1. Introduction

In 1932, Lander discovered that AuCd alloy deformed on cooling and completely restored the shape after heating [1]. In 1951, Chang et al. found that after deformation in the martensitic state, the AuCd series alloys can return to their initial shape after heating in 1951[2]. This is one of the outstanding mechanical properties of shape memory alloys(SMA), that is the shape memory effect(SME). In 1963, Buehler et al. discovered that near-equiatomic NiTi alloys also have shape memory effects [3]. This discovery made the academic and engineering communities recognize the importance of SMA and provided the possibility for its engineering applications. Since then, scientists around the world have discovered SMA with other components. Although different SMA have their own advantages for specific application requirements or scenarios, the excellent performance of NiTi based shape memory alloy materials makes them occupy a leading position in scientific research, especially engineering applications [4].

Since some large flexible components are prone to structural vibration during operation and have a significant impact on the spacecraft, structural vibration control is a very challenging issue that must be taken seriously. As a new type of functional material, it has the most significant property, which is shape memory effect (SME). Of course, it also has many other important properties, such as hyperelasticity, temperature variation of elastic modulus, and good damping performance. Utilizing the outstanding characteristics of SMA such as memory alloy effect and hyperelasticity, it can be applies to many fields such as structural active control, passive control, and structural vibration reduction [5]. This research will focus on the application of SMA in the field of aerospace, using various methods such as literature review, simulation, and experiments to study the characteristics of SMA, understand its existing applications in the engineering field, and explore its future application directions.

2. characteristics of SMA

Compared to other materials, SMA has high specific strength and good corrosion resistance. When utilizing its shape memory effect, it has a high energy density and high power output [6-7], and the designed driver has a compact structure, high reliability, and can be reused for a long time. When using its superelasticity, it can produce a large and full stress-strain hysteresis loop, with excellent energy absorption, vibration reduction, and large deformation recovery performance [5].

2.1. SME

SME refers to a phenomenon in which a trained SMA can recover to its original shape without residual strain under heating conditions when subjected to large strains.

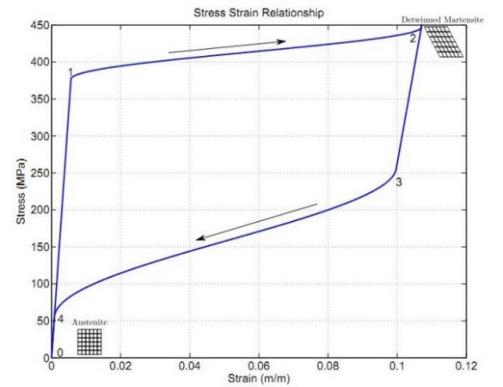

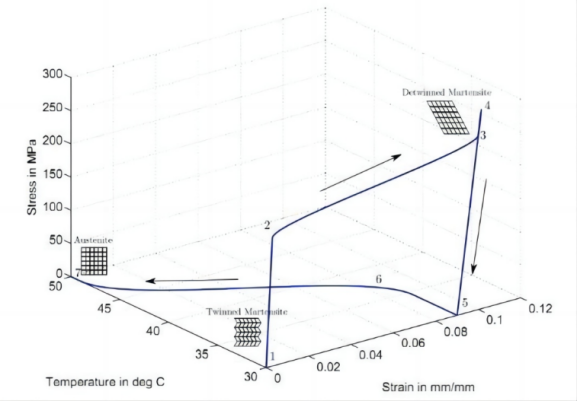

When lowering temperature can increase gravity, the parent phase austenite undergoes phase transformation, forming low-temperature martensite or stress induced martensite. If heated or under reduced stress, the martensite begins to reverse transformation and returns to the parent austenite state, and restoring its original shape (Figure 1). In the aerospace field, the shape memory effect is more often used in the design of SMA actuators, so the macro and micro constitutive models that are more closely related to SMA actuators are more common [4].

Figure 1. Strain-Stress Curve of Superelastic Effect of SMA.

2.2. Superelasticity

At high temperatures, SMA can produce large elastic strains without plastic strain under external load(Figure 2).

Figure 2. SMA stress-strain temperature curve.

When the temperature exceeds a certain value for the completion of austenitic phase transformation, SMA will induce martensitic transformation under the action of external stress. The part where the stress induced martensitic transformation occurs can only exist stably under the action of stress. Once the stress disappears, the material will immediately undergo a reverse phase transformation and return to the austenitic phase transformation state. This property is known as the superelasticity of SMA. The superelastic properties of SMA exhibit strong nonlinearity, so it is necessary to select more accurate mathematical models to describe its hysteresis characteristics and accurately predict its vibration response [4]. The classic models for describing SMA hyperelasticity include Graesser model [8], the Bouc Wen model [9-10], etc.

3. SMA in aerospace

One of the important problems to overcome in designing better spacecraft is spacecraft flutter. Spacecraft flutter is a complex aeroelastic phenomenon, which is a self-excited vibration of a system caused by the combined action of structural elastic forces, self-inertial forces, and aerodynamic forces. Spacecraft flutter mainly consists of two parts: the thermal effect and harmonic excitation. It brings unstable factors to spacecraft attitude response and data signal acquisition, and even leads to some spacecraft failures.

Structural vibration control is a common practical task in engineering, and vibration control has become the focus of engineering research. The SMA material with its large displacement, complete recovery deformation, high stiffness, and other properties can help solve the problems.

3.1. Application of superelasticity

3.1.1. Dampers. Based on the performance of superelasticity and the good damping performance of SMA, high-performance dampers can be made for energy dissipation and vibration control of structures.

Dampers can be used for passive control of structures, which can consume vibration energy and reduce vibration response. Moreover, under heating conditions, because of the shape memory effect of SMA, it can also restore the structure to its original state without being damaged [5]. However, current SMA shock absorbers and dampers have low energy dissipation efficiency and complex structures. In the future, accurate, simple and efficient SMA hyperelastic constitutive models should be combined to design simpler and more efficient devices .

Figure 3. A schematic diagram of an SMA damper.

3.1.2. Adaptive structures. SMA undergoes phase transformation during loading, resulting in significant deformation and can still fully recover after unloading. Therefore, utilizing the characteristics of SMA superelasticity that can generate large deformation and complete recovery can be used in adaptive structures that require large deformation and complete recovery [11].

3.2. Application of SME

The shape memory effect is one of the most important characteristics of SMA, according to which actuators or some specific structures can be designed in the aerospace field. SMA has high strength, good corrosion resistance, high energy density during operation, and high power output. It can make the designed structure more compact and reliable to meet the needs of long-term reuse.

In the process of restoring the original shape of the SMA, if it is restrained, it will generate a huge restoring force. It can be used to make SMA based actuators.

SMA tube is an application form of SMA, that can output various loads. When driving is needed, the SMA tubes are heated to generate a recovery displacement to drive the structural movement, thereby completing the corresponding function. The SMA tube linear driver can be used to drive the compression release mechanism. We can attach the SMA film to the controlled structure and adjust the temperature of the SMA driver film according to the vibration signal obtained by the SMA sensor, generating a control force proportional to the vibration speed as a damping force, and by this way we can achieve the goal of reducing vibration response [5].

SMA can also be used to design torsional actuators. The characteristic of SMA torsional actuators is that they can output more torque at a smaller size. SMA torsion actuators are commonly used in the aviation industry, such as for the torsion of blades, and wings [12].

Figure 4. One kind of SMA compensators.

SMAs are used in aerospace to meet the design requirements of lightweight, high-efficiency because of their excellent properties, there are a lot of other examples of practical applications of SMA.

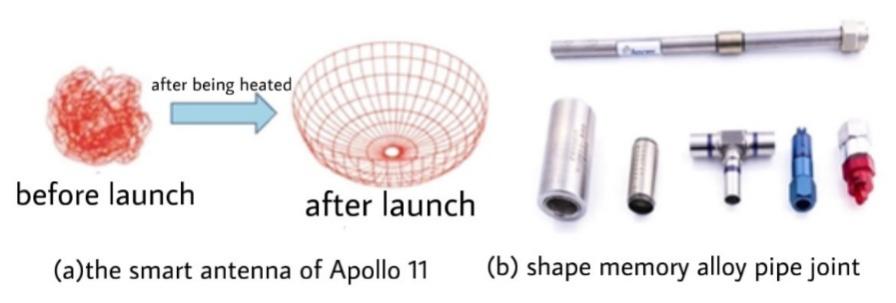

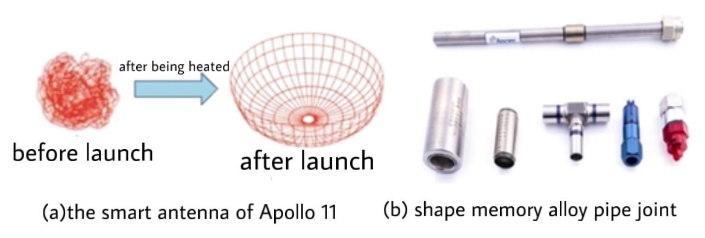

Figure 5 (a) shows the smart antenna of the Apollo 11 lunar module. By designing the antenna on the ground and folding it into the lunar module, the space occupied by the antenna is effectively reduced. After the lunar module arrives, it can be restored to its original shape by heating it [13]. Figure 5 (b) shows the shape memory alloy pipe joint developed by Aerofit, which has been widely used in military aircraft, greatly reducing the occurrence of liquid leakage in aircraft pipelines [13].

(a) |

(b) |

Figure 5. SMAs applications (a) the smart anetenna of Apollo 11; (b)shape memory alloy pipe joints.

4. Simulation and experiments

4.1. simulation

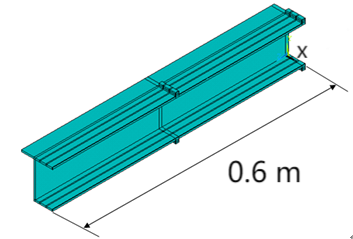

In order to study the material’s function of reducing vibration, this paper establishes a finite element model. This simulation experiment adopts a cantilever supported box beam method to establish a numerical simulation model of the SMA intelligent control model, and uses the software Ansys to model, conduct dynamic analysis, and calculate the frequency and modal calculation of the model.

The established model is shown in Figure 6. The beam is made of Q235 steel, with a density of 7800 Kg/m3, an elastic modulus of E=200Gpa, and a Poisson's ratio of 0.3.SMA is selected as NiTi alloy wire, with a density of 4500 Kg/m3, an elastic modulus of E=41Gpa, and a Poisson's ratio of 0.3.

(a) |

(b) |

Figure 6. Finite element model: (a) the finite element model; (b) the finite element model.

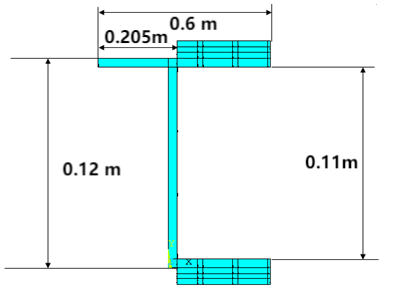

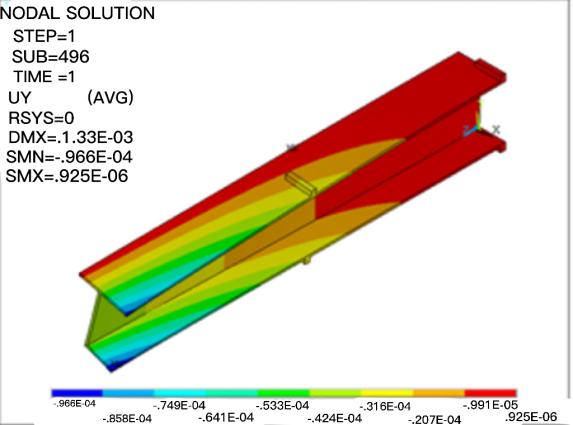

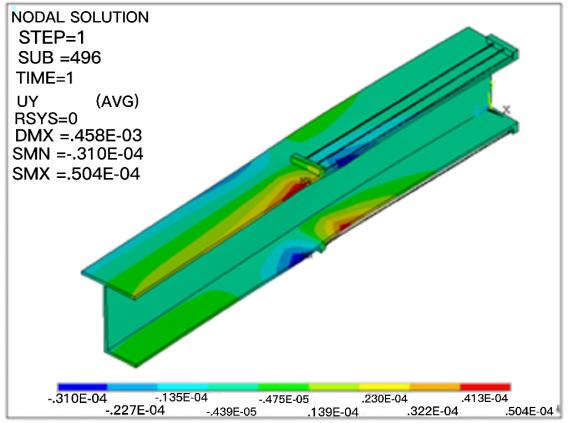

Firstly, according to Figure 7, it’s the result without SMA. It can be seen that the stress and displacement under an impact force, and the y-direction displacement gradually decrease from one side of the beam to the other side.

(a) |

(b) |

Figure 7. The result without SMA: (a) Displacement in y-direction under impact force; (b )Von mises stress.

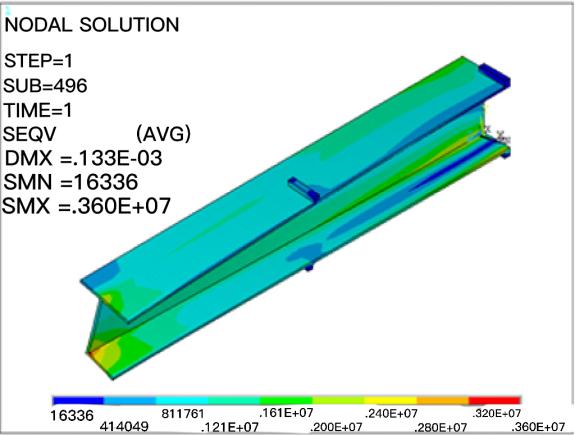

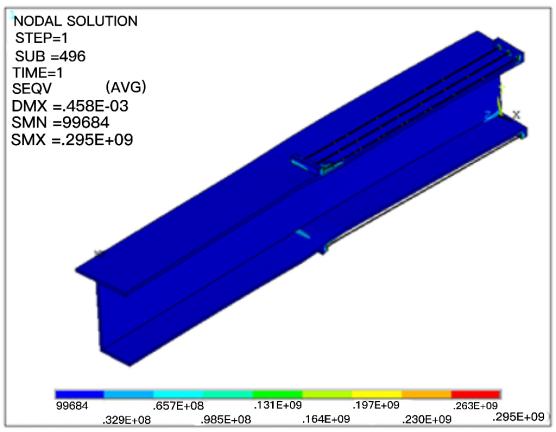

(a) |

(b) |

Figure 8. The result after adding SMA: (a) Displacement in y-direction under impact force; (b) Von mises stress.

4.2. Experiments

The actual experiments use a box girder to place SMA material on the surface of the bridge, apply impact force to it, and study its vibration mode. The first and second order natural frequencies and amplitudes of the cantilever beam without SMA were measured using the hammering method and fixed frequency scanning method. The natural frequencies and amplitudes of the cantilever beam with SMA were studied and compared, and the role of SMA materials in structural vibration control was obtained. When heating is required, directly energize the SMA wire and use the resistance of the SMA wire material for heating (high current, thin wire).

The fixed frequency scanning method is an experiment in which one or two vibration parameters (displacement, velocity, or acceleration) remain constant during the test process, while the vibration frequency continuously changes back and forth within a certain range. Linear scanning is linear, that is, the number of hertz swept per unit time, in units of Hz/s or Hz/min. This type of scanning is used in experiments to find resonance frequencies. Hammering method.

The test is suitable for small structures, especially when the connection of the exciter can cause serious interference to the boundary conditions of the structure. Although it requires a short preparation time, data acquisition is a lengthy tapping process.

For the cantilever beam without SMA material, the excitation point is shown in the Figure 9, and the measurement point is selected at the end of the cantilever beam.

Figure 9. Cantilever beam without SMA material added.

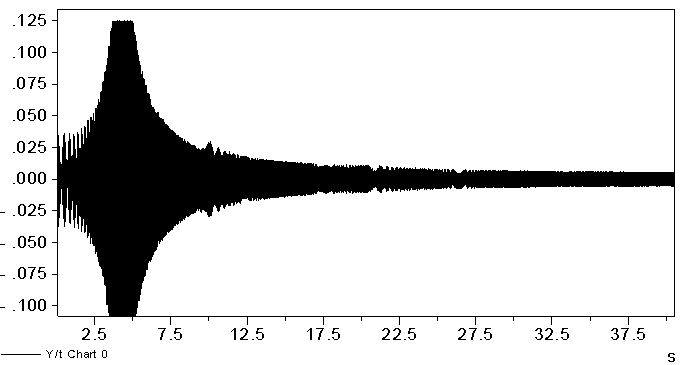

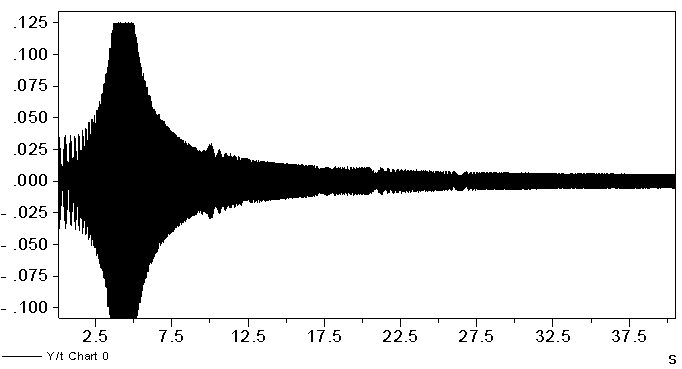

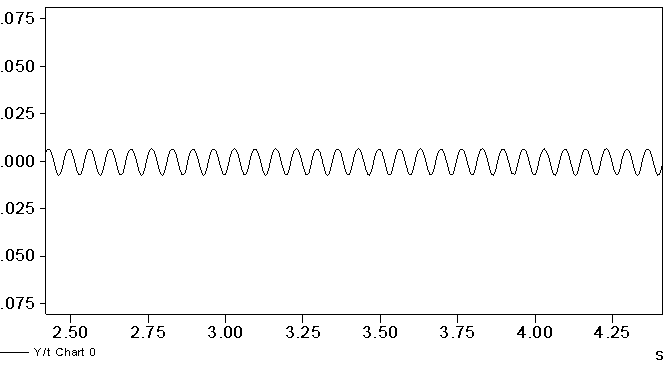

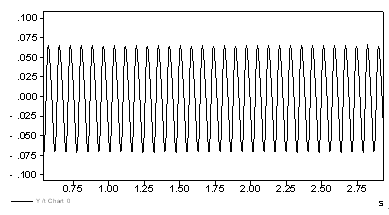

When SMA is not added, the first-order time-history curve obtained by using the fixed frequency scanning method is as Figure10 follows.

Figure 10. Time history curve obtained by fixed frequency scanning method.

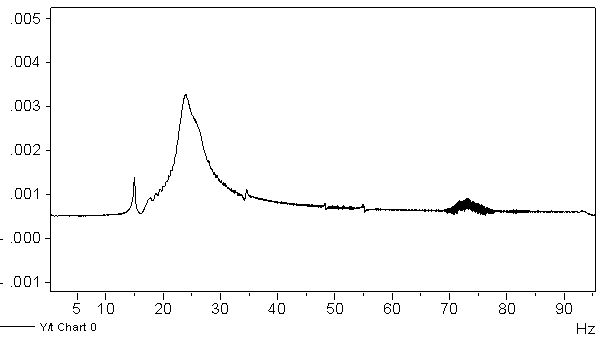

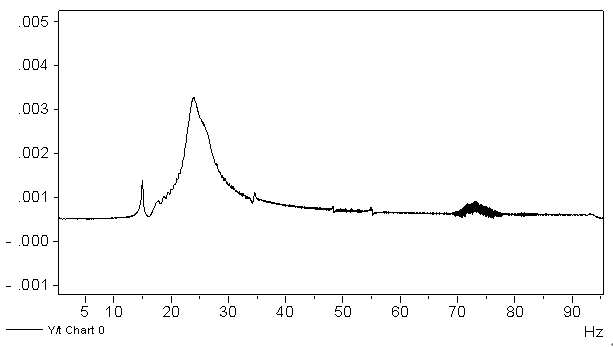

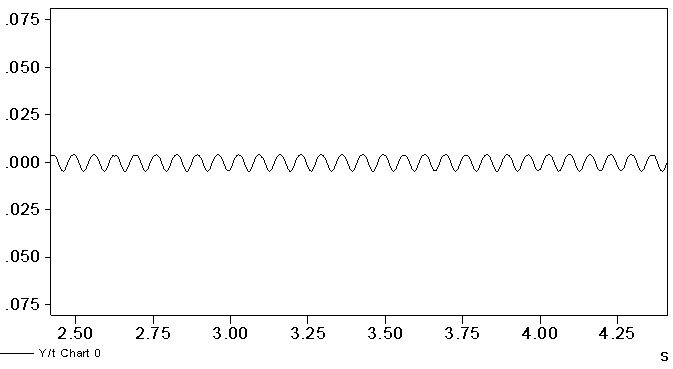

And then, we can add SMA to the beam. This is the time history curve and frequency obtained by the sweep frequency method without applying force (Figure11).

|

|

Figure 11. Time history curve and frequency obtained by sweep frequency method without applying force.

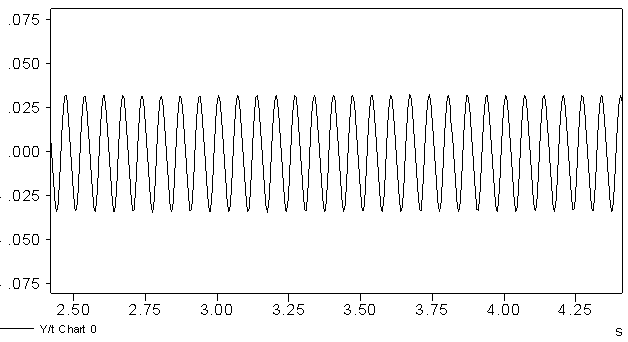

Then, the Figure 12 shows the time history curve and frequency obtained by the sweep frequency method under an applied force.

|

|

Figure 12. Time history curve and frequency obtained by applying force and frequency sweep method.

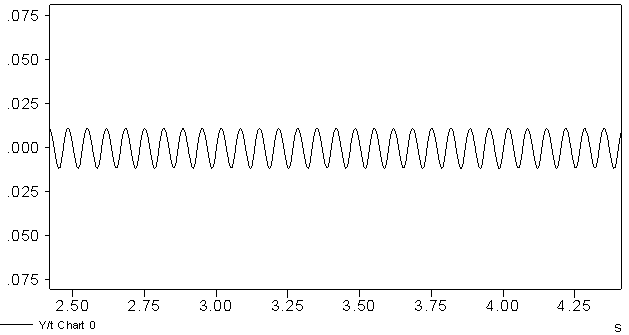

Figure 13 is the result of the experiments using the fixed-frequency scanning method, it can obtain the vibration curve and observe the amplitude.

(a) |

(b) |

(c) |

(d) |

Figure 13. Experimental results using the fixed-frequency sweep method: (a)The first time; (b) The second time; (c) The third time; (d) The fourth time.

4.3. Result

After adding SMA material, it can be observed that the amplitude of vibration is getting smaller and smaller during the first-order fixed-frequency scanning. The decrease in amplitude proves that the addition of SMA materials effectively absorbs vibration energy and plays a role in shock absorption. In this experiment, the super elastic characteristics of SMA play a major role in reducing vibration, and its shape memory effect is also shown.

5. Conclusion

This paper mainly summarizes the specific meaning and practical application of shape memory alloy superelasticity and shape memory effect. It is obvious that if we carefully study this excellent material, we can also invent more components for improving vibration and improving deformation recovery, and assemble them on various new spacecraft in the simulation and experiments.

It mainly shows that SMA can effectively reduce the vibration of the structure and can be applied to the vibration reduction design of the flexible part of the spacecraft (such as the flexible arm), and the actual experimental results are close to the simulation results.

It has broad prospects for development in the future, and we can improve many engineering structures by studying it, and overall, the application research of SMA in the aerospace field will develop towards a wider operating temperature range, more accurate and comprehensive constitutive models, more diverse structural forms, and more intelligent actuator mechanisms.

References

[1]. ÖLANDER A. An electrochemical investigation of solid cadmiumgold alloys[J]. Journal of the American Chemical Society, 1932, 54(10): 3819-3833.

[2]. CHANG L C, READ T A. Plastic deformation and diffusionless phase changes in metals-the gold-cadmium beta phase[J]. Transactions of AIME Journal of Metals, 1951, 47(191): 47-52

[3]. BUEHLER W J, GILFRICH J V, WILEY R C. Effect of low-temperature phase changes on the mechanical properties of alloys near composition TiNi[J]. Journal of Applied Physics, 1963, 34(5): 1475-1477.

[4]. Qu Lei, Yan Zehong, Rao Zhixiang, et al. Review on shape memory alloys’ application in field of aerospace [J]. Journal of Aerodynamics, 2022, 37 (10): 2127-2141. DOI: 10.13224/j.cnki. jasp.202220493

[5]. Research and development on vibration control of bridge structures using shape memory alloys School of Architecture and Engineering, Tianjin University, Tianjin, January 1st, 2009

[6]. STÉPHANE L. Issues in the design of shape memory alloy actuators[D]. Cambridge, US: Massachusetts Institute of Technology, 2002

[7]. HOLLERBACH J M, HUNTER I W, BALLANTYNE J. A comparative analysis of actuator technologies for robotics[M]. Cambridge, US: Massachusetts Institute of Technology (MIT) Press, 1992

[8]. GRAESSER E J, COZZARELLI F A. A proposed three-dimensional constitutive model for shape memory alloys[J]. Journal of Intelligent Material Systems Structures, 1994, 5(1): 78-89

[9]. WEN Y K. Method for random vibration of hysteretic systems[J]. Journal of the Engineering Mechanics Division, 1976, 102(2): 249-263

[10]. WEN Y K. Equivalent linearization for hysteretic systems under random excitation[J]. Journal of Applied Mechanics, 1980, 47(1):150-154.

[11]. DU Yanliang, ZHAO Weigang, LIU Xiandong, et al. Regulation behavior analysis of auto-even-load connecting component. [J]. Journal of Aerospace Power, 1999, 14(1): 51-54. (in Chinese)

[12]. CALKINS F T, MABE J H. Shape memory alloybased morphing aerostructures[J]. Journal of Mechanical Design, 2010, 132(11):111012.1-111012.7.

[13]. Xu Dianguo, Bai Fengqiang, Zhang Xiangjun, et al. A review of research on shape memory alloy actuators [J]. Journal of Electrical Engineering, 2022, 37 (20): 5144 5163. DOI: 10.19595/j.cnki.1000-6753.tces.211043

Cite this article

Chen,Z. (2023). Application of SMA materials in aerospace. Applied and Computational Engineering,25,22-29.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2023 International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. ÖLANDER A. An electrochemical investigation of solid cadmiumgold alloys[J]. Journal of the American Chemical Society, 1932, 54(10): 3819-3833.

[2]. CHANG L C, READ T A. Plastic deformation and diffusionless phase changes in metals-the gold-cadmium beta phase[J]. Transactions of AIME Journal of Metals, 1951, 47(191): 47-52

[3]. BUEHLER W J, GILFRICH J V, WILEY R C. Effect of low-temperature phase changes on the mechanical properties of alloys near composition TiNi[J]. Journal of Applied Physics, 1963, 34(5): 1475-1477.

[4]. Qu Lei, Yan Zehong, Rao Zhixiang, et al. Review on shape memory alloys’ application in field of aerospace [J]. Journal of Aerodynamics, 2022, 37 (10): 2127-2141. DOI: 10.13224/j.cnki. jasp.202220493

[5]. Research and development on vibration control of bridge structures using shape memory alloys School of Architecture and Engineering, Tianjin University, Tianjin, January 1st, 2009

[6]. STÉPHANE L. Issues in the design of shape memory alloy actuators[D]. Cambridge, US: Massachusetts Institute of Technology, 2002

[7]. HOLLERBACH J M, HUNTER I W, BALLANTYNE J. A comparative analysis of actuator technologies for robotics[M]. Cambridge, US: Massachusetts Institute of Technology (MIT) Press, 1992

[8]. GRAESSER E J, COZZARELLI F A. A proposed three-dimensional constitutive model for shape memory alloys[J]. Journal of Intelligent Material Systems Structures, 1994, 5(1): 78-89

[9]. WEN Y K. Method for random vibration of hysteretic systems[J]. Journal of the Engineering Mechanics Division, 1976, 102(2): 249-263

[10]. WEN Y K. Equivalent linearization for hysteretic systems under random excitation[J]. Journal of Applied Mechanics, 1980, 47(1):150-154.

[11]. DU Yanliang, ZHAO Weigang, LIU Xiandong, et al. Regulation behavior analysis of auto-even-load connecting component. [J]. Journal of Aerospace Power, 1999, 14(1): 51-54. (in Chinese)

[12]. CALKINS F T, MABE J H. Shape memory alloybased morphing aerostructures[J]. Journal of Mechanical Design, 2010, 132(11):111012.1-111012.7.

[13]. Xu Dianguo, Bai Fengqiang, Zhang Xiangjun, et al. A review of research on shape memory alloy actuators [J]. Journal of Electrical Engineering, 2022, 37 (20): 5144 5163. DOI: 10.19595/j.cnki.1000-6753.tces.211043