1. Introduction

In 2019, the annual consumption of sand and stone aggregate in China reached 21.3 billion tons, which is the largest mineral resource at present, accounting for about half of the world's annual output [1]. Excessive exploitation has caused a series of problems, such as excessive excavation of river sand, which will damage the riverbed, damage aquatic animals and affect the environment. Since the1990s, due to the scarcity of river sand and rising prices in mainland China, many coastal areas began to use desalted sea sand as fine aggregate in concrete for construction and civil infrastructure projects, such as Shoushan Port, Shanghai Baosteel Group [2]. Now most examples of sea sand used as concrete are desalted by washing with fresh water, for example, to avoid steel corrosion in reinforced concrete structures. China's " Technical specification for application of sea sand concrete" ( JGJ206-2010 ) also has relevant provisions. However, this does not solve all the problems. It may be on account of the cost of desalination sea sand technology will increase relatively, the desalination results will not meet the requirements in the production process, resulting in excessive salt. The final result is that there have been large-scale cracks or even collapses in houses caused by corroded steel bars in sea sand.In the early 21st century, "sea sand houses" were found in Hangzhou, Ningbo, Quanzhou, and other coastal areas of China. These buildings will lose some bearing capacity in five to fifteen years and become dangerous. If not handled in time, sudden collapse may occur [3]. Since the 1940s, FRP materials have been widely used in the aviation, aerospace, shipbuilding, automotive, chemical, medical, and mechanical fields. In recent years, FRP has begun to be applied in civil and construction engineering structures with its advantages of high strength, light weight and corrosion resistance, and has attracted wide attention from the engineering community [4]. At present, the most commonly used fiber-reinforced polymer composites rebar in engineering field are mainly carbon fiber, glass fiber and aramid fiber reinforced resin matrix et al.Which are referred to as GFRP, CFRP and AFRP. In this paper, the application feasibility of corrosion resistance of GFRP and CFRP in SWSSC is only discussed.

2. Corrosion resistance of FRP steel bar

2.1. Corrosion reasons in seawater

It is generally believed that the chloride ion content has a significant impact on the corrosion of ordinary steel bars in reinforced concrete, and the chloride ion in seawater is abundant [5]. Table 1 shows the physical properties and chemical composition of seawater, in which the content of chloride ion is significantly higher than that of other components [6]. Chloride ions have good infiltration of the concrete through pores. If the concrete is not dense, it will lead to the corrosion of steel bars in reinforced concrete, thus causing concrete damage [7]. Studies have shown that when the free Cl concentration in sea sand reaches 0.3 %, the corrosion of reinforcement is obvious. The weight loss rate of corrosive steel in sea sand concrete increases with the increase of sea sand content and water cement ratio [8]. This should also be concerned in the corrosion test of FRP material.

Specific gravity | pH | Na(ppm) | K(ppm) | Ca(ppm) | Mg(ppm) | Cl(ppm) | SO4(ppm) | CO3(ppm) |

1.022 | 7.77 | 9290 | 346 | 356 | 1167 | 17087 | 2378 | 110 |

Table 1. Physical properties and chemical composition of seawater

2.2. Changes of tensile strength of FRP steel bar in simulated pore solution corrosion environment of sea sand concrete

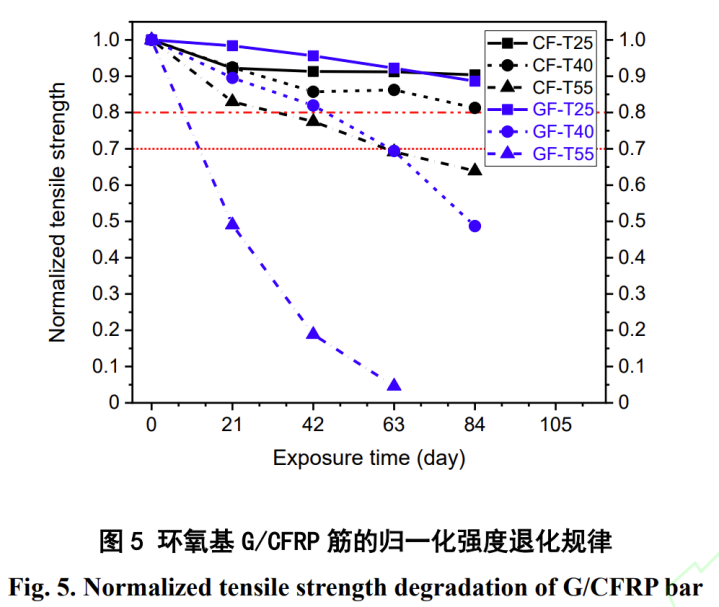

It has been found that FRP steel has better corrosion resistance than ordinary steel [9]. Under the simulated environment of sea sand hole solution, through accelerated corrosion test, the tensile strength retention rate of GFRP steel at 25 °C after 84 days of corrosion reaches 88.6 %, while that of CFRP steel exceeds 90 %. Fig. 1 of normalized tensile strength of epoxy-based G / CFRP bars immersed in SWSSC pore solution at 25 °C, 40 °C and 55 °C for 21 days, 42 days, 63 days and 84 days shows that the degradation degree of standardized tensile strength of CFRP reinforcement is significantly smaller than that of GFRP reinforcement [10]. This is because carbon fibers are not corroded in SWSSC solution, while glass fibers are corroded and destroyed in the corroded area. It can be seen that CFRP reinforcement has better corrosion resistance than GFRP reinforcement. However, in practice, the service temperature of FRP rib under SWSSC package rarely reaches 55 °C. And this experiment simulates the situation that seawater has reached the surface of steel bar through concrete-driven SWSSC solution in the marine environment.

Fig.1 Normalized Strength Degradation of Epoxy G / CFRP Bar[10]

2.3. The failure mode of FRP steel bar under corrosion in seawater environment

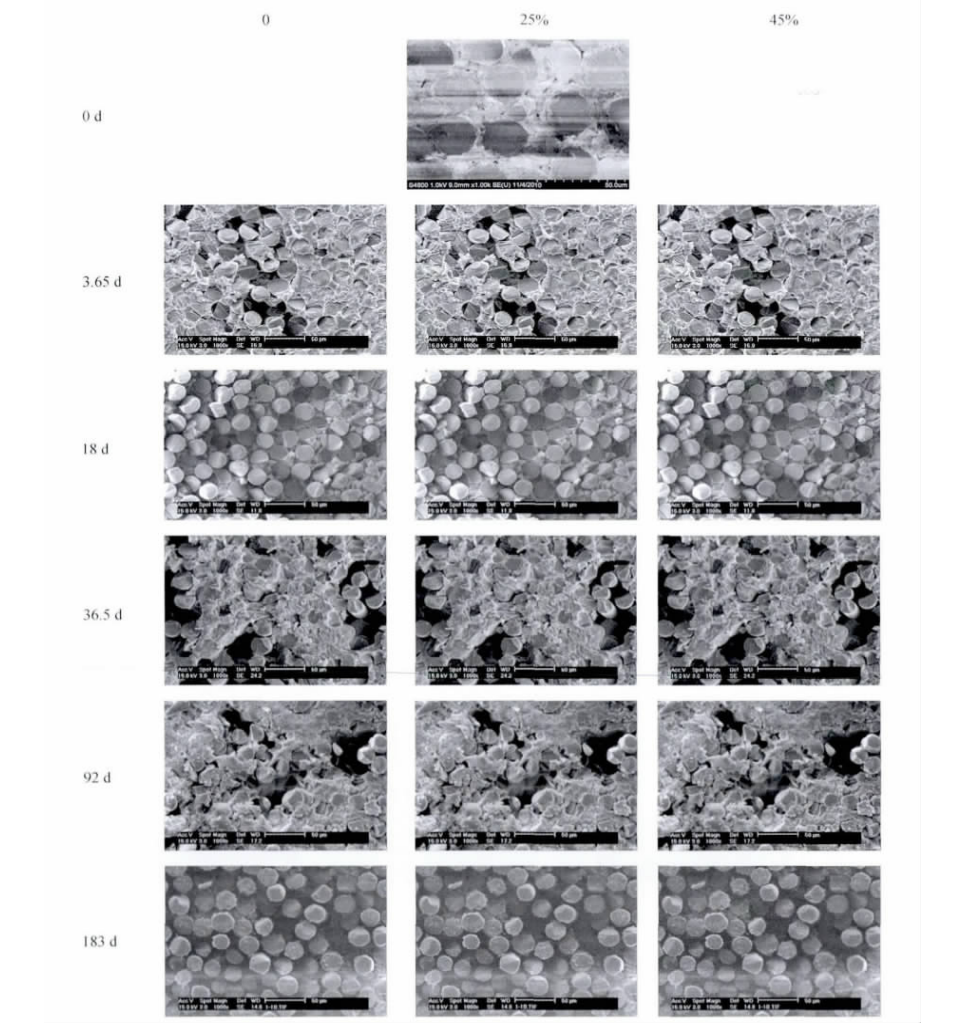

Sun Li artificially prepared a solution of five times the mass concentration of seawater, and studied the change of compressive strength of GFRP reinforcement in seawater immersion environment[11]. They found the same results as other reaschers.The resin matrix in GFRP reinforcement, which plays a protective and bonding role, was first eroded. As the erosion area increased, the fiber and resin were peeled off, resulting in damage. Shear failure is the main failure mode in compression, and the probability of splitting failure increases with the increase of corrosion. The internal structure of glass fiber reinforced plastic ( GFRP ) bars before and after erosion was observed by SEM. The results show that the fiber and resin of GFRP bars are tightly bonded and the fiber is full before erosion. After erosion, the bond between GFRP fiber and resin becomes loose and debonding occurs. With the increase of stress level and erosion time, this phenomenon becomes more obvious, as shown in Figure 2 [12].

Fig.2 SEM image of the GFRP rebars at different levels before and after being exposed to alkaline solution[12].

3. Joint work of FRP steel bar and SWSSC

From the above research results on corrosion, it can be considered that the service effect of CFRP reinforcement in SWSSC may be the best. From the specific strength and specific modulus, the application effect of carbon fiber material is also the best in use. However, other papers found that the elongation of carbon fiber material is very small, and the ductility of FRP reinforcement is mainly through the bonding of resin matrix and concrete. So after a certain degree of corrosion. Although FRP reinforcement has strength, it fails to play a role due to the loss of bonding performance with concrete and cause many cracks at inter face.

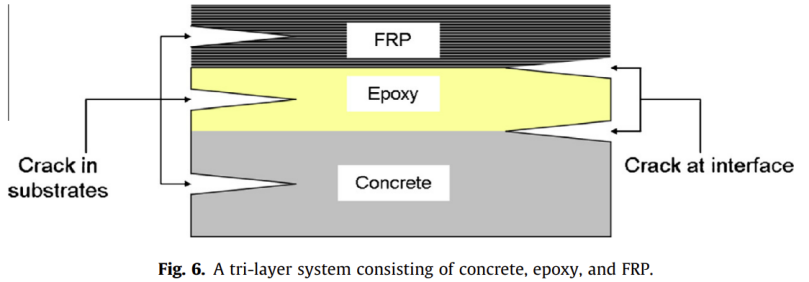

Fig.3 A tri-layer system consisting of concrete,epoxy, FRP.[13]

According to the three-layer system of FRP, epoxy and concrete in the figure, it can be seen that there are two kinds of failure modes when the steel bar and concrete work together. Crack in substractes generally depends on the strength of the matrix, and crack at interface is largely related to the bonding ability of these three components. Epoxy is the most important intermediate layer among them, which ensures the synergistic force of the fiber, and is also the part of the contact between the steel bar and the concrete. Therefore, the key to ensure the cooperative work of the steel bar and the concrete is still the durability of the epoxy resin. However, according to the above research, the resin matrix is also the first part to be directly corroded. Due to the weak alkalinity of seawater and sea sand concrete, even if the alkali resistance of epoxy resin is good [14], it is still unable to withstand the corrosion directly in the alkaline solution environment for a long time. This result is obviously unfavorable to the engineering structure. Therefore, more engineering examples and durability experiments are needed to verify whether the strength degradation level of FRP steel bars and seawater sea sand concrete can meet the conditions of structural design service life required by various national specifications.

4. Conclusion

FRP materials have not been produced for more than 60 years, and only 40 years have been used in civil engineering. In the actual environment, there are many factors that jointly affect the durability of FRP materials. Among the application examples in China, there are examples of FRP structure failure due to durability, and there are engineering examples that have been applied for more than 20 years. As a result, more research is required. In view of the fact that the corrosion resistance of epoxy resin can not reach the ideal state in the experiment, but because the current simulation experiment research generally simulates the possible changes of materials in decades by increasing the temperature to accelerate the reaction rate, it is impossible to obtain the influence of various harsh environments on the performance of epoxy resin[15]. Therefore, more engineering examples and experiments are needed to verify the change process and speed of long-term contact between epoxy resin and seawater sea sand concrete. My point of view is that the resin matrix is critical to the cooperative working ability and durability of FRP with seawater sea sand concrete combination.

In the contrast experiment of GFRP and CFRP, because the carbon fiber is not corroded, the strength decrease of CFRP is obviously less than that of glass fiber, but in fact, the reason for the decrease of strength is that the fiber cannot cooperate with the force caused by the corrosion loss of resin matrix. It is worth noting that the ductility of carbon fiber is poor. Compared with ordinary steel bars, this will adversely affect the construction and the creep of concrete in the later stage. As a result, it is impossible to say that CFRP is superior to GFRP. It can be considered to mix carbon fiber with other fibers to achieve better ductility.

Acknowledgment

Throughout the writing of this review I have received a great deal of support and assistance.I would like to acknowledge Professor oral, for inspiring my interest in the Fiber Reinforced Polymer. In addition, I would like to thank my parents for their steady support, always encourage me to move forward. Finally, I could not have completed this review without the support of my friend Stanley,who Willing to discuss academic issues with me and encourage me by my side when I encountered setbacks in my research.

References

[1]. Soil and Cement Products Association Ready-mixed Concrete Branch. 2020 Ready-mixed Concrete Industry Development Report[J]. Concrete World, 2021(139): 28–37 (CCPA. 2020 annual report on pre-mixed concrete industry development of China[J]. China Concrete, 2021(139):28-37(inChinese))https://www.statista.com/statistics/219343/cement-production-worldwide/ (accessed 18.08.17).

[2]. H.J. Li, The study on emergency management of ‘‘sea sand house” Master degree thesis, Huaqiao University, 2012 (in Chinese).

[3]. Application and development of FRP in engineering structures[J].Journal of Civil Engineering, 2006(03): 24-36.

[4]. T.U. Mohammed, H. Hamada, T. Yamaji Performance of seawater-mixed concrete in the tidal environment Cem Concr Res, 34(4) (2004), pp. 593-601

[5]. J. Xiao, C. Qiang, A. Nanni, K. Zhang Use of sea-sand and seawater in concrete construction: current status and future opportunities Constr Build Mater, 155(2017), pp. 1101-1111

[6]. J.G. Teng, T. Yu, D. Fernando Strengthening of steel structures with fiber-reinforced polymer composites J. Constr. Steel Res., 78(2012), pp. 131-143, 10.1016/j.jcsr.2012.06.011

[7]. W.P.S. Dias, G.A.P.S.N. Seneviratne, S.M.A. Nanayakkara, Offshore sand for

[8]. reinforced concrete, Constr. Build. Mater. 22(7)(2008) 1377–1384.

[9]. Liu Handong, Yu Xinzheng, Li Guowei.Experimental study on tensile mechanical properties of GFRP bolt [ J ].Journal of Rock Mechanics and Engineering, 2005 (20): 121-125.

[10]. Zhao Qi, Zhang Daxu, Zhao Xiaolin, Wang Wenhua. Damage evolution test and model study of epoxy GFRP bars in seawater and sea sand concrete pore solution environment [J/OL].Journal of Civil Engineering: 1-18[2022-08-21].DOI: 10.15951 / j.tmgcxb.21080781.

[11]. Sun Li, Zhang Na. Compressive performance test of GFRP bars under seawater environment corrosion[J]. Journal of Shenyang Jianzhu University(Natural Science Edition), 2013, 29(01): 36–43.

[12]. Xue Weichen, Wang Wei, Fu Kai. Tensile test of GFRP bars with different stress levels in alkali environment[J]. Journal of Composite Materials, 2013,30(06): 67-75.DOI: 10.13801/j.cnki.fhclxb.2013.06.017.

[13]. O. Gunes, D. Lau, C. Tuakta, O. Büyükoztürk, ¨Ductility of FRP–concrete systems: Investigations at different length scales, Constr. Build. Mater. 49(2013) 915–925.

[14]. F. Guo, S. Al-Saadi, R.K. Singh Raman, X.L. ZhaoDurability of Fiber Reinforced Polymer (FRP) in Simulated Seawater Sea Sand Concrete(SWSSC) Environment. https://doi.org/10.1016/j.corsci.2018.06.022

[15]. Li Shan, Ren Huitao, Huang Chengkui, Shi Muhuan. Durability of FRP sheets under temperature and alkali solution[J].Journal of Building Materials, 2010,13(01): 94-99.

Cite this article

Li,J. (2023). Application of corrosion resistance of FRP composites rebar in sea water sea sand concrete. Applied and Computational Engineering,7,131-135.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Materials Chemistry and Environmental Engineering (CONF-MCEE 2023), Part II

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Soil and Cement Products Association Ready-mixed Concrete Branch. 2020 Ready-mixed Concrete Industry Development Report[J]. Concrete World, 2021(139): 28–37 (CCPA. 2020 annual report on pre-mixed concrete industry development of China[J]. China Concrete, 2021(139):28-37(inChinese))https://www.statista.com/statistics/219343/cement-production-worldwide/ (accessed 18.08.17).

[2]. H.J. Li, The study on emergency management of ‘‘sea sand house” Master degree thesis, Huaqiao University, 2012 (in Chinese).

[3]. Application and development of FRP in engineering structures[J].Journal of Civil Engineering, 2006(03): 24-36.

[4]. T.U. Mohammed, H. Hamada, T. Yamaji Performance of seawater-mixed concrete in the tidal environment Cem Concr Res, 34(4) (2004), pp. 593-601

[5]. J. Xiao, C. Qiang, A. Nanni, K. Zhang Use of sea-sand and seawater in concrete construction: current status and future opportunities Constr Build Mater, 155(2017), pp. 1101-1111

[6]. J.G. Teng, T. Yu, D. Fernando Strengthening of steel structures with fiber-reinforced polymer composites J. Constr. Steel Res., 78(2012), pp. 131-143, 10.1016/j.jcsr.2012.06.011

[7]. W.P.S. Dias, G.A.P.S.N. Seneviratne, S.M.A. Nanayakkara, Offshore sand for

[8]. reinforced concrete, Constr. Build. Mater. 22(7)(2008) 1377–1384.

[9]. Liu Handong, Yu Xinzheng, Li Guowei.Experimental study on tensile mechanical properties of GFRP bolt [ J ].Journal of Rock Mechanics and Engineering, 2005 (20): 121-125.

[10]. Zhao Qi, Zhang Daxu, Zhao Xiaolin, Wang Wenhua. Damage evolution test and model study of epoxy GFRP bars in seawater and sea sand concrete pore solution environment [J/OL].Journal of Civil Engineering: 1-18[2022-08-21].DOI: 10.15951 / j.tmgcxb.21080781.

[11]. Sun Li, Zhang Na. Compressive performance test of GFRP bars under seawater environment corrosion[J]. Journal of Shenyang Jianzhu University(Natural Science Edition), 2013, 29(01): 36–43.

[12]. Xue Weichen, Wang Wei, Fu Kai. Tensile test of GFRP bars with different stress levels in alkali environment[J]. Journal of Composite Materials, 2013,30(06): 67-75.DOI: 10.13801/j.cnki.fhclxb.2013.06.017.

[13]. O. Gunes, D. Lau, C. Tuakta, O. Büyükoztürk, ¨Ductility of FRP–concrete systems: Investigations at different length scales, Constr. Build. Mater. 49(2013) 915–925.

[14]. F. Guo, S. Al-Saadi, R.K. Singh Raman, X.L. ZhaoDurability of Fiber Reinforced Polymer (FRP) in Simulated Seawater Sea Sand Concrete(SWSSC) Environment. https://doi.org/10.1016/j.corsci.2018.06.022

[15]. Li Shan, Ren Huitao, Huang Chengkui, Shi Muhuan. Durability of FRP sheets under temperature and alkali solution[J].Journal of Building Materials, 2010,13(01): 94-99.