1. Introduction

Many new energy cars are being produced due to the rapid advancement of science and technology, including fuel-cell vehicles, extended-range electric vehicles, plug-in hybrid electric vehicles, and battery electric vehicles. New energy battery electric vehicles are the most common type of new energy vehicles, which have steadily overtaken the trend of fuel-powered vehicles since the advent of the new energy period. Battery electric vehicles have inherent advantages and drawbacks in the chassis suspension system, steering system, driving system, and other areas since new energy battery electric vehicles and conventional gasoline vehicles differ in power layout and body structure design. Also, they differ in terms of stability, comfort, and safety. So, the topic of this piece is the structural differences between the chassis of new energy vehicles and those of conventional vehicles.

Due to the progressive depletion of oil reserves and rising pollution from fuel-powered cars, environmental protection has gained popularity. To discover the specific directions for improvements and limitations of electric vehicles in chassis, the study on the structural comparison between pure tram and fuel vehicle chassis can be helpful, which provides ideas and enlightenment for enhancing their performance.

This paper primarily introduces the chassis structure, design, and orientation of new energy battery electric vehicles based on conventional fuel vehicles, introduces three different types of chassis structures, and finally anticipates the future development direction of the design of the chassis structure of new energy battery electric vehicles.

2. Vehicle chassis structure

2.1. Structural characteristics of traditional fuel vehicle chassis

The suspension system and transmission system comprise most of the standard automotive chassis, with the subframe serving as its central component and comprising four parts: transmission system, driving system, steering system and braking system. An electric vehicle's chassis structure is primarily utilized to support the mass and power assembly, which forms the vehicle's overall shape and accepts the engine's power to propel the vehicle forward. The chassis' primary responsibility is to maintain the car's stability while it is being driven and to enhance its performance in terms of crash resistance.

2.2. Structural characteristics of battery electric vehicles

The role of the new energy vehicle chassis is the same as that of the traditional automobile that supports and installs the automobile engine. Now it is changed to support and mount the motor powertrain with the battery module as the core.

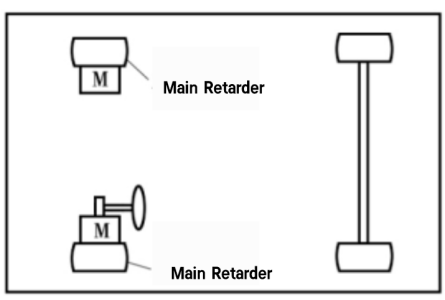

The major purpose of the battery mounting box and support system, which are typically part of the chassis structure of new energy vehicles, is to preserve the integrity of the battery pack and guarantee that it won't tilt or wobble while being driven. Hub motor electric vehicles generally use independent suspension in design. But, the suspension in conventional cars is different. The suspension system for hub motor electric vehicles has the following flaws: poor comfort and handling and unsprung mass via electromagnetic force [1]. The chassis layout of hub electric models of new energy vehicles is shown in Figure 1. The driving wheel is where the motor is mounted, which considerably reduces the distance that power must travel between the two and effectively reduces energy transfer loss.

Figure 1. Chassis layout of new energy vehicle hub electric models [2].

The battery is integrated into the chassis of the new energy-pure electric car, which has a higher percentage of unsprung mass, a lower center of gravity, and improved stability. For vehicle handling and comfort, sprung mass/unsprung mass is a very important index. The vehicle is more stable and controllable when the sprung mass ratio is higher. Less energy is required to move the wheel, the lighter the spring-mass, and it is also easier to see improvements in traditional vehicle fuel efficiency and new energy vehicle mileage.

Battery pack deformation may occur due to chassis crashes, a safety concern. Internal short circuits in battery packs, spontaneous combustion, and other events frequently happen after deformation. However, even if the power battery pack has done an excellent job of protecting against contact forces, the power battery can still be harmed if the strength and frequency of collisions go beyond a predetermined threshold. The likelihood of violent crashes can be significantly decreased by mounting the battery on the chassis, which can prevent the most frequent front-to-rear and rear-end collisions.

3. Vehicle chassis design

3.1. Chassis design features of new energy battery electric vehicles

New energy vehicle chassis drastically differ from conventional fuel vehicle chassis in design. Its body design is firstly given more freedom. The chassis has become flatter as of late. The bottom is typically flat for smooth air movement. It is isolated from the body, giving the body more design freedom. Second, there is more capacity inside. Electrified designs are now getting higher and higher owing to integrated design concepts, including electrified ESPs, which reduce the number of components and free up more interior space on the chassis. Finally, with fewer and fewer items, production and maintenance are also substantially streamlined due to the higher degree of systematic design. Fourth, the vehicle is also more maneuverable because the battery pack is now permanently attached to the bottom of the chassis and has a very low weight and axis.

3.2. Orientation of chassis design

3.2.1. Chassis design requirements. Meeting the vehicle's performance indicators is the main factor when designing the chassis. The automobile should have the basic performance can be summarized as power, economy, braking, stability, ride comfort, safety and durability. Generally speaking, chassis engineering includes front and rear suspension, steering system, brake system and wheel design configuration.

Braking, operating stability, and ride comfort are directly tied to these systems' performance in the vehicle in terms of braking, stability and smoothness. The suspension parts of the flooring should be strong enough, and whether its design is in place directly affects the pressure side of the rack body. Meanwhile, the floor design is also related to durability.

3.2.2. Three aspects considered in the chassis design of new energy vehicles. The first point is the need to consider the application of the basement when designing. i.e., in the design of a basement, the structure of the dish design and its subsystems must remain unchanged.

Second, the automobile's chassis subsystem needs to be correctly improved in accordance with the original frame. Installing a vacuum power pump and properly adjusting the frame are required for the chassis design to improve the vacuum source. Moreover, the reducer interface's new power system needs to be changed. After the part designs are finished, the suspension system should also undergo CAE (Computer Assisted Engineering) analysis to minimize noise.

Third, the layout of the subsystem's rear cabin is altered by the new design philosophy. To ensure the suspension system's safety factor, thorough load quality must be accounted for; otherwise, the subsystem must be reset, and the suspension system's work must be adjusted. The suspension system's specifications should be revised by examining how new energy cars' front axle load and rear axle load are distributed.

4. Different chassis structures

4.1. Sliding plate chassis

Designing the chassis for a new energy vehicle should adhere to scientific, practical, and comfortable standards. We should completely comprehend the features of new energy vehicles, optimize and enhance the chassis design, and reflect the critical function of the chassis. There are four benefits to the sliding plate chassis:

(1) Considerable freedom. Skateboard chassis science can be applied to new energy vehicles to ensure that the flat body and chassis do not conflict with one another, allowing designers to create more imaginative automobile models.

(2) Improved operability. The center of gravity of new energy vehicles built on skateboard chassis is typically maintained at the normal threshold by mounting critical systems and components on the chassis, considerably improving maneuverability and giving drivers a more comfortable driving experience.

(3) High security. It is crucial to ensure the chassis weighs the same as the chassis. To prevent deformation of the rear seat position and to provide the driver and passengers with a suitable level of security in the event of a severe hit, the chassis should be able to eliminate a portion of the impact force as much as is physically possible.

(4) Straightforward maintenance. The slide chassis' principal benefit is its ease of maintenance. While modern new energy cars typically employ a more sophisticated overall design idea and have fewer chassis components than older fuel-powered vehicles, the difficulty of producing and dismantling chassis is also decreased. Despite the many benefits of the skateboard chassis, modern energy vehicles nevertheless have flaws.

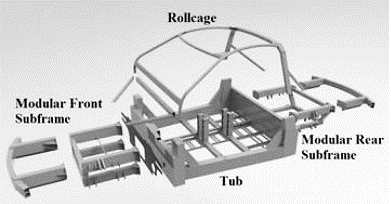

4.2. Bathtub-Type chassis

A bathtub chassis is suggested to increase the frame's anti-collision performance and pursue body lightweight. Manufacturing a bathtub chassis requires a relatively low initial investment. One of the advantages of this design is that the high threshold makes the bathtub very sturdy. The roll cage, front and rear subframes, and bathtub are the typical four primary components of the chassis. (Figure 2).

Figure 2. Schematic diagram of bathtub chassis [3].

One of the typical solutions for electric cars is to place the battery pack on the floor. Nevertheless, in this design, the resistance area of the vehicle is increased by the height of the battery pack, which is unacceptable for sports cars because it raises the overall height of the vehicle. The torsional stiffness can also not be ignored. There is a satisfactory value of 15,100 N m/deg is achieved for a chassis that weighs 114 kg shown in Figure 3 [3]. The battery pack also cannot serve as a crash-proof component for the safety unit in this arrangement. Given these factors, it is recommended to use the T-shaped battery pack shown in Figure 3 [4].

Figure 3. Torsional rigidity analysis.

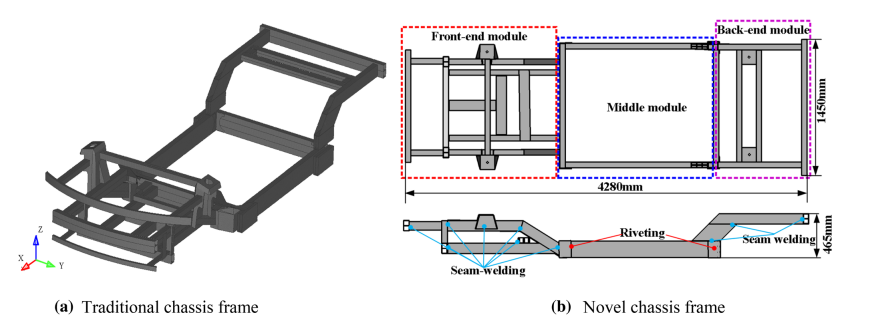

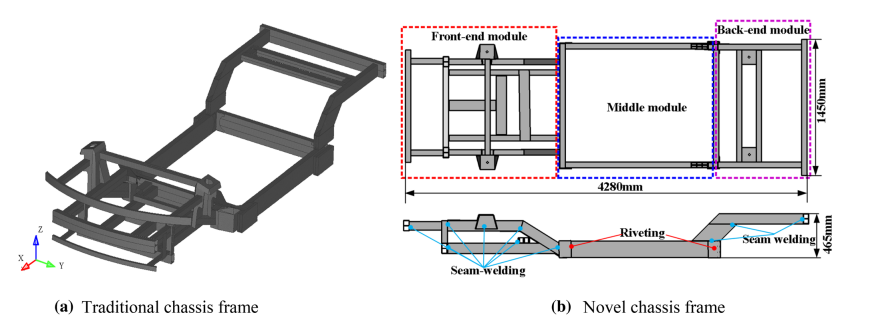

4.3. New Anti-collision chassis frame

An alternative form of floor frame is suggested according to the overall size of the conventional electric car floor frame, as shown in Figure 4. A new kind of multicellular structure with frontend modules and intermediate module structures is suggested based on the conventional framework. The mass distribution of this structure is the same as that of the conventional frame. Figure. 5 depicts the geometrical arrangements of the innovative chassis frame construction under investigation in this work. The chassis structure also measures 4280 mm in length, 1450 mm in width, and 465 mm in height. The frontend, middle, and backend modules used to assemble the chassis frame are modular. The frontend components' main job is to deflect energy from a frontal collision [5].

Figure 4. Traditional chassis frame [5].

Figure 5. Novel chassis frame [5].

The installation of the battery compartment and impact protection for the battery cells are the two main functions of the middle module. The frontend module's numerous components are connected using seam welding, while the center and backend modules are connected using riveting and seam welding, respectively. According to earlier research, this configuration offers more security for the battery compartment of the chassis frame, which can reduce the car's center of gravity and increase handling stability.

5. Prospect of chassis design

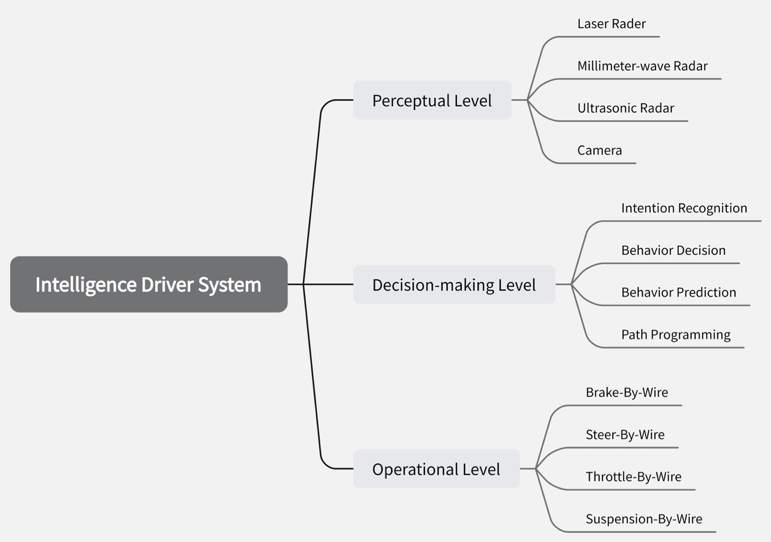

5.1. Intelligent automobile wire control chassis

Throttle-by-wire, steer-by-wire, shift-by-wire, and brake-by-wire are the current four core modules that make up new energy cars' intelligent drive-by-wire chassis system. They can support higher levels of autopilot and has a quicker response and more accurate control. Shift-by-wire, suspension-by-wire, and throttle-by-wire have all been utilized extensively. But there is still room for advancement in steer-by-wire and brake-by-wire. They are all inextricably linked to autonomous driving on autopilot, and the safety issue has also been questioned (Figure 6).

Figure 6. Linear control technology components in intelligent driving.

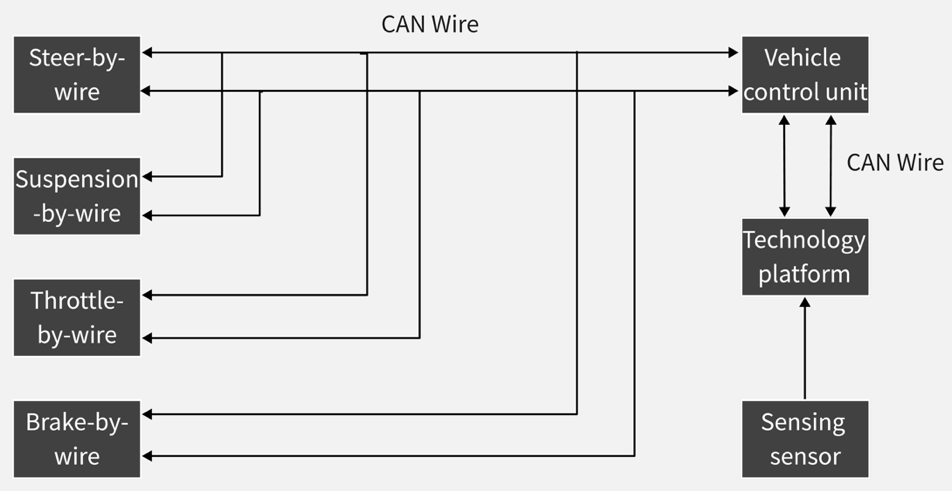

Figure 7. Transmission of information via CAN wire [6].

In a recent work by Yang et. al., it is stated that the CAN (Controller Area Network) bus completes the information transfer and control of each system and vehicle VCU (Vehicle Control Unit) in the drive-by-wire chassis (Figure 7). The vehicle controller analyzes the control data again and sends it to the various modules of the wiring control substrate through CAN bus so that the vehicle can turn, brake, accelerate, switch, and perform other movements in accordance with the actual road environment. The environmental sensor collects environmental information and transmits the control information of the vehicle through the CAN bus through the calculation of the operating platform to the vehicle's entire car controller.

The chassis of new energy vehicles will inevitably develop through wire control and integration. The chassis of the wire control is also in need of a novel design. Therefore, innovative design cannot be limited in terms of architecture. It must also contend with issues including the adaptability of the vehicle architecture, the effective coordination of numerous actuators, and safe operation in the event of a malfunction, all of which need to be considered while designing the chassis [7].

In the context of the requirement of new energy vehicle lifetime, increasing premise and battery energy density temporarily no breakthrough progress, the other systems can streamline, reduce occupation volume, and reduce the weight of the parts is the trend.

5.2. Lightweight development

According to data investigations by Ma’s recent research, new energy vehicles' endurance capacity may be effectively increased by around 5%–10% and battery costs can be reduced by about 15%–120% when their weight is reduced by 20%. Chassis weight reduction technology is more developed and less expensive than body weight reduction. Reducing unsprung mass can significantly enhance handling [8]. All current major new-energy cars include lightweight chassis components. All-aluminum chassis structures are used by vehicles like Tesla, Marvel X, BYD Tang, Nio, and others. Future development directions for the chassis of new energy vehicles include integrated battery (Tesla's CTC/CTB) BYD's and molding (power, braking, steering, and other system components) integrated into the skateboard chassis).

About 70% of the energy loss occurs on the car body since the battery of a modern energy vehicle weighs a lot, making up about 30% of the entire vehicle [9]. The achievement of vehicle chassis control quantification can significantly enhance the energy rate of new energy cars and their driving abilities. To lower the weight of a vehicle's parts, it is frequently utilized to modify or improve the body structure of the chassis [10]. The three key strategies are using advanced materials, structural optimization design, and sophisticated production technologies. Structural considerations include optimizing part size and shape and using hollow part structures to save weight.

There are two major approaches to reducing weight when it comes to materials: first, by employing lightweight alloys like aluminum alloy and alloy in place of steel components, and second, by using greater strength steel plate and thinning it out to reduce weight. The structural considerations include size optimization, weight reduction through part shape, and the usage of empty heart part constructions. The lightweight of the automobile floor can help future energy vehicles perform better while being driven and significantly increase their energy efficiency.

5.3. Integrated development

Lithium iron phosphate batteries and three-way lithium batteries are currently the most widely utilized power batteries due to the development of new energy vehicles. The development of the commonplace liquid lithium-ion battery material technology has been rapid over the last few years, and the advancements in cost reduction and rise in energy density have led to a generally steady development stage. As a result, it can only be optimized from a structural standpoint in a small area. To assure the vehicle's driving performance and mileage power, a suitable chassis structure design and maximizing the load of more batteries are required. The car can gain marginally from increased battery and integration efficiency by becoming significantly lighter, smarter, and more cost-effective.

The external battery itself is a complex integrated component of mechanical, chemical, thermodynamic and electrical coupling. The future of integration technology includes cross-border integration, multi-function integration, space sharing, and complexity simplification. It also incorporates more accurate size management, multi-dimensional and improved design balance, and cross-border integration [11].

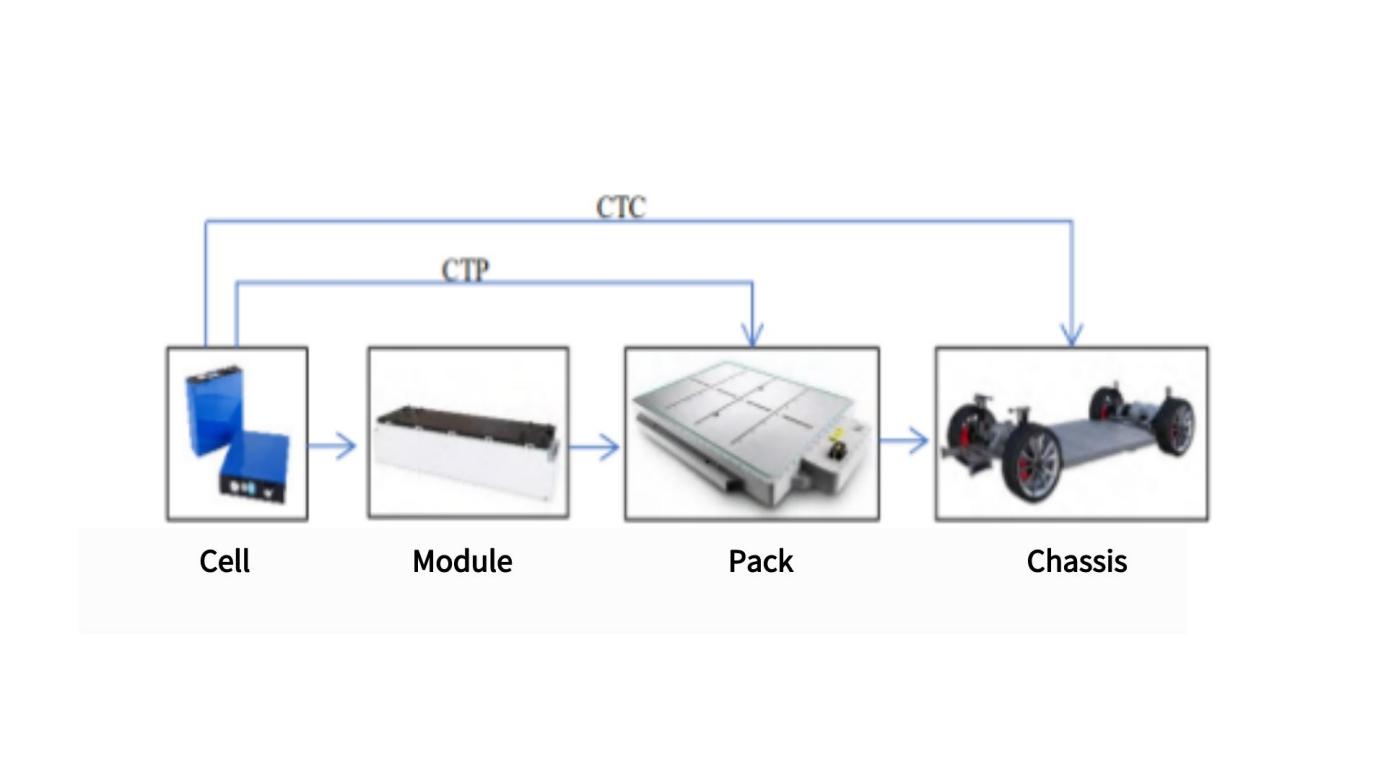

In order to reduce the overall number of parts, save space, cut costs, increase vehicle strength, and improve thermal management performance, structural integration of power batteries refers to the integration technology of structural sharing and functional integration of vehicle structural parts or functional components and power battery. CTP (Cell to Pack) technology is the industry standard for power batteries, with CTC (Cell to Chassis) technology on the horizon as an upgrade (Figure 8).

Figure 8. Integrated path from cell to chassis [11].

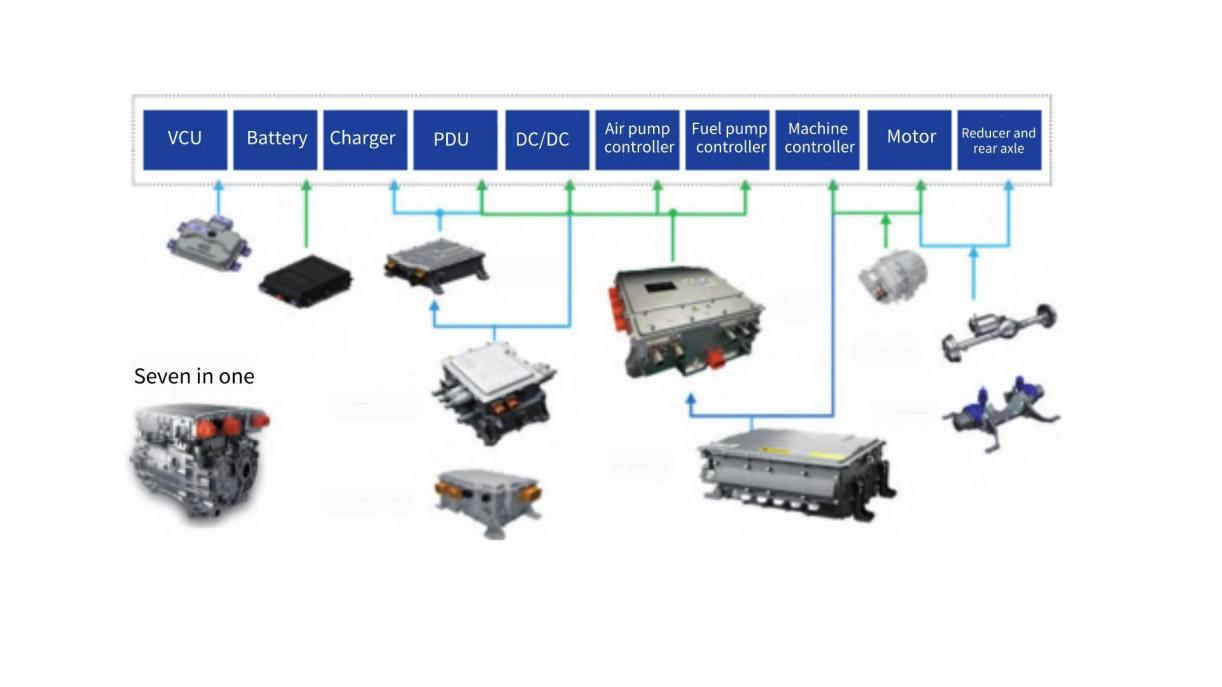

Figure 9. Multi-in-one combination of key components of new energy vehicle [11].

The use of CTP technology can achieve an energy density of more than 200Wh/kg, significantly decrease the manufacturing cycle and cost of batteries, increase the volume utilization rate of battery packs by 10% to 20%, reduce the number of components of battery packs by 30% to 40%, and increase production efficiency by 30% to 50% [12]. The volume utilization rate of battery packs is increased from 55% of first-generation battery packs to 67% of third-generation Kirin batteries thanks to Ningde Contemporary Amperex Technology Limited's [CATL] use of CTP technology. The CTC technology directly integrates the battery cell into the vehicle chassis, and the core is also de-modular, allowing for a higher level of body and chassis integration. The lower the number of pieces, the better the space utilization rate, the better the structural efficiency, the lighter the body is, and the longer the driving range.

The CTB battery body integration technology was used for the first time in the BYD Seal automobile , and it guarantees the safety of the automobile body, and the vehicle's torsional rigidity is more than 40,000NM [12].

6. Conclusion

This paper finds that due to differences in body layout and functional structure, pure new-energy trams also have differences in orientation and design space in chassis mechanism design. Pure electric automobiles offer greater internal structural space than fuel-powered cars since the battery configuration in their chassis tends to be flatter. As a result, it's important to maximize chassis space while taking pure electric vehicle battery safety into account. The active suspension offers more comfort and stability than the mechanical suspension found in traditional fuel automobiles because the motors are built into the tires.

Lightweight offers more driving range and less power usage for new energy battery electric vehicles. It is crucial to build lightweight structures due to the constraints of battery technology, which can result in larger performance gains. Smaller component volumes, quicker response times, higher control precision, and the ability to adapt to a higher level of automatic driving chassis system are all benefits of applying intelligent wire chassis technology. Thereby encouraging the integration of vehicle chassis structure even more. The higher the integration of the vehicle chassis, from CTP to CTC to the most recent CTB, the more lightweight, energy-saving, intelligent, and affordable the vehicle will be. To further enhance the performance of new energy vehicles and support their overall development, their technological innovation must be reinforced. We anticipate future technical research achievements in lightweight, wire control, and integration as they relate to the chassis structure design of new energy battery electric vehicles. To ensure the safety and stability of new energy vehicles, to better serve people's needs for daily transportation, and to compete with traditional fuel vehicles on the market, new energy vehicle manufacturers should take the initiative to adapt to development needs, constantly update the design concept of chassis structure, and expand the design field to lightweight, wire control, and integration into the core.

References

[1]. Wang L B. 2020 Equipment Management and Maintenance, 466(04):27-28.

[2]. Yan L F. 2016 Science and Technology Monthly Magazine, 29(24):122-123.

[3]. Xia Y L. 2022 New Energy Technologies, 27(09):30-32.

[4]. Parlaktaş V, Tanık E, Babaarslan N. 2021 Iran J Sci Technol Trans Mech Eng 45, 103–113

[5]. Wang S, Wang D. 2021 Archives of Civil and Mechanical Engineering, 21(3): 103.

[6]. Yang Y.2022 The Car of Time., 395(23):157-159.

[7]. Wang H 2022 The car over., 136(07):64-68.

[8]. Ma J. 2022 Innovative industrial research, 79(02):45-47.

[9]. Wang D. 2016 Technology and Innovation, 53(05):38+41.

[10]. Ge J Q, Wang Y. 2020 The Car of Time., 326(02):65-66.

[11]. Hu J G. 2022 The Car of Time, 395(23):112-117.

[12]. He Y. 2022 The world car, 482(06):70-71.

Cite this article

Tian,F. (2023). The prospect of chassis structure design for new energy battery electric vehicles. Applied and Computational Engineering,28,16-24.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2023 International Conference on Mechatronics and Smart Systems

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Wang L B. 2020 Equipment Management and Maintenance, 466(04):27-28.

[2]. Yan L F. 2016 Science and Technology Monthly Magazine, 29(24):122-123.

[3]. Xia Y L. 2022 New Energy Technologies, 27(09):30-32.

[4]. Parlaktaş V, Tanık E, Babaarslan N. 2021 Iran J Sci Technol Trans Mech Eng 45, 103–113

[5]. Wang S, Wang D. 2021 Archives of Civil and Mechanical Engineering, 21(3): 103.

[6]. Yang Y.2022 The Car of Time., 395(23):157-159.

[7]. Wang H 2022 The car over., 136(07):64-68.

[8]. Ma J. 2022 Innovative industrial research, 79(02):45-47.

[9]. Wang D. 2016 Technology and Innovation, 53(05):38+41.

[10]. Ge J Q, Wang Y. 2020 The Car of Time., 326(02):65-66.

[11]. Hu J G. 2022 The Car of Time, 395(23):112-117.

[12]. He Y. 2022 The world car, 482(06):70-71.