1. Introduction

Nowadays, the material science industry has become one of the most important industries in the development of science and technology and in life. From moon landing rockets and interstellar satellites to shoes and clothes in people's lives, material science is applied. As a type of material with a short development time, polymer materials have shown great potential in various industries, such as aerospace, construction, medical treatment and textiles. With the development of the economy and the sports industry, better sports equipment and equipment are needed no matter whether it is physical exercise in people's daily life or the competition and training of professional athletes. And all kinds of polymer composite materials have become important materials to improve the performance of sports equipment by virtue of their special mechanical properties and other characteristics, so they are widely used in various competitive sports.

This paper studies the application and influence of polymer composite materials in competitive sports, and analyzes the application of polymer composite materials in sports equipment in connection with the performance of polymer materials and the performance required by sports equipment. And compare the performance of sports equipment using polymer materials at this stage and the performance of relatively long-term basic equipment, and study the impact of polymer materials on sports with the changes in the performance of athletes with the application of polymer materials. There is no lack of research on a single material in a single sport in the past literature, but it lacks a general overview. It expounds the application of different materials in different sports, which is of certain significance for understanding the relationship between sports equipment and polymers.

2. The introduction of several types of polymer materials

The manufacture of carbon fiber needs to predict the PAN fiber first, including following six step.

2.1. Carbon fibre

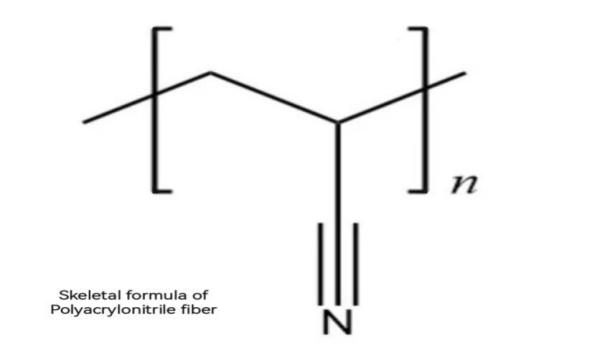

2.1.1. Manufacture of carbon fibre. The raw material of carbon is prepared from polyacrylonitrile, a kind of synthetic synthesis of various synthetic free radical polymerization reaction polymerization Substances, usually end to end (C3H3N), as shown in Figure 1.

Figure 1. Skeletal formula of polyacrylonitrile fiber.

Stretch the PAN fiber on a drawing machine to make it into a long and thin fiber, and then spin it into a monofilament on a spinning machine. This is called spinning.

Than the materials are pre-oxidised. During the pre-oxidation process, polyacrylonitrile fibers first undergo a pyrolysis reaction in the presence of oxygen or air to generate functional groups with oxidative properties, such as ketones, aldehydes, and carboxylic acids. These functional groups will form oxide segments at high temperatures (usually 200°C to 400°C), thereby increasing the thermal stability and high temperature resistance of polyacrylonitrile fibers.

The carbonization is the next process, and it includes low-temperature carbonization and high-temperature carbonization. Low-temperature carbonization is usually carried out in a low-temperature carbonization furnace at about 300°C to 800°C and containing inert gas as a protective gas. The heating temperature in the high-temperature carbonization stage is between 1000°C and 2000°C. Under the protection of high-purity inert gas, the pre-oxidized silk undergoes pyrolysis and polycondensation reactions to remove non-carbon atoms such as chlorine and oxygen elements, forming a chaotic Carbon fiber with layer graphite structure [1].

The next step is surface treatment. Surface treatment of carbon fiber includes steps such as removing surface impurities, sizing and increasing surface roughness to improve its bonding performance with other materials. Surface treatment can be roughly divided into several types.

Chemical surface treatment: use oxidizing agents, reducing agents, acids, alkalis and other chemical agents to treat the surface of carbon fibers to change the chemical properties of the surface and enhance its bonding and adhesion with the matrix.

Physical surface treatment: use mechanical and heat treatment methods to treat the carbon fiber surface, such as grinding, sandblasting, cutting, etc., to improve its surface morphology and structure and enhance its mechanical properties.

Surface sizing treatment: Surface sizing refers to covering the fiber surface with a layer of coating or resin to enhance its surface properties and protect it from environmental and chemical attack. Sizing can improve the surface smoothness, wear resistance, corrosion resistance, water resistance and high temperature resistance of carbon fiber, as well as increase its adhesion and mechanical strength. Commonly used sizing materials include epoxy resin, polyester resin, polyurethane, etc [2].

Than cut and twist the carbon fiber according to the requirements to obtain the carbon fiber with the required length and strength.

2.1.2. The mechanical properties of carbon fibre. Carbon fiber is a high-strength, high-modulus material with excellent mechanical properties. The following is the mechanical performance analysis of carbon fiber: Strength and modulus: The strength of carbon fiber is very high, usually above 3000 MPa, 5-10 times higher than steel. This makes carbon fiber an ideal lightweight material to reduce weight while maintaining structural strength. The following experiments use carbon fiber plain coiled tube as a sample, which is made of carbon fiber and epoxy resin. The cross-sectional shape of the sample is shown in Table 1. The inner diameter of the sample is 18mm, the outer diameter is 20mm, and the length is 100mm. The measured cross-sectional area is 59.69 mm2. Choose WDW-100 microcomputer-controlled electronic universal testing machine to carry out tensile and compression tests on the samples, which resulting in the following data.

Table 1. Mechanical properties data of carbon fibre [3].

Maximum force /N | 21,260.3 |

Tensile strength/Mpa | 356.2 |

Upper yield strength/Mpa | 308.7 |

Lower yield strength /Mpa | 307.1 |

Maximum total elongation /% | 11.9 |

Fatigue resistance: Carbon fiber has excellent fatigue resistance and can withstand millions of cyclic loads without severe fatigue damage.

Corrosion resistance: Because of the high strength and inactive chemical properties of carbon fiber, carbon fiber has good corrosion resistance to chemicals such as water, acid and alkali.

Thermal stability: Due to the macromolecular covalent structure of carbon fiber and the special high-temperature carbonization process, carbon fiber itself has high thermal stability. Partially structured carbon fibers can maintain excellent performance at temperatures above 3000°C. (4) However, most of the carbon fiber composite materials on the market now have a defect. Since the sizing material such as resin generally has a low melting point, even if the carbon fiber itself has high thermal stability, the carbon fiber composite material composed of it still cannot be used in under high temperature environment.

Conductivity: Carbon fiber is an excellent conductive material that can be used to make electronic components and battery electrodes.

2.2. Graphene

Graphene is first used as superconductor beacuse of its electrical conductivity than people discovered its excellent mechanical properties and use in many generations of other facilities. Research on graphene began as early as the 1970s. Until 2004, physicists Andre Geim and Konstantin Novoselov of the University of Manchester in the United Kingdom successfully separated graphene from graphite using micromechanical exfoliation, and thus won the 2010 Nobel Prize in Physics. scholarship. Graphene (Graphene) is exfoliated from graphite material, by C atoms form a hexagonal two-dimensional carbon in a honeycomb lattice with sp² hybrid orbitals Nanomaterials. Graphene material is currently the thinnest material in nature material, only one layer of atomic thickness; it is also the strongest material, its fracture 200 times higher crack strength than the best steel material [4]. A certain amount of phenolic resin is added to the graphene fiber, and the carbonization of the amorphous. The newly formed amorphous carbon exists between the graphene sheets, thus making up for some defects inside the fiber and ensuring the compactness of the composite fiber Chemical [5]. Graphene-based carbon fiber composites processed by this method The performance is further enhanced, the tensile strength and elongation at break can be as high as 1.45 respectively GPa, 1.8%, increased by 113% and 38%.

2.3. Preparation and properties of rubber

Rubber is generally divided into synthetic rubber and natural rubber. Natural rubber is an elastic solid made of natural latex collected from natural plants such as rubber trees and rubber grasses, and processed through coagulation and drying. Natural rubber is a natural polymer compound mainly composed of cis-1,4-polyisoprene. Synthetic rubber is obtained by polymerization of monomers. It mainly includes butadiene, resin, styrene and so on. Natural rubber Natural rubber has good elasticity and high mechanical strength, and its elastic modulus after processing is generally about 3-6Mpa. At the same time, because of its wide molecular weight distribution, it also has the property of being easy to process. It has better dispersibility and co-solubility with the compounding agent, and it is also easy to be machined and pasted. And natural rubber has good insulation, which is a kind of natural good insulator and heat insulator. However, the poor air permeability of natural rubber and poor aging and heat resistance limit the application environment of natural rubber, which is the biggest defect of natural rubber. Its sources are also limited. Compared with natural rubber, synthetic rubber can adapt to a wider range of temperatures and has a wide variety. It also has oil resistance, insulation, high elasticity and air tightness, and can withstand certain high and low temperatures. However, due to its preparation process, synthetic rubber is more difficult to degrade naturally than natural rubber, causing greater environmental pollution, and at the same time, its tear strength and mechanical properties are slightly worse than natural rubber.

2.4. Preparation and properties of polyurethane and its synthetic materials

Polyurethane is a polymer compound invented by German scientists in the 1930s and also a kind of plastic. The main components that make up polyurethane are compounds including diphenylmethane diisocyanate (MDI), toluene diisocyanate (TDI), and polypropylene glycol (PPG). Isocyanate is a general term for various esters of isocyanic acid. If classified by the number of -NCO groups, it includes monoisocyanate \( R-N=C=O \) and diisocyanate O=C=N-R-N=C=O and polyisocyanate; it can also be divided into aliphatic isocyanate and aromatic Aromatic isocyanate, currently the largest use of aromatic isocyanate, such as MDI, TDI and so on [6]. Polyurethane can be made into a variety of synthetic materials, such as polyurethane fiber, polyurethane plastic, polyurethane rubber and polyurethane synthetic leather. Among them, polyurethane synthetic leather is widely used in the sports industry, and it is also the polyurethane material highlighted in this paragraph. Polyurethane synthetic leather is obtained by using raised cloth as the production base, polyurethane solution as the coating, brushing the solution on the raised cloth, and then foaming. The preparation methods of polyurethane synthetic leather are specifically divided into two types, namely dry preparation and wet preparation. The dry method is specifically to volatilize the solvent-based polyurethane resin solution to form a multi-layer structure composed of the base cloth and the multi-layer film, that is, to brush the polyurethane resin solution on the surface of the densified elastic fabric, and then heat and dry it in sections. Quickly volatilize the solvent in the polyurethane resin, which can promote the close combination between the fabric layer and the polyurethane resin to form a dense layer. Specifically, the wet method is to process the solvent-based polyurethane resin by the film-forming method in water and has formed a multi-layer structure with a continuous pore layer [7-8]. Polyurethane synthetic leather has very low thermal conductivity due to its special structure, which means that polyurethane synthetic leather can be a good insulation material. At the same time, the polyurethane synthetic leather script has good anti-aging properties, which can effectively improve the service life of the product. Polyurethane synthetic leather also has a certain degree of water resistance and air permeability. In the interim, the polyurethane prepared by the wet method will have better air permeability and air permeability than that prepared by the dry method. The feel and texture of polyurethane synthetic leather are also relatively good, especially at different temperatures, the feel and hardness of polyurethane synthetic leather hardly change. But polyurethane synthetic leather, like most synthetics, is also not resistant to high temperatures.

3. The application and influence of polymers in competitive sports

3.1. Ball games

With the development of science and technology, various polymer composite materials are applied to various ball sports equipment to improve the performance of the equipment and the sports performance of athletes.

3.1.1. Football. The application of polymer materials in football is usually in sneakers and shin guards. The shin guards are constructed as an outer protective layer for stiffness and an inner cushioning layer. The outer protective layer generally requires sufficient hardness and light weight. The earliest shin guards were made of bamboo and wood. These shin guards were relatively bulky, which made them provide a certain degree of protection but affected the athlete's athletic performance. The mainstream material of modern shin guards is synthetic plastics, such as PE polyethylene, PU polyurethane, TPR thermoplastic rubber, etc. In recent years, carbon fiber has also been used in the manufacture of shin guards. Due to the excellent mechanical properties and low density, the above-mentioned materials can provide good protection while minimizing the foreign body sensation on the athlete's legs and the impact on sports performance. The application of polymer composite materials in football shoes is more extensive, mainly on the upper but also includes soles, friction particle technology, spikes and so on. Early football shoe uppers were mostly natural leather, such as kangaroo leather, goat leather, etc., but now the combination of artificial leather, polyurethane and fabric heating and melting film is also widely used in individual branded sneaker uppers. These materials have their own characteristics. The application of polymer composite materials on the upper provides more choices for football players than the upper replacement. The most representative and widely used natural leather material for football shoe uppers is kangaroo leather. Like most natural leathers used in football shoes, kangaroo leather uppers are relatively soft, which can provide a comfortable foot feeling for wearing and are more sensitive to touch. There is a certain cushion when the ball is played, and the major football brands also widely use leather in their tactile sneakers, such as ADIDAS’s Copa series, Nike’s Tiempo and most of Mizuno’s sneakers. The disadvantages of leather materials are also obvious. Corresponding to the softer touch is less direct force transmission. In addition, sneakers with large areas of leather generally have a shorter service life. Due to the special properties of leather, leather sneakers are easier to unglue. and peeling and low tolerance to water. The application of artificial leather solves the problem of the service life of natural leather to a certain extent. Artificial leather has the softness of natural leather to a certain extent but is lighter and thinner than natural leather. Moreover, the cost of artificial leather materials used in football shoe uppers varies greatly, and artificial leather with different costs and performances can be assembled on different levels of football shoes to provide consumers with more choices. The PU material pays more attention to the transmission of force. The upper made of PU material is harder and thinner than natural leather and synthetic leather, which provides good performance for force transmission. The harder and thinner upper is Athletes provide a clearer touch and shot power, while also reducing the weight of the shoes, this type of material is usually applied to speed shoes, such as the X series of ADIDAS. The combination of fabric and hot-melt film provides better wrapping for the sneakers. The hot-melt film (thermoplastic polyurethane) can enhance the performance of the fabric material and enhance water resistance. With the characteristics of good wrapping and light weight, it is also used in speed sneakers such as Nike's Mercurial. At the same time, because of the strong wrapping, the technology of connecting the upper with fabric material on the instep has largely replaced football shoes. Original tongue design. In addition, carbon fiber has also been used recently to strengthen the support and fixation of the sole of football shoes, which provides sufficient hardness and excellent rebound on the basis of allowing certain deformation.

3.1.2. Basketball. The application of polymer composite materials in basketball is also extensive, including but not limited to basketball, sneakers, court floors, etc. Compared with football and basketball shoes, it pays more attention to the stability of the shoes and the cushioning technology of the soles. The application of polymer composite materials in basketball shoes mainly lies in the air cushion of sneakers. The air cushion plays an irreplaceable role in the cushioning and rebound of basketball shoes, and the wrapping material of the outer layer of air cushion is the polymer composite material in sneakers. Applications. At present, the most commonly used materials for air cushions are polyurethane (PU), polyvinyl chloride (PVC), thermoplastic polyurethane (TPU), etc. In addition, besides the wooden floor, there are three commonly used basketball courts on the market, namely, acrylic material, silicon PU material, and suspended floor material. Among them, silicon PU material is the most widely used on the market, and it is also often used in regular basketball courts. Silicon PU materials not only have stable material properties, but also have good elasticity, wear resistance, weather resistance, good aging resistance, and a long service life. Generally, they can be used for more than ten years. The disadvantage is that the cost is high.

3.2. Golf, tennis, badminton

Golf, tennis and badminton, these three sports have one significant property, both of them contact the ball through a tool and this is the reason they are put in same paragraph to discuss. The steel shaft of the 1930s was the standard American golf ball. In 1972, the United States first used carbon fiber composite materials to make clubs. By 1998, the number of carbon fiber golf clubs greatly exceeded that of steel clubs. Golf clubs are composed of grips, shafts, and club heads. Golf clubs made of carbon fiber composite materials can reduce weight by about 10% to 40%. According to the principle of conservation of momentum, in addition, carbon fiber composite materials have high damping properties, which can prolong the hitting time and make the ball hit farther. The development trend of tennis rackets is large-scale and lightweight. At present, most high-end and mid-range tennis rackets in the world are made of carbon fiber composite materials. Large tennis racquets need to be made of carbon fiber composite materials with light weight, specific strength and large specific modulus. It can bear the stronger tension of the net wire than the wooden racket frame to ensure that it will not deform when hitting the ball. The carbon fiber composite material with good vibration and damping properties not only gives players a sense of comfort, but also enables the tennis ball to obtain a greater initial velocity. The application and influence in badminton are similar to tennis and golf, it's mean improvement is that badminton racket become lighter through using carbon fibre composite material. The meanly safe the energy of athletes and help them to hit the ball with a higher speed.

3.3. Ice and snow sports

Before the 1960s, skis were mainly made of synthetic fiber boards, etc. This type of material has mechanical properties far superior to ordinary wood or metal materials, but the vibration is relatively large when sliding, which cannot give full play to the sliding level of athletes; in the 1970s, material science experts have developed a new type of polymer material - ultra-high molecular weight polyethylene. The skis made of this material have greatly improved the sliding performance; after entering the 21st century, some experts have developed a conductive snowboard to effectively prevent skis. The static electricity generated during the process avoids the snowboard’s adsorption of impurities in the snow; in recent years, some experts have successfully used polyamide fiber and carbon fiber epoxy composite as the main material, and successfully developed a high-strength, anti-friction composite by extrusion and fiber winding technology. A new type of ski with high impact strength and high bending strength [9].

3.4. Other sports

Pole vault was officially absorbed as a sport in the first Olympic Games In the competition event, the poles at that time were made of hickory wood, which was strong and heavy, lacked elasticity, and had poor energy storage capabilities, so that most of the kinetic energy of the players was wasted, so the best jumping result was only 3.3m. Later, bamboo poles replaced wooden poles, the light weight of which is good for run-up, and the elasticity is good for energy conversion. In the 1960s, athletes began to use nylon poles, which were soon replaced by fiberglass poles. The continuous reform of pole materials has made the world record set again and again. Now the pole has developed to the fourth generation, glass fiber and nylon have been replaced by carbon fiber composite materials with better performance, and the material of different parts can be designed according to the difference in the force of the pole to optimize the overall performance. The latest carbon fiber pole can ensure that the pole is tough and strong without breaking or kink. It can convert the kinetic energy part of the athlete’s high-speed run-up with the pole into the elastic deformation energy of the pole. When the pole is bent to the maximum arc, this part of the elastic deformation can be released again and transformed into the potential energy of the athlete, helping the athlete to leap into the air and fly over the bar. Bow and arrow, in the archery project, improving the performance of archery equipment is an important way to improve archery performance, and the main method to improve the performance of its equipment is to increase the specific elasticity of bow and arrow. The best bow in the world today is a series of carbon fiber composite materials. The bow arm (bow piece) made of carbon fiber composite materials can withstand a bending stress of 50 kg/mm2, giving the arrow the largest initial velocity and the longest range [10]. When opening a bow and shooting an arrow, one piece relaxes. The fatigue resistance of carbon fiber composite materials is unmatched by fiberglass and metal materials, so the bow arm made of it has a longer service life. Bicycle, with the rapid development of modern society, bicycle is not only a means of transportation and transportation, but also has multiple functions such as fitness, tourism, and competition. The car frame, front fork parts, wheels, crankshaft and seat bracket of high-end bicycles are all made of carbon fiber composite materials, which not only makes the appearance of the bicycle more beautiful, but also gives the car body good rigidity and shock absorption performance. The weight of the car body is further reduced, and the riding comfort is better. Therefore, once it is successfully developed, it will be used as a special racing car [11].

4. Conclusion

This paper mainly studies the application and influence of polymer composite materials in competitive sports, briefly expounds the preparation of some polymer composite materials and analyzes their properties and characteristics. Different equipment requires different performance characteristics, and different polymer materials also have different effects on the performance of the equipment. For example, the performance requirements of a large part of sports equipment are lighter, stronger, and the cost and service life are also issues that generally need to be considered. In response to these problems, this paper analyzes the current use of these polymer composite materials in various sports-related equipment and the reasons through the different properties of each material. It also studies the product design and performance differences and improved issues before and after the use of polymer materials. At the same time, it compares how athletes' performance and health change with the continuous introduction of new materials in equipment. With the development and research of polymer composite materials today, more new materials will be applied in the future and the competitive sports industry has improved the sports performance of athletes. Part of the performance of sports equipment is often not all-around, which is why the sports equipment of major sports brands are classified in detail. In the future, the application of polymer composite materials on sports equipment may be more inclined to more targeted reinforcement. A certain performance can improve the performance of athletes in a specific aspect, rather than making all equipment all-round but not outstanding general-purpose equipment in one aspect. Due to the lack of equipment conditions and the difficulty of obtaining information on sports equipment in the past, this paper cannot give more performance data on polymer materials and equipment information for a relatively long time.

References

[1]. Ouyang Yanyan, Yaxuan Yao, Liu Zheng, Chen Hui, Ren Lingling. An overview of the research progress of carbon fiber materials at high temperature carbonization process [J]. Metrology Science and Technology, 2020, (10): 68-72.

[2]. Shunli Xie, Honghong Lei, Chunli Zhang, Caili Zhang. Research progress on the effect of surface modification on the properties of carbon fiber and its composite materials [J]. Surface Technology, 2022, (11): 186-195.

[3]. Jian Wang. Mechanical Properties Analysis and Test Method Optimization of Carbon Fiber Tubular Composite Materials [J]. Synthetic Fibers, 2022, 51(02):51-53+57.

[4]. Sheng Xia. Application of Carbon Materials in Sports Equipment [J]. Plastic Industry, 2018, 46(07):125-128, 132.

[5]. Meng Zhao, Xianqian Meng, Huichao Yao, et al. Research progress of carbon fiber/nanomaterial/epoxy resin multi-scale composite materials [J]. High-tech fiber and application Use, 2017, 42(05):1-7.

[6]. Li Cheng, Zigang Wu, Xiaotong Wang, Yan Jing, Shao Kai. Current Situation and Development Trend of Polyurethane Industry [J]. Bonding, 2016, 37(11):63-67.

[7]. Hongyi Chen. Preparation and Feasibility Study of Microfiber Polyurethane Synthetic Leather [D]. Changchun: Jilin University, 2015.

[8]. Chen Yang, Xiaoming Qian, Song Bing. Research and progress of water-based polyurethane synthetic leather foam molding technology [J]. China Leather, 2015, 44(15):48-52.

[9]. Gao Peng, Zhou Hong. Process optimization of carbon fiber composite materials for sports equipment and performance research [J]. Aging and Application of Synthetic Materials, 2019, 48(4):91- 94+156

[10]. Liu Dong, Xie Jia. Properties of Carbon Fiber Reinforced Composite Materials and Its Application in Sports Equipment [J]. Aging and Application of Synthetic Materials, 2020, 49(04):144-146.

[11]. Bo Awei. Performance analysis of advanced polymer material sports equipment and research on its impact on the development of competitive sports [J]. Aging and Application of Synthetic Materials, 2020, 49(06):163-165.

Cite this article

Zhang,Z. (2023). The application and influence of polymer composite materials in competitive sports. Applied and Computational Engineering,25,1-8.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2023 International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Ouyang Yanyan, Yaxuan Yao, Liu Zheng, Chen Hui, Ren Lingling. An overview of the research progress of carbon fiber materials at high temperature carbonization process [J]. Metrology Science and Technology, 2020, (10): 68-72.

[2]. Shunli Xie, Honghong Lei, Chunli Zhang, Caili Zhang. Research progress on the effect of surface modification on the properties of carbon fiber and its composite materials [J]. Surface Technology, 2022, (11): 186-195.

[3]. Jian Wang. Mechanical Properties Analysis and Test Method Optimization of Carbon Fiber Tubular Composite Materials [J]. Synthetic Fibers, 2022, 51(02):51-53+57.

[4]. Sheng Xia. Application of Carbon Materials in Sports Equipment [J]. Plastic Industry, 2018, 46(07):125-128, 132.

[5]. Meng Zhao, Xianqian Meng, Huichao Yao, et al. Research progress of carbon fiber/nanomaterial/epoxy resin multi-scale composite materials [J]. High-tech fiber and application Use, 2017, 42(05):1-7.

[6]. Li Cheng, Zigang Wu, Xiaotong Wang, Yan Jing, Shao Kai. Current Situation and Development Trend of Polyurethane Industry [J]. Bonding, 2016, 37(11):63-67.

[7]. Hongyi Chen. Preparation and Feasibility Study of Microfiber Polyurethane Synthetic Leather [D]. Changchun: Jilin University, 2015.

[8]. Chen Yang, Xiaoming Qian, Song Bing. Research and progress of water-based polyurethane synthetic leather foam molding technology [J]. China Leather, 2015, 44(15):48-52.

[9]. Gao Peng, Zhou Hong. Process optimization of carbon fiber composite materials for sports equipment and performance research [J]. Aging and Application of Synthetic Materials, 2019, 48(4):91- 94+156

[10]. Liu Dong, Xie Jia. Properties of Carbon Fiber Reinforced Composite Materials and Its Application in Sports Equipment [J]. Aging and Application of Synthetic Materials, 2020, 49(04):144-146.

[11]. Bo Awei. Performance analysis of advanced polymer material sports equipment and research on its impact on the development of competitive sports [J]. Aging and Application of Synthetic Materials, 2020, 49(06):163-165.