1. Introduction

The aerospace industry has extremely stringent requirements for complex structural components, including high precision, complex configurations, and lightweight designs. 3D printing technology is essential for meeting these requirements, and directed energy deposition (DED) technology shows great promise for manufacturing large-scale, complex structural components. Adaptive slicing technology precisely controls dimensional accuracy by dynamically matching structural features. Meanwhile, path planning technology optimizes melt pool trajectories, filament feed rates, and energy distribution. These two technologies synergistically collaborate to enhance manufacturing efficiency and quality. In DED technology, reasonable path planning optimizes filament feed rates and laser energy distribution to improve printing results, and adaptive slicing dynamically adjusts to accommodate these characteristics [1].

Although 3D printing technology has made significant progress, it still faces numerous technical challenges during its development: - Traditional technologies generally struggle to balance precision and efficiency, such as geometric deviations and “step effects” caused by improper slicing and poor path planning, as well as poor printing accuracy in overhanging areas [2]. Among these, some 3D printing technologies suffer from issues like “step effects” in complex structures due to improper slicing and inadequate path planning, and lack an integrated optimization logic for slicing and path planning tailored to DED processes [1]. Path generation faces specific bottlenecks, such as overfilling or underfilling near sharp corners, and excessive retraction during filling of complex cross-sections like structures with holes [3]; structures like squares with two holes often have subpath dead ends, hard-to-control endpoints, and complex connections under general path modes (direction parallel and contour parallel), making global path optimization tough and requiring greedy algorithms to form multi-path elements with retraction. - Adaptive slicing algorithms and path planning technologies have not yet been deeply integrated with advanced processes like DED, lacking a unified optimization logic tailored to DED's “layer-line” deposition logic, making it difficult to accommodate its complex melt pool trajectory overlay requirements. - Insufficient multi-process adaptability, with existing algorithms struggling to accommodate the differentiated requirements of different 3D printing technologies (such as FDM and DED), often leading to uneven material deposition or deformation in complex geometric shapes. - In metal additive manufacturing, process parameters such as energy control and powder morphology significantly affect internal defects. For example, gas retention, excessive or insufficient energy can lead to spherical pores, spatter, and unstable melt pools: gas pores are primarily spherical or elliptical in shape, primarily originating from gas retention in metal powders and the gas environment within additive manufacturing equipment; If the energy supplied to the melt pool deviates from the optimized value, it may result in insufficient melting, unstable melt pool height, or vaporization phenomena. Excessive energy can cause intense convective currents and significant vapor backpressure, leading to spatter and instability, thereby forming voids and/or bubbles in the melt pool; spherical powder particles exhibit enhanced flowability, resulting in higher density and reduced spatter, thereby lowering defect counts [4].

This paper focuses on the collaborative optimization of adaptive slicing algorithms based on curvature, slope, features, and path planning technologies, such as LSPB, MTT, and robot command systems. The paper emphasizes the characteristics of the DED process. The goal is to develop an integrated slicing-path planning solution tailored to the DED process's deposition logic. Addressing the trade-off between precision and efficiency in traditional technologies, this study integrates dynamic layer thickness adjustment with precise path planning to reduce defects such as "step effects," overfilling, and underfilling. The solution improves the forming quality of complex structural components, reduces the incidence of internal defects, and ultimately fills the technical gap in DED processes for complex structural components in the aerospace industry. This advancement upgrades manufacturing technologies in this field and provides technical support for improving aircraft-related system performance.

2. Adaptive slicing algorithm types and path planning

2.1. Adaptive slicing based on curvature

2.1.1. Algorithm principles

Curvature-based adaptive slicing determines layer thickness by calculating the normal curvature of the part surface in the vertical direction: the greater the curvature (e.g., at surface transitions), the smaller the layer thickness, to control peak height within tolerance limits; the smaller the curvature (e.g., in planar regions), the larger the layer thickness, to improve efficiency [5]. The core of this algorithm is to approximate the local surface as an arc, calculate the layer thickness based on the curvature radius and allowable tolerance, and directly operate on the NURBS model to avoid precision loss in the STL format. Additionally, it identifies peak features (such as sharp corners and extreme points on boundary curves) to ensure that critical geometric features are not overlooked [5].

2.1.2. Compatibility with path planning and application in complex curved surface parts

Bradley Thompson and Hwan-Sik Yoon studied a path planning algorithm that combines linear segment and parabolic transition (LSPB) and minimum time trajectory (MTT), which was developed for additive manufacturing systems with XY motion platforms [6].

The algorithm achieves two core functions: maintaining a constant speed during printing via LSPB to ensure uniform material deposition; and minimizing time during segment transitions via MTT to reduce material waste caused by shutter obstruction.

The algorithm offers multiple benefits, including improved efficiency while maintaining printing accuracy, avoiding uneven deposition thickness caused by speed changes; adaptability to any printing path, enhancing the system's ability to autonomously complete printing tasks; and reduced material loss during transition phases, lowering manufacturing costs.

In aerospace manufacturing, the algorithm is suitable for complex paths such as circular and spiral shapes, particularly for the production of complex curved parts like turbine blades. It enhances forming precision in high-curvature areas through precise path control and improves efficiency in flat areas through rapid path adjustment. Its constant speed control feature reduces uneven material deposition, meeting the stringent geometric precision requirements of aerospace parts and mitigating performance risks caused by deposition deviations. When combined with processes like directed energy deposition (DED), it can synchronize robot movement and laser power control, enhancing the forming stability of titanium alloy components with thin walls and holes. Its adaptability to complex paths enables precise processing of the curved structures of aircraft engine turbine blades, ensuring manufacturing quality in critical areas; minimizing transition time reduces material waste and lowers manufacturing costs for large, complex aerospace components; the algorithm's autonomy reduces the need for manual intervention, improving consistency in aerospace part mass production, and providing technical support for enhancing aircraft-related performance [6].

2.2. Adaptive slicing based on slope

2.2.1. Algorithm principles

Adaptive slicing based on slope adjusts layer thickness according to the angle between the part surface and the printing direction (slope): When the slope is close to 90° (e.g., overhanging structures), thin slices (e.g., 0.1 mm) are used to reduce staircase effects; when the slope is smaller (e.g., gently sloping surfaces), thicker slices (e.g., 0.3 mm) are used [2]. By calculating the angle

2.2.2. Compatibility with path planning and application in parts with slope features

Vittorio Sala, Ambra Vandone, and others studied online geometric monitoring and path planning adaptation strategies based on melt pool images in directed energy deposition (DED). For parts with overhang features, they proposed a variable scanning scheme that uses support paths or bidirectional cross trajectories with thin slices for overhang areas and unidirectional trajectories with thick slices for gentle slope areas. Eckart Uhlmann et al. validated the influence mechanism of slope on path planning through roughness analysis of titanium alloy parts with different orientations [2] [8]. This strategy achieves two major functions: ensuring forming stability in overhanging regions through coordinated control of trajectories and slices, and improving manufacturing speed in gentle slope regions through optimized trajectories and slice thickness. Additionally, melt pool image monitoring can control contour deviations in overhanging regions within a predefined range.

This strategy offers multiple benefits: it specifically addresses the issue of overhang structures prone to collapse, enhancing the reliability of complex structure forming; through differentiated trajectory and slicing strategies, it improves manufacturing efficiency while maintaining precision; real-time geometric monitoring enables timely detection of deviations and reduces material and time waste; trajectory adaptation under different slopes reduces surface roughness variations, enhancing overall part quality.

In the aerospace field, this strategy is applicable to the manufacturing of titanium alloy ring components with large-angle overhangs (such as engine casing components). In a 70° overhang structure, contour deviations can be controlled within 220 μm without collapse, meeting the stringent dimensional accuracy requirements for complex structures in aerospace applications [2]; For complex curved parts with gentle slopes and steep surfaces, such as turbine blades, unidirectional trajectories combined with thick slices can accelerate manufacturing in gentle areas, while bidirectional trajectories combined with thin slices ensure the forming quality of critical overhanging areas such as blade tips, thereby improving blade aerodynamic performance; In the manufacturing of thin-walled titanium alloy components, it can reduce stress concentration caused by improper trajectories, lower the risk of part deformation, and ensure the mechanical stability of aerospace structures; By adapting slope and trajectory parameters, it reduces roughness variations across different regions of the part, minimizes subsequent grinding processes, and shortens the production cycle for aerospace components [8]; Combining this strategy with DED (Direct Energy Deposition) technology enables the integrated manufacturing of large aerospace components, reducing assembly steps and enhancing overall structural reliability.

2.3. Feature-based adaptive slicing

2.3.1. Algorithm principles

Feature-based adaptive slicing technology focuses on accurately identifying key part features, such as thin walls, holes, and sharp corners, and then flexibly adjusting the slice layer thickness to achieve a balance between manufacturing accuracy and efficiency. When processing feature points, candidate feature points are first comprehensively extracted, and then three key thresholds are used to judge the complexity of the features. By measuring geometric changes between adjacent points, the curvature fluctuations on the model surface can be captured; a large difference indicates severe curvature changes and complex geometric features [7]. Using a slope angle threshold, the steepness of the feature region can be assessed, with a focus on steep slopes prone to step effects [7]. The total number of feature points is also counted; a higher number indicates richer geometric details in the region [7]. Additionally, peak feature identification is also critical. Precise localization of peak features such as boundary curve extrema ensures that critical features are not omitted during slicing, thereby safeguarding the accuracy and integrity of critical model regions [5].

2.3.2. Compatibility with path planning and application in parts containing key features

Bingbing Hu, Guoqing Jin, and others studied a feature-based adaptive slicing method, which extracts candidate feature points from the model and combines three key thresholds (geometric change difference, slope angle, and total number of feature points) to determine the complexity of the features, dynamically adjusting the slice thickness. For thin-walled features, an adaptive trajectory is used in conjunction with thin slices to ensure uniform material deposition [7]. For hole features, a circular trajectory is planned in combination with an appropriate layer thickness to avoid edge collapse and improve manufacturing accuracy [6]. This method can flexibly adjust layer thickness and trajectory according to feature complexity, balancing manufacturing accuracy and efficiency; it reduces material deposition unevenness or defects caused by improper feature processing, improving part forming quality; it adapts to arbitrarily complex paths, enhancing manufacturing capabilities for parts containing diverse critical features; By minimizing transition time, it reduces material waste and lowers manufacturing costs. This collaborative mechanism is applicable to the manufacturing of titanium alloy components with thin walls and holes (such as aircraft wing ribs and engine fuel nozzles), enabling precise control of material deposition in thin-walled areas to avoid structural strength deficiencies caused by uneven thickness, meeting the stringent mechanical performance requirements of aerospace components; For complex hole structures in engine components, the combination of circular trajectories and adapted layer thicknesses prevents edge collapse, ensuring smooth flow channels and improving engine efficiency; In the manufacturing of components with diverse critical features, such as titanium alloy engine casings, it reduces scrap rates caused by improper feature processing, minimizing waste of high-value materials; Collaborative control reduces surface roughness variations, lowering the workload of subsequent grinding processes and shortening the production cycle of aerospace components; Its ability to adapt to complex features enables this technology to support the integrated manufacturing of ultra-complex aerospace components, reducing assembly steps and enhancing overall structural reliability.

3. Applications of additive manufacturing in aerospace parts

3.1. Applications of adaptive slicing in the aerospace industry

In additive manufacturing slicing strategies, there are primarily two categories: uniform slicing and adaptive slicing. Uniform slicing uses a fixed layer thickness, which is widely applied in commercial rapid prototyping (RP/M) systems. However, it struggles to balance geometric accuracy with build efficiency — too thick a layer reduces accuracy, while too thin a layer significantly increases build time [7].

In recent years, adaptive slicing technology has emerged, with its core principle being the flexible adjustment of layer thickness based on the geometric characteristics of different regions of the model: For intricate regions of complex parts like aerospace aircraft components, thinner slices are used to preserve shape features and enhance geometric accuracy; for simpler regions, thicker slices are employed to reduce overall build time, thereby effectively minimizing step effects while balancing accuracy and efficiency. For example, GE Aviation uses laser additive melting technology (laser melting technology) to produce fuel nozzles for the Leap engine, with the material being cobalt-chromium alloy. This technology uses slicing algorithms to decompose the 3D model of the fuel nozzle into thin layers, with each layer's thickness dynamically adjusted based on the part's geometric features (such as complex surfaces, thin-walled structures, etc.) to reduce the “step effect” and ensure forming accuracy. Simultaneously, path planning technology optimizes the laser's scanning trajectory on each layer, ensuring that the metal powder is uniformly and densely melted and deposited [9].

The synergistic effect of slicing and path planning enables the fuel nozzle assembly, which previously required 20 parts to be assembled, to be integrated into a single component for direct printing and forming. Compared to traditional assembly methods, this model eliminates joints between multiple parts, reducing weight and manufacturing costs while enhancing the overall performance and reliability of the part. It has passed ground engine testing and obtained civil aviation certification [9].

3.2. Application in the manufacturing of complex curved aerospace parts

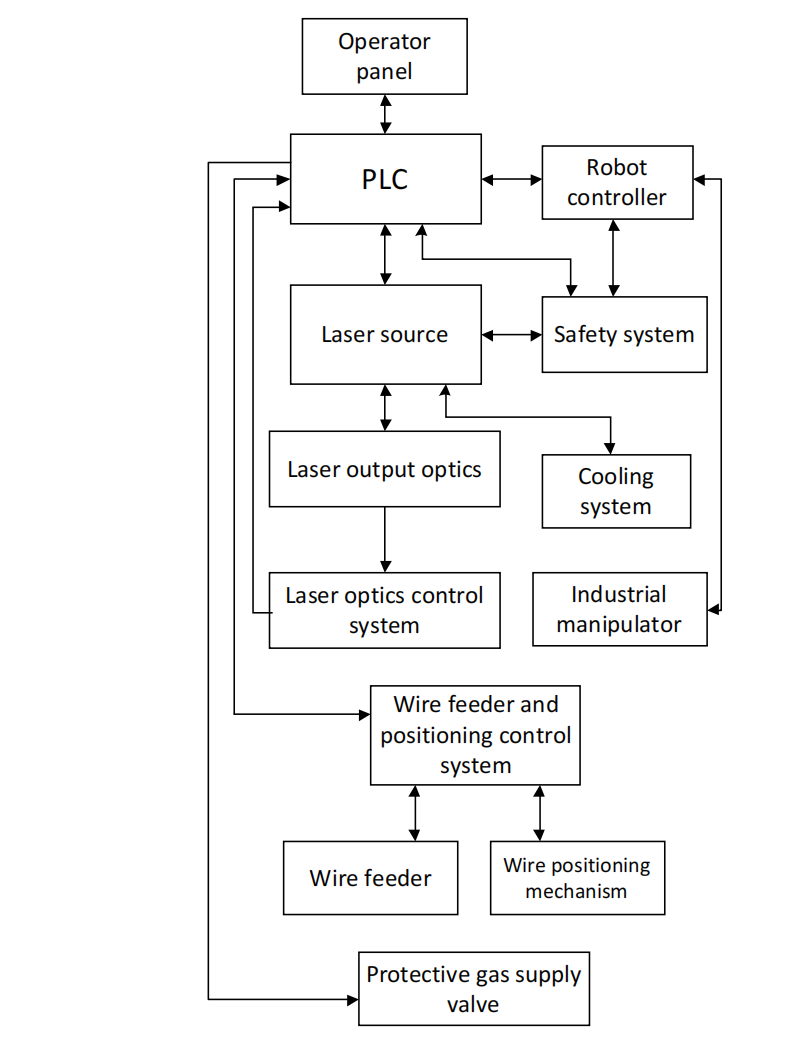

In the manufacturing of complex curved aerospace parts, such as rocket engine combustion chambers, curvature-based adaptive slicing technology extracts candidate feature points from the model surface and dynamically adjusts layer thickness. Thin slices (e.g., 0.1 mm) are used in high-curvature areas to preserve details, while thick slices (e.g., 0.3 mm) are used in flat areas to improve efficiency, achieving a balance between precision and efficiency [7]. The robotic system employs CIRC commands to achieve arc trajectory motion, synchronized with Sinc control to regulate laser power and wire feed speed, ensuring smooth surface deposition and preventing defects [10]. Together, these enhancements significantly boost manufacturing efficiency while meeting aerospace-grade surface precision requirements. The structural configuration of the robotic system implementing this technology is illustrated in Figure 1.

3.3. Application in the manufacturing of aeronautical parts with critical features such as thin walls and holes

For aeronautical parts with thin walls and holes (such as aircraft wing ribs), the feature-based adaptive slicing and zone path planning coordination mechanism has been effectively validated in the manufacturing of titanium alloy cabin brackets for the Airbus A350 XWB: The part was manufactured using laser CUSING technology, with an adaptive slicing algorithm applied to differentiate processing for different feature regions. Thin-walled regions were processed using adapted thin layer thicknesses and dedicated paths, hole regions used corresponding layer thicknesses and circular trajectories, while non-feature regions employed thicker layer thicknesses and efficient scanning trajectories [9]. This collaborative mechanism achieved over 30% weight reduction for the part, with material utilization rates increasing from 5% in traditional milling to 95% (traditional milling generates 95% scrap, while laser CUSING produces only 5% scrap), fully demonstrating the adaptability of feature-based slicing and dedicated path planning for complex-featured parts [9]. This manufacturing method not only optimizes the structural performance of parts but also significantly improves material utilization efficiency, providing an effective solution for the production of aerospace titanium alloy parts with complex features such as thin walls and holes.

4. Challenges and outlook

In terms of compatibility with different additive manufacturing processes (such as DED), DED's “layer-line” deposition requires that the slice contour strictly matches the wire deposition trajectory, but the nonlinear relationship between layer thickness and line width leads to compatibility deviations [1]. Minor deviations in the robot's motion trajectory can cause changes in wire overlap rates, leading to poor interlayer bonding [10]. Additionally, fluctuations in parameters such as laser power and wire feed speed directly affect deposition quality. Existing control methods struggle to establish real-time models linking parameters to slice-path relationships, making it challenging to address latency [10]. In complex aerospace part models, adaptive slicing requires extensive feature calculations, and path planning in multi-feature regions increases trajectory generation time. If precision is prioritized, manufacturing time will be extended; if efficiency is prioritized, precision may exceed tolerances [7]. These factors collectively pose significant challenges.

Future development will focus on the intelligent collaborative optimization of adaptive slicing and path planning, combining AI and digital twin technology to dynamically adjust slice layer thickness and path trajectories through real-time model training using melt pool images, while developing lightweight algorithms to enhance processing efficiency for complex models; A unified slicing-path coordination framework will also be established for multiple processes such as DED and SLM, enabling adaptive matching of process parameters. Cross-scale algorithms will be developed to balance macro-level contour and micro-level microstructure precision control, providing support for the manufacturing of ultra-complex aerospace parts.

5. Conclusion

This paper conducts a systematic study on adaptive slicing algorithms and path planning technologies in aerospace part additive manufacturing, comprehensively reviewing the principles and applications of adaptive slicing algorithms based on curvature, slope, and features, as well as the collaborative mechanisms of path planning technologies such as LSPB and MTT. The research shows that adaptive slicing algorithms can dynamically adjust layer thickness based on part geometric features, such as using thin slices in high-curvature areas to preserve details and thick slices in flat areas to improve efficiency. Path planning technologies achieve uniform material deposition and improved manufacturing efficiency through constant speed control and transition time optimization. The synergistic effects of these two technologies have demonstrated significant results in the manufacturing of complex parts such as aerospace engine turbine blades, fuel nozzles, and titanium alloy thin-walled components, effectively reducing the “step effect,” improving forming accuracy and material utilization, and meeting the stringent requirements of the aerospace industry for high precision and lightweight parts.

This study addresses the challenge of synergistic optimization between adaptive slicing and path planning, providing critical technological support for the additive manufacturing of complex aerospace structural components. It not only compensates for the shortcomings of traditional manufacturing processes in producing complex-shaped parts but also promotes the deep integration of additive manufacturing technology with advanced processes like DED, opening new pathways for efficient and high-precision manufacturing of aerospace parts. This has significant practical value for enhancing aircraft performance and reducing manufacturing costs.

As the aerospace industry continues to raise its demands for part complexity and performance, the intelligentization and multi-process adaptability of adaptive slicing and path planning technologies will become the core direction for future development. By integrating AI and digital twin technologies to achieve real-time dynamic optimization and establishing a collaborative framework across processes and scales, it is expected to further break through current technical bottlenecks, promote the broader application of additive manufacturing in the aerospace field, and drive the industry toward higher precision, efficiency, and lightweighting, thereby injecting sustained momentum into the transformation and upgrading of the aerospace manufacturing industry.

References

[1]. Sukhorukov, S., Ovsyannikov, A., & Lepekhina, S. (2024). A set of technological equipment for a robotic 3D printing system using DED technology. In 2024 International Conference on Industrial Engineering, Applications and Manufacturing(ICIEAM)(pp.812–817).IEEE.

[2]. V. Sala, A. Vandone, M. Banfi, S. Baraldo, F. Mazzucato and A. Valente, "Online 3D Geometry Reconstruction for Direct Energy Deposition Based on Melt Pool Images, " 2023 IEEE International Workshop on Metrology for Industry 4.0 & IoT (MetroInd4.0& IoT), Brescia, Italy, 2023, pp. 96-101

[3]. Jin, Y., He, Y., Fu, G., Zhang, A., & Du, J. (2017). A non-retraction path planning approach for extrusion-based additive manufacturing. Robotics and Computer-Integrated Manufacturing, 48, 132–144.

[4]. Sanaei, N., & Fatemi, A. (2021). Defects in additive manufactured metals and their effect on fatigue performance: A state-of-the-art review. Progress in Materials Science, 117, 100724

[5]. Ma, W., But, W. C., & He, P. (2004). NURBS - based adaptive slicing for efficient rapid prototyping. Computer - Aided Design, 36(13), 1309 - 1325.

[6]. B. Thompson and H. -S. Yoon, "Efficient Path Planning Algorithm for Additive Manufacturing Systems, " in IEEE Transactions on Components, Packaging and Manufacturing Technology, vol. 4, no. 9, pp. 1555-1563, Sept. 2014, .

[7]. B. Hu, G. Jin and L. Sun, "A Novel Adaptive Slicing Method for Additive Manufacturing, " 2018 IEEE 22nd International Conference on Computer Supported Cooperative Work in Design ((CSCWD)), Nanjing, China, 2018, pp. 218-223,

[8]. Uhlmann, E., Kersting, R., Klein, T. B., Cruz, M. F., & Borille, A. V. (2015). Additive manufacturing of titanium alloy for aircraft components. Procedia CIRP, 35, 55-60.

[9]. Kumar, L.J., Krishnadas Nair, C.G. (2017). Current Trends of Additive Manufacturing in the Aerospace Industry. In: Wimpenny, D., Pandey, P., Kumar, L. (eds) Advances in 3D Printing & Additive Manufacturing Technologies. Springer, Singapore.

[10]. S. Sukhorukov and N. Shusharin, "Command System for a Robotic 3D Printing Complex Using DED Technology, " 2024 International Russian Smart Industry Conference (SmartIndustryCon), Sochi, Russian Federation, 2024, pp. 184-189,

Cite this article

Tian,Z. (2025). Adaptive Slicing Algorithm and Path Planning for Additive Manufacturing of Aerospace Parts. Applied and Computational Engineering,186,78-86.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-FMCE 2025 Symposium: Semantic Communication for Media Compression and Transmission

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Sukhorukov, S., Ovsyannikov, A., & Lepekhina, S. (2024). A set of technological equipment for a robotic 3D printing system using DED technology. In 2024 International Conference on Industrial Engineering, Applications and Manufacturing(ICIEAM)(pp.812–817).IEEE.

[2]. V. Sala, A. Vandone, M. Banfi, S. Baraldo, F. Mazzucato and A. Valente, "Online 3D Geometry Reconstruction for Direct Energy Deposition Based on Melt Pool Images, " 2023 IEEE International Workshop on Metrology for Industry 4.0 & IoT (MetroInd4.0& IoT), Brescia, Italy, 2023, pp. 96-101

[3]. Jin, Y., He, Y., Fu, G., Zhang, A., & Du, J. (2017). A non-retraction path planning approach for extrusion-based additive manufacturing. Robotics and Computer-Integrated Manufacturing, 48, 132–144.

[4]. Sanaei, N., & Fatemi, A. (2021). Defects in additive manufactured metals and their effect on fatigue performance: A state-of-the-art review. Progress in Materials Science, 117, 100724

[5]. Ma, W., But, W. C., & He, P. (2004). NURBS - based adaptive slicing for efficient rapid prototyping. Computer - Aided Design, 36(13), 1309 - 1325.

[6]. B. Thompson and H. -S. Yoon, "Efficient Path Planning Algorithm for Additive Manufacturing Systems, " in IEEE Transactions on Components, Packaging and Manufacturing Technology, vol. 4, no. 9, pp. 1555-1563, Sept. 2014, .

[7]. B. Hu, G. Jin and L. Sun, "A Novel Adaptive Slicing Method for Additive Manufacturing, " 2018 IEEE 22nd International Conference on Computer Supported Cooperative Work in Design ((CSCWD)), Nanjing, China, 2018, pp. 218-223,

[8]. Uhlmann, E., Kersting, R., Klein, T. B., Cruz, M. F., & Borille, A. V. (2015). Additive manufacturing of titanium alloy for aircraft components. Procedia CIRP, 35, 55-60.

[9]. Kumar, L.J., Krishnadas Nair, C.G. (2017). Current Trends of Additive Manufacturing in the Aerospace Industry. In: Wimpenny, D., Pandey, P., Kumar, L. (eds) Advances in 3D Printing & Additive Manufacturing Technologies. Springer, Singapore.

[10]. S. Sukhorukov and N. Shusharin, "Command System for a Robotic 3D Printing Complex Using DED Technology, " 2024 International Russian Smart Industry Conference (SmartIndustryCon), Sochi, Russian Federation, 2024, pp. 184-189,