1. Introduction

With the rapid advancement of technology and the continuous improvement of public health awareness, the demand for various advanced materials in the biomedical field has become increasingly urgent, leading to the emergence of biomedical textile materials, which have now become a hot research topic.

From a health perspective, the global population is aging rapidly, and the incidence of various diseases is on the rise, such as cardiovascular diseases and diabetes, with a large number of patients suffering from these chronic conditions. These diseases often require long-term or even lifelong treatment and care, and traditional medical methods and materials have significant limitations in terms of functionality and comfort. For example, traditional wound dressings only provide basic protective functions, whereas new biomedical textile materials (such as silk protein, chitin, and PCL) can offer multiple functions such as promoting wound healing, antibacterial and anti-inflammatory properties, and monitoring wound conditions, significantly improving patients' quality of life.

From an industrial development perspective, textile technology continues to innovate, with significant advancements in fiber manufacturing and weaving processes, providing a solid foundation for the research and development of biomedical textile materials. Additionally, the interdisciplinary integration of materials science, biomedical engineering, and other fields enables researchers to explore and design new biomedical textile materials from various perspectives, optimizing material performance and expanding functional capabilities. For example, by applying nanotechnology to textile materials, properties such as antibacterial, anticoagulant, and drug-releasing functions can be imparted to the materials.

Furthermore, biomedical textile materials demonstrate significant potential in the field of regenerative medicine. In tissue engineering and organ repair, biodegradable biomedical textile materials can serve as tissue engineering scaffolds, providing a three-dimensional supportive environment for cell adhesion, proliferation, and differentiation. As cells grow, the materials gradually degrade and are ultimately absorbed by the human body, eliminating the need for secondary surgery to remove them, thereby reducing patient discomfort and medical risks.

However, current biomedical textile materials still face numerous challenges, such as the need to further improve their biocompatibility and biosafety to ensure they do not trigger immune reactions or toxicity when used long-term in the human body. The need to optimize their mechanical properties to better match human tissue requirements for different anatomical locations; and the urgent need to address issues such as cost control and large-scale production technologies to enable their widespread application. Therefore, in-depth research on biomedical textile materials holds significant theoretical significance and practical application value.

2. Synthesis of biomedical textile materials

The mainstream synthesis methods for textile materials encompass electrospinning technology and traditional weaving techniques. Electrospinning technology, after decades of development, has transitioned from laboratory research to industrial applications, playing a pivotal role in the production of nanofibers and demonstrating significant potential across multidisciplinary fields such as biomedicine, environmental protection, and energy storage. Its core advantage lies in the ability to precisely control fiber diameter, porosity, and other microstructural parameters, maximizing the specific surface area of the material while being compatible with various biocompatible polymers and active additives. Currently, this technology has established standardized processes encompassing solution preparation, optimization of electric field parameters, and fiber post-processing, enabling the stable production of nanofiber membranes or fiber scaffolds with consistent performance. It has become a key enabling technology for the development of advanced functional textiles.

2.1. Electrospinning

2.1.1. Principle of electrospinning

The basic principle of electrospinning involves the interaction between electric field forces and surface tension. Under the influence of a high-voltage electric field, a polymer-containing solution is stretched at the needle tip, forming a Taylor cone structure. As the electric field strengthens, charge separation occurs within the droplet, leading to increased surface tension, which further stretches the droplet into an electrically charged jet. This jet carries a large number of polymer molecules and travels at extremely high speeds toward the receiving device, forming fine and uniform fiber bundles. During this process, the jet undergoes various interactive forces that aid in cutting and refining the jet into a nanofiber membrane during solvent evaporation. [1]

Typically, electrospinning can be divided into four consecutive stages:

1. Droplet charging and Taylor cone formation: The polymer solution becomes charged at the needle tip under the influence of an electric field, and the surface tension balances with the electric field force to form a conical liquid surface (Taylor cone).

2. Jet formation: When the electric field force exceeds the surface tension, the charged droplet is ejected from the tip of the Taylor cone, forming a stable jet.

3. Jet stretching and instability due to whipping motion: As the jet travels toward the receiving device, it undergoes intense whipping motion due to electrostatic repulsion and air resistance, causing its diameter to sharply decrease and refine to the nanoscale.

4. Fiber solidification and collection: After solvent evaporation, the polymer solidifies into nanofibers, which ultimately deposit on the receiving device to form a fiber membrane or felt.

2.1.2. Classification of electrospinning

Depending on the spinning solution or nozzle used, electrospinning can be further classified into three distinct types: single-axis (blended) electrospinning, coaxial electrospinning, and emulsion electrospinning, as shown in Figure 1. Among these methods, single-axis electrospinning is the most widely used technique, where a uniform solution of the spinning matrix and active substance is electrospun through a single nozzle. In contrast, coaxial electrospinning uses a coaxial nozzle to produce nanofibers with a “core-shell” structure. Finally, emulsion electrospinning involves directly spinning pre-prepared stable emulsions (water-in-oil or oil-in-water emulsions), which are mixed with the nozzle before spinning.

![Figure 1. Schematic diagram of electrospinning classification: (A) Single-axis electrospinning (B) Coaxial electrospinning (C) Emulsion electrospinning. [2]](https://file.ewadirect.com/press/media/markdown/document-image1_A45eNYU.png)

2.1.3. The development and application of electrospinning

The origins of electrospinning technology can be traced back to early research. In 1745, Bose described the phenomenon of generating aerosols by applying a high potential to droplets [3]. In 1882, Lord Rayleigh investigated the amount of charge required to overcome the surface tension of droplets [4]. Subsequently, Cooley and Morton each filed patents in 1902 and 1903 for the first devices to eject liquids by applying charges [5-7]. In 1929, Hagiwaba et al. reported a method for preparing artificial silk using charges [8]. In 1934, Anton Formhals of Mainz first proposed the key patent describing plastic electrospinning (traceable to a German patent application from 1929) [9]. Despite the significance of these early discoveries, the process did not achieve commercial application. In the 1970s, Simm et al. applied for a patent for the production of fibers with diameters less than 1 micrometer [10], but this work and subsequent patents remained unnoticed. Electrospun fibers were first commercially applied in the filtration field, becoming part of the nonwoven fabric industry [11].

. In the field of medicine, electrospinning technology has garnered significant attention due to its unique advantages. This technology enables the production of nanofibers with high specific surface area, excellent porosity, and adjustable fiber structure, opening new avenues for the development of wound dressings, fiber scaffolds, and drug delivery systems. In the context of wound dressings, electrospun nanofibers can mimic the human extracellular matrix, promoting cell adhesion and proliferation, thereby accelerating wound healing. Additionally, their porous structure facilitates wound ventilation and the absorption of exudates. As fiber scaffolds, they can be used in tissue engineering and regenerative medicine to provide cells with a three-dimensional growth environment and guide tissue regeneration. In the field of drug delivery, nanofibers can load various drugs, enabling slow-release drug delivery, extending drug action time, and enhancing therapeutic efficacy. Therefore, in-depth research into the application of electrospinning technology in the medical field holds significant importance for advancing the development of medical materials.

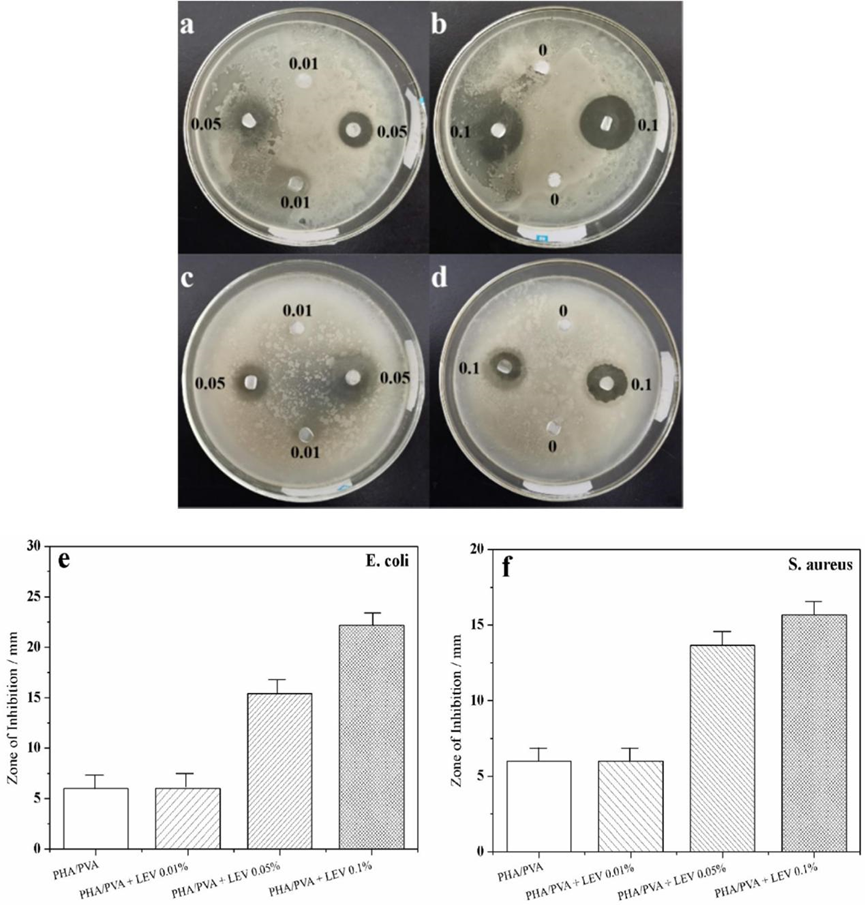

Chen et al. successfully prepared a novel porous composite membrane based on polyhydroxyalkanoate/polyvinyl alcohol (PHA/PVA) by combining electrospinning and spin-coating technologies (Figure 2). The prepared PHA/PVA composite membrane can serve as an efficient drug delivery system for levofloxacin (LEV), as its porous structure facilitates material transport. Composite membranes containing 0.05 wt% and 0.1 wt% LEV exhibited excellent antibacterial activity against Escherichia coli (E. coli) and Staphylococcus aureus (S. aureus) [12].

2.2. Weaving technology

2.2.1. Principles of weaving technology

Weaving is the process of forming fabric through the interlacing of warp and weft yarns. The basic principle involves crossing warp and weft yarns according to a specific pattern to create an interlaced structure. This process is typically carried out using a loom, whose movements include warp feeding, shedding, weft insertion, and take-up.

Knitting is the process of using a knitting machine to bend yarn into loops using hooks or needles, then linking these loops together in sequence to form fabric. The basic structure of knitting is the loop; each yarn forms one or more loops in the fabric, which are interconnected through the hooking and compression of the hooks.

Weaving is a process that involves manually or mechanically crossing or twisting yarns in a specific order to form an integrated structure. Weaving can be divided into various forms, such as plain weave, twill weave, and jacquard weave. The working principle of a weaving machine involves the coordination of yarn guiding devices, triangular devices, and weaving needles to weave yarns into fabric along a predetermined path.

2.2.2. Development and application of weaving technology

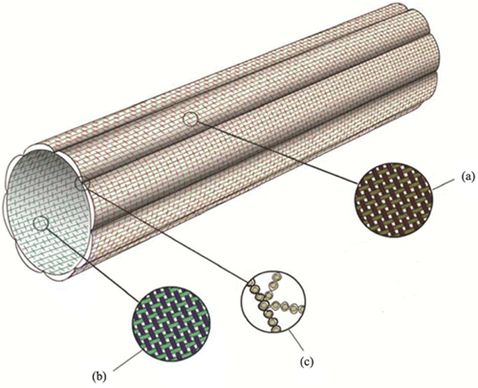

Chen et al. developed a biomimetic woven vascular prosthesis sample with a double-walled structure to minimize radial compliance mismatch between natural arteries and the vascular prosthesis across the entire blood pressure range (Figure 3). The inner layer of the sample uses poly(trimethylene terephthalate) (PTT) filaments as circumferential yarns to enhance the radial compliance of the inner wall; the outer layer is composed of poly(ethylene terephthalate) (PET) filaments, providing a sturdy and more rigid external prosthesis wall. Through a special woven design, the cross-section of the tubular sample includes an outer layer that is circumferentially curled around the inner layer. This double-wall structure causes only the inner layer to undergo radial deformation under small loads equivalent to low normal physiological (diastolic) blood pressure. As the load increases, the inner layer stretches until it contacts the outer layer. At higher (systolic) pressures, further loading causes both inner and outer layers to deform together. Therefore, when the load is within the normal diastolic pressure range, the prosthesis exhibits high pressure-induced compliance, while compliance is lower at higher systolic pressures. [13]

3. Research progress in biomedical textile materials

In addition to platinum, other members of the platinum family of metals exhibit electrocatalytic properties, but still face bottlenecks such as high preparation costs, limited catalytic efficiency and insufficient cycling stability in practical applications. In order to solve the above technical shortcomings, the development of non-precious metal catalyst systems needs to meet the key design indexes: the construction of new catalytic systems needs to follow the following core guidelines: (1) The catalytic efficiency and operational stability needs to reach a comparable level of performance with platinum-based catalysts. (2) electrolyte corrosion resistance, not easy to redox reactions leading to corrosion; (3) good electrical conductivity; (4) high specific surface area, capable of adequate adsorption; (5) structural stability, good durability; (6) high surface mass transfer rate.

Based on the above design principles, a transition metal-based non-precious metal catalyst (NPMC) can be used to replace the Pt cathode.NPMCs can be broadly categorized into two types: transition metal compounds and transition metal-carbon composites. This paper mainly summarizes the catalysts from three categories: transition metal carbides, transition metal nitrides, and transition metal nitrogen-carbon composites.

3.1. Biomass polymers

Common biomass polymers include chitosan and gelatin. Chitosan is a natural antimicrobial agent with broad-spectrum antimicrobial properties, effectively inhibiting the growth of various bacteria and fungi. The antimicrobial mechanism of chitosan against bacteria includes disrupting bacterial cell walls, inhibiting bacterial mRNA and protein synthesis, and chelating with metal ions. When the pH value is below 6, the C-2 amino group of chitosan carries a positive charge, leading to interactions between chitosan and bacterial cells. This interaction alters the integrity of the cell wall and causes DNA attachment, ultimately inhibiting DNA replication and leading to bacterial cell death. The antifungal properties of chitosan manifest as its ability to effectively inhibit fungal spore germination, germ tube elongation, and radial growth, which may be attributed to the regulatory changes induced by chitosan in host-fungus interactions. Therefore, chitosan can be used to prepare antimicrobial dressings. Yin et al. used a homemade spherical cross-section free-surface electrospinning device to prepare a large amount of electrospun porous polylactic acid (PLA)/chitosan (CS)/aloe vera nanofiber membranes (NFMs) for antimicrobial wound dressings.The porous nanofiber membranes exhibited high porosity, acceptable mechanical properties, moderate hydrophobicity, good swelling properties, and high water vapor permeability. Additionally, they demonstrated excellent hemostatic, antimicrobial, and biocompatible properties, showing potential for use in antimicrobial wound dressings. [14]

Gelatin is a natural hydrophilic polymer with excellent biological properties, including biodegradability, biocompatibility, non-immunogenicity, and low cost. Additionally, this polymer contains the arginine-glycine-aspartic acid (RGD) sequence, which promotes cell adhesion. The gelatin sheath exhibits significant fiber hydrophilicity, which is crucial for enhancing the biological efficiency of biomaterials during cell contact. Therefore, it is used to prepare scaffolds with the biocompatible characteristics required for cell adhesion and proliferation. Due to its excellent properties, gelatin is widely used as a biomaterial in drug delivery systems (DDSs) and tissue engineering. Dongargaonkar et al. successfully electrospun gelatin blended with gelatin-dendrimer conjugates containing different loads of silver acetate into nanofiber constructs. By reacting with PEG DA575, a photoreactive polyethylene glycol diacrylate, the structure stability of the nanofiber constructs was enhanced without compromising the nanofiber morphology. Due to their porous structure, the sIPN nanofiber constructs (NCs) exhibit excellent swelling capacity and permeability to aqueous solutions. They enable sustained release of silver and exhibit antimicrobial activity against two common pathogens—Staphylococcus aureus and Pseudomonas aeruginosa. By introducing dendrimers into gelatin nanofibers via covalent conjugation, not only is the drug-loading capacity of the nanofiber constructs expanded, but it also provides significant flexibility for developing multifunctional electrospun dressing materials. [15].

3.2. Synthetic polymers

The application of synthetic polymers in the field of biomedical textile materials has provided a new solution for the development of modern medicine. Synthetic polymers, with their designable structure and properties, as well as excellent processability, have become an important component of biomedical textile materials, demonstrating broad application prospects.

Common synthetic polymers include PLGA and UHMWPE. PLGA nanoparticles are highly favored due to their excellent biocompatibility, biodegradability, controlled release properties, and the ability to regulate drug delivery through adjustments in molecular weight and chemical structure. It has been reported that the amphiphilic nature of PLGA can be utilized for the delivery of drugs such as insulin, oligonucleotides, rifampicin, and budesonide. PLGA nanoparticles provide a platform for various surface modifications, which enable targeted delivery and enhance cellular uptake. Combining PLGA polymer nanoparticles with antimicrobial agents can reduce adverse reactions and achieve more effective local delivery. Mayattu et al. synthesized PLGA-erythromycin nanoparticles (PLGA-Ery NPs) for drug delivery targeting Escherichia coli, Staphylococcus aureus, and Pseudomonas aeruginosa. PLGA-Ery NPs exhibit high drug loading capacity and slow sustained release characteristics. These nanoparticles exhibit highly effective inhibitory activity against bacteria, and scanning electron microscopy reveals that they can disrupt the bacterial outer cell wall. PLGA-Ery NPs are non-cytotoxic and non-hemolytic. Additionally, they can effectively inhibit biofilm formation by Pseudomonas aeruginosa. Such nanoparticle-drug nanomedicines can be applied for the eradication of bacterial diseases and as inhalation formulations for combating pulmonary infections.

As a load-bearing surface material, ultra-high molecular weight polyethylene (UHMWPE) is widely used due to its exceptional physical and mechanical properties—including lubricity, low friction coefficient, excellent wear resistance, and impact resistance, as well as high resistance to corrosive chemicals — has long been the preferred material for biomedical implants. Ren et al. prepared a highly antibacterial ultra-high molecular weight polyethylene (UHMWPE) implant by incorporating tea polyphenols. The presence of tea polyphenols not only enhances the oxidative stability of irradiated UHMWPE but also confers ideal antibacterial properties. This potent antibacterial activity is attributed to the ability of tea polyphenols to generate excessive intracellular reactive oxygen species and disrupt bacterial membrane structures. UHMWPE containing tea polyphenols exhibits no biotoxicity toward human adipose-derived stem cells and effectively alleviates bacterial-induced inflammation in vivo. These results suggest that UHMWPE containing tea polyphenols holds promise for use in joint replacement implants, meeting patient needs with its multifunctionality. [16]

However, the application of synthetic polymer materials in the field of biomedical textile materials still faces numerous challenges, such as biocompatibility and control of degradation rates. Further research into their application in biomedical textile materials will not only enhance medical standards but also promote the sustainable development of related industries, contributing more significantly to human health.

4. Conclusion and outlook

This paper provides a comprehensive exploration of biomedicinal textile materials, including their synthesis technologies and recent research advancements. Electrospinning technology holds a significant position due to its ability to precisely control fiber diameter, porosity, and other microscopic structures, while also being compatible with various biocompatible polymers and active additives. Its principles, classification, development, and applications are detailed, including its unique advantages in medical applications such as wound dressings, fiber scaffolds, and drug delivery systems. Traditional weaving techniques, including woven, knitted, and braided fabrics, also play important roles and have widespread applications in artificial ligaments, vascular prostheses, and wearable sensors. In terms of research progress, this paper analyzes the application of biomass polymers and synthetic polymers in biomedical textile materials. Biomass polymers such as chitosan and gelatin possess environmentally friendly characteristics such as renewability and biodegradability, demonstrating significant potential in antimicrobial dressings and drug delivery systems, though they also face challenges such as performance optimization. Synthetic polymers such as PLGA and UHMWPE leverage their designable structures and properties, as well as excellent processability, to play a significant role in the field of biomedical textile materials. However, issues such as biocompatibility and degradation rate control remain.In summary, biomedical textile materials hold significant importance in modern medicine, with broad research and application prospects. However, existing challenges must be continuously overcome to achieve broader application and sustainable development, thereby contributing to improved medical standards and the advancement of related industries.

Future research on biomedical textile materials should focus on new material development, process improvements, and interdisciplinary collaboration. More high-performance biomass and synthetic polymer materials should be explored to enhance their biocompatibility, mechanical properties, and functionality. Parameters of electrospinning and weaving technologies should be optimized, combined with emerging technologies such as 3D printing and nanotechnology, to achieve material customization. Collaboration between materials science, biology, and medicine should be strengthened to conduct in-depth mechanistic studies and clinical trials, accelerating the transformation of innovative materials into actual medical products to meet the growing demand for healthcare.

References

[1]. Wenshi Xu, Kaixuan Sun, Senlin Hou, Aibing Chen. Research progress of advanced polymer composite antibacterial materials based on electrospinning. European Polymer Journal. 2025, 222, 113623.

[2]. Tao Wang, Erzheng Su. Electrospinning meets food packaging: A promising pathway towards novel opportunities in food preservation. Food Packaging and Shelf Life. 2024, 41, 101234.

[3]. Bose, Georg Matthias. Recherches sur la cause et sur la véritable théorie de l'électricité. Wittenberg, 1745.

[4]. Rayleigh, Lord. On the Equilibrium of Liquid Conducting Masses Charged with Electricity. Philosophical Magazine 14, no. 87 (1882): 184–186.

[5]. Cooley, John Francis. Apparatus for Electrically Dispersing Fluids. U. S. Patent 692, 631. Issued February 4, 1902.

[6]. Morton, William James. Method of Dispersing Fluids. U. S. Patent 705, 691. Issued July 29, 1902.

[7]. Cooley, John Francis. "Electrically-Driven Fluid-Dispensing Apparatus. " U. S. Patent 745, 276. Issued December 1, 1903.

[8]. Hagiwara, Kotaro, Osamu Oji-Machi, and Kikuo Ku. Method for Manufacturing Artificial Filaments. Japanese Patent JPA S44-26915. Issued August 14, 1969.

[9]. Formhals, Anton. Process and Apparatus for Preparing Artificial Threads. U. S. Patent 1, 975, 504. Issued October 2, 1934.

[10]. Simm, Walter, Karl Gosling, Rainer Bonart, and Bela von Falkai. Improvements in or Relating to the Production of Non-Woven Webs. British Patent GB 1, 346, 231. Issued February 6, 1974.

[11]. Jacobsen, M. Elektrospinntechnologie. Chemiefasern/Textilindustrie 41, no. 93 (1991): 36–41.

[12]. Shengnan Chen, Jianwei Gao, Eryun Yan, Yan Wang, Yuxin Li, Hong Lu, Linlin Fan, Dianyu Wang, Qinglong An. A novel porous composite membrane of PHA/PVA via coupling of electrospinning and spin coating for antibacterial applications. Materials Letters. 2021, 301, 130279.

[13]. Ying Chen, Xin Ding, Yuling Li, Martin W. King, Jie Gao, Xueqian Zhao. A bilayer prototype woven vascular prosthesis with improved radial compliance. The Journal of The Textile Institute. 2012, 103(1):106-111.

[14]. Jing Yin, Lan Xu, Adnan Ahmed. Batch Preparation and Characterization of Electrospun Porous Polylactic Acid-Based Nanofiber Membranes for Antibacterial Wound Dressing. Advanced Fiber Materials. 2022, 4, 832-844.

[15]. Alpana A. Dongargaonkar, Gary L. Bowlin, Hu Yang. Electrospun Blends of Gelatin and Gelatin–Dendrimer Conjugates As a Wound-Dressing and Drug-Delivery Platform. Biomacromolecules. 2013, 14(11):4038-4045.

[16]. Yue Ren, Fei-Yu Wang, Zi-Jian Chen, Ri-Tong Lan, Ren-Huan Huang, Wan-Qun Fu, Rizwan M. Gul, Jing Wang, Jia-Zhuang, Zhong-Ming Li. Antibacterial and anti-inflammatory ultrahigh molecular weight polyethylene/tea polyphenol blends for artificial joint applications. Journal of Materials Chemistry B. 2020, 8, 10428-10438.

Cite this article

Yin,Z. (2025). Research Progress in Biomedical Textile Materials. Applied and Computational Engineering,172,73-81.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-FMCE 2025 Symposium: Semantic Communication for Media Compression and Transmission

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Wenshi Xu, Kaixuan Sun, Senlin Hou, Aibing Chen. Research progress of advanced polymer composite antibacterial materials based on electrospinning. European Polymer Journal. 2025, 222, 113623.

[2]. Tao Wang, Erzheng Su. Electrospinning meets food packaging: A promising pathway towards novel opportunities in food preservation. Food Packaging and Shelf Life. 2024, 41, 101234.

[3]. Bose, Georg Matthias. Recherches sur la cause et sur la véritable théorie de l'électricité. Wittenberg, 1745.

[4]. Rayleigh, Lord. On the Equilibrium of Liquid Conducting Masses Charged with Electricity. Philosophical Magazine 14, no. 87 (1882): 184–186.

[5]. Cooley, John Francis. Apparatus for Electrically Dispersing Fluids. U. S. Patent 692, 631. Issued February 4, 1902.

[6]. Morton, William James. Method of Dispersing Fluids. U. S. Patent 705, 691. Issued July 29, 1902.

[7]. Cooley, John Francis. "Electrically-Driven Fluid-Dispensing Apparatus. " U. S. Patent 745, 276. Issued December 1, 1903.

[8]. Hagiwara, Kotaro, Osamu Oji-Machi, and Kikuo Ku. Method for Manufacturing Artificial Filaments. Japanese Patent JPA S44-26915. Issued August 14, 1969.

[9]. Formhals, Anton. Process and Apparatus for Preparing Artificial Threads. U. S. Patent 1, 975, 504. Issued October 2, 1934.

[10]. Simm, Walter, Karl Gosling, Rainer Bonart, and Bela von Falkai. Improvements in or Relating to the Production of Non-Woven Webs. British Patent GB 1, 346, 231. Issued February 6, 1974.

[11]. Jacobsen, M. Elektrospinntechnologie. Chemiefasern/Textilindustrie 41, no. 93 (1991): 36–41.

[12]. Shengnan Chen, Jianwei Gao, Eryun Yan, Yan Wang, Yuxin Li, Hong Lu, Linlin Fan, Dianyu Wang, Qinglong An. A novel porous composite membrane of PHA/PVA via coupling of electrospinning and spin coating for antibacterial applications. Materials Letters. 2021, 301, 130279.

[13]. Ying Chen, Xin Ding, Yuling Li, Martin W. King, Jie Gao, Xueqian Zhao. A bilayer prototype woven vascular prosthesis with improved radial compliance. The Journal of The Textile Institute. 2012, 103(1):106-111.

[14]. Jing Yin, Lan Xu, Adnan Ahmed. Batch Preparation and Characterization of Electrospun Porous Polylactic Acid-Based Nanofiber Membranes for Antibacterial Wound Dressing. Advanced Fiber Materials. 2022, 4, 832-844.

[15]. Alpana A. Dongargaonkar, Gary L. Bowlin, Hu Yang. Electrospun Blends of Gelatin and Gelatin–Dendrimer Conjugates As a Wound-Dressing and Drug-Delivery Platform. Biomacromolecules. 2013, 14(11):4038-4045.

[16]. Yue Ren, Fei-Yu Wang, Zi-Jian Chen, Ri-Tong Lan, Ren-Huan Huang, Wan-Qun Fu, Rizwan M. Gul, Jing Wang, Jia-Zhuang, Zhong-Ming Li. Antibacterial and anti-inflammatory ultrahigh molecular weight polyethylene/tea polyphenol blends for artificial joint applications. Journal of Materials Chemistry B. 2020, 8, 10428-10438.