1. Introduction

The number of fires that break out in buildings accounts for most of all fires worldwide [1]. People are very concerned about the damage to the concrete structure after the fire because the safety of the fire-damaged concrete structure needs to be assessed. In general, the size and length of the fire determine how severely reinforced concrete structures are damaged by fire. If the scale of the flame is small and constant for a short time, the damage to concrete components may be limited. In contrast, if the concrete structure is in a high-temperature environment for a long time, many concrete members may be seriously damaged, significantly reducing their mechanical strength and durability, and the safety of the entire structure is no longer guaranteed.

Table 1. Five levels of fire damage [2, 3].

Temperature | Damage extent | Grades |

Lower than 300 ℃ | Zero destruction | I |

Damage to finishing material (Exfoliation on the surface, soot) | II | |

300 to 600 ℃ | Concrete damaged, but steel not damaged (Concrete has minor fissures or is spalling.) | III |

600 to 950 ℃ | Bond damage of steel bars (Concrete with large fissures or exposed steel bars) | IV |

950 to 1200 ℃ | Buckling or destruction to steel bars (Excessive exposure to steel bars over a vast region, severe damage, or deformation to structural elements) | V |

Great than 1200 ℃ | Concrete melting |

The fire damage estimation method proposed by the Korea Concrete Institute (KCI) [2] and the Architectural Institute of Japan (AIJ) [3] divides the level of fire damage into five grades. From Table 1, under fire with a temperature lower than 300 ℃, the structures that are not damaged are classified as grade I, and those that are slightly damaged by fire are classified as grade II. When the temperature is between 300 ℃ and 600 ℃, the fire damage is classified as grade III. Small cracks in concrete or spalling can be observed at this grade, but the steel structure is not damaged. Primary and secondary investigations are used to conduct fire damage inspections. Preliminary evaluation includes on-site visual observation of concrete discoloration, cracks, peeling, and peeling to determine whether the degree of fire damage is classified as Level I. If not, a secondary evaluation is required through non-destructive evaluation, mechanical testing, material sample inspection, analytical techniques, etc [4]. Among these evaluation methods, non-destructive evaluation, especially the Ultrasonic Pulse Velocity Method, is often used. Several research related to UPV or using UPV to evaluate fire-damaged concrete have helped improve UPV and contributed to the development of fire safety engineering. However, few papers systematically summarize the application of UPV in fire-damaged concrete and its development in this field in recent years. The lack of a systematic summary may lead to limitations in the future development of this technology. This paper summarizes the traditional methods of using UPV in fire-damaged concrete, the application of UPV in new fireproof materials, and the use of UPV on other potential test objects. These summaries may provide an introduction for scholars who are new to UPV or the evaluation method of fire-damaged concrete and contribute to supplementing the plans of fire safety engineers on the future development of related technologies.

2. Ultrasonic pulse velocity method

The Ultrasonic Pulse Velocity (UPV) method is implemented by transmitting ultrasonic waves through materials. Short-sized ultrasonic pulses are transferred into the fabric to test internal defects or define the material. The UPV method has been widely used in the concrete industry for over fifty years. It is an essential non-destructive technique because it uses relatively inexpensive equipment and can provide reliable results quickly. The UPV method is suitable for determining concrete density, strength, elastic dynamic modulus, uniformity, durability, surface crack depth, and other characteristics [5].

2.1. Fundamental equipment

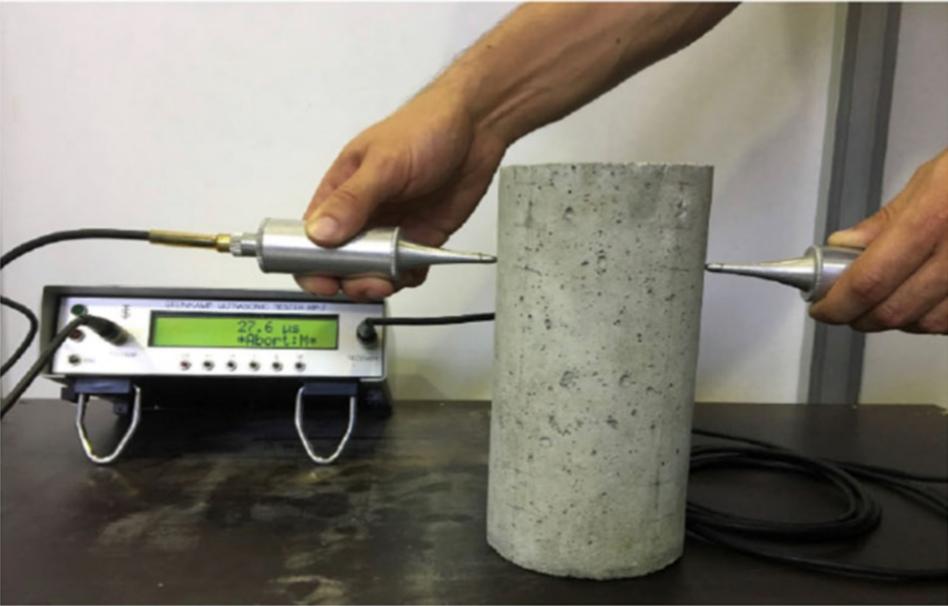

UPV is typically utilized in field evaluation to assess the extent of damaged concrete in the burned-out structure. The underlying idea is that the concrete construction's wear, flaws, or cracks will slow down ultrasonic wave transmission. Ufuk Dilek, PhD, P.E [6] evaluated a reinforced concrete structure destroyed by fire. The tested device uses a 5 cm (2 in) digital readout pulse velocity meter that is commercially available. The diameter reference bar insulated coaxial connection cables for the transducers, and the acoustic coupling substance was a jelly that can be soluble in water.

In 1985, Chung and Law [7] proposed using UPV to determine the depth of the fire-damaged surface layer with a lower wave speed than the underlying surface layer, this method uses multiple measurements taken on the exposed surface of concrete components (Figure 1). At the same time, the distance between transducers steadily increases. One can estimate the relative depth of the impacted layer using the slope shift between the transducer distance and the pulse travel time graph.

Figure 1. UPV test [8].

2.2. UPV-related calculations

Determining concrete's compressive strength is the UPV test's most common goal. De Silva and Sivahar [9] constructed a linear relationship between the strength of UPV and regular cement mortar to evaluate the compressive strength when the porosity is zero. Bogas, Gomes, and Gomes [10] proposed the equation below.

\( {f_{c}}≈{(\frac{UPV}{{K_{UPV}}×{ρ^{0.5}}})^{2/3}} \) (1)

KUPV is a constant value, and ρ is the density. In contrast, there is less research on the connection between UPV and porosity. Lafhaj, Goueygou, Djerbi, and Kaczmarek [11] studied the correlation between UPV and the porosity of mortars with different water/cement (w/c) ratios and water content.

\( UPV={UPV_{0}}×{(1-ρ)^{a}} \) (2)

UPV0 is the sample’s UPV when porosity is zero, ρ represents the porosity, and \( a=\frac{(c-1)}{2} \) , c is an empirical fitting parameter.

2.3. Advantages of UPV

UPV is widely used because it has many advantages, such as not affecting the analyzed structure's appearance or function. Cables, fibers, and other equipment do not need to be installed on the concrete structure; Data from the same test points can be gathered repeatedly; Crack detection can also be done using the ultrasonic pulse velocity, although the accuracy of using it alone is not satisfactory, it can be improved by using other technologies together [12].

3. Applications of UPV in evaluating new fireproof materials

Since roughly a century ago, Portland cement concrete has been a frequently utilized material in architecture, and its sustainability is gradually becoming a worrying issue. In contrast, lightweight foam concrete has become popular in recent years. Lightweight foam concrete has many advantages that traditional concrete does not have. Lightweight foam concrete is seen as being more environmentally friendly. It also has better thermal insulation, increased fluidity, and fire resistance. It has less weight to save material and construction costs [13].

During construction, lightweight foam concrete's internal microstructure and composition will change its quality, and timely on-site evaluation is necessary. Non-destructive testing is a standard and efficient method of on-site assessment because it does not cause damage to the items being tested. The UPV method is widely used in Non-destructive evaluation methods because it is easy to use and costs less [14]. Because lightweight foam concrete is homogeneous and only contains cement paste and evenly dispersed foam, it can provide more stable non-destructive evaluation results than typical concrete, which includes complex components and aggregates [13].

However, before testing, it is also necessary to clarify the changes in the model or formula caused by the different compositions of lightweight foam concrete and traditional concrete. The pores created by outside air into lightweight foam concrete often determine its porosity. Additionally, lightweight foam concrete lacks aggregate; therefore, there can be different relationships between UPV and porosity. Due to the participation of aggregate in the research of Bogas, Gomes, and Goms [15], the equation to determine the compressive strength given in section 2 cannot be used to determine lightweight foam concrete’s compressive strength. Therefore, redefining the connection between UPV, porosity, and compressive strength of lightweight foam concrete is necessary. Lizhao Liu, Saeed Miramini, and Ailar Hajimohammadi [13] have done related research and experiment; detailed results can be viewed in their research.

4. Existing problems in UPV testing

Although there has been a long history of UPV testing, it still has certain limitations, and its accuracy is affected by many factors: external temperature; water-cement ratio; air in concrete; age, type, and properties of the concrete; the impact of external conditions (rain, snow, etc.); need to keep surface free (such as restricting traffic).

An excellent way to increase the precision of UPV evaluation is to choose a partner to use with it. Since the concrete core test can reveal details regarding the remaining mechanical qualities or associated traits of the damaged layer or area, it has long been utilized in conjunction with UPV [6]. The residual mechanical property of fire-damaged concrete is one of the critical indicators for engineers to decide whether to repair or replace damaged concrete structures. Recent resolution, penetration, and power consumption advances have made non-destructive testing methods for microwave and millimeter wave frequencies feasible. Microwave imaging techniques can more accurately forecast the precise depth of fire damage than UPV testing, which is heavily dependent on material properties and surface preparation [16]. Although microwave and millimeter wave technologies cannot replace UPV because of the ease of use and low cost of UPV testing, these technologies can assist UPV testing in obtaining more accurate detection results when necessary.

Moreover, there are some lacking research aspects with UPV evaluation. Compared to mechanical properties, high temperature has a much more severe impact on the durability-related properties of concrete. The loss of chlorination resistance and carbonation performance of concrete is higher than 75% and 60% at 200 ℃ [17]. However, the mechanical properties of concrete can only be damaged obviously if the fire damage grade is above II, where the temperature is usually higher than 300 ℃. People know little between the UPV test and the sensitivity of durability-related performance loss of fire-damaged concrete. Andre ́Valente Monteiro. Manuel Vieira’s experiment that studied this problem contributed to the development of UPV testing [17]. The research found that the sample was kept in water before the test became saturated. Although the sensitivity of the UPV test using this saturated sample may be worried, it prevents water (water used in drilling) from destroying the reliability of the UPV test results [17], which improves the accuracy of UPV testing.

5. Conclusion

This paper reviews the traditional use of UPV in fire-damaged concrete, its application in new fire-resistant materials, and its application to other potential test objects. It can be seen that there are still many problems with UPV testing. The most important is how to increase the accuracy of UPV testing and reduce the limitation of testing. Although this technique has been used for a long time, its improvement still deserves engineers’ attention. The development of the aspects of combination with other non-destructive evaluations, the applications of new materials, and further research objects have shown its potential.

References

[1]. M. Chen (2009) Study on Application and Method of Diagnosing Flaw in Concrete Structure after Fire Using Ultrasonic Wave, Central South University, Hunan.

[2]. Korea Concrete Institute (KCI). (2005) Fire Resistance of Reinforced Concrete Structures; KCI: Seoul, Korea, pp.205.

[3]. Architectural Institute of Japan (AIJ). (2004) Diagnosis and Repair Methods of Fire-Damaged Buildings; AIJ: Tokyo, Japan, pp.140.

[4]. Cho, Hae-Chang et al. (2017) Fire Damage Assessment of Reinforced Concrete Structures Using Fuzzy Theory. Applied sciences, 7.5: 518.

[5]. Naik T., Malhotra V., Popovics J. (2003) The ultrasonic pulse velocity method, handbook on nondestructive testing of concrete. 2nd ed. Boca Raton: CRC Press; pp. 182–200.

[6]. Dilek, Ufuk. (2007) Assessment of Fire Damage to a Reinforced Concrete Structure During Construction. Journal of performance of constructed facilities, 21.4: 257–263.

[7]. Chung, H. W., and Law, K. S. (1985). Assessing fire damage of concrete by the ultrasonic pulse technique. Cement, concrete, and aggregates, ASTM, 72, West Conshohocken, pp. 84–88.

[8]. Valente Monteiro, André, and Manuel Vieira. (2021) Effect of Elevated Temperatures on the Residual Durability-Related Performance of Concrete. Materials and structures, 54.6.

[9]. De Silva S., Sivahar V., (2016) Non-destructive evaluation of strength gain of ordinary Portland cement mortar by ultrasonic pulse velocity method, Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, IEEE, pp. 337–342.

[10]. Bogas J.A., Gomes M.G., Gomes A. (2013) Compressive strength evaluation of structural lightweight concrete by non-destructive ultrasonic pulse velocity method. Ultrasonics. 53(5):962–972.

[11]. Lafhaj Z., Goueygou M., Djerbi A., et al. Correlation between porosity, permeability and ultrasonic parameters of mortar with variable water/cement ratio and water content. Cem Concr Res. 2006;36(4):625–633.

[12]. Ivanchev, Ivan, and Veselin Slavchev. (2019) About the Possible Limitations in the Usage of the Non-Destructive Ultrasonic Pulse Velocity Method for Assessment of Cracks in Reinforced Concrete Structures, Subjected to Direct Environmental Exposure.” Buildings (Basel), 9.9: 202.

[13]. Liu, Lizhao, Saeed Miramini, and Ailar Hajimohammadi. ((2019) Characterising Fundamental Properties of Foam Concrete with a Non-Destructive Technique. Nondestructive testing and evaluation, 34.1: 54–69.

[14]. Komlos̆ K., Popovics S., Nürnbergerová T., et al. (1996) Ultrasonic pulse velocity test of concrete properties as specified in various standards. Cem Concr Compos, 18(5):357–364.

[15]. Bogas J.A., Gomes M.G., Gomes A. (2013) Compressive strength evaluation of structural lightweight concrete by non-destructive ultrasonic pulse velocity method. Ultrasonics, 53(5):962–972.

[16]. Singh, Sanjeev K., Naina Narang, and Dharmendra Singh. (2021) Development of a Novel Approach to Detect Damage in Concrete Structures with Millimeter Wave Radar Assessment System. Review of scientific instruments, 92.4: 44710–044710.

[17]. Valente Monteiro, André, and Manuel Vieira. (2021) Effect of Elevated Temperatures on the Residual Durability-Related Performance of Concrete. Materials and structures, 54.6.

Cite this article

Zhang,J. (2023). Research on the application of ultrasonic pulse velocity method in fire-damaged concrete. Applied and Computational Engineering,23,141-145.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2023 International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. M. Chen (2009) Study on Application and Method of Diagnosing Flaw in Concrete Structure after Fire Using Ultrasonic Wave, Central South University, Hunan.

[2]. Korea Concrete Institute (KCI). (2005) Fire Resistance of Reinforced Concrete Structures; KCI: Seoul, Korea, pp.205.

[3]. Architectural Institute of Japan (AIJ). (2004) Diagnosis and Repair Methods of Fire-Damaged Buildings; AIJ: Tokyo, Japan, pp.140.

[4]. Cho, Hae-Chang et al. (2017) Fire Damage Assessment of Reinforced Concrete Structures Using Fuzzy Theory. Applied sciences, 7.5: 518.

[5]. Naik T., Malhotra V., Popovics J. (2003) The ultrasonic pulse velocity method, handbook on nondestructive testing of concrete. 2nd ed. Boca Raton: CRC Press; pp. 182–200.

[6]. Dilek, Ufuk. (2007) Assessment of Fire Damage to a Reinforced Concrete Structure During Construction. Journal of performance of constructed facilities, 21.4: 257–263.

[7]. Chung, H. W., and Law, K. S. (1985). Assessing fire damage of concrete by the ultrasonic pulse technique. Cement, concrete, and aggregates, ASTM, 72, West Conshohocken, pp. 84–88.

[8]. Valente Monteiro, André, and Manuel Vieira. (2021) Effect of Elevated Temperatures on the Residual Durability-Related Performance of Concrete. Materials and structures, 54.6.

[9]. De Silva S., Sivahar V., (2016) Non-destructive evaluation of strength gain of ordinary Portland cement mortar by ultrasonic pulse velocity method, Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, IEEE, pp. 337–342.

[10]. Bogas J.A., Gomes M.G., Gomes A. (2013) Compressive strength evaluation of structural lightweight concrete by non-destructive ultrasonic pulse velocity method. Ultrasonics. 53(5):962–972.

[11]. Lafhaj Z., Goueygou M., Djerbi A., et al. Correlation between porosity, permeability and ultrasonic parameters of mortar with variable water/cement ratio and water content. Cem Concr Res. 2006;36(4):625–633.

[12]. Ivanchev, Ivan, and Veselin Slavchev. (2019) About the Possible Limitations in the Usage of the Non-Destructive Ultrasonic Pulse Velocity Method for Assessment of Cracks in Reinforced Concrete Structures, Subjected to Direct Environmental Exposure.” Buildings (Basel), 9.9: 202.

[13]. Liu, Lizhao, Saeed Miramini, and Ailar Hajimohammadi. ((2019) Characterising Fundamental Properties of Foam Concrete with a Non-Destructive Technique. Nondestructive testing and evaluation, 34.1: 54–69.

[14]. Komlos̆ K., Popovics S., Nürnbergerová T., et al. (1996) Ultrasonic pulse velocity test of concrete properties as specified in various standards. Cem Concr Compos, 18(5):357–364.

[15]. Bogas J.A., Gomes M.G., Gomes A. (2013) Compressive strength evaluation of structural lightweight concrete by non-destructive ultrasonic pulse velocity method. Ultrasonics, 53(5):962–972.

[16]. Singh, Sanjeev K., Naina Narang, and Dharmendra Singh. (2021) Development of a Novel Approach to Detect Damage in Concrete Structures with Millimeter Wave Radar Assessment System. Review of scientific instruments, 92.4: 44710–044710.

[17]. Valente Monteiro, André, and Manuel Vieira. (2021) Effect of Elevated Temperatures on the Residual Durability-Related Performance of Concrete. Materials and structures, 54.6.