1. Introduction

Gallium oxide (Ga₂O₃), as an emerging wide bandgap semiconductor material, has attracted significant attention in the field of power devices due to its unique physical properties [1]. Its primary characteristic is its wide bandgap, approximately 4.5 electron volts (eV), which is considerably higher than traditional semiconductors such as silicon (Si) and gallium arsenide (GaAs). This property endows gallium oxide with excellent performance under extreme operating conditions including high temperature, high voltage, and high frequency, making it an ideal material for next-generation high-efficiency power converters and radio frequency power amplifiers.

In addition, the excellent thermal conductivity of gallium oxide is another key advantage in the development of power devices, with a thermal conductivity of approximately 0.4 to 0.5 W/(m·K) [2]. This property enables gallium oxide power devices to dissipate heat effectively at higher power outputs, thereby enhancing overall reliability [3]. During thermal analysis, good thermal conductivity helps reduce the device’s operating temperature, mitigating the risk of failure caused by thermal stress and consequently extending the device’s lifespan.

Gallium oxide power devices are playing an increasingly important role in modern electronic devices, and their development history reflects continuous advancements in semiconductor materials and device technologies [4]. The introduction of gallium oxide (Ga₂O₃) from elemental gallium (Ga) marks a new starting point in the research of high-power, high-efficiency devices [5]. Early investigations into gallium oxide primarily focused on its material properties, such as high conductivity and a wide bandgap (approximately 4.8 eV). Compared to traditional silicon (Si) and gallium arsenide (GaAs), it exhibits significantly improved stability under high-temperature and high-pressure conditions.

With breakthroughs in gallium oxide thin-film growth technologies, particularly the application of innovative techniques such as metal-organic chemical vapor deposition (MOCVD) and molecular beam epitaxy (MBE), gallium oxide power devices have gradually progressed toward practical implementation [6]. In the 1990s, the first gallium oxide-based diodes began to demonstrate their superiority in practical applications, validating their performance under high-voltage operation. Since then, due to their potential advantages in high-frequency and high-power applications, an increasing number of researchers have devoted efforts to the development of gallium oxide power devices.

2. Operating principles of gallium oxide power devices

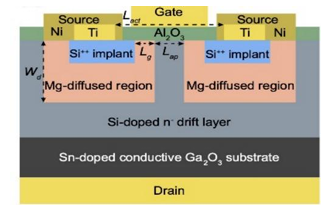

Gallium oxide power devices play an important role in modern power electronics due to their superior electronic properties and broad application prospects. A precise analysis of their basic structure and constituent components is essential for understanding their operating principles and performance characteristics.

Gallium oxide (Ga₂O₃) power devices mainly consist of three core components: the active layer, the insulating layer, and the substrate [7]. The active layer is crucial for achieving high efficiency and high speed in power devices, with its electron mobility and breakdown voltage characteristics significantly affecting device performance. In gallium oxide materials, the smaller atomic spacing leads to electronic conduction properties superior to traditional materials such as silicon (Si) and gallium nitride (GaN). This makes gallium oxide particularly outstanding in high-frequency and high-temperature operation, enabling higher switching frequencies and reduced energy loss.

As an emerging semiconductor material, gallium oxide (Ga₂O₃) power devices have attracted considerable attention due to their excellent operational characteristics [8]. Their core operating principle relies on the wide bandgap properties, allowing the devices to function normally under high-voltage and high-temperature conditions. This advantage endows gallium oxide power devices with promising applications in the power electronics field, such as electric vehicles, renewable energy conversion systems, and high-frequency switching power supplies.

Due to their superior electrical properties and thermal stability, gallium oxide power devices have demonstrated significant potential across multiple application scenarios. In the energy sector, gallium oxide power devices are widely used in power conversion and power management systems [9]. Their high breakdown voltage and low on-resistance result in improved performance in efficient energy conversion. For example, solar inverters employing gallium oxide power devices achieve over a 5% efficiency increase in actual operation compared to conventional silicon-based devices, significantly enhancing the overall energy utilization of the system [10]. Furthermore, the high-frequency characteristics of gallium oxide enable greater reliability in grid integration of renewable energy sources.

3. Failure modes of gallium oxide power devices

In the development of gallium oxide (Ga₂O₃) power devices, a thorough understanding of failure mechanisms is a critical step to ensure their reliability and performance [11]. Gallium oxide, with its wide bandgap properties and excellent thermal conductivity, is widely used in high-power and high-temperature applications. However, device failure during long-term use and under extreme environments is not accidental; it often results from the combined effects of multiple physical factors.

The fundamental characteristics of gallium oxide materials, such as crystal structure and defect types, directly influence the device failure modes. Gallium oxide crystals exhibit a monoclinic crystal system, with defect types mainly including dislocations, impurities, and lattice defects. These defects can serve as centers for electron migration and may cause stress concentration under external stress, thereby inducing device failure. Particularly under high-voltage operating conditions, the defect aggregation effects within the material are significantly enhanced, leading to electron instability and ultimately triggering localized thermal runaway.

|

Failure Mode |

Description |

Influencing Factors |

|

Thermal Failure |

Damage caused by heat accumulation when the device operates under high frequency and high load conditions. |

Thermal conductivity, heat dissipation design, packaging process |

|

Although gallium oxide has high thermal conductivity advantages, improper design may still cause failure. |

||

|

Electrical Breakdown Failure |

Failure occurring when the device withstands high voltage, possibly caused by dielectric breakdown. |

Doping concentration, electric field distribution |

|

Proper structural design and voltage management can extend device lifespan. |

||

|

Failure Mechanisms |

Physical failure mechanisms: lattice defects, carrier saturation phenomena. |

Chemical environmental reactions: effects of moisture, oxygen, etc. |

|

Chemical failure mechanisms affect device performance and durability. |

||

|

Data Analysis |

Statistical collection of failure data, application of accelerated aging tests and long-term durability experiments. |

|

|

Monitoring System |

Enhancing reliability research effectiveness by monitoring temperature, humidity, and load characteristics. |

|

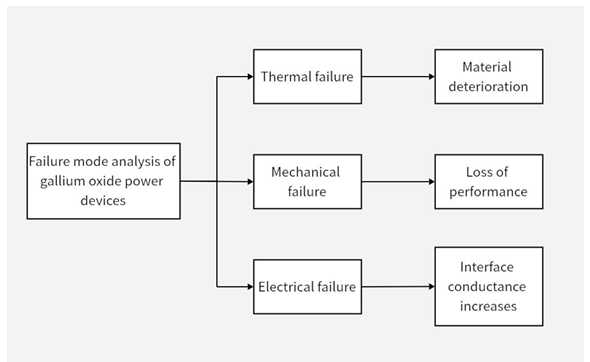

In the in-depth study of the reliability of gallium oxide (Ga₂O₃) power devices, the identification and analysis of failure modes play a crucial role [12]. For modern electronic devices, understanding their failure mechanisms not only aids in optimizing design but also enhances product competitiveness in the market. As an emerging semiconductor material, gallium oxide demonstrates broad application potential in power devices due to its outstanding electrical properties and high breakdown voltage. However, the complexity of its failure modes also requires thorough consideration.

Thermal failure is one of the common failure types in gallium oxide power devices [13]. This failure typically occurs when the device operates under high frequency and high load conditions, resulting in damage caused by heat accumulation. Such failures are closely related to the material’s thermal conductivity, heat dissipation design, and packaging processes. For example, although gallium oxide’s high thermal conductivity (up to 0.4 W/cm·K) offers advantages in heat dissipation, improper design of the cooling system may still lead to localized overheating, thereby triggering device failure.

Next, electrical breakdown failure is another critical factor in assessing the reliability of gallium oxide power devices. This failure generally occurs when the device endures high voltage stress and may be caused by dielectric breakdown, surface electrode damage, or material defects. Studies indicate that the key to mitigating electrical breakdown failure lies in optimizing the doping concentration of gallium oxide materials and the electric field distribution. Through rational structural design and voltage management, the device’s operational lifetime can be effectively extended.

The analysis of failure mechanisms can be conducted from two perspectives: physical failure mechanisms and chemical failure mechanisms. The former includes the generation of lattice defects and carrier saturation phenomena, while the latter involves reactions between gallium oxide and environmental chemicals such as moisture and oxygen. These chemical interactions can alter surface states, thus impacting device performance and durability. The selection of data collection and statistical analysis methods is particularly important here. By employing various failure data collection approaches—such as accelerated aging tests and long-term endurance experiments—combined with data analysis tools, correlations between device lifespan and failure mechanisms can be deeply examined. Based on these insights, manufacturers can develop targeted improvement strategies to enhance product reliability.

Regarding the significance of failure data statistics and analysis, it is necessary to emphasize the establishment of more refined monitoring systems. Capturing failure-related data during production and operation—such as temperature, humidity, and load characteristics—will significantly improve the effectiveness of reliability research. The visualization of failure data not only provides researchers with more intuitive insights into failure causes but also supports subsequent design optimization and technological improvements with solid data evidence.

The analysis of failure modes in gallium oxide power devices encompasses an understanding of thermal failure and electrical breakdown failure, as well as corresponding physical and chemical mechanism analyses. This research holds important reference value for promoting the practical application of gallium oxide materials.

4. Failure data statistics and analysis

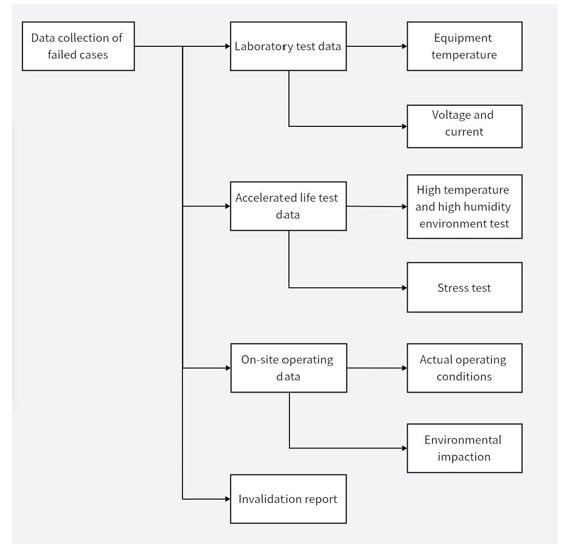

Gallium oxide (Ga₂O₃) power devices, as the next generation of power electronic devices, possess outstanding electrical properties and high breakdown voltage. However, with their increasing application in practice, research on their reliability issues becomes especially important. This section aims to explore the failure modes of gallium oxide power devices in depth and, combined with failure data statistics and analysis, to demonstrate the detailed process of failure data collection methods.

The failure modes of gallium oxide power devices can be categorized into various types, including thermal failure, mechanical failure, and electrical failure. Specifically, thermal failure typically arises from excessive power density, leading to significant internal temperature increases that cause material degradation or cracking. Mechanical failure often occurs due to material structural nonuniformity, strain concentration, or packaging defects, resulting in complete loss of device performance. Electrical failure is closely related to the device’s high sensitivity and includes factors such as overcurrent and overvoltage, which can cause bandgap displacement or increase interfacial conductivity, leading to adverse effects.

In-depth analysis of these failure modes makes the statistical analysis of failure data especially critical. To effectively collect and process failure data, a systematic data collection framework must first be established. This framework should encompass multi-level data aggregation and comprehensive failure reporting from laboratory testing, accelerated life testing, to field operation data, ensuring diversity and comprehensiveness of data sources. Considering the significant impact of different environmental conditions on device performance, conducting tests under high temperature and high humidity conditions will help evaluate the actual reliability performance of gallium oxide power devices.

In the process of failure data statistical analysis, employing statistical methods such as survival analysis and fault tree analysis can effectively reveal the causes of failure and their interrelationships. Survival analysis not only evaluates the device lifetime under normal operating conditions but also derives failure distribution curves using methods like the Kaplan-Meier estimator. Fault tree analysis aids in identifying possible failure pathways and their probabilities in depth, thereby providing strong guidance for device design optimization and improvement.

It is noteworthy that after analyzing failure data, the final conclusions should not only delineate the relative impact of various failure modes but also propose corresponding improvement measures to enhance the overall reliability of gallium oxide power devices. Through this series of failure mode analyses and statistical processes, a solid theoretical foundation and practical guidance will ultimately be provided for the engineering application of gallium oxide power devices, promoting further development and application of related technologies [14].

The highly complex failure modes and the sophisticated data collection and analysis processes offer profound insights into the reliability research of gallium oxide power devices, enabling related studies to explore the application potential of gallium oxide in the future power electronics field through scientific and systematic methodologies [15].

In the study of failure modes of gallium oxide power devices, the statistical analysis of failure data is particularly important [16]. In this section, we will explore various tools and methods used for failure data analysis, emphasizing how the accuracy of data analysis directly affects the understanding of failure mechanisms and consequently promotes device performance improvement.

When conducting failure data analysis, commonly used statistical analysis software offers a range of functions to support data collection, processing, and analysis. For example, open-source software such as the R programming language can be employed to construct and validate complex statistical models, including Generalized Linear Models (GLM) and Survival Analysis. These methods assist researchers in identifying key factors that influence device reliability.

5. Reliability testing of gallium oxide power devices

In the reliability analysis of gallium oxide power devices, mechanical stress testing is an indispensable component, whose importance is self-evident. This section will discuss in detail the principles, procedures, and the role and significance of mechanical stress testing in evaluating the reliability of gallium oxide power devices (GO PDs).

The core of mechanical stress testing lies in applying external forces or deformations to assess the material’s or device’s behavior under stress conditions. These tests follow the standards of the International Electrotechnical Commission (IEC) and relevant American Society for Testing and Materials (ASTM) guidelines, significantly enhancing the standardization and scientific rigor of the testing process. Testing methods generally include static and dynamic stress tests: the former focuses on failure modes under static loads, while the latter examines performance degradation under dynamic environments such as vibration and shock.

Environmental aging tests play a vital role in the reliability research of gallium oxide power devices, especially in evaluating their long-term operational performance and potential failure modes [17]. Environmental aging testing is a systematic evaluation method designed to simulate the real usage conditions of power devices under extreme and variable environments, thereby revealing potential failure mechanisms and performance degradation trends. Conducting such tests provides researchers with critical data to identify and analyze various environmental factors affecting gallium oxide power devices.

In reliability testing of gallium oxide power devices, accelerated life testing (ALT) serves as an important method to assess the long-term reliability of devices within a relatively short period. Therefore, the reasonable definition of testing metrics is key to ensuring the validity and credibility of the test results. This process not only involves the selection of appropriate metrics but also requires comprehensive consideration of their relevance to actual usage conditions. The test metrics should be based on the operational characteristics of gallium oxide power devices, including voltage rating, thermal resistance, and environmental adaptability. In-depth analysis of these characteristics provides a scientific basis for subsequent test design.

In reliability testing, particularly after accelerated life testing, data analysis and lifetime prediction play a critical role [18]. Accelerated life testing accelerates the manifestation of material failure mechanisms under abnormal operating conditions, enabling the acquisition of reliability data within a shortened timeframe. This method typically includes extreme environments such as high temperature, high voltage, and extreme current to simulate the stresses devices may encounter during actual operation, thus improving testing efficiency.

Data analysis following accelerated life testing is crucial in multiple aspects. Statistical methods such as the Weibull distribution model are effectively used to process device failure time data. Due to its strong adaptability and good fitting performance, this model is widely applied in failure analysis of power devices. Extreme value statistical analysis of failure data can reveal failure modes under different stress conditions and calculate corresponding parameters such as shape and scale parameters, which are vital for subsequent lifetime prediction.

6. Strategies for improving the reliability of gallium oxide power devices

Doping technology plays a key role in the modification of gallium oxide (Ga₂O₃) materials. Its application can significantly enhance the reliability and performance of gallium oxide power devices, promoting their performance in high-power and high-frequency applications. By introducing appropriate doping elements, researchers can adjust the electronic structure and crystal defects of gallium oxide, thereby improving its electrical properties and thermal stability.

Specifically, studies using aluminum (Al) or zinc (Zn) as doping elements have shown that these elements not only effectively form solid solutions but also improve the uniformity of gallium oxide crystals through high-temperature solid-state reactions. After doping, the bandgap width of the material can be adjusted within a certain range, enhancing the material’s conductivity and electron mobility. For example, research has demonstrated that aluminum-doped gallium oxide samples exhibit electron mobility up to 20% higher than undoped samples, reducing switching losses and increasing operating frequency in device applications [19].

Gallium oxide power devices exhibit outstanding performance and potential market value in high-power and high-frequency applications; however, reliability issues remain a significant factor limiting their widespread adoption. Surface treatment technologies, as an effective material improvement approach, can significantly enhance the performance and reliability of power devices by optimizing device surface properties. Surface engineering analysis offers a series of systematic methods and strategies that help improve the stability and durability of gallium oxide power devices under extreme operating conditions.

In the process of enhancing the reliability of gallium oxide power devices (Ga₂O₃ Power Devices), advancements in inspection technologies play a crucial role [20]. Implementing efficient and precise inspection techniques can effectively identify potential defects in materials and processes, thus ensuring the quality and performance of electrical components. Techniques such as Optical Coherence Tomography (OCT) combined with Scanning Electron Microscopy (SEM) provide researchers with clearer microscopic defect imaging, enabling more effective identification and localization of defects on material surfaces, interfaces, and within the bulk. For example, the combined use of OCT and SEM not only captures tiny defects on the surface of gallium oxide thin films but also analyzes the uniformity and integrity of internal film structures through tomographic imaging. This capability is essential for improving device operational stability under high-power and high-temperature environments.

7. Conclusion

The study of failure modes in gallium oxide (Ga₂O₃) power devices is crucial for improving their reliability and lifespan. Thermal failure remains one of the primary issues; although gallium oxide possesses good thermal conductivity, inadequate heat dissipation under high load conditions can still cause overheating failures. Therefore, optimizing thermal management design is essential. Electrical breakdown failure is also a critical concern, especially in high-voltage applications, requiring precise doping control and structural optimization to mitigate risks. Additionally, environmental factors such as temperature and humidity accelerate material degradation, necessitating enhanced real-time monitoring. In the future, multidisciplinary research to refine failure mechanisms and optimize device design will promote the application of gallium oxide devices in fields such as new energy and electric vehicles. Standardized failure analysis and reliability research form an important foundation for the technological commercialization of these devices.

References

[1]. Zhou, X. (2023). Preparation, property modulation and optoelectronic device research of gallium oxide thin films (Doctoral dissertation, East China Normal University). Supervisors: Chu, J. H., & Hu, Z. G.

[2]. Li, J. L. (2022). Anti-interference reliability testing of GaN power devices. Environmental Technology, 40(2), 45–50.

[3]. Huang, S. (2022). Numerical simulation of thermal characteristics and reliability of power semiconductor devices (Doctoral dissertation, Harbin University of Science and Technology). Supervisor: Liu, Y.

[4]. Xidian University makes significant progress in research on ultra-wide bandgap semiconductor gallium oxide power devices. (2022). Shaanxi Education (Higher Education), (10), 9.

[5]. Dong, S. (2021). Simulation of gallium oxide Schottky devices and research on high-aluminum-content aluminum gallium oxide (Doctoral dissertation, Dalian University of Technology). Supervisor: Zhang, H. Z.

[6]. Xu, Y. (2022). Epitaxial growth of gallium oxide by mist chemical vapor deposition and device research (Doctoral dissertation, Xidian University). Supervisor: Zhang, C. F.

[7]. Cheng, S. L. (2021). Research on gate drive technology for GaN power devices (Doctoral dissertation, Southwest Jiaotong University). Supervisor: Xiang, Q. Y.

[8]. Wu, Z. B. (2021). Research on packaging thermal characteristics of silicon-based GaN power devices (Doctoral dissertation, South China University of Technology). Supervisors: Wang, H., & Peng, Z. J.

[9]. Liu, S. L. (2022). Research on high-capacity RF power supply system based on GaN power devices (Doctoral dissertation, University of Electronic Science and Technology of China). Supervisor: Sun, M.

[10]. Sun, C. (2021). Design of high-efficiency AC-DC converter based on GaN power devices (Doctoral dissertation, Southeast University). Supervisors: Li, W. Y., & Yao, S. K.

[11]. Guan, R. F., Jia, Q., Zhao, J., Zhang, H. Q., Wang, Y. S., Zou, G. S., & Guo, F. (2023). Research progress on high-performance power device packaging and power cycling reliability. Transactions of the China Welding Institution, 44(12), 124–136+144.

[12]. Zhang, H. T., & Jiang, N. (2021). Reliability analysis of bonding buffer technology for wide-bandgap power devices. Electric Drive for Locomotives, (05), 28–32.

[13]. Guo, L. L., Luan, S. Z., Zhang, H. P., Qiao, R. D., Yu, J. G., Zhang, Y. M., & Jia, R. X. (2022). Self-heating effect in vertical enhancement-mode gallium oxide MOSFET devices. Scientia Sinica: Physica, Mechanica & Astronomica, 52(09), 75–84.

[14]. Sun, C. (2022). Research on key technologies of high-speed permanent magnet synchronous motor drive system based on GaN power devices (Doctoral dissertation, Zhejiang University). Supervisor: Yang, H.

[15]. Xie, X., Hao, W. B., Liu, Q., Zhou, X. Z., Xu, G. W., & Long, S. B. (2022). Extraction method for interface trap density in gallium oxide-based devices. Scientia Sinica: Physica, Mechanica & Astronomica, 52(09), 47–52.

[16]. Yang, Y. (2023). Design and research of novel vertical GaN power device structures (Doctoral dissertation, Guilin University of Electronic Technology). Supervisor: Chen, Y. H.

[17]. Li, S. W. (2021). Research on photoelectric properties of pulsed laser-deposited gallium oxide thin films and related devices (Doctoral dissertation, Xiamen University of Technology). Supervisors: Lin, H. J., Wang, C., & Yang, X.

[18]. Chen, H. (2022). Data analysis and management for reliability testing of power semiconductor devices (Doctoral dissertation, Nanchang University). Supervisors: Tu, H. N., & Shi, Y. M.

[19]. Song, K. L. (2022). Research on silicon-based GaN passive devices (Doctoral dissertation, Xidian University). Supervisors: Liu, Z. H., & Wang, C. H.

[20]. Nie, H. L., Chen, J. R., Ren, W. C., Guo, L., Cai, S. F., Li, K., Chen, F. F., & Pu, J. D. (2022). Optimizing key process parameters to improve wire bonding reliability in power devices. Electronic Test, (19), 43–47.

Cite this article

Shi,Y. (2025). Reliability Study of Gallium Oxide Power Devices. Applied and Computational Engineering,188,74-82.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-MCEE 2026 Symposium: Advances in Sustainable Aviation and Aerospace Vehicle Automation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Zhou, X. (2023). Preparation, property modulation and optoelectronic device research of gallium oxide thin films (Doctoral dissertation, East China Normal University). Supervisors: Chu, J. H., & Hu, Z. G.

[2]. Li, J. L. (2022). Anti-interference reliability testing of GaN power devices. Environmental Technology, 40(2), 45–50.

[3]. Huang, S. (2022). Numerical simulation of thermal characteristics and reliability of power semiconductor devices (Doctoral dissertation, Harbin University of Science and Technology). Supervisor: Liu, Y.

[4]. Xidian University makes significant progress in research on ultra-wide bandgap semiconductor gallium oxide power devices. (2022). Shaanxi Education (Higher Education), (10), 9.

[5]. Dong, S. (2021). Simulation of gallium oxide Schottky devices and research on high-aluminum-content aluminum gallium oxide (Doctoral dissertation, Dalian University of Technology). Supervisor: Zhang, H. Z.

[6]. Xu, Y. (2022). Epitaxial growth of gallium oxide by mist chemical vapor deposition and device research (Doctoral dissertation, Xidian University). Supervisor: Zhang, C. F.

[7]. Cheng, S. L. (2021). Research on gate drive technology for GaN power devices (Doctoral dissertation, Southwest Jiaotong University). Supervisor: Xiang, Q. Y.

[8]. Wu, Z. B. (2021). Research on packaging thermal characteristics of silicon-based GaN power devices (Doctoral dissertation, South China University of Technology). Supervisors: Wang, H., & Peng, Z. J.

[9]. Liu, S. L. (2022). Research on high-capacity RF power supply system based on GaN power devices (Doctoral dissertation, University of Electronic Science and Technology of China). Supervisor: Sun, M.

[10]. Sun, C. (2021). Design of high-efficiency AC-DC converter based on GaN power devices (Doctoral dissertation, Southeast University). Supervisors: Li, W. Y., & Yao, S. K.

[11]. Guan, R. F., Jia, Q., Zhao, J., Zhang, H. Q., Wang, Y. S., Zou, G. S., & Guo, F. (2023). Research progress on high-performance power device packaging and power cycling reliability. Transactions of the China Welding Institution, 44(12), 124–136+144.

[12]. Zhang, H. T., & Jiang, N. (2021). Reliability analysis of bonding buffer technology for wide-bandgap power devices. Electric Drive for Locomotives, (05), 28–32.

[13]. Guo, L. L., Luan, S. Z., Zhang, H. P., Qiao, R. D., Yu, J. G., Zhang, Y. M., & Jia, R. X. (2022). Self-heating effect in vertical enhancement-mode gallium oxide MOSFET devices. Scientia Sinica: Physica, Mechanica & Astronomica, 52(09), 75–84.

[14]. Sun, C. (2022). Research on key technologies of high-speed permanent magnet synchronous motor drive system based on GaN power devices (Doctoral dissertation, Zhejiang University). Supervisor: Yang, H.

[15]. Xie, X., Hao, W. B., Liu, Q., Zhou, X. Z., Xu, G. W., & Long, S. B. (2022). Extraction method for interface trap density in gallium oxide-based devices. Scientia Sinica: Physica, Mechanica & Astronomica, 52(09), 47–52.

[16]. Yang, Y. (2023). Design and research of novel vertical GaN power device structures (Doctoral dissertation, Guilin University of Electronic Technology). Supervisor: Chen, Y. H.

[17]. Li, S. W. (2021). Research on photoelectric properties of pulsed laser-deposited gallium oxide thin films and related devices (Doctoral dissertation, Xiamen University of Technology). Supervisors: Lin, H. J., Wang, C., & Yang, X.

[18]. Chen, H. (2022). Data analysis and management for reliability testing of power semiconductor devices (Doctoral dissertation, Nanchang University). Supervisors: Tu, H. N., & Shi, Y. M.

[19]. Song, K. L. (2022). Research on silicon-based GaN passive devices (Doctoral dissertation, Xidian University). Supervisors: Liu, Z. H., & Wang, C. H.

[20]. Nie, H. L., Chen, J. R., Ren, W. C., Guo, L., Cai, S. F., Li, K., Chen, F. F., & Pu, J. D. (2022). Optimizing key process parameters to improve wire bonding reliability in power devices. Electronic Test, (19), 43–47.