1. Introduction

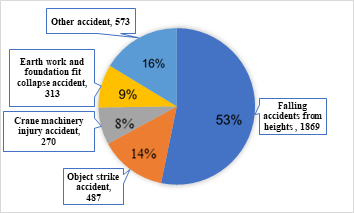

Due to the large scale of construction projects, complex construction technology, unfavorable site conditions, general lack of labor quality, huge investment, and various types of work involved, the construction processes face many challenges [1]. For example, the construction unit lacks perfect safety management system and regulations, pays insufficient attention to safety operation training, does not implement the safety production responsibility system in place, and the rationality of construction methods has not been fully reflected. These problems increase the risks of accidents in the construction process. Among them, the most serious types of accidents include falling from heights, being hit by objects, crane accidents. Based on information released by the Ministry of Housing and Urban-Rural Development of China, the number and proportion of various types of accidents from 2016 to 2020 is list in figure 1. As can be seen, falls from heights have been the most serious and most common type of construction accident over the years. It is visible that China still faces severe challenges in construction safety risk management. Therefore, in the construction industry, how to reduce costs and increase efficiency, how to strictly control construction quality, reduce or avoid safety accidents is the key to improving the competitiveness of construction companies in the construction industry [2].

Figure 1. Proportion of various construction accidents in China from 2016 to 2020 [3].

Construction safety management research mainly focuses on construction safety management measures, hazard analysis and evaluation, safety culture construction, etc., in order to improve the safety and management level of construction sites. The main methods used in its construction safety management research are questionnaire survey, case analysis, field investigation. However, due to the complexity and high risk of domestic construction sites, these methods still need to be further improved and improved. In terms of research results, Construction safety management research results are gradually increasing, mainly including: construction of construction site safety management system, research on hazard identification and evaluation methods, and construction of construction site safety culture. Through the analysis of the game process of construction safety management of factory reconstruction projects, Zhang concluded that factories should actively increase safety investment, strengthen supervision, increase investment in project construction safety operations, and ensure a stable construction safety operation state during reconstruction project construction [4]. Researches on construction safety management mainly also focuses on the establishment and improvement of construction safety management system, improvement of occupational health and safety awareness, and construction of safety culture. methods such as quantitative analysis, statistical analysis, and on-the-spot observation are mainly used. Through data analysis and comparative research, the reliability and accuracy of the research results are improved. Its research results are relatively rich, mainly including: the establishment and improvement of construction safety management system, the construction of construction site safety culture, the improvement of occupational health and safety awareness, hazard management and control, etc. A Malaysian study analyzed 108 fall accidents in Malaysia between 2010 and 2018. By developing AHP models of main factors and sub-factors related to fall accidents, the relative weights and priorities are determined. It was concluded that the most critical sub-factors were financial constraints, the complexity of high-altitude work, dangerous work procedures, unattended edges/holes, and a rush to get the job done [5].

Common construction safety accidents are falling from high altitude, object impact, electric shock, mechanical injury, collapse, etc. This paper selects several of the most common accidents and defines them. And three cases of falling from high altitude accident, object collision accident and lifting machinery injury accident are analyzed, and preventive measures are put forward.

2. Falling accidents from heights

2.1. Definition of falling accidents from heights

In order to understand falling accidents from heights, the definition of working at heights should be understood first. Working at heights refers to the way of working at a high place where a fall may occur with a fall height reference plane of 2m or more. "Falling from height accidents" refer to incidents where a person falls from a high level, such as from a building, a ladder, or a scaffold. These types of accidents can be extremely dangerous and often result in serious injuries or even death. Falling from a height can cause fractures, head injuries, spinal cord injuries, or internal injuries, which can lead to long-term disabilities or even permanent paralysis. These accidents can occur in a variety of settings, including construction sites, industrial workplaces, and domestic or recreational environments. Preventive measures such as using proper safety equipment and adhering to safety regulations can greatly reduce the risk of falling from height accidents.

2.2. Event case analysis of falling accidents from heights

2.2.1. Accident process. On December 13, 2016, at around 9:10, a fall occurred at the construction site of the Shunda Commercial Building. The site is located in the Genxi Cooperative Economic Cooperative Section of Shibei Village, Guangdong Province. The fall happened during the dismantling of the outdoor hoisting machine of the electric hoist. Unfortunately, the fall resulted in the death of one person [6].

2.2.2. Accident cause analysis. The worker disassembled a multifunctional electric hoist outdoor hoist but the disassembly method was unreasonable. As a result, the hoist lost its center of gravity during disassembly. The direct cause of the accident was that the hoist brought him to the ground when it fell, causing death.

The construction party contracted the accident project to an unqualified worker for construction without going through the required procedures. The lack of effective supervision of the safety of the construction site was one of the indirect causes of the accident. The worker did not have the corresponding construction qualifications to undertake the accident project. Lacking effective supervision of site safety, and failed to detect and stop workers' illegal operations in time, which was the second indirect cause of the accident.

2.3. Precautions of falling accidents from heights

2.3.1. Safety technical measures. Wearing safety helmets, installing protective railings and equipped with safety ropes are the basic safety technical measures stipulated by law, which can protect the head from impact and injury when working at heights, and effectively prevent workers from falling accidents due to falls. Meanwhile, it is necessary to avoid undertaking construction work during inclement weather. Construction workers are prone to slip and fall during operation, thus losing their center of gravity and causing falling accidents. After experiencing rainy and snowy weather, the management personnel in charge of construction should check and repair the equipment in time. If it is necessary to carry out night work, it must be carried out under the condition of sufficient light [7]. In addition, selecting a suitable and stable working position and checking and maintaining the equipment before working at altitude to ensure that it is in good working condition and meets safety standards are effective means to reduce the occurrence of falling from altitude accidents. Before scaffolding is erected, the technical person in charge shall be responsible for preparing a construction plan that meets the actual situation. After approval, the technical person in charge shall conduct a three-level disclosure before construction. After the construction is completed, special acceptance is required. Also, Scaffolding is not allowed in windy, frosty, rainy and snowy weather. If it is not necessary, scaffolding construction should not be carried out at night, otherwise it should have good lighting, and there should be no dead angles or shadows [8].

2.3.2. Safety management measures. It is helpful to provide adequate safety training for all workers engaged in high-altitude operations, including how to correctly use safety ropes, how to install and use protective equipment, etc. Also, establishing a corporate safety culture, emphasizing safety awareness, and educating employees on how to correctly handle safety accidents, can minimize the occurrence of falling accidents from heights.

Besides, it is necessary to establish and improve the scientific evaluation index system. Absolute value indicators do not take into account the differences in the market or the size of employees in different regions, and a relative value indicator system should be constructed, such as the death rate per 100,000 employees, and the injury and death rate per 1,000 people. Apart from that, strengthen work accident statistics is another effective way. The Heinrich theory in the United States holds that the ratio of serious injuries to minor injuries is 1:29, and the current incident reports and investigations are mainly focused on fatal accidents, while minor injuries an order of magnitude higher are free from supervision. Strict control of minor injury accidents, investigation of accident reports and investigation procedures, etc., are conducive to pre-empting the warning function of accidents and reducing the total number of fatal accidents [9].

3. Object strike accident

3.1. Definition of object strike accident

Accidents involving objects typically occur when an object strikes a person or a vehicle, causing injury or damage. These accidents can happen in a variety of contexts, such as on a construction site, in a warehouse, on the road, or even in the home. Common examples of accidents involving objects include being hit by falling debris, flying objects, or projectiles, being struck by a vehicle or heavy machinery, or being injured by equipment or tools. The severity of the injuries can range from minor cuts and bruises to severe trauma, and in some cases, can even be fatal.

3.2. Event case analysis of object strike accident

3.2.1. Accident process. At about 7:00 am on July 3, 2018, when Li was cleaning the steel pipes on the formwork surface, he carried a steel pipe on his shoulders and prepared to transport it to the scaffolding. Unexpectedly, his feet were caught by the steel bars of the beams, and he stumbled and fell. The steel pipes on his shoulders penetrated the safety net of the scaffold and fell. During the fall to the ground, it hit Zhu in the head who was walking on the ground on the first floor. The hard hat that Zhu was wearing was crushed and Zhu fell to the ground [10].

3.2.2. Accident cause analysis. The Lakeside Yuyuan project department of Zhejiang Sanrong Construction Co., Ltd. still took the risk of arranging staff to carry out scaffolding erection operations in light rainy weather, and no anti-slip measures were taken on site. In addition, when Li was transporting steel pipes on the formwork surface after the rain, he did not pay attention to strengthening his own safety protection, slipped and slipped, causing the steel pipes on his shoulders to fall. The above two points are the direct causes of the accident.

The company did not carry out unified coordination on construction safety, and the management work was not in place. Safety inspections and hidden danger rectification were not carried out in depth, and construction units were not supervised to implement safe and civilized construction measures. When the incident happened, it did not conduct special inspections and inspections on the scaffolding operation, and did not urge the construction unit to implement safe and civilized construction measures. The company safety management was not in place, it failed to refuse illegal instructions, and workers failed to take safety monitoring measures when they were working. The above points are the indirect causes of the accident.

3.3. Precautions of object strike accident

3.3.1. Safety technical measures. As shown in table 1, a few general precautions are listed. Firstly, wearing appropriate personal protective equipment (PPE) such as hard hat, safety glasses, and steel-toed boots could reduce injury from object strikes. In addition, regular inspection of equipment, tools and machinery can ensure that they are in good working order and free of defects can reduce the possibility of accidents. In addition, placing barriers or fences in hazardous areas where objects may strike, restricting access, and keeping the work area clean and organized can effectively reduce tripping or falling hazards that may lead to objects striking accidents.

3.3.2. Safety management measures. Proper training and education of workers in the safe operation of equipment and machinery, and encouraging workers to report to supervisors or safety officers immediately in case of unsafe situations or dangers, are conducive to the timely and rapid detection of problems from the perspective of workers. The establishment and implementation of safe working standards and procedures for the handling and storage of tools and equipment can standardize the management system of various tools. In addition, reasonable arrangement of work and rest time of personnel, reduction of nighttime construction and improvement of lighting environment of nighttime construction site can prevent fatigue of workers and reduce the probability of accidents [11].

Table 1. Precautions of object strike accident [11].

Safety technical measures | Safety management measures |

Wearing personal protective equipment | Provide training and education to workers |

Conduct regular inspections | Establish and enforce safe work practices |

Implement a clear communication protocol | Encourage workers to report unsafety |

Keep the work area clean and organized | Reduce nighttime construction |

Restrict access to hazardous areas | Arrange the work and rest time of personnel |

4. Crane machinery injury accident

4.1. Definition of crane machinery injury accident

A Crane Machinery Injury Accident refers to an incident in which a person is injured as a result of an accident involving a crane or other heavy lifting machinery. These accidents can occur in various settings, such as construction sites, warehouses, and ports. Crane Machinery Injury Accidents can be caused by a variety of factors, including operator error, equipment malfunction, and poor maintenance. These accidents can result in serious injuries, including fractures, amputations, and even fatalities.

4.2. Event case analysis of crane machinery injury accident

4.2.1. Accident process. On July 14, 2008, at the construction site of a commercial and residential building in Baoji City, Shaanxi Province, an accident occurred when a tower crane collapsed during the jacking process, resulting in 3 deaths, 3 injuries, and a direct economic loss of 1.55 million yuan. At around 16:00, the oil cylinder was raised to a height of 700mm. This caused the tower cap to shake and the tie rod connecting the balance arm and the tower cap fell off at the top joint of the tower cap. As a result, the balance arm became unstable and the tower crane shook. The two counterweights also broke and smashed about 16m below the balance arm. Eventually, the balance arm as a whole fell to about 13m below the arm and the second attachment was broken. This caused the tower crane to become unstable, and the tower body twisted and collapsed, and the workers on the tower also fell [12].

4.2.2. Accident cause analysis. The pin shaft at the connection between the tower cap and the balance arm rod of the tower crane falls off. Due to the shaking of the balance arm during the "5.12" earthquake, the pin shaft and the pin hole were severely deformed, and the cotter pin at the end of the pin shaft was cut off and fell off, and was not repaired or replaced. The jacking operation caused shaking, which caused the deformed and loose pin to slip off at the 7L of the south ear plate tie rod, the balance arm became unstable, and the tower crane collapsed. The above points are the direct causes of the accident.

The construction unit starts construction without obtaining the construction project planning permit and construction permit. The construction unit and supervision unit were not selected according to the prescribed procedures, and the quality and safety supervision agency was not entrusted to supervise the project. The measures to ensure safe construction were not submitted to the construction administrative department for record. The above points are the indirect causes of the accident.

4.3. Precautions of crane machinery injury accident

4.3.1. Safety technical measures. Regularly inspecting the crane machinery for any wear and tear, defects, or malfunctions that could cause accidents to ensure that the crane machinery is properly maintained and serviced to prevent equipment failure or breakdown. In addition, always adhere to the load limits specified for the crane machinery to prevent overloading, because it will cause the crane to tip over or collapse.

In addition, accidents can be avoided to the maximum extent if the following three points can be ensured. First, all necessary safety devices, such as load limiter, anti-collision system and emergency stop button, are installed accurately and work properly. Second, the ground of crane machinery operation is firm and smooth, and there are no obstacles and dangers in the operation area. Third, all workers involved in crane operations wear appropriate personal protective equipment, such as hard hats, gloves and seat belts.

4.3.2. Safety management measures. It is necessary to ensure that all crane operators and workers receive adequate training on the use of the crane machinery, including safety procedures, and the risks involved in crane operations. Appropriate training can enable workers to avoid part of the injuries through the knowledge learned from training. Next, misunderstandings and accidents can be prevented by using clear communication protocols between crane operators and other workers on the job site to avoid using cranes in bad weather conditions. In addition, emergency planning in the event of a mechanical accident or injury, including procedures for reporting and responding to accidents, would be a useful approach.

Moreover, the installation and dismantling links must be strictly controlled [13]. The installation and disassembly of hoisting machinery is a relatively dangerous operation. According to the characteristics of the hoisting machinery type and the requirements of the manual, a detailed construction plan shall be formulated in combination with the operating conditions.

In addition, large-scale mechanical operations must be supervised by "one machine, one person"[14]. During the operation, the guardian and the operator must have a fixed and clear communication method. The operator must obey the command of the guardian, and the guardian must hold a warning stick or a red flag.

5. Conclusion

This paper summarizes the construction safety accidents that occurred in China from 2016 to 2020, and studies three common accidents among them, including falling accidents from heights, objects strike accidents, and crane machinery injury accident. By analyzing the cases, this paper draws some effective precautions against the above three kinds of accidents. Results show that it is necessary to improve the scientific evaluation index system, strictly control the investigation and investigation procedures of minor accidents, accident reports, etc., improve the lighting environment for night work, and strictly control the installation and disassembly links.

It is found that the research on construction safety accidents in this paper still has limitations, as only three types of common construction safety accidents are discussed, and no in-depth research has been done on the analysis of accidents such as electric shock and collapse. Improvements can be made in the following aspects. Firstly, more types of construction safety accidents would be discussed, and the causes and preventive measures of construction accidents should be comprehensively analyzed. Secondly, the accident samples can be enriched to make the research completer and more convincing. Third, more control measures can be put forward in the future to eliminate the safety hazards more effectively at the construction site.

References

[1]. Yang Y 2022 Research on Construction Safety Risk Management of XH Project (Master's thesis, Hebei University of Geosciences)

[2]. Mo S 2022 Research on construction safety risk evaluation of comprehensive transportation hub engineering based on bayesian network (Master's thesis, Hebei Institute of Architecture and Engineering)

[3]. Notification of the General Office of the Ministry of Housing and Urban-Rural Develop-ment on Production Safety Accidents in Housing and Municipal Engineering https://w-ww.mohurd.gov.cn/

[4]. Zhang W 2022 Game study on construction safety management of pharmaceutical factory reconstruction project-taking plant b as an example (Master's thesis, Zhejiang University)

[5]. Aminu D, Madzlan N, Ideis O, Milijan M, Abdulrahman H, Hamzh A and Yasser Y 2022 Analysis of the causes and preventive measures of fatal fall-related accidents in the construction industry Ain Shams Eng. J. 13 101712

[6]. "12.13" Shishan Heights Fall Accident Investigation Report 2023-4-12 http: www.safehoo.com

[7]. Qian X 2021 Analysis and prevention of building construction fall accidents based on fishbone diagram-fault tree (FTA) House pp 172-174

[8]. Li J 2021 The management research on workers’ unsafe behavior of high falling risk in W construction project (Master's thesis, Qingdao University)

[9]. Luo W 2022 Research on the characteristics and prevention of falling accidents in building construction Cconst. Safety 37(1) pp 55-58

[10]. Investigation Report on the "7.3" Object Strike Accident of the Lakeside Royal Garden Construction Project 2022-11-29 http: www.safehoo.com

[11]. Li X and Chen Q 2012 Main types and prevention measures on construction production safety accidents in China CHN Civ. Eng. J. 45(2) pp 245-248

[12]. "7.14" Tower Crane Collapse Accident in Baoji City, Shaanxi Province 2015-3-3 http: www.safehoo.com

[13]. Wang J 2010 Causal Analysis and Safety Management Discussion on Hoisting Machinery Accidents E&M Engr. Tech. 39(2) pp 105-108+112

[14]. Qi J 2013 Discussion on how to do a good job in mechanical safety management on construction site from several mechanical injury accidents Const. Safety 3 pp 34-36

Cite this article

Fei,F. (2023). Analysis on safety management measures in civil engineering construction. Applied and Computational Engineering,24,51-57.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2023 International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Yang Y 2022 Research on Construction Safety Risk Management of XH Project (Master's thesis, Hebei University of Geosciences)

[2]. Mo S 2022 Research on construction safety risk evaluation of comprehensive transportation hub engineering based on bayesian network (Master's thesis, Hebei Institute of Architecture and Engineering)

[3]. Notification of the General Office of the Ministry of Housing and Urban-Rural Develop-ment on Production Safety Accidents in Housing and Municipal Engineering https://w-ww.mohurd.gov.cn/

[4]. Zhang W 2022 Game study on construction safety management of pharmaceutical factory reconstruction project-taking plant b as an example (Master's thesis, Zhejiang University)

[5]. Aminu D, Madzlan N, Ideis O, Milijan M, Abdulrahman H, Hamzh A and Yasser Y 2022 Analysis of the causes and preventive measures of fatal fall-related accidents in the construction industry Ain Shams Eng. J. 13 101712

[6]. "12.13" Shishan Heights Fall Accident Investigation Report 2023-4-12 http: www.safehoo.com

[7]. Qian X 2021 Analysis and prevention of building construction fall accidents based on fishbone diagram-fault tree (FTA) House pp 172-174

[8]. Li J 2021 The management research on workers’ unsafe behavior of high falling risk in W construction project (Master's thesis, Qingdao University)

[9]. Luo W 2022 Research on the characteristics and prevention of falling accidents in building construction Cconst. Safety 37(1) pp 55-58

[10]. Investigation Report on the "7.3" Object Strike Accident of the Lakeside Royal Garden Construction Project 2022-11-29 http: www.safehoo.com

[11]. Li X and Chen Q 2012 Main types and prevention measures on construction production safety accidents in China CHN Civ. Eng. J. 45(2) pp 245-248

[12]. "7.14" Tower Crane Collapse Accident in Baoji City, Shaanxi Province 2015-3-3 http: www.safehoo.com

[13]. Wang J 2010 Causal Analysis and Safety Management Discussion on Hoisting Machinery Accidents E&M Engr. Tech. 39(2) pp 105-108+112

[14]. Qi J 2013 Discussion on how to do a good job in mechanical safety management on construction site from several mechanical injury accidents Const. Safety 3 pp 34-36