1. Introduction

For their outstanding mechanical properties and cheap production cost, petroleum synthetic plastic materials, such as PE and PS, have been essential materials in industrial products and have taken over the majority of the plastic market [1]. However, their outstanding mechanical properties also bring big environmental issues. Theoretically, petroleum synthetic plastics are able to degrade in various environments, as shown in Figure 1. The problem is that due to their high resilience to degradation, it usually takes more than tens or hundreds of years for them to fully degrade. Therefore, their high resilience to degradation along with their low recycling rate makes them stubborn waste that has been spread all over the world, causing significant damage to the environment [2]. The current common practice of dealing with waste is landfilling, which is very ineffective in petroleum-synthesized plastics. As global warming attracts more and more public attention to environmental protection, dealing with plastic waste has become a hot topic in the last decades. In addition, scientists report that the current known petroleum storage will be depleted in a few centuries, leaving no raw material for petroleum-synthesized plastics. Nevertheless, while plastic products have already penetrated every part of our lives, it is almost impossible to stop using plastics.

|

Figure 1. Microbial degradation of petroleum-based plastic in different environments. |

The main solutions to this problem are increasing the recycling rate of plastic products or making plastics more biodegradable. Thus, biodegradable polymers have emerged as promising candidates as a substitute for petroleum-synthesized plastics. However, due to their high production cost and relatively weak mechanical performances, petroleum-synthesized plastics still dominate the plastic market [3]. Therefore, many current studies are focusing on developing new biodegradable polymers or improving the existing biodegradable polymers to replace petroleum-synthesized plastic someday in the future. This review paper aims to provide an overview of the various biodegradable polymers and their current application as well as new developments and gain new insights into the future of biodegradable polymers, so new studies can be done based on the current developments, optimizing the biodegradable polymers to substitute the petroleum synthesized plastics for a better future.

2. Definition and classification of biodegradable polymers

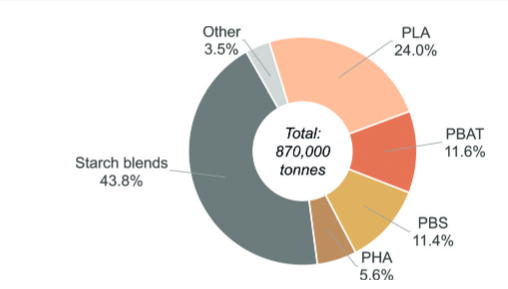

In this section, in order to recognize biodegradable polymers as a diverse group, the definition will be demonstrated and classifications of various biodegradable polymers will be demonstrated in categories of their origin. Figure 2 below demonstrates a general view of the current distribution of production capacities of different types of biodegradable polymers. In addition, we will explore the properties and applications of various categories of biodegradable polymers.

Figure 2. Global production capacities of biodegradable plastics in 2017ta derived from European Bioplastics

2.1. Definition and standard of biodegradable polymers

The fundamental definition of biodegradable polymers is biodegradability, biocompatibility, and the release of non-toxic degradation products, specifically water, carbon dioxide, etc. [4].

Biodegradability is divided into three degrees with different standards, readily degradable, inherently biodegradable, and ultimately biodegradable. Under certain conditions, with the 10% degradation as the starting point, readily, inherently, and ultimately biodegradable materials are required to degrade 60%, 70%, and 90% in 10 days, respectively [5].

2.2. Biodegradable polymers that are extracted from natural products

The biodegradable polymers gained from natural resources such as crops and animals are called Agro-polymers [6]. Among this category, polysaccharides, proteins, and lignin are three important biodegradable polymers.

2.3. Polysaccharide

Polysaccharide is one of the most abundant natural biodegradable polymers. They are commonly used in plants, fungi, and animals as energy storage and structural material. Therefore, we can extract polysaccharides from multiple sources, and the polysaccharide extraction process has been relatively mature [7]. Films made of polysaccharides are considered a good substitute for petroleum-synthesized plastic films in the food packaging industry since they are able to increase the shelf-life of the food and degrade to water and carbon dioxide afterward easily, causing no harm to the environment [8].

Polysaccharides include many materials with various applications. For example, starch and chitin are commonly used in paper coating, which is a process that coats paper with a layer of substances to improve the properties of the paper. According to the research of Li et al., starch nanoparticles (SNPs), a kind of starch material in nano size, and chitin is used in paper coating. An addition of SNPs in cassava starch-based film can improve the water and oxygen barrier ability of the film. Chitin layer coating improves the strength of the coated paper while its hydrophily makes it unable to work well in a moist environment [9]. In addition, the blend of seaweed, a polysaccharide gained from marinal substances, and cellulose have also attracted great attention. The blend boosted the strength and water vapor barrier ability of normal seaweed material while keeping low production costs and many other advantages [10].

2.3.1. Proteins. Protein is another big class of biodegradable polymers, which are long-chain macromolecules consisting of various amino acids. The variety of the type, number, and sequence of different proteins provide them with a great variety of chemical and physical properties. As polysaccharides, proteins can also be found in natural products in abundance. Although protein-based biodegradable polymers have high gas barrier ability, good mechanical strength, and the added value from their ability to be turned into fertilizer during degradation, proteins still confront vital challenges as a commercialized bioplastic, such as complex production processes and low water barrier ability [11].

Despite those challenges, researchers have found suitable applications for proteins. Collagen is one of the most promising ones among other proteins in the application as a biodegradable polymer. One typical example is the collagen scaffold used in tissue engineering. Its compatibility with the extracellular matrix(ECM) serves as a great advantage of collagen scaffolds compared to other hydrogel scaffolds, but its relatively low mechanical strength, viscoelasticity, and stability prevent it from wider application [12]. In addition, soy protein and cottonseed protein have been employed in the wood adhesive industry. They can adhere to wood particles strongly while being resistant to heat and water, making them suitable for wood adhesives [13].

2.3.2. Lignin. Lignin also appears in nature with a plenty amount, just slightly less abundant than polysaccharides. Because of its abundance, the most significant advantage of lignin is its low production cost. Lignin has been applied as an additive to other polymers for the purpose of improving chemical and mechanical properties. Much research has also been done on applying lignin as fillers in the polymer system. However, one of the difficulties researchers are facing on the way to use lignin is that the addition of lignin makes the material brittle [14].

Despite this disadvantage, much work has been done to develop the full potential of lignin. Puglia et al. explored the application of lignin in renewable thermoplastics, taking advantage of the many functionalities of lignin[15]. Besides, lignin can also be used in film production, which could improve the UV barrier ability and mechanical properties of the film. Various applications of lignin also include pesticides, drugs, and sunscreen [16].

Overall, biodegradable polymers extracted from natural products have the advantage of natural abundance, cheap production costs, and high biodegradability. However, as mentioned above, those kinds of biodegradable polymers are usually used with additives, as pure forms of them are not able to provide enough barrier, thermal and mechanical properties [17, 18].

2.4. Biodegradable polymers synthesized artificially

The two main categories of human-synthesized biodegradable polymers are biodegradable polymers synthesized from biotechnology and biodegradable polymers synthesized from conventional petroleum products [6].

2.4.1. Biodegradable polymers synthesized from biotechnology. Some biodegradable polymers are synthesized from conventional bio-monomers by a human. The most typical example of biodegradable polymers in this category is polylactic acid (PLA). PLA is synthesized from various biomass, such as corn and sugarcane, having the advantage of abundant raw materials. Furthermore, the special structure of PLA gives it relatively better mechanical strength and thermal stability [19]. Compared to some other biodegradable plastics, PLA has high malleability, high transparency, and the ability to be recycled [20].

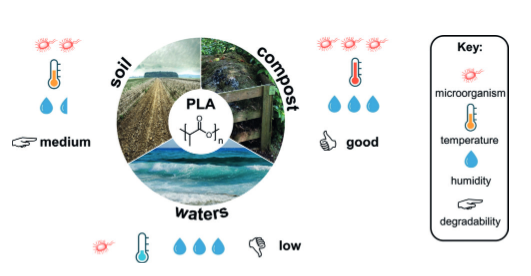

Nevertheless, despite the outstanding properties and renewable raw materials, PLA still faces the common obstacle of many bio-based plastics---high production cost and low production capacity. According to the statistics in 2020, biodegradable plastics were only less than 1% of the total plastics of that year. However, the mixture of PLA and starch has a relatively large proportion of the total production of biodegradable plastics [21]. Another disadvantage of PLA is its comparatively low degradation rate, making it not as environmentally friendly [22]. As shown in figure 3, only in environment with relatively high temperature and high humidity will PLA has comparatively high biodegradability.

Despite those problems, as one of the most promising bioplastics, PLA is applied in many industries, and many optimizations have been made to maximize its commercial value. For example, the addition of triacetin(TA) and polyethylene(PEG) to PLA films is reported to modify the brittleness of PLA films, making them more suitable for food packaging [23]. Another application of PLA is the newly developed PLA-PEG-based drug delivery system, which could improve the surgery outcome without causing extra side effects [24].

|

Figure 3. Influence of humidity temperature and concentration of (suitable) micro-organisms on the biodegradation of PLA in different environments. |

2.4.2. Biodegradable polymers synthesized from conventional petroleum products. This class of biodegradable polymers includes polycaprolactone (PCL), polyesteramides (PEA), aliphatic co-polyesters (e.g., PBSA), etc. Besides, though debatable, some polymers with additives can also be classified as biodegradable polymers, such as polyolefin with pro-oxidant additives [25].

Among these materials, PCL has been an important specie with great interest. PCL is a material that is approved for specific applications in human bodies. Due to its ability to degrade in human bodies without releasing any toxic substances and its high compatibility with organisms, PCL has been utilized extensively in medical devices. Also, PCL has some advantages over other biodegradable polymers that are used widely in medical devices, such as higher flexibility and lower surface energy [26]. PCL is also considered to have low mechanical strength and is 3D printable material; thus, it is furtherly favored as a scaffold for soft tissue reconstruction [27].

In addition to medical applications, PCL has been used in the packaging industry. The PCL-PLA blend is reported to have enhanced properties and commercially valuable paper coating material [28]. Research has also shown that the PCL-PHB blend shows an increase in the impact resistance capacity while maintaining the biocompatibility of PHB [29].

Generally, synthesized biodegradable polymers, such as PCL and PLA, have many impressive mechanical properties that are similar to traditional plastics. For biodegradable polymers synthesized from biotechnology, high production cost and low production capacity greatly influence their application coverage. For biodegradable polymers synthesized from petroleum, although they give even better mechanical properties such as better flexibility, we should note that they are synthesized from a nonrenewable resource, petroleum, which makes they less sustainable compared to other kinds of biodegradable polymers.

2.5. Biodegradable polymers synthesized from microbes

Among other raw material sources, micro-organisms also produce unique biodegradable polymers which have great potential, including Polyhydroxyalkanoates(PHA) [6].

PHA has many similar chemical and physical properties with commonly used petroleum-synthesized non-biodegradable plastics. Among the family of PHAs, polyhydroxybutyrate (PHB) has been focused on by many researchers. PHBV, a kind of PHB, is especially important in the family as it has properties that resemble those of Polypropylene (PP), a currently commonly used non-biodegradable plastic. With those outperforming properties and biodegradability, PHA has been applied in many industries, such as packaging, disposable containers, and drug delivery carriers [30, 31]. The diverse substrates for microbial production of PHAs, such as whey, grass, and waste cooking oils, contribute to its great potential as the plastics of the future [32].

However, the high production cost is still a significant obstacle on its way to commercialized use. Many optimizations have been made to lower the production cost of PHA. In the research of Lascu et al., a marina bacteria strain is identified as an optimal bacteria strain for the production of PHA, as it requires a lower temperature to grow [33]. Another optimization has been done by Narayanan et al. to identify a production-efficient bacteria strain, which they claimed could be a good candidate for the mass production of PHAs [34].

3. Current study and development of biodegradable polymers

In this section, applications of biodegradable polymers are demonstrated in categories of industries, including the medical industry, agriculture, and packaging industry.

3.1. Current study on medical applications

Due to their versatility, biocompatibility, and biodegradability, biodegradable polymers find multiple applications in medical areas, including surgical structures, implants, and parenteral injections [35]. For example, Drug-eluting stents (DES) made of biodegradable polymers have received much attention. Previous generations of DESs are mostly made of metals with sirolimus-eluting layers, which may cause thrombosis after the complete release of the drug. In recent years, scientists reported that the DES constricted by biodegradable polymers are safer and more effective than the previous generations of DES, enabling them to lower the risk of thrombosis [36].

The biocompatibility of biodegradable polymers contributes significantly to their applications in cellular scaffolds used in reconstructive therapy. Orlowska J. et al. demonstrated the usage of calcium alginate and dibutyrylchitin polymers in cell seeding. Evaluation of this material displays that it is able to facilitate cell adhesion and shows no toxicity [37].

Besides those applications mentioned above, there are numerous other applications of biodegradable polymers in medical areas, such as stents [38, 39], drug delivery [40], and diabetic wound dressing [41]. Their biodegradability makes them able to degrade safely in the human body while providing a barrier or structure as needed. Currently, biodegradable polymers have gained great importance in medical areas not only because of their impressive biological properties but also because of the higher acceptance level of the high cost in the medical industry as more focus is put on functionalities.

3.2. Current study on agricultural applications

The biodegradability in the soil environment of many biodegradable polymers cooperates well with many agricultural applications, such as floor membranes and the preservation film of mushrooms. To overcome some unfavoured characteristics, optimizations have been made. Cellulose acetate(CA) is added to polypropylene carbonate (PPC) to enhance the degradation rate of PPC while retaining its transparency and good barrier properties of it; PCL is added to PPC to gain better gas barrier and water vapor permeability, with an extra function of maintaining the color of mushroom [42]. Additional efforts have also been made to achieve a more innovative land filming method with biodegradable polymers. A kind of hydrolyzed protein deriving from the waste of the leather industry is claimed to have the ability to be used by spraying polymeric water while retaining the ability to suppress weed growth and preserve soil nutrients [43].

Another emerging agricultural application is plant films made of biodegradable polymers. Da Silva Porto et al. reported that chitosan dissolved in distilled pyroligneous liquor(DPL) could be used to produce protective films of plants that have strong UV light absorption capability [44]. Besides applications as films, some research showed that they could be used to construct disposable plant pots. By adjusting the ratio of its component(starch, glycerol, rapeseed cake, and urea), the pH of the plant pots can be raised to reduce some danger to plants [45].

Various applications of biodegradable polymers in agriculture show their potential of them in this industry. As environmentally friendly agricultural practices are increasingly encouraged, more optimizations and applications of biodegradable-polymer-based agricultural applications will emerge in the future.

3.3. Current study on packaging applications

Packaging has long been an important industry of human society, as it is able to protect the commodity or extend the shelf lives of food. Petroleum-synthesized plastics are commonly used in this industry, but more and more biodegradable film packaging has appeared and is promising to substitute petroleum-synthesized plastics in certain circumstances. Currently, more packaging applications of biodegradable polymers are being developed in the food packaging industry.

As a single biodegradable polymer is usually not able to provide enough oxygen-water barrier and mechanical strength meanwhile, which are required properties of an ideal food package, mixtures of different biodegradable polymers are commonly applied. A chitin-chitosan mixture is reported to be suitable for food packaging, with the ability to extend the shelf lives of food and biodegradability [46]. Another example would be seaweed-microcrystalline cellulose(MCC), which has improved tensile strength and water barrier properties [47].

Adding plasticizers such as glycerol is another approach to strengthen the physical and barrier properties of biodegradable polymers. It is reported that a kind of agricultural-waste-derived carboxymethyl cellulose (CMC) mixture added by glycerol has impressive mechanical strength and water barrier properties. While this kind of material is cost-reduced and still biodegradable, it is claimed to be a novel material for food packaging [48]. Moreover, some processes have been developed to make antimicrobial biodegradable polymer films to suit the need of food packaging. The material mixed copper nano-particle(CuNP) and stearic acid with acetate/polycaprolactone, exhibiting great antimicrobial activity against some bacteria [49].

A large number of improvements have been made to boost the mechanical strength, adjust the water/oxygen permeability, and lower the cost, which all aim to suit the biodegradable polymers in the food packaging industry.

4. Future applications of biodegradable polymer

Medical devices have long been an important portion of applications of biodegradable polymers and will also be an essential part of future applications. A variety of medical grafts made of biodegradable polymers have been developed. Those medical grafts claimed to be able to reduce the high cost of cultured human tissue by shortening the time needed for it to be thick enough, which shows that the biodegradable polymer grafts are potentially a better generation of medical devices of the future [50]. However, besides the high production cost, the controllability of degradation is also a vital problem that needs to be solved for those biodegradable polymers that are applied in medical devices. Especially for drug delivery devices, optimizations by chemical modification or nanotechnology are needed in the future [51]. The potential of biodegradable polymers has been stimulated by advancing technologies. Injectable hydrogel (IH) is reported to have novel properties and received FDA approval for clinical trials. While it is applicable in drug delivery, tissue regeneration, etc., new applications for HI are still being explored by new research [52].

In addition, agricultural applications are also of great interest for future biodegradable polymer developments. Semi-synthetic polymeric superabsorbent hydrogel is a great candidate for agricultural use in dry regions, with the advantages of both natural polymers and synthetic polymers. This material can be used to gradually release nutrients to the soil for the purpose of increasing crop yields [53]. Researchers also see land mulching films as great application places for biodegradable polymers, as they do not need to be removed manually and can degrade on soil automatically. Innovations on photo-biodegradable materials are proposed to push the development of land film applications of biodegradable polymers [54].

The medical sphere and agricultural sphere will be two important directions of future biodegradable polymers, as biodegradability and biocompatibility are two targeted properties of those industries. As biodegradable polymers have already gained some importance in these two spheres, future developments in them will continue to widen their applications.

5. Conclusions

Biodegradable polymers have gained great attention in the last few years as more concerns over plastic pollution have been raised. More and more research has been done to identify new types of biodegradable polymers and to optimize the current ones. This review paper included the current market share of biodegradable polymers, the classification of current types of biodegradable polymers, and applications of those novel materials. As biodegradability and biocompatibility are identified as impressive properties of biodegradable polymers, inferior mechanical and thermal properties, as well as high production costs, are disadvantages that need to be overcome. While biodegradable polymers only have a small market share compared to traditional petroleum synthetic polymers, they have been applied in plenty of products in the medical, agricultural, and packaging industries. Because of the great efforts that have been made to improve those biodegradable polymers and their novel properties, they will probably be the plastics of the future [3, 55]. The current research should focus on the development of new materials which is low-cost and high-performance.

References

[1]. Siracusa V, Rocculi P, Romani S and Dalla Rosa M 2008 Trends in food science & technology 19 634-43.

[2]. Sun Y, Hu J, Yusuf A, Wang Y, Jin H, Zhang X, Liu Y, Wang Y, Yang G and He J 2022 Biodegradation 33 1-16.

[3]. Haider T P, Völker C, Kramm J, Landfester K and Wurm F R 2019 Angewandte Chemie International Edition 58 50-62.

[4]. Luckachan G E and Pillai C 2011 Journal of Polymers and the Environment 19 637-76.

[5]. Filiciotto L and Rothenberg G 2021 ChemSusChem 14 56-72.

[6]. Avérous L and Pollet E 2012 Environmental silicate nano-biocomposites 13-39.

[7]. Du B, Peng F, Xie Y, Wang H, Wu J, Liu C and Yang Y 2022 Molecules 27 2380.

[8]. Díaz-Montes E 2022 Polysaccharides 3 480-501.

[9]. Li Q, Wang S, Jin X, Huang C and Xiang Z 2020 Polymers 12 1837.

[10]. Khalil H, Tye Y, Saurabh C, Leh C, Lai T, Chong E, Fazita M, Hafiidz J M, Banerjee A and Syakir M 2017 Express Polymer Letters 11.

[11]. Senthilkumaran A, Babaei-Ghazvini A, Nickerson M T and Acharya B 2022 Polymers 14 1065.

[12]. Ji Q, Zhang H, Zhang X, Ma Q, Teng L and Qiu L 2020 Journal of Biomaterials Science, Polymer Edition 31 2199-219.

[13]. Cheng H, Wyckoff W, Dowd M K and He Z 2019 Journal of Adhesion Science and Technology 33 66-78.

[14]. Adams B, Abdelwahab M, Misra M and Mohanty A K 2018 Journal of Polymers and the Environment 26 2360-73.

[15]. Puglia D, Luzi F and Torre L 2022 Polymers 14 5470.

[16]. Gomide R A C, de Oliveira A C S, Rodrigues D A C, de Oliveira C R, de Assis O B G, Dias M V and Borges S V 2020 Journal of Polymers and the Environment 28 1326-34.

[17]. Gupta V, Biswas D and Roy S 2022 Materials 15 5899.

[18]. Ibrahim M, Sapuan S, Zainudin E and Zuhri M 2019 International journal of food properties 22 925-41.

[19]. Xu B, Chen Y, He J, Cao S, Liu J, Xue R, Xin F, Qian X, Zhou J and Dong W 2022 Environmental Reviews 30 30-8.

[20]. Perin D, Rigotti D, Fredi G, Papageorgiou G Z, Bikiaris D N and Dorigato A 2021 Journal of Polymers and the Environment 29 3948-63.

[21]. de Castro T R, de Macedo D C, de Genaro Chiroli D M, da Silva R C and Tebcherani S M 2022 Journal of Polymers and the Environment 30 810-32.

[22]. Atalay S E, Bezci B, Özdemir B, Göksu Y A, Ghanbari A, Jalali A and Nofar M 2021 Journal of Polymers and the Environment 29 3412-26.

[23]. YousefniaPasha H, Mohtasebi S S, Tabatabaeekoloor R, Taherimehr M, Javadi A and Soltani Firouz M 2021 Journal of Food Processing and Preservation 45 e16089.

[24]. Germanova V N, Karlova E V, Volova L T, Zolotarev A V, Rossinskaya V V, Zakharov I D, Korigodskiy A R, Boltovskaya V V, Nefedova I F and Radaykina M V 2022 Polymers 14 3419.

[25]. Zhou J, Li L, Wang D, Wang L, Zhang Y and Feng S 2023 Polymers 15 183.

[26]. Solechan S, Suprihanto A, Widyanto S A, Triyono J, Fitriyana D F, Siregar J P and Cionita T 2022 Materials 15 7396.

[27]. Jwa S-J, Won J-M, Kim D-H, Kim K-B, Lee J-B, Heo M, Shim K-S, Jo H-S, Lee W-J and Roh T-S 2022 Polymers 14 3817.

[28]. Sundar N, Keerthana P, Kumar S A, Kumar G A and Ghosh S 2020 Journal of Polymer Research 27 1-18.

[29]. Laoutid F, Lenoir H, Molins Santaeularia A, Toncheva A, Schouw T and Dubois P 2022 Materials 15 8233.

[30]. Amanat N, Matturro B, Rossi M M, Valentino F, Villano M and Petrangeli Papini M 2021 Water 13 897.

[31]. Li W, Cicek N, Levin D B, Logsetty S and Liu S 2020 Journal of Biomaterials Science, Polymer Edition 31 394-406.

[32]. Dalton B, Bhagabati P, De Micco J, Padamati R B and O’Connor K 2022 Catalysts 12 319.

[33]. Lascu I, Tănase A M, Jablonski P, Chiciudean I, Preda M I, Avramescu S, Irgum K and Stoica I 2022 International Journal of Molecular Sciences 23 13754.

[34]. Narayanan M, Kumarasamy S, Kandasamy G, Kandasamy S, Narayanamoorthy B, Shanmugam S, Alharbi S A, Almoallim H S and Pugazhendhi A 2022 Journal of Polymers and the Environment 1-14

[35]. Patel B and Chakraborty S 2016 Journal of Excipients and Food Chemicals 4

[36]. Xu W, Sasaki M and Niidome T 2022 Pharmaceutics 14 492

[37]. Orłowska J, Kurczewska U, Derwińska K, Orłowski W and Orszulak-Michalak D 2015 Postępy Higieny i Medycyny Doświadczalnej 69

[38]. Jiang W, Jing X, Zhang K, Xu X, Shen Z, Liu T and Li Y 2010 Revista CENIC. Ciencias Biológicas 41 1-10

[39]. Álvarez Ó A, Castaño Llano R and Restrepo D 2015 Revista colombiana de Gastroenterología 30 178-86

[40]. Ginoya S U and Atara S A 2014 Pharma Science Monitor 5

[41]. Yue Y, Liu X, Pang L, Liu Y, Lin Y, Xiang T, Li J, Liao S and Jiang Y 2022 Evidence-based Complementary and Alternative Medicine 2022

[42]. Li X, Meng L, Zhang Y, Qin Z, Meng L, Li C and Liu M 2022 Polymers 14 2159

[43]. Sartore L, Vox G and Schettini E 2013 Journal of Polymers and the Environment 21 718-25

[44]. da Silva Porto F G, dos Santos Vasconcelos E, Campos  D, Carreño N L V and Garcia I T S 2021 Journal of Polymers and the Environment 29 1591-9

[45]. Grazuleviciene V, Treinyte J and Zaleckas E 2012 Journal of Polymers and the Environment 20 485-91

[46]. Srinivasa P and Tharanathan R 2007 Food reviews international 23 53-72

[47]. Hasan M, Lai T K, Gopakumar D A, Jawaid M, Owolabi F, Mistar E, Alfatah T, Noriman N, Haafiz M and Abdul Khalil H 2019 Journal of Polymers and the Environment 27 1602-12

[48]. Yaradoddi J S, Banapurmath N R, Ganachari S V, Soudagar M E M, Mubarak N, Hallad S, Hugar S and Fayaz H 2020 Scientific reports 10 1-13

[49]. El-Naggar M E, Hasanin M and Hashem A H 2021 Journal of Polymers and the Environment 1-13

[50]. Pal A, Pathak C and Vernon B 2018 Journal of Biomaterials science, Polymer edition 29 217-35

[51]. Wang L, Yang G, Xie H and Chen F 2018 Journal of Biomaterials Science, Polymer Edition 29 1657-66

[52]. Almawash S, Osman S K, Mustafa G and El Hamd M A 2022 Pharmaceuticals 15 371

[53]. Krasnopeeva E L, Panova G G and Yakimansky A V 2022 International Journal of Molecular Sciences 23 15134

[54]. Yang N, Sun Z-X, Feng L-S, Zheng M-Z, Chi D-C, Meng W-Z, Hou Z-Y, Bai W and Li K-Y 2015 Materials and Manufacturing Processes 30 143-54

[55]. Zhao L, Rong L, Zhao L, Yang J, Wang L and Sun H 2020 Microplastics in Terrestrial Environments: Emerging Contaminants and Major Challenges 423-45

Cite this article

Xue,Z. (2023). A review on biodegradable polymer: Shortcomings, developments, and future direction. Applied and Computational Engineering,23,86-95.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2023 International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Siracusa V, Rocculi P, Romani S and Dalla Rosa M 2008 Trends in food science & technology 19 634-43.

[2]. Sun Y, Hu J, Yusuf A, Wang Y, Jin H, Zhang X, Liu Y, Wang Y, Yang G and He J 2022 Biodegradation 33 1-16.

[3]. Haider T P, Völker C, Kramm J, Landfester K and Wurm F R 2019 Angewandte Chemie International Edition 58 50-62.

[4]. Luckachan G E and Pillai C 2011 Journal of Polymers and the Environment 19 637-76.

[5]. Filiciotto L and Rothenberg G 2021 ChemSusChem 14 56-72.

[6]. Avérous L and Pollet E 2012 Environmental silicate nano-biocomposites 13-39.

[7]. Du B, Peng F, Xie Y, Wang H, Wu J, Liu C and Yang Y 2022 Molecules 27 2380.

[8]. Díaz-Montes E 2022 Polysaccharides 3 480-501.

[9]. Li Q, Wang S, Jin X, Huang C and Xiang Z 2020 Polymers 12 1837.

[10]. Khalil H, Tye Y, Saurabh C, Leh C, Lai T, Chong E, Fazita M, Hafiidz J M, Banerjee A and Syakir M 2017 Express Polymer Letters 11.

[11]. Senthilkumaran A, Babaei-Ghazvini A, Nickerson M T and Acharya B 2022 Polymers 14 1065.

[12]. Ji Q, Zhang H, Zhang X, Ma Q, Teng L and Qiu L 2020 Journal of Biomaterials Science, Polymer Edition 31 2199-219.

[13]. Cheng H, Wyckoff W, Dowd M K and He Z 2019 Journal of Adhesion Science and Technology 33 66-78.

[14]. Adams B, Abdelwahab M, Misra M and Mohanty A K 2018 Journal of Polymers and the Environment 26 2360-73.

[15]. Puglia D, Luzi F and Torre L 2022 Polymers 14 5470.

[16]. Gomide R A C, de Oliveira A C S, Rodrigues D A C, de Oliveira C R, de Assis O B G, Dias M V and Borges S V 2020 Journal of Polymers and the Environment 28 1326-34.

[17]. Gupta V, Biswas D and Roy S 2022 Materials 15 5899.

[18]. Ibrahim M, Sapuan S, Zainudin E and Zuhri M 2019 International journal of food properties 22 925-41.

[19]. Xu B, Chen Y, He J, Cao S, Liu J, Xue R, Xin F, Qian X, Zhou J and Dong W 2022 Environmental Reviews 30 30-8.

[20]. Perin D, Rigotti D, Fredi G, Papageorgiou G Z, Bikiaris D N and Dorigato A 2021 Journal of Polymers and the Environment 29 3948-63.

[21]. de Castro T R, de Macedo D C, de Genaro Chiroli D M, da Silva R C and Tebcherani S M 2022 Journal of Polymers and the Environment 30 810-32.

[22]. Atalay S E, Bezci B, Özdemir B, Göksu Y A, Ghanbari A, Jalali A and Nofar M 2021 Journal of Polymers and the Environment 29 3412-26.

[23]. YousefniaPasha H, Mohtasebi S S, Tabatabaeekoloor R, Taherimehr M, Javadi A and Soltani Firouz M 2021 Journal of Food Processing and Preservation 45 e16089.

[24]. Germanova V N, Karlova E V, Volova L T, Zolotarev A V, Rossinskaya V V, Zakharov I D, Korigodskiy A R, Boltovskaya V V, Nefedova I F and Radaykina M V 2022 Polymers 14 3419.

[25]. Zhou J, Li L, Wang D, Wang L, Zhang Y and Feng S 2023 Polymers 15 183.

[26]. Solechan S, Suprihanto A, Widyanto S A, Triyono J, Fitriyana D F, Siregar J P and Cionita T 2022 Materials 15 7396.

[27]. Jwa S-J, Won J-M, Kim D-H, Kim K-B, Lee J-B, Heo M, Shim K-S, Jo H-S, Lee W-J and Roh T-S 2022 Polymers 14 3817.

[28]. Sundar N, Keerthana P, Kumar S A, Kumar G A and Ghosh S 2020 Journal of Polymer Research 27 1-18.

[29]. Laoutid F, Lenoir H, Molins Santaeularia A, Toncheva A, Schouw T and Dubois P 2022 Materials 15 8233.

[30]. Amanat N, Matturro B, Rossi M M, Valentino F, Villano M and Petrangeli Papini M 2021 Water 13 897.

[31]. Li W, Cicek N, Levin D B, Logsetty S and Liu S 2020 Journal of Biomaterials Science, Polymer Edition 31 394-406.

[32]. Dalton B, Bhagabati P, De Micco J, Padamati R B and O’Connor K 2022 Catalysts 12 319.

[33]. Lascu I, Tănase A M, Jablonski P, Chiciudean I, Preda M I, Avramescu S, Irgum K and Stoica I 2022 International Journal of Molecular Sciences 23 13754.

[34]. Narayanan M, Kumarasamy S, Kandasamy G, Kandasamy S, Narayanamoorthy B, Shanmugam S, Alharbi S A, Almoallim H S and Pugazhendhi A 2022 Journal of Polymers and the Environment 1-14

[35]. Patel B and Chakraborty S 2016 Journal of Excipients and Food Chemicals 4

[36]. Xu W, Sasaki M and Niidome T 2022 Pharmaceutics 14 492

[37]. Orłowska J, Kurczewska U, Derwińska K, Orłowski W and Orszulak-Michalak D 2015 Postępy Higieny i Medycyny Doświadczalnej 69

[38]. Jiang W, Jing X, Zhang K, Xu X, Shen Z, Liu T and Li Y 2010 Revista CENIC. Ciencias Biológicas 41 1-10

[39]. Álvarez Ó A, Castaño Llano R and Restrepo D 2015 Revista colombiana de Gastroenterología 30 178-86

[40]. Ginoya S U and Atara S A 2014 Pharma Science Monitor 5

[41]. Yue Y, Liu X, Pang L, Liu Y, Lin Y, Xiang T, Li J, Liao S and Jiang Y 2022 Evidence-based Complementary and Alternative Medicine 2022

[42]. Li X, Meng L, Zhang Y, Qin Z, Meng L, Li C and Liu M 2022 Polymers 14 2159

[43]. Sartore L, Vox G and Schettini E 2013 Journal of Polymers and the Environment 21 718-25

[44]. da Silva Porto F G, dos Santos Vasconcelos E, Campos  D, Carreño N L V and Garcia I T S 2021 Journal of Polymers and the Environment 29 1591-9

[45]. Grazuleviciene V, Treinyte J and Zaleckas E 2012 Journal of Polymers and the Environment 20 485-91

[46]. Srinivasa P and Tharanathan R 2007 Food reviews international 23 53-72

[47]. Hasan M, Lai T K, Gopakumar D A, Jawaid M, Owolabi F, Mistar E, Alfatah T, Noriman N, Haafiz M and Abdul Khalil H 2019 Journal of Polymers and the Environment 27 1602-12

[48]. Yaradoddi J S, Banapurmath N R, Ganachari S V, Soudagar M E M, Mubarak N, Hallad S, Hugar S and Fayaz H 2020 Scientific reports 10 1-13

[49]. El-Naggar M E, Hasanin M and Hashem A H 2021 Journal of Polymers and the Environment 1-13

[50]. Pal A, Pathak C and Vernon B 2018 Journal of Biomaterials science, Polymer edition 29 217-35

[51]. Wang L, Yang G, Xie H and Chen F 2018 Journal of Biomaterials Science, Polymer Edition 29 1657-66

[52]. Almawash S, Osman S K, Mustafa G and El Hamd M A 2022 Pharmaceuticals 15 371

[53]. Krasnopeeva E L, Panova G G and Yakimansky A V 2022 International Journal of Molecular Sciences 23 15134

[54]. Yang N, Sun Z-X, Feng L-S, Zheng M-Z, Chi D-C, Meng W-Z, Hou Z-Y, Bai W and Li K-Y 2015 Materials and Manufacturing Processes 30 143-54

[55]. Zhao L, Rong L, Zhao L, Yang J, Wang L and Sun H 2020 Microplastics in Terrestrial Environments: Emerging Contaminants and Major Challenges 423-45