1. Introduction

Leveraging the inherent strengths of ceramics, Ceramic Matrix Composites (CMCs) are advanced structural materials that achieve superior fracture toughness through an architecture of ceramic fibers embedded in a ceramic matrix [1]. To enhance toughness and durability while preserving the high-temperature, wear, and corrosion resistance of ceramics, these composites are engineered with continuous reinforcing fibers. This design greatly boosts fracture toughness, allowing for superior performance under high loads and harsh conditions. As such, continuous fiber-reinforced CMCs have become a leading candidate for turbine engine hot-section components [2]. Typically, a CMC is composed of three key components: the matrix material, reinforcing fibers, and interphase layer [3]. Each component plays a distinct and critical role in determining the composite’s performance. The matrix provides structural integrity and load distribution, while the reinforcing fibers enhance strength and toughness. The interphase, meanwhile, governs fiber-matrix interactions, influencing crack resistance and damage tolerance [4]. Generally, the ceramic matrix consists of either oxide ceramics (such as Al2O3) or non-oxide ceramics (like SiC and Si3N4), which bind the fibers together and distribute mechanical loads [5]. The reinforcing fibers, commonly carbon or silicon carbide fibers, bear the primary load and greatly boost the composite’s mechanical properties. Collectively, these elements define the composite’s performance.

In CMCs, the interface, where fibers interact with the ceramic matrix, is crucial for load transfer efficiency, fracture toughness, and thermal stability. Its design significantly impacts mechanical performance and durability.The failure mechanisms of CMCs are closely tied to the nature of the interfacial bond between the fiber and matrix. This bond can be characterized as either an interface or an interphase, both of which play a critical role in load transfer [6]. The fiber/matrix interface critically governs mechanical behavior, damage tolerance, and long-term durability. Thus, the paper reviews recent advances in interface modification technologies, including coating methods and interphase design. By analyzing the strengths and limitations of various approaches, it provides a comprehensive overview of current research progress in CMCs interface engineering, assesses the effectiveness of different modification techniques, and proposes future directions for developing advanced interfaces suitable for extreme environments.

2. Evolution of interface research in ceramic matrix composites

2.1. Early research on CMCs interfaces

CMCs have attracted widespread attention in high-temperature and high-stress applications due to their excellent thermal stability, mechanical strength, and damage tolerance. CMCs mainly consist of three components: reinforcing fibers, an interphase layer, and the matrix material. Among these, the fiber/matrix interface plays a decisive role in determining the mechanical properties, toughness, and long-term durability of the composite.

Early research primarily focused on the development and application of foundational systems such as C/C (carbon/carbon), SiC/SiC (silicon carbide/silicon carbide), and oxide/oxide composites. Non-oxide CMCs consist of various base matrices combined with fillers and reinforcements [7]. For example, C/C composites were extensively employed in spacecraft thermal protection systems for their exceptional high-temperature performance, low density, high strength, and thermal shock resistance. SiC/SiC composites, thus offering outstanding oxidation resistance, mechanical strength, and corrosion resistance at elevated temperatures, emerged as ideal materials for hot-section components in aero-engines. Oxide/oxide composites, valued for their excellent oxidation resistance, cost-effectiveness, and favorable dielectric properties, were widely applied in high-temperature wave-transparent structures such as radomes.

These studies focused on improving the mechanical strength, temperature resistance, and fracture toughness of CMCs. Special emphasis was placed on the fiber-matrix interface, as it plays a crucial role in governing the composite’s mechanical properties and toughness. Nonetheless, early CMCs faced major challenges in interface design: strong bonding caused brittle fracture, weak bonding led to fiber-matrix debonding, and high-temperature oxidation degraded the interface, all compounded by complex processing. Accordingly, thin interphase coatings such as carbon or boron nitride (BN), were introduced to enhance stress redistribution and improve fracture resistance.

The last two decades have seen extensive research on the processing and toughening of Fiber Reinforced Ceramic Matrix Composites (FRCMCs), particularly in the United States, Japan, and the European Community. Notable progress has been achieved, with several systems, such as C/C, C/SiC, SiC/SiO2, and SiC/SiC composites, successfully applied in aerospace components, including rocket nozzles, radomes, engine nose caps, and turbine blades [8]. Table 1 presents a comparison between the properties of FRCMCs and monolithic ceramics [9].

|

Material |

|

K_IC (MPa·m1/2) |

Remarks |

|

Nicalon/Glass |

830 |

18.9 |

Slurry infiltration and hot pressing |

|

LAS |

200 |

2 |

Slurry infiltration, hot pressing |

|

Nicalon/LAS |

830 |

17 |

Slurry infiltration, hot pressing |

|

SCS-6/SiO2 |

950 |

10.5 |

Fully dense |

|

SCS-6/Al2O3 |

550 |

4–5 |

Melt infiltration and hot pressing |

|

Polycrystalline Al2O3 |

800 |

8.7 |

Chemical vapor infiltration (CVI) |

|

SiC Crystal/Al2O3 |

400 |

26 |

CVI |

|

Nicalon/SiC |

476 |

σ = 200 MPa at 3% strain |

Brittle |

|

Sintered SiC |

439 |

- |

CVI |

|

CVD-SiC/SiC |

950 |

3.4–4.5 |

Hot pressing |

|

Si3N4 |

473 |

15.6 |

Slurry infiltration and hot pressing |

|

C/Si3N4 |

454 |

- |

Slurry infiltration |

|

SCS-6/RBSN |

900 |

24 |

Weibull modulus |

|

RBSN |

260 |

56 |

Slurry infiltration and hot pressing |

|

SiC Crystal/Si3N4 |

800 |

- |

Hot pressing |

|

Si3N4 |

873 |

- |

Hot pressing |

Compared with monolithic ceramics, FRCMCs exhibit significantly improved fracture toughness, which is key to their superior thermal shock resistance. As shown in the table, composites such as Nicalon/Glass, Nicalon/LAS, and SCS-6/SiO2 demonstrate much higher fracture toughness (K_IC) than traditional ceramics. For instance, SiC crystal/Al2O3 reaches 26 MPa·m1/2, SCS-6/RBSN 24 MPa·m1/2, and RBSN up to 56 MPa·m1/2, whereas sintered SiC only achieves 3.4-4.5 MPa·m1/2, making it more susceptible to cracking under thermal shock. This enhanced resistance is closely tied to interfacial engineering. The interphase between fibers and matrix, often consisting of carbon or BN coatings, effectively deflects crack propagation and dissipates energy at the interface, thus preventing direct crack penetration into the fibers. This mechanism reduces material brittleness and preserves structural integrity under extreme thermal fluctuations. As a result, optimizing interfacial design is critical to improving both toughness and thermal shock resistance in FRCMCs. In addition, extensive studies have focused on the thermal stability and oxidation resistance of CMC interfaces, which are critical for high-temperature aerospace and automotive applications. And improvements in interface engineering have significantly improved CMC performance in oxidative environments, thereby extending service life.

Environmental factors such as moisture, thermal cycling, and chemical exposure have also been extensively studied, as understanding their effects is essential for predicting the long-term reliability of CMCs. Modern microscopy and spectroscopy techniques have enabled micro- and nanoscale analysis of interfaces, offering deeper insight into the mechanisms governing composite behavior. These findings are vital for the continued development and optimization of CMCs, ensuring reliable performance under extreme conditions and expanding their application range.

2.2. Recent advancements in interface engineering

In the past five years, there has been notable advancement in CMC interface research, particularly in the development of new interface materials, studies on thermodynamic performance, and the application of advanced characterization techniques. Novel interface materials have been developed, including nanoscale multifunctional coatings fabricated through chemical vapor deposition (CVD) and atomic layer deposition (ALD) techniques. These coatings are designed to enhance the adhesion between fibers and the matrix, thereby improving the overall performance of the composites.

Besides, notable advancements have been made in the thermodynamic and chemical stability of CMC interfaces, particularly for applications in extreme temperatures and corrosive environments. Optimized interface designs have greatly improved oxidation resistance and thermal shock stability at high temperatures. And advanced characterization technologies like high-resolution transmission electron microscopy (HRTEM), scanning electron microscopy (SEM), and synchrotron radiation X-ray microanalysis have enabled detailed observation of the microstructure and defects at the interfaces, providing deep insights into the mechanisms of interface failure, which are crucial for guiding future material designs.

Recent advances in nanotechnology and surface treatments have led to innovative methods for interface engineering. Techniques such as coating fibers with nanoparticles or using interphases that bond chemically with both the fiber and the matrix enable more precise control over the properties of the interface, leading to composites with tailored performance characteristics. Additionally, the mechanical behavior of interfaces has achieved breakthroughs, particularly under complex loading conditions. Experiments and simulations have demonstrated that precise interface engineering can greatly improve fracture toughness and fatigue life under multiaxial loading. With advancements in computational technology, numerical simulations of CMCs interfaces have become increasingly accurate, offering valuable insights for predicting material behavior and optimizing designs. These research achievements advance CMC technologies while providing a solid scientific foundation for their application in industries such as aerospace, automotive, and energy.

3. Performance enhancements of CMCs through interface engineering

The interface in CMCs plays a pivotal role in defining their thermal stability, oxidation resistance, mechanical strength, and environmental durability. Through advanced engineering techniques, such as interfacial coatings, nanostructured layers, and chemical modifications, CMC performance has been greatly enhanced, supporting their use in demanding environments like aerospace, automotive, and energy systems.

3.1. Enhancing thermal and oxidation stability through interface design

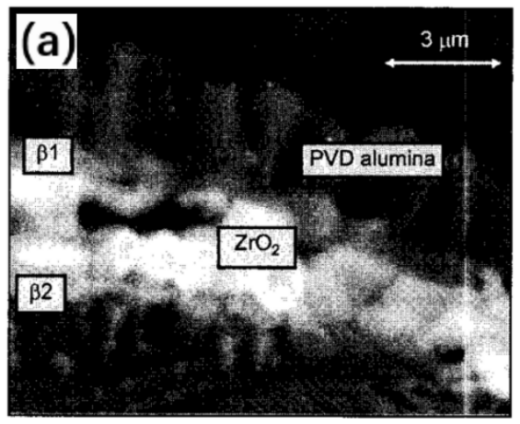

CMCs operate under extreme thermal conditions, making thermal stability a critical factor in their design. Previous studies have shown that CMC surfaces gradually degrade and fail with increasing transient thermo-mechanical cycles [10]. The mismatch between the thermal expansion coefficients (TECs) of fibers and the matrix can lead to residual stresses, microcrack formation, and premature material failure. Besides, that Al2O3 and SiC coatings enhance thermal stability, helping maintain CMC integrity at temperatures above 1400°C [11]. Well-engineered interfaces accommodate TEC mismatches, reducing residual stresses and mitigating thermal shock damage. As shown in Figure 1, heat treatment in reducing atmospheres leads to in-situ reaction layers and improves phase stability, while air-treated samples exhibit grain coarsening without β-alumina formation, highlighting the importance of interface engineering and atmosphere control for high-temperature durability

In high-temperature oxidative environments, oxidation resistance is a key challenge for CMCs. The degradation of fiber-matrix interfaces due to oxidation leads to strength loss and structural failure. Lee et al. indicated that yttrium disilicate (Y2Si2O7) and hafnium-based oxides serve as protective environmental barrier coatings (EBCs), thus effectively preventing steam oxidation and surface recession in SiC-based CMCs [12]. Similarly, Kerans et al. highlighted that by greatly reducing oxygen diffusion, BN interphases help preserve fiber strength and enable controlled failure mechanisms [13]. T Gyoktepeliler-Akin et al. found that the development of dense SiC coatings substantially reduces oxidation pathways, significantly extending CMC service life in aerospace propulsion systems [14]. These advancements ensure that CMC components in aircraft engines and space vehicles remain durable under oxidative stress.

3.2. Enhancing mechanical strength and fracture toughness

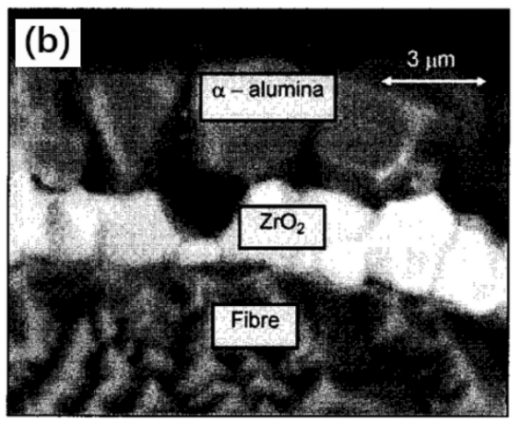

The mechanical performance of CMCs is strongly influenced by interface design, which determines load transfer efficiency, stress distribution, and fracture behavior. Poorly engineered interfaces can lead to brittle failure, while optimized interfaces enhance damage tolerance and overall structural strength. Xu et al. Showed that weak interphases, such as BN or carbon coatings, enhance fracture toughness by enabling controlled fiber pull-out and crack deflection [15]. In contrast, Guo et al. demonstrated that SiC or TiB2 nanoparticle reinforcement at the interface strengthens the matrix, improving load transfer efficiency and wear resistance [16]. Furthermore, Wang et al. Found that plasma and chemical surface treatments modify fiber surfaces, improving fiber-matrix bonding characteristics and ensuring superior stress distribution and fatigue resistance under cyclic loading, and its crack propagation diagram at the interphase is shown in Figure 2 [17].

3.3. Enhancing environmental resistance for long-term durability

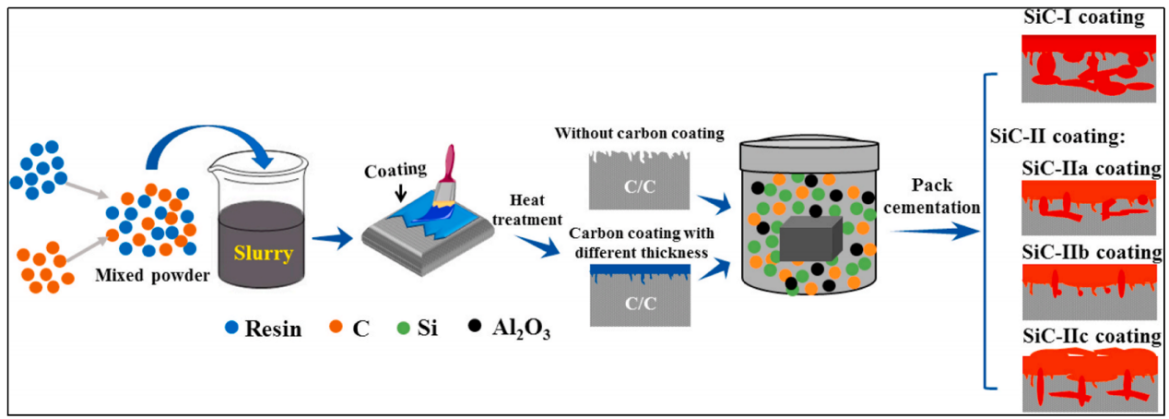

The performance of CMCs is often compromised due to the degradation of fiber-matrix interfaces when exposed to corrosive, humid, and chemically aggressive environments. Li et al. demonstrate that SiC-BN-SiC multilayer coatings effectively protect against chemical degradation, especially in marine and industrial applications, with the schematic preparation of the SiC-I and SiC-II coatings shown in Figure 3 [18,19]. Moreover, Gerendaś and Cadoret emphasize that high-entropy ceramic coatings provide both thermal and chemical protection, reducing chemical attack from hot gas environments and maintaining structural integrity in rocket engines and energy conversion systems.

By utilizing advanced interface engineering, CMCs have been optimized to perform effectively in high-temperature, high-stress, and chemically aggressive environments. The potential of CMCs in aerospace, energy, and advanced manufacturing is continually expanding via ongoing research in nanotechnology, interphase design, and environmental barrier coatings.

4. Industrial Applications of engineered interface CMCs

Engineered CMCs have transformed industries like aerospace, automotive, energy, biomedical, and defense by offering exceptional thermal stability, mechanical strength, and environmental durability. Modifications at the fiber-matrix interface enhance load transfer, oxidation resistance, and crack deflection, enabling CMCs to perform in extreme environments where traditional materials fail. The following case studies highlight key applications where interface engineering has expanded CMC capabilities and driven technological advancements.

4.1. Aerospace: jet engine components and spacecraft structures

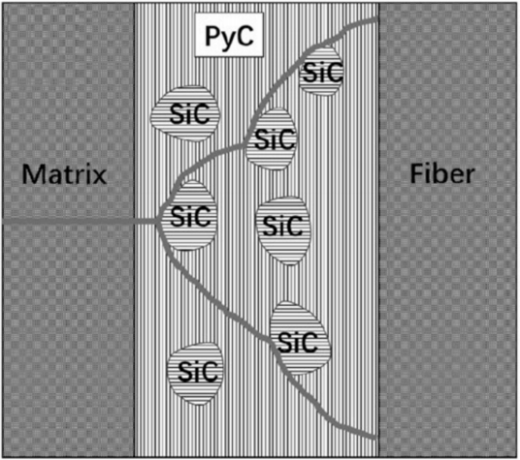

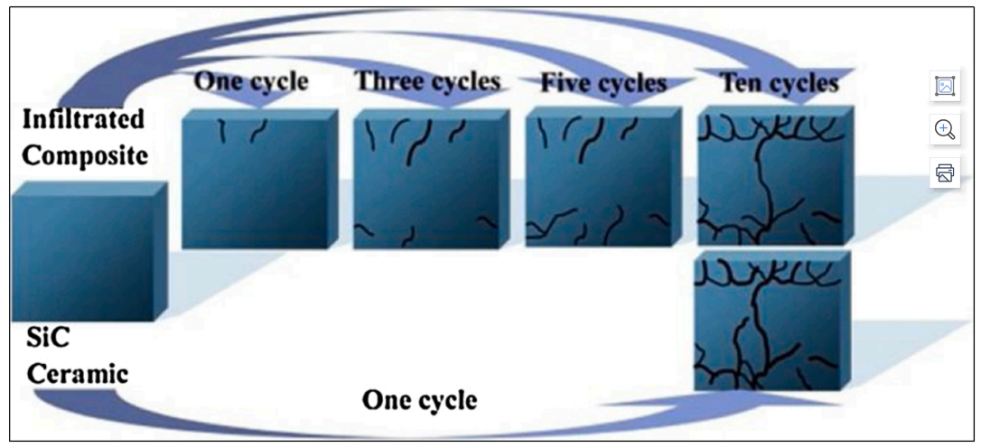

The aerospace industry requires materials that are lightweight and capable of withstanding extreme temperatures and harsh operational environments. CMCs have emerged as a superior alternative to traditional metal alloys, thus offering advantages such as low density, high strength, and excellent oxidation resistance. When integrated into jet engines, CMCs help reduce overall weight, enhance fuel efficiency, and boost high-temperature performance. Li et al. Found that silicon carbide/silicon carbide (SiC/SiC) CMCs with BN interphases exhibit markedly enhanced thermal shock resistance and fracture toughness [20]. The BN interphases mitigate thermal expansion mismatches and inhibit premature oxidation, hence enhancing component longevity and reducing the reliance on extensive cooling systems. Consequently, CMCs with such features have been increasingly adopted by NASA and commercial aerospace manufacturers in thermal protection systems (TPS) for space exploration missions, where extreme temperature fluctuations and mechanical loads are prevalent. Wang et al. further emphasize that engineered multilayer CMCs offer superior resistance to thermal shock and oxidation. As shown in Figure 4, the incorporation of an Al alloy into the SiC CMC gaps reduces thermal stress, which halts crack nucleation and dissipates propagation energy, preventing crack growth [21]. These advantages make such materials well-suited for critical aerospace applications, including heat shields, propulsion systems, and structural components in spacecraft [22].

4.2. Automotive: brake discs, exhaust systems, and engine components

For automotive applications, particularly in brake disc systems, ceramic composites offer notable advantages in thermal conductivity, wear resistance, and noise reduction. Recent research highlights the development of new materials, such as ceramic and resin matrices reinforced with fibers, that enhance brake disc performance. Among these, carbon-fiber ceramic composites have attracted growing attention for their superior thermal and mechanical properties, making them a promising focus for future innovation. Traditional materials often fall short in providing the thermal stability and wear resistance demanded by high-performance braking systems. A significant advancement is the use of oxide/oxide (Alumina/Alumina) CMCs modified with zirconia-toughened alumina (ZTA) nanoparticles at the fiber-matrix interface. This interface engineering substantially boosts thermal resistance and mechanical strength. These enhanced CMCs have been successfully applied in brake discs for sports and high-performance vehicles, offering better heat dissipation, reduced wear under high-friction conditions, and superior overall performance compared to conventional materials. Vehicles equipped with advanced CMC brake discs exhibit enhanced braking efficiency, minimized brake fade, and extended service life, boosting safety and the market appeal of high-performance automotive technologies. These case studies underscore the transformative potential of interface engineering in CMCs, enabling their broader adoption in sectors requiring high durability and performance under extreme conditions. Each innovation addresses specific technical challenges and expands the scope of CMC applications in critical industries, reinforcing their growing significance in modern engineering.

4.3. Energy and power generation: gas turbines and nuclear reactors

The energy sector demands materials that can endure extreme temperatures, corrosive environments, and high-pressure conditions. CMCs, particularly SiC and oxide/oxide composites, have proven essential in advanced power generation systems. For instance, gas turbine engines in power plants benefit from interface-engineered CMC components, offering improved thermal shock resistance and longer operational lifespans. Lee et al. indicate that CMCs with EBCs effectively resist hot corrosion and oxidation, thereby extending the durability of critical components like turbine vanes, combustor liners, and exhaust nozzles [23]. In a similar context, Lane et al. showed that hybrid oxide/oxide CMCs with functionally graded interphases enhances creep resistance and thermal efficiency, making them ideal for high-performance gas turbines and energy recovery systems [24].

4.4. Biomedical: orthopedic implants and medical devices

Beyond industrial applications, CMC-based materials are making significant strides in biomedicine, particularly in orthopedic implants, dental prosthetics, and medical imaging devices. As shown in Table 2, bioinert ceramics such as alumina, zirconia, and silicon nitride have been successfully used in a range of applications, from joint replacements to dental crowns and MRI-compatible surgical tools [25]. These materials provide outstanding wear resistance, biocompatibility, and mechanical strength, revealing the potential of ceramic matrix composites as reliable and functional materials in the biomedical sector.

|

Materials |

Applications |

|

Alumina |

Femoral heads and inserts for THA bearings Osteosynthetic devices |

|

Zirconia |

Dental implants, dental blanks for CAD/CAM Fixed partial dentures VERILAST technology |

|

ZTA/ATZ |

Femoral heads and inserts for THA Surfaces for TKA bearings Components for disc replacements (in spine surgery) |

5. Challenges and future directions in interface engineering

Despite significant progress in CMCs, several challenges still impede their widespread adoption. A key concern is achieving durable fiber-matrix bonding capable of withstanding both thermal and mechanical stresses without failure. High temperatures amplify thermal expansion mismatches, thus resulting in residual stresses and microcracking. Additionally, chemical incompatibility can further degrade the interface in extreme environments. To address these challenges, engineered interphases are being developed using materials like self-healing EBCs and high-entropy ceramics to improve oxidation resistance and thermal stability. Nevertheless, manufacturing inconsistencies in processes such as CVI and Polymer Infiltration and Pyrolysis (PIP) can compromise interface quality and increase production costs. Ongoing efforts aim to develop scalable and cost-effective methods, such as additive manufacturing, improved slurry-based techniques, and rapid densification, to lower costs while maintaining interface integrity. Interface characterization remains challenging due to complex microstructures and system variability, which complicate standardization and accurate property prediction. Advancements in multiscale modeling and machine learning are expected to improve performance predictions. Also, standardized testing protocols are needed for consistent assessment. Future research will prioritize the development of multifunctional interfaces with capabilities such as self-healing, electrical or thermal conductivity, and enhanced resistance to environmental factors. By combining novel materials, AI-driven design, and sustainable processing techniques, the path will be paved for scalable, cost-effective, and high-performance CMCs.

6. Conclusion

The study demonstrates that significant advancements in CMC interface technology have notably improved mechanical properties and broadened their application range. Key developments include enhanced fiber-matrix interactions and the use of nanotechnology to achieve stronger interface bonding. Despite this progress, challenges persist, such as manufacturing consistency, thermal and chemical incompatibility, and long-term durability in extreme environments. Future research should explore novel material combinations and advanced nanoscale engineering to further boost interface toughness and load transfer efficiency. Besides, refining computational models to accurately predict interface behavior is essential. The resolution of these challenges will expand CMC applications in aerospace, automotive, and energy sectors, driving advancements in high-performance materials.

References

[1]. Chawla, K.K. (2019) Ceramic matrix composites. In Composite Materials. Springer, Cham. https: //doi.org/10.1007/978-3-030-28983-6_7

[2]. Sørensen, B.F., & Goutianos, S. (2019) Micromechanical model for prediction of the fatigue limit for unidirectional fibre composites. Mechanics of Materials, 131, 169-187.

[3]. Dhanasekar, S., et al. (2022) A comprehensive study of ceramic matrix composites for space applications. Advances in Materials Science and Engineering, 2022(1), 6160591.

[4]. Yan, Y., Mei, H., Zhang, M., et al. (2022) Key role of interphase in continuous fiber 3D printed ceramic matrix composites. Composites Part A: Applied Science and Manufacturing, 162, 107127.

[5]. Wang, W., et al. (2022) Additive manufacturing of fiber reinforced ceramic matrix composites: Advances, challenges, and prospects. Ceramics International, 48, 19542-19556.

[6]. Yin, X.W., et al. (2017) Fibre-reinforced multifunctional SiC matrix composite materials. International Materials Reviews, 62(3), 117-172.

[7]. Padture, N.P. (2016) Advanced structural ceramics in aerospace propulsion. Nature Materials, 15, 804-809.

[8]. Shrivastava, S., et al. (2024) Ceramic matrix composites: Classifications, manufacturing, properties, and applications. Ceramics, 7, 652-679.

[9]. Carrere, N., Martin, E. and Lamon, J. (2000) The influence of the interphase and associated interfaces on the deflection of matrix cracks in ceramic matrix composites. Composites Part A, 31(11), 1179-1190.

[10]. Huang, H.W., et al. (2025) A thermo-mechanical localizing gradient damage model with modified Mazars strain. International Journal for Numerical Methods in Engineering, 126, 7652.

[11]. Cain, M.G., Cain, R.L., Tye, A., et al. (1996) Structure and stability of synthetic interphases in CMCs. Key Engineering Materials, 127, 37-50.

[12]. Lee, K.N., Garg, A. and Jennings, W.D. (2021) Effects of the chemistry of coating and substrate on the steam oxidation kinetics of environmental barrier coatings for ceramic matrix composites. Journal of the European Ceramic Society, 41(11), 5675-5685.

[13]. Kerans, R.J., Hay, R.S., Parthasarathy, T.A., et al. (2002) Interface design for oxidation-resistant ceramic composites. Journal of the American Ceramic Society, 85(11), 2599-2632.

[14]. Gyoktepeliler-Akin, E., Pastor, J.M., Semmler, C., et al. (2024) Environmental barrier coatings on alumina-reinforced CMCs: Experimental validation and numerical modeling of thermal stability. Surface and Coatings Technology, 494, 131432.

[15]. Xu, J., et al. (2015) Stability of interfaces in hybrid EBC/TBC coatings for Si-based ceramics in corrosive environments. International Journal of Refractory Metals and Hard Materials, 49, 339-349.

[16]. Guo, Q., et al. (2022) High-temperature interface stability of tri-layer thermal environmental barrier coatings. Ceramics International, 48(7), 9313-9323.

[17]. Wang, H., et al. (2020) Preparation and tensile behavior of SiCf/SiC mini composites containing different types and thicknesses of interphase. Ceramics International, 46(14), 22297-22306.

[18]. Li, T., et al. (2021) High strength retention and improved oxidation resistance of C/C composites by utilizing a layered SiC ceramic coating. Ceramics International, 47(10), 13500-13509.

[19]. Gerenda´s, M., et al. (2011) Improvement of oxide/oxide CMC and development of combustor and turbine components in the HiPOC program. In Turbo Expo: Power for Land, Sea, and Air, 54617, 477-490.

[20]. Chen, M., et al. (2022) Boron nitride (BN) and BN based multiple-layer interphase for SiCf/SiC composites: A review. Ceramics International, 48(23), 34107-34127.

[21]. Wang, W., et al. (2019) Excellent thermal shock resistance of Al alloy-infiltrated SiC composites. Journal of Materials Processing Technology, 269, 16-25.

[22]. Wang, X., et al. (2021) Advances in modifications and high-temperature applications of silicon carbide ceramic matrix composites in aerospace: A focused review. Journal of the European Ceramic Society, 41(9), 4671-4688.

[23]. Lee, M.C., et al. (2010) Gas turbine combustion performance test of hydrogen and carbon monoxide synthetic gas. Fuel, 89(7), 1485-1491.

[24]. Lane, J.E., et al. (2007) Hybrid oxide-based CMCs for combustion turbines: How hybrid oxide CMC mitigates the design hurdles typically seen for oxide CMC. In Turbo Expo: Power for Land, Sea, and Air, 4790, 267-273.

[25]. Eschweiler, J., Greven, J., Rath, B., et al. (2024) High-performance ceramics in musculoskeletal surgery: Current use and future perspectives. Ceramics, 7(1), 310-328.

Cite this article

Xia,W. (2025). Recent Advances in Interface Engineering for Enhancing the Performance of Ceramic Matrix Composites. Applied and Computational Engineering,167,62-72.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-FMCE 2025 Symposium: Semantic Communication for Media Compression and Transmission

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Chawla, K.K. (2019) Ceramic matrix composites. In Composite Materials. Springer, Cham. https: //doi.org/10.1007/978-3-030-28983-6_7

[2]. Sørensen, B.F., & Goutianos, S. (2019) Micromechanical model for prediction of the fatigue limit for unidirectional fibre composites. Mechanics of Materials, 131, 169-187.

[3]. Dhanasekar, S., et al. (2022) A comprehensive study of ceramic matrix composites for space applications. Advances in Materials Science and Engineering, 2022(1), 6160591.

[4]. Yan, Y., Mei, H., Zhang, M., et al. (2022) Key role of interphase in continuous fiber 3D printed ceramic matrix composites. Composites Part A: Applied Science and Manufacturing, 162, 107127.

[5]. Wang, W., et al. (2022) Additive manufacturing of fiber reinforced ceramic matrix composites: Advances, challenges, and prospects. Ceramics International, 48, 19542-19556.

[6]. Yin, X.W., et al. (2017) Fibre-reinforced multifunctional SiC matrix composite materials. International Materials Reviews, 62(3), 117-172.

[7]. Padture, N.P. (2016) Advanced structural ceramics in aerospace propulsion. Nature Materials, 15, 804-809.

[8]. Shrivastava, S., et al. (2024) Ceramic matrix composites: Classifications, manufacturing, properties, and applications. Ceramics, 7, 652-679.

[9]. Carrere, N., Martin, E. and Lamon, J. (2000) The influence of the interphase and associated interfaces on the deflection of matrix cracks in ceramic matrix composites. Composites Part A, 31(11), 1179-1190.

[10]. Huang, H.W., et al. (2025) A thermo-mechanical localizing gradient damage model with modified Mazars strain. International Journal for Numerical Methods in Engineering, 126, 7652.

[11]. Cain, M.G., Cain, R.L., Tye, A., et al. (1996) Structure and stability of synthetic interphases in CMCs. Key Engineering Materials, 127, 37-50.

[12]. Lee, K.N., Garg, A. and Jennings, W.D. (2021) Effects of the chemistry of coating and substrate on the steam oxidation kinetics of environmental barrier coatings for ceramic matrix composites. Journal of the European Ceramic Society, 41(11), 5675-5685.

[13]. Kerans, R.J., Hay, R.S., Parthasarathy, T.A., et al. (2002) Interface design for oxidation-resistant ceramic composites. Journal of the American Ceramic Society, 85(11), 2599-2632.

[14]. Gyoktepeliler-Akin, E., Pastor, J.M., Semmler, C., et al. (2024) Environmental barrier coatings on alumina-reinforced CMCs: Experimental validation and numerical modeling of thermal stability. Surface and Coatings Technology, 494, 131432.

[15]. Xu, J., et al. (2015) Stability of interfaces in hybrid EBC/TBC coatings for Si-based ceramics in corrosive environments. International Journal of Refractory Metals and Hard Materials, 49, 339-349.

[16]. Guo, Q., et al. (2022) High-temperature interface stability of tri-layer thermal environmental barrier coatings. Ceramics International, 48(7), 9313-9323.

[17]. Wang, H., et al. (2020) Preparation and tensile behavior of SiCf/SiC mini composites containing different types and thicknesses of interphase. Ceramics International, 46(14), 22297-22306.

[18]. Li, T., et al. (2021) High strength retention and improved oxidation resistance of C/C composites by utilizing a layered SiC ceramic coating. Ceramics International, 47(10), 13500-13509.

[19]. Gerenda´s, M., et al. (2011) Improvement of oxide/oxide CMC and development of combustor and turbine components in the HiPOC program. In Turbo Expo: Power for Land, Sea, and Air, 54617, 477-490.

[20]. Chen, M., et al. (2022) Boron nitride (BN) and BN based multiple-layer interphase for SiCf/SiC composites: A review. Ceramics International, 48(23), 34107-34127.

[21]. Wang, W., et al. (2019) Excellent thermal shock resistance of Al alloy-infiltrated SiC composites. Journal of Materials Processing Technology, 269, 16-25.

[22]. Wang, X., et al. (2021) Advances in modifications and high-temperature applications of silicon carbide ceramic matrix composites in aerospace: A focused review. Journal of the European Ceramic Society, 41(9), 4671-4688.

[23]. Lee, M.C., et al. (2010) Gas turbine combustion performance test of hydrogen and carbon monoxide synthetic gas. Fuel, 89(7), 1485-1491.

[24]. Lane, J.E., et al. (2007) Hybrid oxide-based CMCs for combustion turbines: How hybrid oxide CMC mitigates the design hurdles typically seen for oxide CMC. In Turbo Expo: Power for Land, Sea, and Air, 4790, 267-273.

[25]. Eschweiler, J., Greven, J., Rath, B., et al. (2024) High-performance ceramics in musculoskeletal surgery: Current use and future perspectives. Ceramics, 7(1), 310-328.