization for high heat flux chip cooling. International Journal of Heat and Mass Transfer, 129, 681-689.

[15]. Qiu, J., Zhou, J., Zhao, Q., Qin, H., & Chen, X. (2021). Numerical investigation of flow boiling characteristics in cobweb-shaped microchannel heat sink. Case Studies in Thermal Engineering, 28, 101677.

[16]. Leng, C., Wang, X.-D., Wang, T.-H., & Yan, W.-M. (2015). Optimization of thermal resistance and bottom wall temperature uniformity for double-layered microchannel heat sink. Energy Conversion and Management, 93.

[17]. Kulkarni, K., Afzal, A., & Kim, K.-Y. (2016). Multi-objective optimization of a double-layered microchannel heat sink with temperature-dependent fluid properties. Applied Thermal Engineering, 99, 262-272.

[18]. Leng, C., Wang, X.-D., Wang, T.-H., & Yan, W.-M. (2015). Multi-parameter optimization of flow and heat transfer for a novel double-layered microchannel heat sink. International Journal of Heat and Mass Transfer, 84, 359-369.

[19]. Osanloo, B., Mohammadi-Ahmar, A., Solati, A., & Baghani, M. (2016). Performance enhancement of the double-layered micro-channel heat sink by use of tapered channels. Applied Thermal Engineering, 102, 1345-1354.

[20]. Leng, C., Wang, X.-D., & Wang, T.-H. (2015). An improved design of double-layered microchannel heat sink with truncated top channels. Applied Thermal Engineering, 79, 54-62.

[21]. Leng, C., Wang, X.-D., & Wang, T.-H. (2015). An improved design of double-layered microchannel heat sink with truncated top channels. Applied Thermal Engineering, 79, 54-62.

[22]. Ryu, J. H., Choi, D. H., & Kim, S. J. (2003). Three-dimensional numerical optimization of a manifold microchannel heat sink. International Journal of Heat and Mass Transfer, 46, 1553-1562.

[23]. Luo, Y., Zhang, J., & Li, W. (2020). A comparative numerical study on two-phase boiling fluid flow and heat transfer in the microchannel heat sink with different manifold arrangements. International Journal of Heat and Mass Transfer, 156, 119864.

[24]. Lin, Y., Luo, Y., Li, W., Cao, Y., Tao, Z., & Shih, T.-I.-P. (2021). Single-phase and two-phase flow and heat transfer in microchannel heat sink with various manifold arrangements. International Journal of Heat and Mass Transfer, 171, 121118.

[25]. Sreehari, D., & Sharma, A. K. (2019). Single-phase and two-phase flow and heat transfer in microchannel heat sink with various manifold arrangements. International Journal of Heat and Mass Transfer.

[26]. Ou, Y.-R., Wang, F.-L., Li, W.-C., et al. (2020). Research progress on microchannel heat exchangers. Petroleum and Petrochemical Equipment, 49(06), 39-46.

[27]. Xie, H.-T., Li, X.-C., Sheng, C.-C., et al. (2020). Research progress on microchannel heat exchangers structure and optimization design. Vacuum and Low Temperature, 26(04), 310-316.

[28]. Zhu, X.-Y., Chen, C.-W., Zhang, J.-Z., et al. (2023). Research progress and outlook on manifold MCHS. Journal of Refrigeration, 44(04), 15-33.

[29]. Ma, X.-R., & Bai, H.-W. (2018). Thermal performance and optimization design of double-layer Y-shaped bifurcated bionic microchannel heat exchangers. Science and Technology and Engineering, 18(24), 112-117.

[30]. Wang, Z., Sun, L.-C., Liu, H.-T., et al. (2018). Heat transfer analysis and structural optimization of self-similar microchannel heat exchangers. Engineering Science and Technology, 50(01), 101-106. https://doi.org/10.15961/j.jsuese.201700295

Cite this article

Huang,Z. (2025). Recent Development in Optimization of Flow and Heat Transfer Performance for Microchannel Heat Sinks. Applied and Computational Engineering,159,31-40.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 5th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Zhang, X., Ji, Z., Wang, J., & Lv, X. (2023). Research progress on structural optimization design of MCHS applied to electronic devices. Applied Thermal Engineering, 235, 121294.

[2]. He, Z., Yan, Y., & Zhang, Z. (2021). Thermal management and temperature uniformity enhancement of electronic devices by micro heat sinks: A review. Energy, 216, 119223.

[3]. Wang, Y., Shin, J.-H., Woodcock, C., et al. (2018). Experimental and numerical study about local heat transfer in a microchannel with a pin fin. International Journal of Heat and Mass Transfer, 121, 534-546.

[4]. Sajedi, R., Osanloo, B., Talati, F., et al. (2016). Splitter plate application on the circular and square pin fin heat sinks. Microelectronics Reliability, 62, 91-101.

[5]. Tullius, J. F., Tullius, T. K., & Bayazitoglu, Y. (2012). Optimization of short micro pin fins in minichannels. International Journal of Heat and Mass Transfer, 55, 3921-3932.

[6]. Wang, H., Chen, Z., & Gao, J. (2016). Influence of geometric parameters on flow and heat transfer performance of micro-channel heat sinks. Applied Thermal Engineering, 107, 870-879.

[7]. Mohammed, H. A., Gunnasegaran, P., & Shuaib, N. H. (2011). Numerical simulation of heat transfer enhancement in wavy microchannel heat sink. International Communications in Heat and Mass Transfer, 38, 63-68.

[8]. Yuan, D., Zhou, W., Fu, T., & Liu, C. (2020). Experimental and numerical investigation of heat and mass transfer in non-uniform wavy microchannels. International Journal of Thermal Sciences, 152, 106320.

[9]. Lin, L., Zhao, J., Lu, G., Wang, X.-D., & Yan, W.-M. (2017). Heat transfer enhancement in microchannel heat sink by wavy channel with changing wavelength/amplitude. International Journal of Thermal Sciences, 118, 423-434.

[10]. Sreehari, D., & Sharma, A. K. (2019). On thermal performance of serpentine silicon microchannels. International Journal of Thermal Sciences, 146, 106067.

[11]. He, Z., Yan, Y., Zhao, T., Zhang, L., & Zhang, Z. (2021). Multi-objective optimization and multi-factors analysis of the thermal/hydraulic performance of the bionic Y-shaped fractal heat sink. Applied Thermal Engineering, 195, 117157.

[12]. Fan, Y., Wang, Z., Fu, T., & Wu, H. (2022). Numerical investigation on lithium-ion battery thermal management utilizing a novel tree-like channel liquid cooling plate exchanger. International Journal of Heat and Mass Transfer, 183, 122143.

[13]. Huang, P., Dong, G., Zhong, X., & Pan, M. (2020). Numerical investigation of the fluid flow and heat transfer characteristics of tree-shaped microchannel heat sink with variable cross-section. Chemical Engineering and Processing: Process Intensification, 147, 107769.

[14]. Tan, H., Wu, L., Wang, M., Yang, Z., & Du, P. (2019). Heat transfer improvement in microchannel heat sink by topology design and optimization for high heat flux chip cooling. International Journal of Heat and Mass Transfer, 129, 681-689.

[15]. Qiu, J., Zhou, J., Zhao, Q., Qin, H., & Chen, X. (2021). Numerical investigation of flow boiling characteristics in cobweb-shaped microchannel heat sink. Case Studies in Thermal Engineering, 28, 101677.

[16]. Leng, C., Wang, X.-D., Wang, T.-H., & Yan, W.-M. (2015). Optimization of thermal resistance and bottom wall temperature uniformity for double-layered microchannel heat sink. Energy Conversion and Management, 93.

[17]. Kulkarni, K., Afzal, A., & Kim, K.-Y. (2016). Multi-objective optimization of a double-layered microchannel heat sink with temperature-dependent fluid properties. Applied Thermal Engineering, 99, 262-272.

[18]. Leng, C., Wang, X.-D., Wang, T.-H., & Yan, W.-M. (2015). Multi-parameter optimization of flow and heat transfer for a novel double-layered microchannel heat sink. International Journal of Heat and Mass Transfer, 84, 359-369.

[19]. Osanloo, B., Mohammadi-Ahmar, A., Solati, A., & Baghani, M. (2016). Performance enhancement of the double-layered micro-channel heat sink by use of tapered channels. Applied Thermal Engineering, 102, 1345-1354.

[20]. Leng, C., Wang, X.-D., & Wang, T.-H. (2015). An improved design of double-layered microchannel heat sink with truncated top channels. Applied Thermal Engineering, 79, 54-62.

[21]. Leng, C., Wang, X.-D., & Wang, T.-H. (2015). An improved design of double-layered microchannel heat sink with truncated top channels. Applied Thermal Engineering, 79, 54-62.

[22]. Ryu, J. H., Choi, D. H., & Kim, S. J. (2003). Three-dimensional numerical optimization of a manifold microchannel heat sink. International Journal of Heat and Mass Transfer, 46, 1553-1562.

[23]. Luo, Y., Zhang, J., & Li, W. (2020). A comparative numerical study on two-phase boiling fluid flow and heat transfer in the microchannel heat sink with different manifold arrangements. International Journal of Heat and Mass Transfer, 156, 119864.

[24]. Lin, Y., Luo, Y., Li, W., Cao, Y., Tao, Z., & Shih, T.-I.-P. (2021). Single-phase and two-phase flow and heat transfer in microchannel heat sink with various manifold arrangements. International Journal of Heat and Mass Transfer, 171, 121118.

[25]. Sreehari, D., & Sharma, A. K. (2019). Single-phase and two-phase flow and heat transfer in microchannel heat sink with various manifold arrangements. International Journal of Heat and Mass Transfer.

[26]. Ou, Y.-R., Wang, F.-L., Li, W.-C., et al. (2020). Research progress on microchannel heat exchangers. Petroleum and Petrochemical Equipment, 49(06), 39-46.

[27]. Xie, H.-T., Li, X.-C., Sheng, C.-C., et al. (2020). Research progress on microchannel heat exchangers structure and optimization design. Vacuum and Low Temperature, 26(04), 310-316.

[28]. Zhu, X.-Y., Chen, C.-W., Zhang, J.-Z., et al. (2023). Research progress and outlook on manifold MCHS. Journal of Refrigeration, 44(04), 15-33.

[29]. Ma, X.-R., & Bai, H.-W. (2018). Thermal performance and optimization design of double-layer Y-shaped bifurcated bionic microchannel heat exchangers. Science and Technology and Engineering, 18(24), 112-117.

[30]. Wang, Z., Sun, L.-C., Liu, H.-T., et al. (2018). Heat transfer analysis and structural optimization of self-similar microchannel heat exchangers. Engineering Science and Technology, 50(01), 101-106. https://doi.org/10.15961/j.jsuese.201700295