1. Introduction

The global level of industrial automation has significantly improved, and 3D printing technology for robots has been a rapidly developing frontier field in recent years.The integration of robots and 3D printing builds three-dimensional entities by layering materials, providing a more efficient solution for intelligent manufacturing, reducing the step effect and adapting to rapid production. Robots have the ability to move along multiple axes, which can break through the limitations of traditional 3D printing workspace and also enable the printing of large components and complex curved surfaces.

3D printing technology has advantages such as high manufacturing freedom, rapid prototyping, waste reduction, production flexibility and distributed manufacturing.Although this technology has made progress in application fields, material selection, large-scale production, and the integration of multiple materials and processes, traditional 3D printing still has some problems. For instance, due to the structural limitations of the equipment, the printing volume is usually less than 300mm × 300mm × 300mm, which cannot meet the demands of large-sized parts.The raw materials are usually in the form of coiled wire rods, and the extrusion volume is limited.Path planning algorithms may lead to stepped layering on the surface of finished products and require a large number of support structures for cantilever structure parts, which wastes raw materials and reduces work efficiency [1].

This article elaborates on the robotic arm and motion system of robots, as well as the influence of 3D printing processes and materials on the precision of robot 3D printing technology.The precision improvement of 3D printing technology based on robots requires collaborative optimization from multiple dimensions such as hardware design, control algorithms, material adaptation and printing technology.To enhance production quality, industrial robots can adjust their working positions in real time during the printing process, thus enabling precise printing from multiple angles.To enhance production efficiency, the improvement of precision helps optimize the printing path and process parameters, reducing the adjustment and correction time during the printing process.Meanwhile, the efficient motion execution capability of robots can achieve continuous and automated production, enhancing overall production efficiency.

2. The motion system of the robot

2.1. Fundamentals of motion execution and drive

High-precision robot bodies are the foundation for ensuring the precision of 3D printing.The mechanical precision and movement stability of the robot will directly affect the positioning precision of the print head during the printing process.In the model calibration method, the error factors affecting the precision performance of multi-joint industrial robots were first analyzed, which typically include joint transmission errors, kinematic parameter errors, and joint flexibility errors, among which kinematic parameter errors account for more than 80% of the total errors [2].Combined with 3D printing technology, the control system of the robotic arm is designed, including forward and inverse solution calculations of the robotic arm's movement, interpolation calculations of the path, and finally trajectory planning, to enable the robotic arm to achieve 3D printing functions and improve the smoothness of the printer's movement and printing precision [3].

If there are gaps, vibrations and wear in the robot's working system, it will cause deviations in the printing path, thereby affecting the printing precision.In the actual printing process, to ensure successful printing, the printing platform must not interfere with itself or the printed object. The movement speed of the robotic arm and the feeding speed of the extruder should both remain stable [4].The robotic arm and the receiving platform are installed horizontally and firmly fixed on the base plate to ensure the structural stability of the system. The robotic arm 3D printing system mainly consists of the EC66 robotic arm, stepper motor, printer cylinder, single screw, heating block and nozzle, ensuring the stability and printing precision of the system during operation [5].

2.2. Language, spelling, and grammar

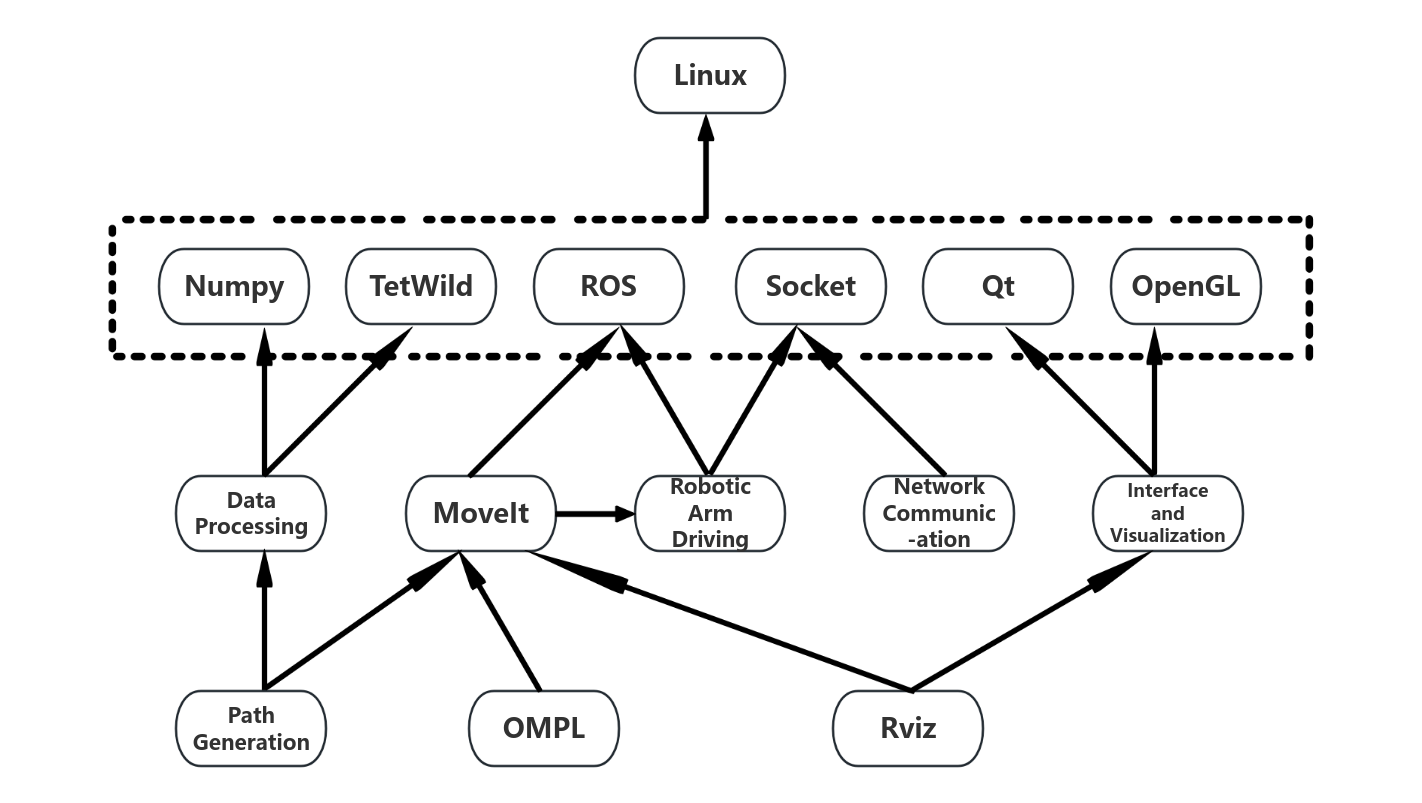

The 3D printing software system is the key to achieving efficient and precise 3D printing.Robot motion control algorithms also affect precision. Scientific and advanced algorithms can achieve more precise trajectory planning and speed control, thereby reducing movement errors.The software was burned into the single-chip microcomputer Arduino MEGA2560. First, a simple drawing experiment was conducted with the robotic arm. The results showed that the circular path planning was better.Then, a writing experiment was conducted with a robotic arm, and finally a 3D printing experiment was carried out with the robotic arm to print models of gears and bearing housings. The printer ran smoothly and the quality of the printed products was good [3].The realization of a 3D printing system for robotic arms requires the deep integration and collaborative operation of multiple software and tools. The framework relationship of some software libraries used in this design is shown in Figure 1. Through the close collaboration of the above-mentioned software, comprehensive support is provided for the precise motion control of the robotic arm and 3D printing tasks [5].

The robot program used was written in RAPID. For controlling the robotic arm during the additive manufacturing process, a robot program nicknamed RoboP3D is used. The program was developed in-house for use within the TB-RAM CoE project and it is proprietory to University of Vaasa, NOVIA and VAMK organizations [6]. Cognibotics uses high-speed, wide-range and high-precision robot systems that support robot calibration and precision enhancement, are compatible with multiple brands, and can be integrated into existing robot systems, which helps to enhance the 3D printing capabilities and precision of large metal components.

3. 3D printing technology

3.1. Printing technology and forming principles

The layering and slicing precision of 3D printing technology in three-dimensional modeling affects the enhancement of precision. Only by strengthening the precision and quality control of parts can the precision be enhanced.The robot 3d printing composite flexible manufacturing system maintains a stable motion trajectory and correct position adjustment precision through high-precision robot control technology, achieving high-precision composite printing and high-quality molding.Micro-nano 3D printing technology is developing rapidly. For example, the optical precision of the nanoArch S130 of Mofang Precision is 2 μm, while that of the nanoArch S140 is 10 μm. It can produce high-precision robot components, providing a guarantee for improving the overall precision of robots.

With the multi-degree-of-freedom advantage of the robotic arm, robot 3D printing can not only drive the nozzle mechanism installed at its end to reach any point in space, but also the posture of the nozzle mechanism is no longer limited to the vertical direction. It can approach the printing point at any Angle for multi-directional deposition [7].The main difference between the two lies in the deposition path. The deposition path direction of traditional FDM is fixed, usually adopting unidirectional or bidirectional parallel paths within the layer, which are limited to fixed angles within the plane.The multi-directional deposition path is highly flexible, not confined to a fixed plane or Angle, and can be dynamically adjusted according to the structural characteristics of the parts.Traditional FDM deposition, due to its layered accumulation, is prone to step effects on inclined surfaces or curved surfaces, resulting in a relatively high surface roughness.Multi-directional deposition, when deposited along curved surfaces or inclined paths, can reduce the step effect and make the surface smoother.The step effect is the main factor affecting the surface smoothness of formed parts. For models such as brakes and handles, the step effect is the primary issue determining whether the formed parts can be used.Robot 3D printing, based on multi-angle forming, can print coating layers along the model surface, effectively avoiding the negative impacts brought by the step effect [7].

Leong et al. proposed an innovative method that combines 3D printing with robotic arms and modular construction for constructing lattice facade structures at the meter scale. It demonstrated the wide range of flexibility of the series multi-axis robotic arm, enabling efficient manufacturing and assembly of complex geometric structures [8].The robotic arm features high degrees of freedom and flexibility, breaking the movement limitations of traditional 3D printing technology. It can adapt to various scenarios and is suitable for large-scale construction sites.Based on the ROS and MoveIt platform, motion planning and collaborative control of the robotic arm motion and pneumatic extrusion printing motion in the conformal 3D printing system are carried out. In terms of the motion planning of the robotic arm, the traditional trapezoidal acceleration and deceleration algorithm is adopted to plan the initial trajectory. Then, in combination with the uniform motion requirements at the end of the robotic arm tool, an optimization processing strategy is proposed for the trajectory [8].

3.2. Author list

Process parameters such as printing speed, temperature, layer height and fill rate directly affect printing precision.Too fast a printing speed will extrude uneven materials, affecting the molding quality. Improper temperature control can alter the material flow, leading to deformation and dimensional deviation of printed products.Improper adjustment of the layer height can affect the surface roughness and the dimensional precision of the printed workpiece.The fill rate affects the print strength and weight, and indirectly influences the precision.

Ezair et al. proposed a spatial surface generation algorithm for adaptive matching of model geometric features based on ternary bodies. This algorithm takes the non-interference condition between the nozzle and the print as a constraint, which is a more natural slicing method. It can not only improve the slicing efficiency by reducing or eliminating the support structure, but also enhance the surface quality [9].

A reasonable extrusion flow rate is crucial to the printing quality of FFF. Both excessive extrusion and insufficient extrusion will seriously affect the printing quality and the strength of the object.In FFF printing, the printing material melts through the heating block and undergoes plastic deformation at the nozzle, then is uniformly extruded at the nozzle outlet under pressure.Under normal circumstances, the printing material will not leak during this process.Therefore, it can be considered that the volume of the material fed into the nozzle Qin is equal to the volume of the melt in the extrusion nozzle Qout [4].Considering the ability of 3D printing to create parts with different properties derived from the printing parameters, the most relevant parameters were selected and used in our own experiments. For each selected parameter, namely infill percentage (%), layer thickness (mm), and raster angle (°), three relevant values were selected that could also be materialized on the available printers [10].Parameters need to be matched and adjusted according to specific application scenarios (such as component size, material type, and precision requirements) to maintain printing precision.

4. 3D printed materials

Different types of 3D printing materials have distinct characteristics and have a significant impact on printing precision. For instance, thermoplastic materials shrink during the cooling process, which leads to changes in the size of the printed parts.The viscosity, fluidity of the material and its adhesion to the printing platform will also affect the uniform extrusion and molding quality of the material, and thus influence the precision.Material differences and quality stability also affect printing precision. Unstable material properties can lead to unstable printing precision.PDMS silicone rubber, also known as polydimethylsiloxane elastomer, belongs to the AB two-component addition type. Its characteristics are that it can be accelerated to cure at room temperature with heating, and no by-products are generated after curing. It has low stress and modulus, and excellent physiological inertness [11].

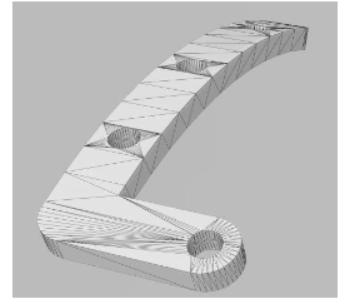

The test model is the curved plate model as shown in Figure 2. This type of model has a distinct support structure and is suitable for physical printing and comparative analysis. For this model, after processing with the traditional slicing processing system and the robotic arm 3D printing system, the corresponding Gcode path instruction file is generated. The printing consumable selected for this printing experiment is PLA (polylactic acid) [12].

In architectural 3D printing, by using lightweight and high-strength materials such as carbon fiber and aluminum alloy in combination and optimizing the distribution of the center of gravity, the end precision of the printing system can be improved.For instance, the 3D printed pumping head improved by a certain team has reduced its overall weight by 47%, significantly enhancing the precision at the end. Different materials require corresponding robot printing systems (such as nozzle type, heating temperature, extrusion parameters, etc.) to ensure printing precision.

5. Limitations and prospects

5.1. Limitations

The precision error of multi-axis robots is much greater than that of 3D printers. When the robotic arm is in a multi-axis linkage, the cumulative error is more obvious than that of traditional 3D printers, which affects the forming quality.The multi-axis linkage of 3D printing robots is prone to problems such as joint clearance, cumulative errors, etc., which can affect the printing precision, lead to insufficient terminal printing precision, and reduced structural strength. These issues can reduce the printing effect or cause printing errors, affecting the stability of high precision.

The physical and chemical properties of different materials vary greatly, affecting the printing process and results. Selecting the appropriate materials for application scenarios and optimizing their performance remains a challenge.The printing precision may vary depending on the material properties. Some high-viscosity and high-melting-point materials may produce unstable printing results during the robot printing process due to issues such as long conveying paths and uneven heating.

5.2. Prospects

The precision enhancement of 3D printing technology for robots has reduced the quality fluctuations caused by human operational errors in the biomedical field through the automated operation of industrial robots.Robot automation high-precision 3D printing technology can produce tissue engineering bases that better conform to the physiological structure of the human body. It can customize bones, teeth, etc. that match patients, and even implant organ models into human organs with cellular precision, bringing new breakthroughs to disease treatment and regenerative medicine.

In the field of industrial manufacturing, robotic arms move flexibly, stacking materials layer by layer from different angles to achieve the construction of building structures.It can manufacture high-precision molds and precision mechanical components, and can develop towards higher quality and higher efficiency, reducing subsequent processing and material waste.Breaking the spatial limitations of traditional construction, the flexible operation of the robotic arm can adapt to the printing of complex architectural forms (such as curved surfaces and irregular structures), reduce the reliance on molds, and shorten the cycle from design to construction.In combination with the automated dispatching system, it is possible to achieve multi-robot collaborative operations in the future, further enhancing the structural accuracy and construction speed of large buildings.

6. Conclusion

This paper focuses on 3D printing of industrial robots. The operating system ensures the stability of the robotic arm, achieving 3D printing by controlling the movement of the robotic arm. Meanwhile, through advanced control algorithms and the collaboration with software, it provides precise 3D printing operations.In terms of printing technology, multi-degree-of-freedom printing is adopted to reduce the step effect and set appropriate printing parameters, thereby improving the printing quality.Select appropriate printing materials that are compatible with the robot printing system to ensure printing precision.

High-precision robot 3D printing technology can ensure the dimensional precision of parts, thereby enhancing the overall performance of parts, achieving the printing of complex structures, reducing their own weight while ensuring precision and performance, realizing full-process automation, and improving production efficiency.Provide higher-precision building components for the construction industry, enhance building quality, customize buildings to meet individual needs, and ensure sustainable work to improve work efficiency and construction safety.

Artificial intelligence and machine learning technologies will be important driving factors for improving the precision of 3D printing technology for robots in the future. By integrating these technologies, industrial robots can analyze data such as pressure, temperature and speed in real time during the printing process.Through algorithms, print parameters are automatically optimized to enhance print precision and quality.Future printing technology will not only achieve functions such as laser coating and metal additive manufacturing, but also realize surface treatment and reinforcement of components, while improving performance and precision, and will continue to be optimized in the future.Furthermore, due to the advancement of multi-material printing technology, robots can more precisely control the distribution and proportion of different materials, thereby manufacturing components with complex functions.It will promote the development of robot 3D printing technology towards higher precision and stability.

References

[1]. Liu, W. (2024). Research and development of D printing system for screw extrusion robotic arm and design of printing path [Doctoral dissertation, Zhejiang Normal University].

[2]. He, X., Li, S., Rui, P., et al. (2025). Multi-joint industrial robot accuracy enhancement method research. Journal of Measurement and Control Technology, 44(5), 46–51.

[3]. Xu, H., Fang, J., Han, X., et al. (2021). Research on 3D printer control system based on robotic arm. Mechanical Engineer, (5), 9–10+14.

[4]. Zhang, Y. (2021). A multi-degree-of-freedom spatial 3D printing method and implementation based on robotic arm, Shanghai University].

[5]. Chen, X. (2025). Design and research of 3D printing film system with six-degree-of-freedom robotic arm, North Minzu University].

[6]. Toshev, R., Bengs, D., Helo, P., et al. (2024). Advancing free-form fabrication: Industrial robots' role in additive manufacturing of thermoplastics. Procedia Computer Science, 232, 3131–3140.

[7]. Xiao, S. (2022). Research and system implementation of 3D printing control synergy for multi-axis robots based on EtherCAT, Wuhan University of Technology.

[8]. Wei, Y. (2025). Research on multi-degree-of-freedom 3D printing technology for conformal electron fabrication, University of Electronic Science and Technology of China.

[9]. Gong, Y., Zhang, F., Tan, Y., et al. (2023). Adaptive hierarchical algorithm for 3D printing of multi-degree-of-freedom robotic arm based on voxel decomposition. Mechanical Design and Research, 39(4), 141–146+151.

[10]. Paduraru, E., Dumitras, G. C., Chitariu, F. D., et al. (2023). Research on additive technique parameter optimization for robotic gripper construction. Machines, 11(6).

[11]. Feng, L. (2023). Research on multi-angle process of mechanical arm direct writing 3D printing system and nozzles Jiangnan University.

[12]. Gong, Y. (2023). Research and system implementation of high-efficiency adaptive hierarchical algorithm for 3D printing of multi-degree-of-freedom robotic arm, Wuhan University of Technolog.

Cite this article

Zhang,H. (2025). Precision Enhancement in 3D Printing Technology Based on Robots. Applied and Computational Engineering,186,52-58.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-FMCE 2025 Symposium: Semantic Communication for Media Compression and Transmission

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Liu, W. (2024). Research and development of D printing system for screw extrusion robotic arm and design of printing path [Doctoral dissertation, Zhejiang Normal University].

[2]. He, X., Li, S., Rui, P., et al. (2025). Multi-joint industrial robot accuracy enhancement method research. Journal of Measurement and Control Technology, 44(5), 46–51.

[3]. Xu, H., Fang, J., Han, X., et al. (2021). Research on 3D printer control system based on robotic arm. Mechanical Engineer, (5), 9–10+14.

[4]. Zhang, Y. (2021). A multi-degree-of-freedom spatial 3D printing method and implementation based on robotic arm, Shanghai University].

[5]. Chen, X. (2025). Design and research of 3D printing film system with six-degree-of-freedom robotic arm, North Minzu University].

[6]. Toshev, R., Bengs, D., Helo, P., et al. (2024). Advancing free-form fabrication: Industrial robots' role in additive manufacturing of thermoplastics. Procedia Computer Science, 232, 3131–3140.

[7]. Xiao, S. (2022). Research and system implementation of 3D printing control synergy for multi-axis robots based on EtherCAT, Wuhan University of Technology.

[8]. Wei, Y. (2025). Research on multi-degree-of-freedom 3D printing technology for conformal electron fabrication, University of Electronic Science and Technology of China.

[9]. Gong, Y., Zhang, F., Tan, Y., et al. (2023). Adaptive hierarchical algorithm for 3D printing of multi-degree-of-freedom robotic arm based on voxel decomposition. Mechanical Design and Research, 39(4), 141–146+151.

[10]. Paduraru, E., Dumitras, G. C., Chitariu, F. D., et al. (2023). Research on additive technique parameter optimization for robotic gripper construction. Machines, 11(6).

[11]. Feng, L. (2023). Research on multi-angle process of mechanical arm direct writing 3D printing system and nozzles Jiangnan University.

[12]. Gong, Y. (2023). Research and system implementation of high-efficiency adaptive hierarchical algorithm for 3D printing of multi-degree-of-freedom robotic arm, Wuhan University of Technolog.