1. Introduction

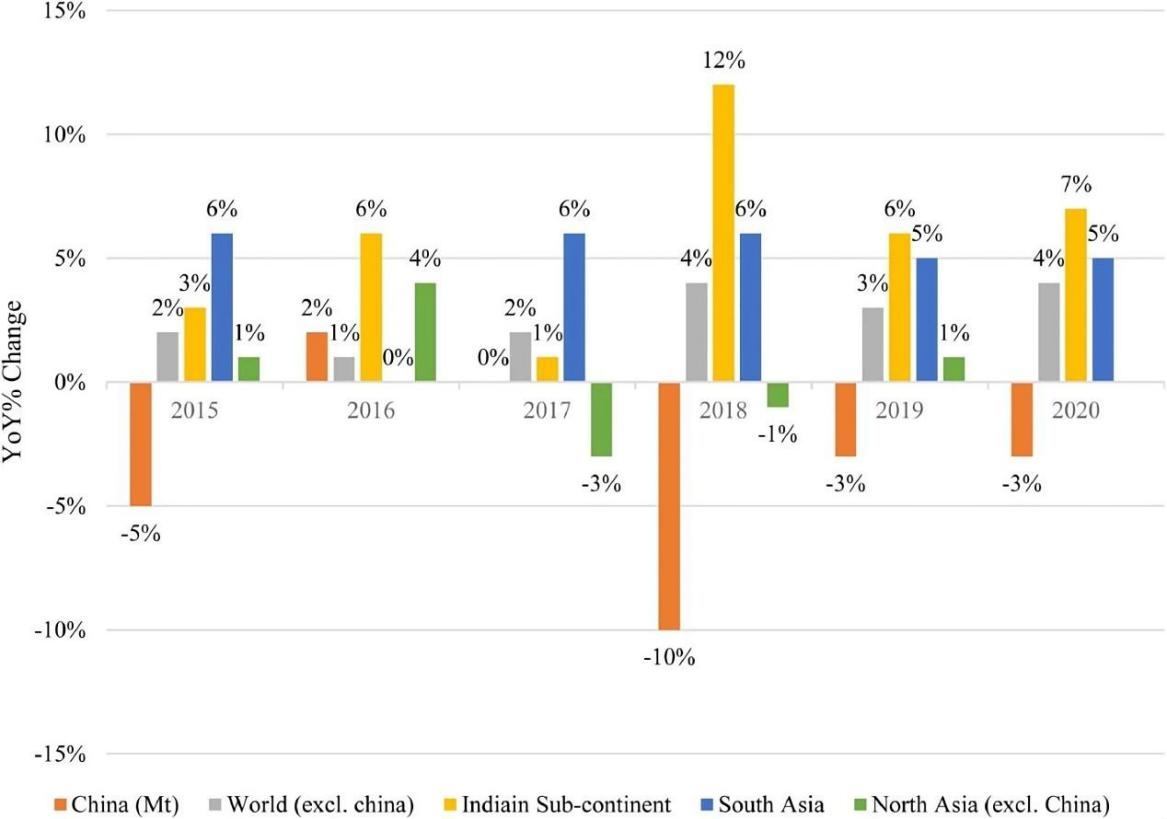

In the context of increasingly severe global climate change, China actively responds to international calls by proposing the ambitious goals of reaching carbon peak by 2030 and achieving carbon neutrality by 2060. As shown in Figure 1, the demand for cement production in Asia continues to grow. Given the serious environmental pollution issues, the research and application of carbon reduction technologies are crucial.

The cement industry is a vital foundational sector of the national economy and a key area of energy consumption and carbon dioxide emissions. The carbon emissions generated during its production process account for approximately 7% to 8% of global carbon emissions [1]. In the cement production process, the calcination of limestone is the primary stage of carbon emissions, with approximately 866 kilograms of carbon dioxide emitted for every ton of cement clinker produced [2-3]. Therefore, an important issue facing the cement industry is how to effectively reduce carbon emissions during production while ensuring the quality of cement products. In recent years, with advancements in technology and increased environmental awareness, a series of carbon reduction technologies for cement have emerged. These technologies encompass various aspects, including raw material substitution, process optimization, energy structure adjustment, carbon capture and storage, and the development of new materials, providing technical support for the green transformation of the cement industry.

Figure 1: Growth rate of cement demand in Asia from 2015 to 2020 (projected) (ICR, 2018)

Raw material substitution technologies, such as using industrial waste, municipal solid waste, and other materials to partially replace limestone, not only reduce the extraction of raw materials but also achieve resource recycling. Process optimization technologies improve production processes to enhance energy efficiency and reduce unnecessary energy consumption. Energy structure adjustment involves using clean and renewable energy sources to decrease the reliance on fossil fuels, thereby lowering carbon emissions. Carbon capture and storage technologies capture the carbon dioxide produced during the manufacturing process and either sequester it geologically or utilize it in other industrial processes, achieving permanent carbon reduction. The application of these technologies not only aids the cement industry in achieving its carbon reduction goals but also holds significant importance for promoting green development across society. However, the promotion and application of these technologies are not straightforward; they must overcome challenges related to technological maturity, economic costs, and policy support. Therefore, cooperation among governments, enterprises, and research institutions is crucial to jointly advance the research, development, and application of carbon reduction technologies in the cement industry, which is key to achieving carbon neutrality goals.

This paper aims to explore the current status, challenges, and future development directions of carbon reduction technologies in the cement industry within the context of carbon neutrality. Through a review and analysis of existing technologies, this paper will propose a series of practical recommendations to provide references for the green transformation of the cement industry. Additionally, the paper will emphasize the importance of policy support, calling for the government to offer more assistance in areas such as tax incentives, financial support, and standard-setting to promote the widespread application and sustainable development of carbon reduction technologies in the cement industry.

2. Status

2.1. Basic process of cement production

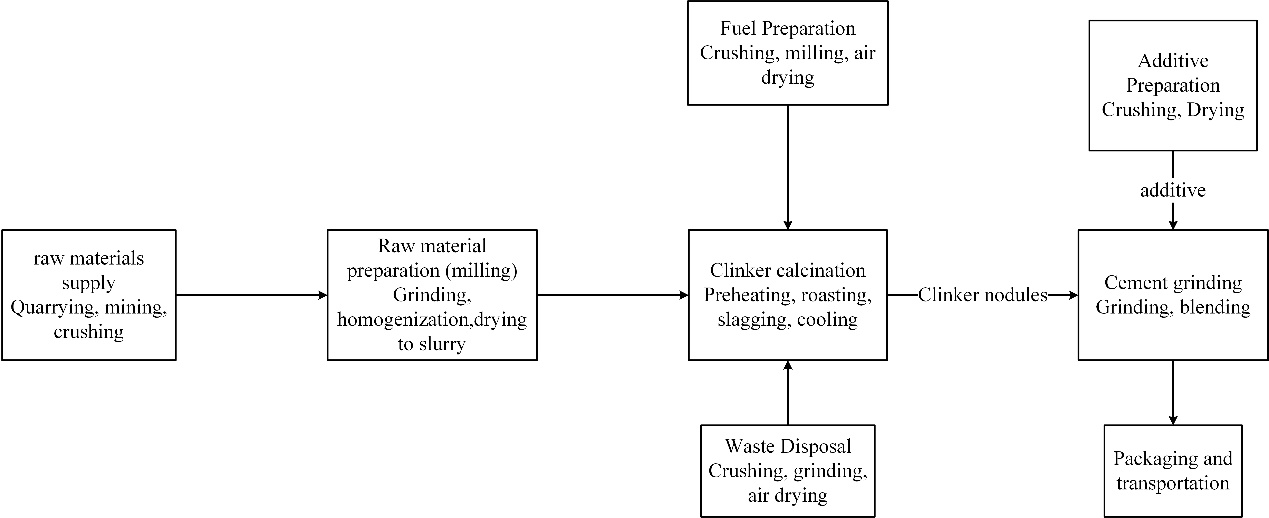

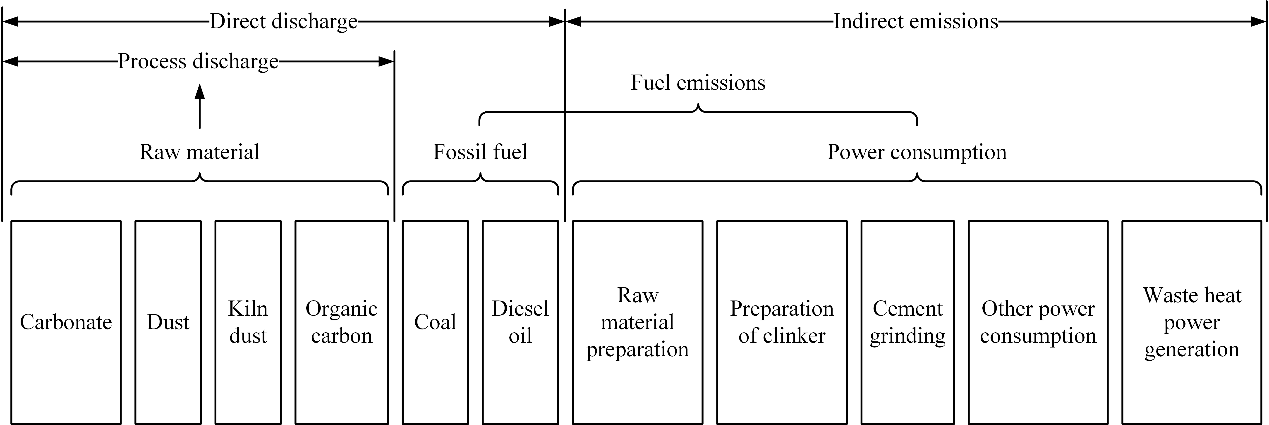

The cement production process can be summarized as two grinding and one burning, which involves the preparation of raw materials, the calcination of clinker, and the grinding of cement, where the cooled clinker is mixed and ground with additives (see Figure 2). The carbon emissions in cement production mainly arise from carbonate decomposition and fuel consumption. Generally, carbon emissions from cement production consist of direct and indirect emissions. Direct emissions include process emissions and emissions from the consumption of fossil fuels, while indirect emissions primarily stem from electricity consumption, as well as emissions from purchased clinker and purchased ground mixed materials (see Figure 3) [4].

Cement production is a carbon-intensive process, with the main carbon emission stages including raw material preparation (approximately 5-10%), clinker burning (approximately 50-60%, where high-temperature calcination of limestone generates calcium oxide and CO2), energy use (approximately 25-35%, with fossil fuel combustion providing thermal energy), and auxiliary processes (less than 5%, such as grinding, mixing, and packaging).

Figure 2: Cement production process

Figure 3: Composition of emissions in cement production

Table 1: Carbon emission accounting boundaries in cement production

Emission Type | Accounting Item | IPCC | WBCSD/CSI | CDMA |

Direct Emissions | Decomposition of carbonate minerals in raw materials: | |||

a. Decomposition of raw material carbonates | √ | √ | √ | |

b. Decomposition of carbonates in kiln exhaust dust | √ | √ | √ | |

c. Decomposition of carbonates in bypass exhaust dust | √ | √ | √ | |

Combustion of non-fuel carbon in raw materials | √ | √ | ||

Combustion of physical coal | √ | √ | ||

Combustion of alternative fuels | √ | √ | ||

Combustion of fuel oil | √ | √ | ||

Direct & Indirect | Utilization of waste heat | √ | ||

Electricity consumption | √ | √ | ||

Indirect Emissions | Purchased cement clinker | √ | √ | |

Purchased ground mixed materials | √ | |||

Source: Compiled based on the IPCC “2006 Guidelines for National Greenhouse Gas Inventories,” WBCSD/CSI “Cement Industry CO2 Reduction Protocol,” and CDMA “Calculation Methods for CO2 Emissions from Cement Production Enterprises (Draft for Consultation).”

2.2. Carbon emission calculation methods for cement production (concise text)

The IPCC (1996, 2006, 2019) has separately addressed energy emissions in its national greenhouse gas inventory guidelines. Therefore, when considering carbon emissions from cement production, only process emissions are accounted for to avoid double counting. The following primarily introduces the calculation methods for process emission factors in cement production as established by the three major organizations: IPCC, WBCSD/CSI, and CDMA.

Overall, the IPCC method is more general and straightforward, suitable for international comparisons; the WBCSD/CSI method is more detailed and precise, appropriate for enterprise-level management; and the CDMA method combines international approaches with China’s specific circumstances, making it more suitable for application in China.

Table 2: Calculation formulas and emission factor selection for carbon emissions in cement production

IPCC Method | The main emission sources considered include the calcination process of limestone (which produces CO2) and the fuel combustion process. Emission factors are typically based on the clinker output in cement production and the carbon emission factor for clinker (kg CO2/tonne of clinker), as well as the emission factors for fuel combustion. |

WBCSD/CSI Method | The calculation method includes both direct and indirect emissions. Emission factors are generally based on actual production data. |

CDMA Method | CDMA provides methods for calculating emission factors for cement production in its guidelines, similar to the CSI method. The main emission sources considered include carbon emissions during the clinker production process and emissions from fuel combustion. Emission factors are typically based on actual production data and industry best practices. |

3. Carbon reduction

3.1. Raw material substitution

Currently, the proportion of alternative fuel usage in China’s cement industry is less than 2%. By incorporating mixed materials (such as fly ash, slag, etc.) to produce blended cement, clinker consumption can be reduced, energy consumption lowered, and performance improved, which is expected to achieve a 5% to 20% reduction in global cement production emissions. Solid waste or non-carbonate materials can replace calcium carbonate raw materials, further promoting emissions reduction. However, the performance of cement products is unstable, with insufficient strength and durability. Fly ash from coal-fired power plants relies on alternative binders (such as alkali-activated binders), and through life cycle assessment and synergy index evaluation, it quantitatively reduces energy and resource consumption, as well as pollutants and CO2 emissions. Silica fume [5] (microsilica) is a byproduct of electric arc furnaces and is added to cement to produce high-performance concrete, but it requires a large amount of water, with the addition limited to less than 6%. While silica fume helps reduce CO2 emissions, it is not easily obtainable and has high production energy costs. Microwave heating, as an emerging technology, directly absorbs and volumetrically absorbs energy, and the electrification of the heating process avoids fossil fuel emissions, reducing combustion gas pollutants such as NOx and SOx [6].

3.2. Clean fuel substitution

In the calcination of cement clinker, carbon emissions from coal account for 25% to 40%. Biomass fuels (such as straw and rice husks) and municipal waste can replace fossil fuels. According to the “Accounting Methods for CO2 Emissions in the Building Materials Industry”, flammable renewable energy and waste are considered to have zero carbon emissions, and using carbon-neutral clean fuels can reduce carbon emissions. Alternative fuels such as waste and biomass can effectively lower carbon emissions in the cement industry. According to the "Accounting Method for Carbon Dioxide Emissions in the Building Materials Industry" (China Building Materials Federation, 2021), "flammable renewable energy sources and waste include solid and liquid biological remains, biogas, industrial waste (including coal gangue used for fuel), and urban waste. The carbon emissions from flammable renewable energy sources and waste are considered to be zero." Therefore, replacing some fossil fuels with carbon-neutral clean fuels can reduce carbon emissions to a certain extent. Consider using alternative fuels such as waste and biomass. [7]

3.3. Carbon capture technology

Carbon capture technology can mitigate climate change in cement production, but its current application is limited, costly, and not yet mature. Carbon capture technology has been introduced, with the process outlined as follows: Initially, within the flue gas of cement kilns, the concentration of CO2 is relatively high, providing favorable conditions for its capture. The capture system typically employs a chemical absorption method, utilizing specific solvents (such as amine compounds) that chemically react with CO2 in the flue gas, forming stable compounds and thereby separating CO2 from the gas stream. Subsequently, the captured CO2 is released and purified through heating or depressurization, ready for storage or utilization. Currently, the application of carbon capture technology in the cement industry remains in the developmental stage. Some cement producers have already initiated pilot projects and deployed carbon capture facilities to reduce their carbon footprint. For instance, several cement plants in Europe and North America have installed small-scale carbon capture units for technical validation and demonstration purposes. However, due to the high costs associated with carbon capture technology and the need for further advancements in its maturity, its widespread adoption in the cement industry has not yet been realized. Despite these challenges, the prospects for the application of carbon capture technology in cement production are still promising. With anticipated advancements in technology and reductions in cost, as well as the increasing global emphasis on reducing greenhouse gas emissions, it is expected that more cement plants will adopt this technology in the future to achieve sustainable development goals. [8-9].

3.4. High-performance new cement

Carbon emissions from cement production are primarily influenced by the type of production technology, the carbonate content in clinker raw materials, the type of fuel, the clinker/cement ratio, and the emission factors for electricity production. Accordingly, carbon reduction measures in cement production mainly include upgrading production technology and equipment, substituting fuels, reducing the clinker/cement ratio (substituting raw materials), adopting carbon capture and storage technologies, and utilizing concrete as a carbon sink [10].

4. Discussion

Currently, the proportion of alternative fuels used in China’s cement industry is less than 2%, and only 5% of cement production lines utilize solid waste co-disposal processes, while the application of CCS technology is even less than 1%. Research indicates that a single emission reduction technology cannot achieve deep emissions cuts in the cement industry. To meet the goal of peak emissions in the cement sector by 2030, it is essential to improve energy efficiency, use carbon-neutral fuels instead of coal, reduce clinker content, scientifically manage cement production levels, and complement these efforts with CCS technology. A multidimensional approach to pollution reduction and carbon reduction is crucial for achieving carbon peak and carbon neutrality in the cement industry.

The development of low-carbon cement faces both technical and economic challenges.

Firstly, the acquisition of raw materials presents the first major challenge. The production of low-carbon cement often requires specialized raw materials, such as industrial by-products (e.g., fly ash, slag), whose supply may be unstable and can affect the quality of the final product. Although the concept of low-carbon cement has been proposed for many years, the maturity of related technologies remains limited. For example, the application of carbon capture and storage (CCS) technology in the cement industry is still in its infancy and requires further technological development and validation. The commercialization process of low-carbon cement is influenced by various factors, including technological maturity, cost-effectiveness, and market demand. Currently, the market share of low-carbon cement is relatively small, and its commercialization level needs to be improved.

Economic challenges are equally formidable. The production cost of low-carbon cement is generally higher than that of traditional cement, primarily due to the need for specialized raw materials and more complex production processes. Enterprises must balance environmental investments with economic outputs, which may lead them to be reluctant to adopt low-carbon cement technology on a large scale in the short term. On the other hand, market acceptance of low-carbon cement is influenced by various factors, including consumer awareness of environmentally friendly products, government policy support, and industry standards. Market research can help companies better understand consumer needs and market trends. Widespread commercial application will require time and the overcoming of challenges in technology, economics, and market acceptance.

As one of the main sources of global carbon emissions, the research and application of carbon reduction technologies in the cement industry hold significant environmental and economic value.

In terms of technological development, using industrial by-products such as fly ash and slag to replace part of the cement raw materials, as well as adopting biomass fuels and waste tires to replace traditional fossil fuels, can significantly reduce carbon emissions. Carbon capture and storage (CCS) technology captures CO2 emissions produced during cement production and either sequesters or utilizes it, representing an effective way to reduce carbon footprints. Additionally, developing new high-performance low-carbon cements such as low-calcium cement and magnesium-based cement can result in lower CO2 emissions during production.

With the rise of green buildings, the demand for low-carbon cement is growing, providing opportunities for the commercialization of carbon reduction technologies in the cement sector. The integration of the cement industry with the circular economy not only reduces resource consumption but also lowers carbon emissions. By introducing smart manufacturing technologies, optimizing production processes, and improving energy efficiency, energy consumption and carbon emissions can be reduced.

Currently, many countries and regions have implemented policies to support the green transition of the cement industry, including providing R&D funding, tax incentives, and subsidies. Establishing and promoting standards and certification systems for low-carbon cement encourages market acceptance and procurement of low-carbon cement products. Creating and improving carbon trading markets with a focus on policy guidance and market mechanisms can facilitate the widespread application of low-carbon cement products, fostering a virtuous cycle where market demand drives technological progress. Through market mechanisms, companies can be incentivized to reduce carbon emissions, providing economic motivation for the development of carbon reduction technologies.

5. Conclusion

Under the auspices of the dual carbon target, the cement industry is proactively charting new trajectories for reducing carbon emissions. Presently, alongside traditional technological innovations such as the deployment of new low-carbon cement varieties and carbon capture and storage technologies, the industry is also delving into more advanced carbon reduction methodologies. Moreover, the research and development of novel materials such as biochar and nanomaterials offer fresh perspectives for mitigating carbon emissions in cement production.In terms of energy structure optimization, in addition to the adoption of alternative fuels and clean energy sources, investigations are also underway regarding the direct incorporation of high-efficiency additives in cement manufacturing processes. The promotion of a circular economy extends beyond the utilization of waste materials; it encompasses the comprehensive lifecycle management of cement products, including the research and application of recycled concrete.Government policy support transcends fiscal subsidies and tax incentives; it also involves the establishment of a carbon emissions trading market to incentivize enterprises to curtail emissions. Furthermore, regulatory frameworks and standards are being refined to ensure the integrity and effectiveness of these measures.Through these multifaceted measures, the cement industry is progressively advancing towards low-carbon, environmentally benign, and sustainable pathways. This not only aligns with global climate change mitigation efforts but also fosters innovation and competitiveness within the industry. By integrating technological advancements, material innovations, energy efficiency improvements, and policy support, the cement sector is poised to make significant strides in its journey towards a greener and more sustainable future.

References

[1]. Cormos, C. C. (2022). Decarbonization options for the cement production process: A techno-economic and environmental evaluation. Fuel, 320, 123907.

[2]. Farfan, J., Fasihi, M., & Breyer, C. (2019). Trends in the global cement industry and opportunities for long-term sustainable CO2 capture potential for Power-to-X. Journal of Cleaner Production, 217, 821-835.

[3]. Zhou, S., Gu, A., Tong, Q., et al. (2022). Multi-scenario simulation on reducing CO2 emissions from China’s major manufacturing industries targeting 2060. Journal of Industrial Ecology, 26(3), 850-861.

[4]. Williams, F., Yang, A., & Nhuchhen, D. R. (2023). Decarbonisation pathways of the cement production process via hydrogen and oxy-combustion. Energy Conversion and Management, 300.

[5]. Alsaegh, Maram. (2021). Effects of Silica Fumes on properties of Normal Concrete. 10.13140/RG.2.2.33135.97447.

[6]. Kumar, A., Kuang, Y., Liang, Z., & Sun, X. (2020). Microwave chemistry, recent advancements, and eco-friendly microwave-assisted synthesis of nanoarchitectures and their applications: a review. Materials Today Nano, 11, 100076.

[7]. Alper, Koray & Tekin, Kubilay & Karagöz, Selhan & Ragauskas, Art. (2020). Sustainable energy and fuels from biomass: a review focusing on hydrothermal biomass processing. Sustainable Energy & Fuels. 4. 10.1039/D0SE00784F..

[8]. Cormos, C. C. (2022). Decarbonization options for the cement production process: A techno-economic and environmental evaluation. Fuel, 320, 123907.

[9]. Farfan, J., Fasihi, M., & Breyer, C. (2019). Trends in the global cement industry and opportunities for long-term sustainable CO2 capture potential for Power-to-X. Journal of Cleaner Production, 217, 821-835.

[10]. Vermeiren, J., Dilissen, N., Goovaerts, V., et al. (2024). Electrification of clinker and calcination treatments in the cement sector by microwave technology – A review. Construction and Building Materials, 428, 136271.

Cite this article

Liu,L. (2025). Carbon Emission Assessment and Environmental Impact of Cement in the Context of Carbon Neutrality. Applied and Computational Engineering,159,77-84.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 5th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Cormos, C. C. (2022). Decarbonization options for the cement production process: A techno-economic and environmental evaluation. Fuel, 320, 123907.

[2]. Farfan, J., Fasihi, M., & Breyer, C. (2019). Trends in the global cement industry and opportunities for long-term sustainable CO2 capture potential for Power-to-X. Journal of Cleaner Production, 217, 821-835.

[3]. Zhou, S., Gu, A., Tong, Q., et al. (2022). Multi-scenario simulation on reducing CO2 emissions from China’s major manufacturing industries targeting 2060. Journal of Industrial Ecology, 26(3), 850-861.

[4]. Williams, F., Yang, A., & Nhuchhen, D. R. (2023). Decarbonisation pathways of the cement production process via hydrogen and oxy-combustion. Energy Conversion and Management, 300.

[5]. Alsaegh, Maram. (2021). Effects of Silica Fumes on properties of Normal Concrete. 10.13140/RG.2.2.33135.97447.

[6]. Kumar, A., Kuang, Y., Liang, Z., & Sun, X. (2020). Microwave chemistry, recent advancements, and eco-friendly microwave-assisted synthesis of nanoarchitectures and their applications: a review. Materials Today Nano, 11, 100076.

[7]. Alper, Koray & Tekin, Kubilay & Karagöz, Selhan & Ragauskas, Art. (2020). Sustainable energy and fuels from biomass: a review focusing on hydrothermal biomass processing. Sustainable Energy & Fuels. 4. 10.1039/D0SE00784F..

[8]. Cormos, C. C. (2022). Decarbonization options for the cement production process: A techno-economic and environmental evaluation. Fuel, 320, 123907.

[9]. Farfan, J., Fasihi, M., & Breyer, C. (2019). Trends in the global cement industry and opportunities for long-term sustainable CO2 capture potential for Power-to-X. Journal of Cleaner Production, 217, 821-835.

[10]. Vermeiren, J., Dilissen, N., Goovaerts, V., et al. (2024). Electrification of clinker and calcination treatments in the cement sector by microwave technology – A review. Construction and Building Materials, 428, 136271.