1 Introduction

Commercial airlines are currently dealing with pressing environmental challenges such airport noise and climate change, as well as the need to save fuel and building expenses. In response to this urgent need, the United States Aviation Research Advisory Council has established a comprehensive civil aviation development indicator, which will be completed by 2050. Specifically, the plan will reduce average passenger speed CO2 emissions by 75 per cent, NOx emissions by 90 per cent and aviation noise emissions by 65 per cent. For this reason, major scientific research institutes and civil airlines at home and abroad have invested in in-depth research and research in this field [1]. In order to achieve these goals, numerous organizations and civil aviation companies are committed to research and technological exploration in the field of aeronautical and aero-engine engineering [2]. These studies involve research across a number of key aeronautical areas, including structural design, aerodynamics, aero-engine engineering and noise pollution control and prediction.

Engineering problems in aviation often necessitate a sufficient number of sample points, which can be generated using design of experiment methods. For instance, when dealing with numerous variables and employing finite difference methods to assess gradients, to construct the Hessian at the design point, a substantial number of analyses must be performed by sampling the design space [3]. In actuality, a lot of improvements rely on internal models of some kind to explore design space. [4]. As an illustration, modeling of flow fields surrounding variously shaped airfoils [5] or newly morphed geometry [6] have to be filled the design space in order to find the optimization results. That is to say, obtaining enough information to predict a design requirements and result is a barrier in many optimizations [7]. In order to investigate how various variables affect a system, a variety of system models must be designed and simulated through techniques such as the control factor method. An optimization method must be both intellectual and effective, and credible for balancing the modelling efforts, computational cost and design requirements [8]. Besides, predicting and controlling aero noise are also complicated. Aeroengine noise sources are complex and diverse, including combustion noise, exhaust noise, mechanical noise and aerodynamic noise, etc. [9-10] The dynamic interconnection among these noise sources, coupled with the concurrent influence of various factors like flight conditions, engine load and operating status make noise prediction complex. The interaction between physical fields (physical fields, including combustion, fluid mechanics, acoustics and structure) [11-13], requires complex numerical simulations and calculations. Overall, the economic and computational expenses linked with conducting experiments and simulations to address these challenges are substantial.

Artificial Neural Networks (ANNs) represent a form of artificial intelligence (AI) designed to replicate the neural network observed in the human brain. Thus, ANN allows the processor to interpret brain signals and make human-like decisions in a computing system [3]. These synapses store data in a distributed manner, facilitating the retrieval of multiple segments of information from memory simultaneously, driven by necessity and capacity, the human brain operates on an inherently parallel processing basis [8]. In a recent review article authored by Brunton et al. [6], the trends and perspectives of machine learning in the aerospace industry are examined. This encompasses applications in smart manufacturing, along with the diverse stages of aircraft development, production, and product support. With the growth of large amount of data, the improvement of computing power, the continuous improvement of learning algorithms, and the continuous emergence of more application scenarios, the research of this research has received extensive attention: machine learning (ML) and deep learning (DL).

ML is a subfield of AI that focuses on the development of algorithms and models that enable computer systems to learn and make predictions or decisions without being explicitly programmed [14]. It is based on the idea that machines can learn from data, identify patterns, and make intelligent decisions or predictions [15]. DL is a subfield of machine learning that focuses on the development and application of artificial neural networks with multiple layers, allowing the system to learn hierarchical representations of data [16]. Due to its powerful ability, deep learning is increasingly used to solve engineering problems, such as aircraft design, dynamics, and control field, many works hinge on the information-rich data-driven approach to reducing the amount of numerical simulation computation and so on [17]. Currently, machine learning and deep learning techniques are highly regarded in academia and industry with widespread success. Big Data is related to AI and ML, a word used to describe the massive volume of data that either originates from CFD models and experimental observations in aerospace engineering, or is constantly flooded into the aviation industry [5,18]. Recently, the "Big Model" of fluid dynamics jointly released by Northwestern Polytechnical University and Huawei is a hydrodynamic model based on deep machine learning of previous simulation results from neural networks, which greatly reduces the computational cost of numerical simulation of high-speed fluids. Moreover, big data facilitates in-process monitoring, analysis, and improved decision-making for aerospace industry applications of aircraft structure manufacturing.

This review examines recent research that combines ML and DL for applications in aeronautics, including aero-engines and intends to explore the possibilities of ML and DL in field of aerodynamic, aircraft structural design, aero-engine and noise prediction. With this review, we hope you will gain a better understanding of the ML and DL languages and be able to apply them to problems related to aircraft and aerospace engines. The review is structured as follows: Section 2 introduces machine learning and deep learning methodologies. In Section 3, a literature review of the applications in aerospace engineering is presented, focusing on CFD, aircraft component design and aeroacoustics. and Section 4 focuses on aero-engine applications, including health state evaluation, component optimization, blade defect detection and combustion. The paper concludes with the main conclusions outlined in Section 5.

2 Machine learning and deep learning

2.1. Machine learning

Machine learning tackles the challenge of constructing computers capable of autonomous improvement through experience [19]. Within this field, algorithms and models are developed to empower computers in learning and extracting knowledge from data. Machine learning is an essential part of artificial intelligence which renders it easier to automate tasks and make decisions by allowing computers to learn on their own and improve their capabilities by using data. The fundamental concept underlying machine learning is the identification of patterns and predictions derived from data. Leveraging mathematical methods like statistics, probability theory, and optimization theory, it systematically uncovers patterns and trends in data by scrutinizing extensive input and output datasets.

Machine learning harnesses artificial neural networks to process and glean information from databases. This computing paradigm draws inspiration from the intricate biological neural networks present in the human brain. In this context, neurons are interconnected through axons and dendrites, with synapses serving as the connecting points. Neurons receive input signals from various sources and generate distinct output signals. The sophistication of a biological neural network plays a pivotal role in determining the level of intelligence [20,21].

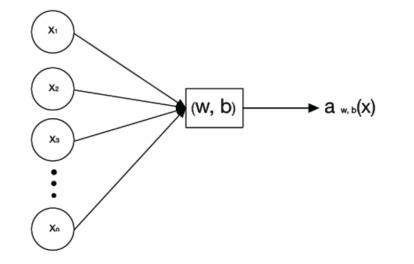

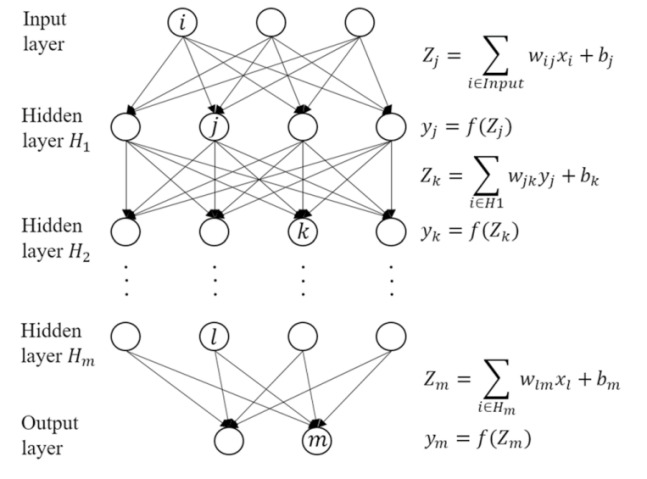

The perceptron serves as a fundamental component within the architecture of artificial neural networks. It comprises three nodes: an output, a hidden, and an input. Neurons within the perceptron modulate inputs using parameters such as weights (w) and biases (b). The regulated values are relayed to an activation function (a) which shapes the output from the neuron. The parallel connections among neurons establish a hierarchy, and the connections among several hierarchies come together to form a network of neurons (Figure 1).

Figure 1. Definition of a neuron and neural network structure

By varying the closed variables w and b, a neural network approximates the connection between input and output. This adjustment (referred to as training) is typically accomplished using backpropagation [22]. The parameters enclosed within the network are initialized in a (random) manner. Subsequently, the algorithm modifies these settings in order to reduce the difference between the network output and the actual output. The widely used technique for this process is the baseline gradient dimensionality reduction algorithm, although alternative training approaches are also accessible [22]. Following adequate training, the hierarchical configuration of the network excels in regression mapping. The hierarchical configuration of the network excels in regression mapping. By employing ample data and training endeavours, arbitrary levels of precision can be attained [23].

The primary methods of machine learning encompass deep learning, reinforcement learning, supervised learning, and unsupervised learning, and other related techniques.

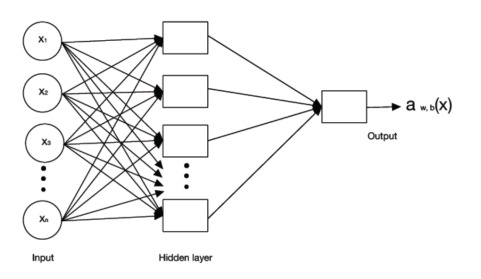

Supervised learning involves training algorithms on labelled data, where a target or output value corresponds to each input sample. The algorithm learns the mapping of inputs to outputs by studying the provided examples. Widely employed supervised learning algorithms encompass Linear Regression, Logistic Regression, Decision Trees, Random Forests, Support Vector Machines (SVMs), and Artificial Neural Networks [24]. Regression and classification stand out as popular and highly effective techniques in this context. But if data (or categories) are missing, this can lead to erroneous results and thus problems in the training and/or classification process [25].

Figure 2. Provides a list of machine learning techniques for classification and regression. From the left to the right, the depicted methods include linear regression, logistic regression, K-nearest neighbours, and support vector machines [25]

On the other hand, unsupervised learning involves training algorithms on unlabelled data with the goal of discovering underlying patterns, structures, or relationships in the data [26]. Clustering algorithms, such as K-means clustering and hierarchical clustering, group similar data points together. Dimensionality reduction techniques [27], like Principal Component Analysis (PCA) [28] and t-distributed Stochastic Neighbour Embedding (t-SNE) [29], aim to reduce the dimensionality of the data while retaining important information. Thus, techniques for unsupervised learning have a lot of applicability in aerospace.

Reinforcement Learning: Reinforcement learning entails educating a representative to communicate with the environment and learn the optimal actions to maximize the reward signal [30]. Through a process of experimentation and mistakes, the agent acquires knowledge, which is then communicated as either rewards or penalties depending on its behaviour. Widely utilized reinforcement learning algorithms include Q-learning, deep Q-networks (DQNs) [31], and policy gradients. These methods leverage small sets of demonstration data to significantly expedite the learning process, even when the available demonstration data is relatively limited and is able to automatically assess the necessary ratio of demonstration data while learning thanks to a prioritized replay mechanism [31].

Historically, the number of hidden layers in a network was typically restricted due to inadequate computational power. This frequently led to imprecise results because there weren't as many learning and training sessions as there were in comparison to those that produced more precise results. In recent years, due to the rapid development of GPUs and CPUs, as well as the emergence of new activation functions and parallel computing, more layers have been used in artificial neural network, making the results more accurate. Thus, deep neural network was created.

2.2. Deep learning

Deep learning is an important division of machine learning that seeks to automate feature learning and pattern recognition by building and training multi-layer neural network models [32]. One of the primary benefits of deep learning is its capacity for process large-scale and high-dimensional data [32]. Traditional machine learning techniques might struggle with extracting and depicting features in intricate issues, but deep learning, employing various stages of non-linear transformations, is capable of autonomously assimilating abstract attributes from the data to enhance its representation and application.

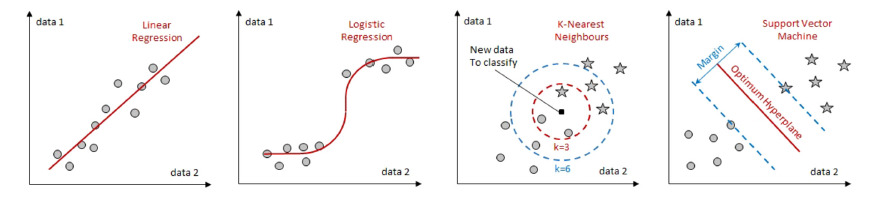

Neural network models, the most popular of which are referred to as Deep Feedforward Neural Networks (DFNs), are the fundamental building blocks of deep learning. Such networks consist of multiple stacked hidden layers, each consisting of many neuron nodes (Figure 3) [33]. Data traverses from the initial layer, goes through various layers executing nonlinear transformations, and ultimately arrives at the final output layer, where functions like classification and regression are carried out.

Figure 3. Architecture of multilayer feedforward neural network [34]

In order to teach deep neural networks, the Backpropagation algorithm (Backpropagation) [35] is commonly used. By comparing the actual labels with the model's anticipated output, this technique aims at reducing inaccuracy. Then, beginning at the output layer before making its way through the network, it modifies the weights and biases to minimize inaccuracy. This process is repeated until the network reaches a predetermined level of performance.

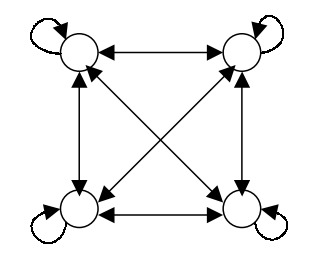

ANNs of the Recurrent Neural Network (RNN) type are often utilized in applications involving deep learning using sequential or temporal data. In contrast to feedforward neural networks, RNNs feature connections that enable cycled information flow, which enables them to maintain an internal memory or context (Figure 4) [36]. One essential property of RNNs is their ability to process input sequences and identify the temporal relationships between the sequence segments. In an RNN, each element of the sequence corresponds to a specific time step. The RNN processes the input data incrementally, one time step at a time, while considering the information from previous steps through recurrent connections [36]. During each time step, the RNN combines the input data with the internal state or memory from the previous time step [37]. After that, this mixture is run through an activation function, which updates its internal state for the present time step and produces the output. The updated state is used as the input for the next time step in this iterative process, which continues until all of the sequence has been processed. Nevertheless, When the input gap is significant, RNNs made up of sigma or tanh cells are unable to extract relevant information from the input data. Long-term dependency problems can be effectively managed by long short-term memory (LSTM) by incorporating gate functions into the cell structure [38].

Figure 4. An example of a completely integrated recurrent neural network.

Convolutional Neural Networks (CNNs) are specifically designed to capture and exploit the spatial dependencies in the input data [39]. The key feature of CNNs is the convolutional layer, which applies a set of learnable filters (also known as kernels) to the input data [39]. When swiping over the input signal and computing the dot value of the local receptive field at each location and the filter weights, a CNN's filtering conducts convolution operations. By using this method, the network is able to identify and extract local patterns or features, such as edges, textures, and corners, from the input data [40].

Generative Adversarial Network (GANs) is a widely adopted framework in deep learning for generating realistic and high-quality synthetic data. GANs offer a means to learn deep representations without the need for extensive annotated training data [41]. Consisting of two main components, GANs function by using a generator to produce artificial data samples (such sounds and images) from random noise vectors. This is done through the use of a discriminator network and a generator network. The objective of the generator is to produce samples that are indistinguishable from real data examples. Conversely, the discriminator functions as a binary classifier, tasked with distinguishing between real and synthetic samples. Throughout training, the generator and discriminator are simultaneously taught in a way that is competitive.

3 ML and DL applications in aerodynamics

Improving aerodynamic design in aircraft is one of the main goals of the aviation and aerospace industry. The aviation and aerospace industry places significant emphasis on studying aircraft wings, airfoils, and turbine engine to achieve more efficient designs that minimize drag and noise. Therefore, structural optimization, fluid control and aeroacoustics are still the challenging topics to be tackled in aerospace engineering in the coming years. Researchers are working very hard right now to accomplish these aims. For instance, minimizing the impact of critical loads on an airplane requires regulating shockwaves and unstable loads. This covers actions like postponing buffeting's start, avoiding flutter generated by linear aerodynamics [42], and managing other aeroelastic reactions that may result in limit cycle oscillations (LCOs) brought on by aerodynamic nonlinearities [43]. These actions not only lessen airflow separation but also contribute to the aircraft's increased stability and safety. Furthermore, some wing designs can lessen the likelihood of turbulence and noise production, which lowers drag and noise levels. One way to lessen wingtip turbulence and pressure differences is to design wingtip forms [44]. A well-designed wing tip minimizes drag and the production of turbulence noise. It is also possible to lessen turbulence, drag, and noise by smoothing out airfoils with treatment of the surfaces and thin coatings.

Wind tunnel testing and Computational Fluid Dynamics (CFD) simulations are the standard procedures used to gather data about the aircraft's performance. Aerodynamic data obtained from numerical and experimental sources can be categorized into two groups: (a) distributed data, comprising skin friction and surface pressure distribution, and (b) integral quantities, including drag, lift, and moment coefficients [45]. But in order to answer design and multiphysics challenges, researchers frequently turn to simpler aerodynamic models because numerical simulations and experiments can be very expensive. This leads to a decrease in the credibility and accuracy of computational results.

3.1. ML and DL applications in CFD

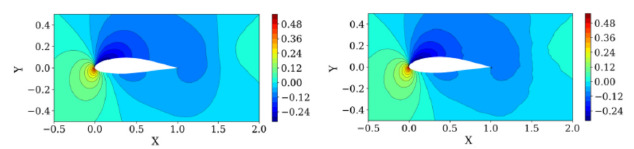

Data-driven techniques are widely used in many different applications, including aerodynamic optimization iterations, turbulence modelling, as well as flow field forecasting in computational fluid dynamics (CFD). They also directly take the place of the costly CFD procedure. These techniques use data throughout the aerodynamic optimization procedure to increase the precision and efficiency of CFD simulations or to replace the highly computational CFD procedures. For example, an alternative approach based on data analysis was proposed to forecast airfoil incompressible laminar steady flow [46]. This method employed both CNN and DNN. CNN was utilized to retrieve the geometric characteristics (shape) data of the airfoil. These data, coupled with the airfoil's Angle of attack and Reynolds number, were fed into the Deep Neural Network (DNN). The flow field results displayed in Figure 5 prediction findings illustrate the effectiveness and precision of this Deep Learning-based technique.

Figure 5. DL-based flow field prediction; findings obtained with NACA 63415 airfoil; left: pressure distribution via CFD, right: pressure distribution using DL method [46]

In recent years, there have been numerous uses of ML and DL to enhance aerodynamic design and solve optimization issues. For instance, NNs have been used to create models that speed up CFD simulations. By facilitating the quick computation of integral numbers and dispersed data for a variety of design geometries, this acceleration improves optimization efficiency. This approach simplifies the process of identifying optimal designs within a shorter timeframe [47,48]. Furthermore Based on sensor measurements, these models can be used to recover high-fidelity data [49]. They can also offer valuable insights into the optimal wing area, engine thrust, and aircraft weight combined, aiding decision-making during the initial phases of aircraft design [50]. When combined with other analysis tools, low-order models may be utilized to predict aerodynamic loads and describe aerodynamic systems, allowing for a wide range of analyses to be performed with the least amount of computational overhead.

In a specific application, Linse & Stengel [51] employed neural networks (NNs) to estimate aerodynamic coefficients. By taking additional training data from the initial partial derivations of these coefficients, they introduced a novel method. The approach was successfully applied to non-linear aircraft control and the non-linear twin-jet transport problem was solved using numerically generated flight test data. Recurrent neural networks (RNNs) were employed in a different study by Suresh et al. [52] to look at the dynamic stall effect on the rotor blade of an OA212 airfoil. The authors used an experimental database to estimate lift coefficients at significant angles of attack in order to show the practical use of their method. They also proposed a method to generalize model training errors; Hou et al [54] investigated the impact of aerodynamic disturbances, including manoeuvres and gusts, on the wing surface by employing pressure measurements. Through pressure measurements, neural networks are utilized to investigate how aerodynamic perturbations affect the surfaces of the wings. Secco & Mattos [53] created a reliable stand-in model with NNs to forecast transport aircraft aerodynamic coefficients. The NNs-based model made use of data from about 100,000 examples that were computed using numerical CFD simulations, with input parameters including flight conditions, airfoil geometry, and wing planform. The computational time required to estimate the aerodynamic coefficients was about 4000 times faster than that of the CFD solver. This model was also effectively employed in optimization design tasks. Lastly, Tao et al. [55] introduced a multi-fidelity surrogate model for robust optimizations of airfoil and 3D wings at varying Mach numbers. They created a linear multi-fidelity surrogate regression model by merging high-fidelity CFD data, enabling the optimization of aerodynamic designs over a range of Mach values in an efficient and reliable manner.

In conclusion, applying ML and DL techniques can improve the accuracy and efficiency of CFD simulations. Using the available CFD data, fluid flow behaviour may be predicted more rapidly and accurately. ML and DL algorithms can then learn and recognize patterns from this data. These algorithms reduce the amount of time and computational expense required for complex simulations. Furthermore, ML and DL may be used to generate surrogate models that resemble complex CFD simulations. Design iterations and optimization studies are accelerated by the rapid and accurate approximation of CFD findings made possible by these surrogate models. ML and DL algorithms may also be used to analyse and extract large datasets in order to determine the optimal configurations, control settings, or design modifications that will improve the efficiency and performance of aerodynamic systems. However, there are still certain problems with using ML and DL in conjunction with CFD. Future engineers and researchers should take into account concerns like the computational expense of getting big volumes of data and how to obtain a large enough amount of data for machine learning and training.

3.2. ML and DL applications in design optimization

In the discipline of aircraft engineering, design and optimization play important roles. The field of machine learning has grown to be a potent instrument for the structural and design optimization of aircraft. Aerial vehicle wings, airfoil geometry, unmanned aerial vehicles, turbine engine blades, and flying circumstances are all included in the optimization of aircraft design. Aerodynamic design optimization includes many different elements, including airfoil shape, turbine engine blades, UAVs, and aircraft wings. In a review that Sun & Wang wrote [56], The authors give a summary of the contributions made by the scientific community on using NNs for surrogate modeling in design optimization. The study examines the impact of different types of ANNs, the selection of training data, and the need for specialized data processing, and demonstrates how ANNs can be used for optimization. In order to achieve optimal design results at the lowest possible computational cost, the authors show that multilevel surrogate modelling—which combines multiple layers of information—is highly effective. ANNs can be integrated with a variety of optimization algorithms to extract the information required to solve optimization problems. Large databases can be processed using ANNs to extract the data required to solve optimization challenges. Another review published recently by Li et al.[57], The use of machine learning for design optimization is investigated, covering elements such optimization convergence rate, design space, objective modelling, and constraint modelling. Intelligent, effective, and able to balance modelling efforts with design space considerations are critical components of optimization. Notably, design optimization significantly impacts the performance of aircraft in areas such as aerodynamics, combustion, and aeroacoustics. In a study by Sun et al. [58], a novel approach utilizing NNs was introduced for inverse design in wing and airfoil databases. Their method leveraged the trained NNs to facilitate the design process. Furthermore, Xiang et al. [59] suggested a DRL-based sampling strategy for evaluating structural reliability. In this method, the sample was seen as the activity of the DRL method and the sample space as its existing state. A reward function was incorporated to guide the deep neural network in choosing the optimal sampling points. More recently, Yang et al. [60] found the ML technique is capable of monitoring and predicting wingtip deflection in an accurate and efficient manner.

Researchers have dedicated significant effort to advancing the discipline of aerospace engineering and the best practices for designing and producing airplanes in three key areas: aerodynamic force identification, linear and non-linear response estimation (aeroelasticity and Fluid-Structure Interaction), and design optimization. ML and DL algorithms have been applied in these domains, enabling the creation of accurate ROMs and surrogate models that can effectively handle a variety of issues, including different flying circumstances and incompressible to transonic compressible flows. However, there are still challenges to overcome. The inability of current approaches to generalize and the possibility of combining several data kinds (numerical and experimental) with variable degrees of reliability, motivates researchers to continue advancing the field. The ultimate goal is to create machine learning models that are extremely precise and that can be quickly and readily applied to a variety of issues with little or no manual labour. Such advancements could contribute to the long-term success of aviation and transform the profession of aerospace engineering.

3.3. ML and DL in aeroacoustics

Aeroacoustics is a subject area that studies the interaction of air flow with sound waves. This field of study focuses on the characteristics of sound waves as they pass through fluid medium and the sound generated through aerodynamic processes. Studies on combining ML and DL with aeroacoustics have only been developed in the last few years. In a comprehensive review conducted through Bianco et al. [61], the benefits of utilizing Machine Learning (ML) for modeling pure phenomenon of sound are summarized. The authors explore various topics, such as source localization in environmental sounds, bioacoustics, and ocean acoustics. The references cited demonstrate that ML-based methods often outperform traditional signal-processing techniques. While ML-based approaches offer advancements in signal processing techniques, it's crucial to acknowledge that their effectiveness is constrained by the availability of data, as they require extensive data sets for effective training.

In the context of aviation, the domains of aeroacoustics and computational aeroacoustics (CAA) are very important. Due to the necessity to take into account sound generation and transmission, turbulence and geometry, and sound interaction, aeroacoustics issues are more complicated than merely acoustic issues. Aerodynamic noise, jet noise, and rotating machinery noise are the main sources of noise in aeronautical applications. Regarding recent advancements in these areas, Moreau [62] provides a comprehensive overview which shows that there are surprisingly few publications available at this time that specifically address applying ML to accelerate aeroacoustics modelling or CAA simulations.

Two separate issues are present in aeroacoustics and CAA: noise propagation (far field) and noise generation (near field) [63]. While direct acoustic simulation—in which the near and distant fields are solved simultaneously—is still feasible, it is currently limited to small-scale applications. Instead, the hybrid approach is typically chosen to reduce costs in large-scale, intricate simulations. The lattice Boltzmann method (LBM) simulations combined with Ffowcs Williams–Hawkings (FW-H) solver have been used extensively for aeroacoustics a variety of issues, ranging from straightforward geometries to intricate ground vehicles and aeronautical applications [64]. Due to Large volumes of fluid calculations can be efficiently computed with LBM because of its great scalability in parallel computing systems, small template size, and time explicit nature. Kazuya and associates.[65] evaluated LBM using the momentum propagation problem. The results demonstrated that For compressible Navier-Stokes (N-S) equations, the fourth-order Runge-Kutta approach was 12.3 times more accurate and quicker than the centralized fourth-order scheme; LBM reduces computational effort while providing computational accuracy and easy access to data; In order to forecast the far-field acoustic field in a two-dimensional square space with monopole sources, and irregularly spaced round and rectangular items, Rüttgers et al. [69] trained a deep ANN using LBM.

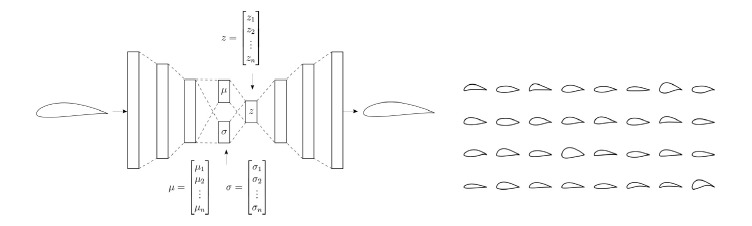

Aeroacoustics is a field that deals with sound creation, sound propagation, or both. Various models and connections based on acoustic analogies can be applied. NNs can be employed as models or correlations through techniques such as deep learning. However, there aren't many research that offer interesting concepts regarding sound propagation in the context of aeroacoustics. For instance, Tang et al. [66] investigated dynamic interactive sound propagation through the use of ray tracing algorithms to combine learned scattered fields based on neural networks. This approach facilitated the generation of realistic effects, including specular reflections, diffuse reflections, diffraction, and occlusion. Alguacil et al. [67] employed deep CNNs to predict the propagation of acoustic waves. Additionally, they have created deep learning surrogates that describe the dispersion transfer function and the sound waves' propagation in streams that are not disturbed. The use of linear regression models to improve vehicle acoustics was suggested by Kužnar et al. [68]. Moeen Uddin et al. [70] used acoustic analogies based on RANS and Ffowcs Williams and Hawkings to estimate the aeroacoustics tire noise at near-field and far-field receivers surrounding the tire. These studies represent a significant effort in the field of acoustic wave propagation in aeroacoustics using ML, DL and regression models. Finally, auto coders were employed in a study by Kou et al. [71] to enhance wing optimization by the incorporation of a multidisciplinary goal function that integrates aerodynamic and aeroacoustics objectives. A variational autoencoder for airfoil parametrization is implemented in Figure 7. which presented a novel approach challenging the traditional CST parameterization method. The results demonstrated that variational autoencoders were capable of representing a broad range of airfoil geometries using only four variables that are encoded. This enabled economical optimizations and ultimately led to the discovery of quieter optimal airfoil shapes.

Figure 6. Aeroacoustics optimization using variational autoencoder for airfoil parametrization with n-dimensional latent variables (left). The latent variables z's mean and standard deviation are shown by the symbols μ and σ. Using a variational autoencoder, smooth airfoils are produced (right) [71]

In order to minimize acoustic signatures and reduce aircraft noise, machine learning techniques must be applied immediately. Reducing the acoustic impact of airplanes and noise pollution are major concerns for the aviation industry and airports. ML and DL techniques provide answers to a number of problems related to lowering aircraft noise. For instance, in order to reduce noise emissions, ML and DL algorithms can optimize the design of aircraft components. They can be used, for instance, to jointly optimize the geometry of aircraft wing structures (like the vertex generator) or engine components (like the pre-swirl), which will lower noise levels. Engineers can find the best settings to reduce noise generation by using machine learning. Furthermore, through the optimization of operating operations like as take-off and landing, ML and DL systems may reduce noise. By analysing the many variables and characteristics involved in these processes, ML and DL approaches may be used to determine the most efficient and noiseless methods for a certain aircraft. This may include analysing the immediate environment, changing the propulsion settings, or optimizing the flight route in order to lessen the influence of noise during critical flying periods. Additionally, ML and DL approaches may estimate noise levels associated with different aircraft designs or operational practices. By including factors like aircraft type, configuration, and flight circumstances into ML and DL models trained on historical data, accurate noise level estimate is made possible. This information aids in decision-making, allowing participants to select aircraft configurations and operation methods that lower noise levels. To sum up, ML and DL approaches are critical to reducing aircraft noise pollution. ML and DL algorithms have a major impact on reducing noise pollution and improving the overall acoustic impact of aircraft on nearby towns through refining aircraft designs, operational procedures, and noise level prediction.

4 ML and DL applications in aero-engine

4.1. ML and DL applications in aero-engine health state evaluation

In general, an aero-engine typically relies on the troubleshooting and repair of airway components to continue to operate at peak efficiency and safety. It is crucial that these defects be precisely diagnosed because gas system components are responsible for around 90% of aircraft engine failures. Even though it is hard to see, the easiest way to assess the state of engine component breakdown is to directly observe changes in flow and efficiency. On the other hand, variables related to aeroengines, such temperature, pressure, and rotation speed, might not always indicate a problem with the engine's parts. The purpose of health assessment is to provide reliable information for predictive maintenance. Consequently, this poses significant challenges when it comes to aeroengine fault diagnosis.

When it comes to turbofan engines, high-pressure compressor deterioration was established and predicted using a health index that was created from engine sensor data collected throughout each flight. [72,73]. Stress occurs in varying rates to distinct engine parts because each portion competes to determine the engine's overall lifetime. Maintaining the engine's overall usable life is complicated, as seen by the struggle between parts that have become the limiting factor. Consequently, accurately forecasting the present wear state of these components has evolved into a pivotal responsibility in fleet management. A substantial amount of data has been gathered as a result of the use of on-board diagnostic technologies and health monitoring systems. Thanks to this wealth of data, engineers may do in-depth research and gain special insight into the complicated mechanics of wear on engines and performance. This wealth of data facilitates the refinement and improvement of classical condition-based maintenance practices [74]. Given the intricate nature of turbofan engine components and the challenges associated with accurately predicting their operational status, Matuszczak et al. [75] chose a deep learning approach—specifically, the ANN Multilayer Perceptron. This method underwent comparison with alternative models, such as support vector machines, random forest trees, and linear regression, and XGB Regressor. Finally, the author noted that the multilayer perceptron networks (MLP) algorithm was used to evaluate the condition of engine components and predicted maintenance times as expected. This approach proved effective in reducing staff workload, thereby significantly cutting operational costs. Sina Tayarani Bathaie et al. [76] explored an alternative deep learning model. The findings indicate that dynamic neural networks, particularly those based on MLPs,are promising for turbofan engine failure prediction. Maria et al. [77] developed a mechanism to track the health state of aero-engines. The study tested a number of machine learning techniques, and models based on ANN and SVM yield good results for engine performance measures that are calculated from small amounts of operating data; These tools can be used in real-time conditions because to their extremely short processing times. In addition, the authors discovered that the ANN-based engine model outperforms the SVM-based model by a little margin. Later, an ANNs-based instrument is created by Maria et al. [78] to detect the degradation of a gas turbine engine's two main components, the turbine and compressor. With a mean prediction efficiency value of 96,5% involving in the input vector fuel flow rate, exhaust gas temperature, Mach number, and burner exit temperature, the results demonstrated that the input vector based on (Mach, fuel flow rate mf, EGT, and inlet turbine temperature) can perform the best. Finally, Aurthur et al. [79] developed ML-based model to predict the optimized net efficiency. The suggested model assists in both component-level development for more efficient gas microturbines and performance feature prediction, allowing for the installation of a degradation monitoring system to virtually monitor the state of the system. Since actual performance data is costly, More advantages have been derived from the usage of simulation data. It is necessary to validate the physics-based model for operating condition simulations. The information is taken from the software ASTRA, which Samara University developed.[80].

In conclusion, based on existing research, this aero-engine health condition evaluation method, which combines ML and DL, can effectively evaluate the condition of aircraft engines health. It can also have accurate precision and effectively reduce the computation cost in terms of computation. Generated data will be obtained from simulation with increasing frequency as research in this field progresses, and the database will keep expanding. And this approach not only streamlines later engine maintenance but also enhances accuracy, reduces costs, and provides engineers with a broader array of options for studying the engine's lifespan.

4.2. ML and DL applications in aero-engine component optimization

Artificial Intelligence (AI) is used in machine learning, particularly in the prediction of gas turbine (GT) performance. This entails estimating emissions, assessing various ambient circumstances, and filling in the gaps in the experimental data. By leveraging artificial intelligence, the system enhances its predictive capabilities, contributing to a more comprehensive understanding of gas turbine behaviour under various scenarios [81,82]. The highly-loaded transonic compressor stages' design space is intricate, encompassing various loss mechanisms such as interactions between the boundary layer and shock wave, end-wall separation, and tip clearance vortical structures [83]. In response to this complexity, a machine learning approach is proposed to accelerate the optimization of high-load transonic compressor blade designs. Improving compressor efficiency and reducing stability losses are the main goals. During the pre-compression phase, the most effective contenders are additionally checked. The losses are distributed along the span, with a significant decrease in turbulent kinetic energy downstream of the blade, especially in the first 70% of the span. [84]. This finding highlights the need for machine learning frameworks to complete agent-assisted optimization faster and more accurately.

Additionally, for the pre-compression phase, additional checks will be performed on the most effective contenders. The losses are distributed along the span, with a significant decrease in turbulent kinetic energy downstream of the blade, especially around 70% of the span [85]. This finding highlights the need for machine learning frameworks to complete agent-assisted optimization faster and more accurately. Michae et al proposed a machine learning framework for faster and more accurate alternative auxiliary optimization of compressor rotor optimization. [86]. First, the mathematical Kursawe function is used to benchmark the proposed framework. This reveals a complex and discontinuous Pareto front that favours RF-based surrogates over more traditional surrogates such as neural networks and Gaussian process (or kriging) models [86].

In conclusion, because of different loss causes, it is exceedingly challenging to explore the design space of highly loaded transonic compressor stages. Additionally, an effective strategy for improving the pre-compression phase of heavy-duty transonic compressor blades is the application of ML and DL frameworks. Analysing loss contributions across the span emphasizes the importance of reducing turbulent kinetic energy downstream of the blade. This previous observation enhances our comprehension of the intricate details involved and emphasizes the necessity of a proficient machine learning framework for manoeuvring through and optimizing an intricate design space. This framework, which makes use of surrogates and streamlined models, provides a swifter and more accurate approach to aerodynamic design, especially when standard methods encounter computational problems. ML and DL integrations have the potential to revolutionize optimization procedures as the sector develops, improving performance and efficiency in transonic compressor stages that are subject to high loads.

4.3. ML and DL applications in the detection of flaws in aero-engine blades

The aero-engine blades stand as a critical component within aircraft engines [87], sustaining extreme circumstances of temperature and pressure while working at exceedingly high speeds. The accurate inspection of these blades is critical in the manufacture, maintenance, and repair operations [88], because any flaw might cause engine shutdowns, which can lead to potentially disastrous accidents. For aero-engine blade inspections, non-destructive inspection methods such as eddy current testing [89], ultrasonic testing [90], magnetic particle testing [91], and radiography [92] have been used, notably for internal flaw detection. Surface flaw identification, on the other hand, frequently relies on expert inspectors, injecting inefficiencies and subjective judgments into the process [93]. Even experienced inspectors can miss minor flaws. Deep learning models have a lot of potential in industrial applications like defect identification, quality control, predictive maintenance, and process optimization [94]. These algorithms, which can analyse a variety of data sources (images, videos, and sensor data), may detect and classify faults automatically. Automation not only saves time and money, but it also improves the consistency and reliability of problem identification [95].

Despite challenges, blade defect detection has garnered attention in recent publications, exploring various methods. Both classic machine learning methods and deep learning models are included [96]. Deep learning models provide a considerable benefit in automatically extracting representative features from images of aero-engine blades, increasing the efficiency and precision of fault identification. These algorithms can identify patterns and features indicative of blade flaws by learning from a broad set of photos. minimizing the likelihood of overlooked problems and boosting the detection rate. These findings are important for investigators and those involved in jet engine blade inspection, highlighting the need of employing powerful CNN models and big datasets. Various datasets to improve defect detection precision. Future research in this area should look into both self-supervised and unsupervised learning methods. Incorporating both self-supervised and unsupervised learning models into the various approaches used in aero engine blade inspection could thereby increase overall accuracy. These models have demonstrated considerable promise in a wide range of applications, including anomaly detection, object detection, and image classification [97]. Their specific features include reducing the need for substantial labelled data and making it easier to discover novel flaws.

4.4. ML and DL applications in aero-engine combustion

The objective of combustion research in aircraft engines is to create predictive models that are reliable and broadly applicable to explain combustion processes in these engines. In recent years, significant progress has been achieved in the development and simplification of chemical kinetic mechanisms for hydrocarbon fuels, as well as Direct Numerical Simulation (DNS) and Large Eddy Simulation (LES). LES is getting more common in industrial applications, and parametric DNS investigates relatively close scenarios thanks to the available computer capacity. However, Because of its lower computing cost, Reynolds-Averaged Navier-Stokes (RANS) remains the dominant method. Despite significant improvements, present modeling approaches often fall short of the requisite universality and predictability [98]. The principal issues stem from the large number of species engaged in aero-engine combustion processes, the tiny scales at which these processes occur and the intricate interactions between turbulence and chemistry [99-101]. Machine learning (ML) approaches have the potential to advance combustion science by tackling previously unresolved challenges. They can create new closures for parameterizing unresolved fluctuations, provide interpretable ways for extracting features, and offer relevant methodologies for locally adapting complete chemical mechanisms and sub-grid models and develop reduced-order models (ROMs) that enable fast yet-accurate system evaluations [102].

Traditionally, the discipline of combustion research has struggled with massive amounts of data produced from experiments and large-scale numerical models. For nearly three decades, combustion has dealt with massive data thanks to advances in huge volume computing, which enable comprehensive simulations of laboratory-scale turbulent flames with sophisticated chemistry [103]. Numerous strategies for handling and processing combustion data from experiments and simulations have been developed, which can be viewed as early uses of machine learning [104]. Some research has concentrated on dimensionality reduction techniques such as Principal Component Analysis (PCA) [105], aiming to identify empirical low-dimensional structures within aero-engine combustion systems [106-107]. These analyses have been conducted on both experimental [108-109] and numerical simulation data [110-111]. However, as PCA assumes linearity, Frequently, it identifies additional components to compensate for non-linearity in the data, resulting in an overestimate of the actual number of dimensions in question, given that typical response flow data exhibit strong non-linear characteristics. To address this limitation of traditional PCA in non-linear systems, In the field of combustion research, there has been a proposal to utilize non-linear methods such as non-linear PCA, Kernel PCA (KPCA) [112], Isometric Mapping (IsoMap) [113], T-distributed Stochastic Neighbour Embedding (T-SNE) [114], and Autoencoders (AEs) [115] are some of the techniques used. Recently, fresh data-driven algorithms for regime identification using Convolutional Neural Networks (CNNs) have been developed [116]. Furthermore, non-linear regression with Neural Networks [117] has been used to identify the important characteristics of Moderate or Intense Low-oxygen combustion.

5 Conclusions and further discussion

Based on the big-data, ML and DL have provided viable approaches to the field of aerospace engineering. Our goal is to introduce this new technique to the aerospace community and initiate a conversation about its potential applications to various aerospace science and engineering issues. This review briefly describes some methods of ML and DL in the beginning, and then focuses on the aerodynamic aspects of aircraft and the aero-engine aspects of how these methods can be applied with descriptions and examples. At the conclusion of each section, we also summarize our findings and provide some recommendations. In applying ML and DL into aerospace problems and highlighting the various obstacles that these technologies confront. Besides, ANN has been instrumental in the effective application of ML and DL in aerospace engineering. In the future, with the continued advancement of computers and the advent of quantum computers, the use of ML and DL will become more and more widespread, and predictions and training results will become more and more accurate.

References

[1]. European Commission. Directorate-General for Mobility and Transport, Directorate-General for Research and Innovation, Flightpath 2050: Europe’s vision for aviation: maintaining global leadership and serving society’s needs[J]. 2011.

[2]. Åkerman J. Sustainable air transport––on track in 2050[J]. Transportation Research Part D: Transport and Environment, 2005, 10(2): 111-126.

[3]. Goel A, Goel A K, Kumar A. The role of artificial neural network and machine learning in utilizing spatial information[J]. Spatial Information Research, 2023, 31(3): 275-285.

[4]. Grant C. Automated processes for composite aircraft structure[J]. Industrial Robot: An International Journal, 2006, 33(2): 117-121.

[5]. Corrochano, A.F. Neves, B. Khanal, S. Le Clainche, N.J. Lawson, Des of a slingsby firefly aircraft: unsteady flow feature extraction using pod and hodmd, J. Aerosp. Eng. 35(5) (2022) 04022063.

[6]. Brunton S L, Nathan Kutz J, Manohar K, et al. Data-driven aerospace engineering: reframing the industry with machine learning[J]. AIAA Journal, 2021, 59(8): 2820-2847.

[7]. Kani JN and Elsheikh AH. Dr-rnn: a deep residual recurrent neural network for model reduction. arXiv preprint arXiv:170900939, 2017.

[8]. Wu Y, Feng J. Development and application of artificial neural network[J]. Wireless Personal Communications, 2018, 102: 1645-1656.

[9]. Bu H, Huang X, Zhang X. An overview of testing methods for aeroengine fan noise[J]. Progress in Aerospace Sciences, 2021, 124: 100722.

[10]. Filippone A. Aircraft noise prediction[J]. Progress in Aerospace Sciences, 2014, 68: 27-63.

[11]. Liu Y, Dowling A P, Swaminathan N, et al. Prediction of combustion noise for an aeroengine combustor[J]. Journal of Propulsion and Power, 2014, 30(1): 114-122.

[12]. Moore A. A 3D prediction of the wing reflection of aero engine noise[C]//10th AIAA/CEAS Aeroacoustics Conf.. 2004: 2865.

[13]. Jordan M I, Mitchell T M. Machine learning: Trends, perspectives, and prospects[J]. Science, 2015, 349(6245): 255-260.

[14]. El Naqa I, Murphy M J. What is machine learning? [M]. Springer International Publishing, 2015.

[15]. LeCun Y, Bengio Y, Hinton G. Deep learning[J]. nature, 2015, 521(7553): 436-444.

[16]. Goodfellow I, Bengio Y, Courville A. Deep learning[M]. MIT press, 2016.

[17]. Mendez C, Le Clainche S, Moreno-Ramos R, et al. A new automatic, very efficient method for the analysis of flight flutter testing data[J]. Aerospace Science and Technology, 2021, 114: 106749.

[18]. Berke L, Patnaik S N, Murthy P L N. Optimum design of aerospace structural components using neural networks[J]. Computers & structures, 1993, 48(6): 1001-1010.

[19]. Hagan M T, Menhaj M B. Training feedforward networks with the Marquardt algorithm[J]. IEEE transactions on Neural Networks, 1994, 5(6): 989-993.

[20]. Rojas R. Neural networks: a systematic introduction[M]. Springer Science & Business Media, 2013.

[21]. Cunningham P, Cord M, Delany S J. Supervised learning[M]//Machine learning techniques for multimedia: case studies on organization and retrieval. Berlin, Heidelberg: Springer Berlin Heidelberg, 2008: 21-49.

[22]. Le Clainche S, Ferrer E, Gibson S, et al. Improving aircraft performance using machine learning: a review[J]. Aerospace Science and Technology, 2023: 108354.

[23]. Alloghani M, Al-Jumeily D, Mustafina J, et al. A systematic review on supervised and unsupervised machine learning algorithms for data science[J]. Supervised and unsupervised learning for data science, 2020: 3-21.

[24]. Sorzano C O S, Vargas J, Montano A P. A survey of dimensionality reduction techniques[J]. arXiv preprint arXiv:1403.2877, 2014.

[25]. Van Der Maaten L, Postma E, Van den Herik J. Dimensionality reduction: a comparative[J]. J Mach Learn Res, 2009, 10(66-71).

[26]. Pezzotti N, Höllt T, Lelieveldt B, et al. Hierarchical stochastic neighbor embedding[C]//Computer Graphics Forum. 2016, 35(3): 21-30.

[27]. Kaelbling L P, Littman M L, Moore A W. Reinforcement learning: A survey[J]. Journal of artificial intelligence research, 1996, 4: 237-285.

[28]. Hester T, Vecerik M, Pietquin O, et al. Deep q-learning from demonstrations[C]//Proc. of the AAAI Conf. on artificial intelligence. 2018, 32(1).

[29]. Zhang W, Li H, Li Y, et al. Application of deep learning algorithms in geotechnical engineering: a short critical review[J]. Artificial Intelligence Review, 2021: 1-41.

[30]. Glorot X, Bengio Y. Understanding the difficulty of training deep feedforward neural networks[C]//Proc. of the thirteenth international Conf. on artificial intelligence and statistics. JMLR Workshop and Conf. Proc., 2010: 249-256.

[31]. Shrestha A, Mahmood A (2019) Review of deep learning algorithms and architectures. IEEE Access 7:53040–53065

[32]. Rumelhart D E, Durbin R, Golden R, et al. Backpropagation: The basic theory[M]//Backpropagation. Psychology Press, 2013: 1-34.

[33]. Medsker L R, Jain L C. Recurrent neural networks[J]. Design and Applications, 2001, 5(64-67): 2.

[34]. Pascanu R, Gulcehre C, Cho K, et al. How to construct deep recurrent neural networks[J]. arXiv preprint arXiv:1312.6026, 2013.

[35]. Yu Y, Si X, Hu C, et al. A review of recurrent neural networks: LSTM cells and network architectures[J]. Neural computation, 2019, 31(7): 1235-1270.

[36]. Gu J, Wang Z, Kuen J, et al. Recent advances in convolutional neural networks[J]. Pattern recognition, 2018, 77: 354-377.

[37]. O'Shea K, Nash R. An introduction to convolutional neural networks[J]. arXiv preprint arXiv:1511.08458, 2015.

[38]. Creswell A, White T, Dumoulin V, et al. Generative adversarial networks: An overview[J]. IEEE signal processing magazine, 2018, 35(1): 53-65.

[39]. Abbas A, De Vicente J, Valero E. Aerodynamic technologies to improve aircraft performance[J]. Aerospace science and technology, 2013, 28(1): 100-132.

[40]. Swaddle J P, Lockwood R. Wingtip shape and flight performance in the European Starling Sturnus vulgaris[J]. Ibis, 2003, 145(3): 457-464.

[41]. K. Li, J. Kou, W. Zhang, Deep learning for multi-fidelity aerodynamic distribution modelling from experimental and simulation data, arXiv:2019 .12966v2, 2021.

[42]. Ling J, Kurzawski A, Templeton J. Reynolds averaged turbulence modelling using deep neural networks with embedded invariance[J]. Journal of Fluid Mechanics, 2016, 807: 155-166.

[43]. E. Iuliano, E.A. Pérez, Application of Surrogate-Based Global Optimization to Aerodynamic Design, Springer, New York, 2016.

[44]. N. Van Nguyen, J. Lee, M. Tyan, et al., Repetitively enhanced neural networks method for complex engineering design optimisation problems, Aeronaut. J. 119 (2015) 1253–1270.

[45]. J.N. Kani, A.H. Elsheikh, Dr-rnn: a deep residual recurrent neural network for model reduction, arXiv:1709 .00939[cs .CE], 2017.

[46]. M.A.A. Oroumieh, S.M.B. Malaek, M. Ashrafizaadeh, et al., Dr-rnn: a deep residual recurrent neural network for model reduction, Aerosp. Sci. Technol. 26 (2013) 244–258.

[47]. S. Suresh, S.N. Omkar, V. Mani, T.N. Guru Prakash, Lift coefficient prediction at high angle of attack using recurrent neural network, Aerosp. Sci. Technol. 7(8) (2003) 595–602.

[48]. N.R. Secco, B.S.d. Mattos, Artificial neural networks to predict aerodynamic coefficients of transport airplanes, Aircr. Eng. Aerosp. Technol. 89 (2017) 211–230.

[49]. W. Hou, D. Darakananda, J.D. Eldredge, Machine-learning-based detection of aerodynamic disturbances using surface pressure measurements, AIAA J. 57(12) (2019) 5079–5093.

[50]. X. Wang, J. Kou, W. Zhang, Unsteady aerodynamic modeling based on fuzzy scalar radial basis function neural networks, Proc. Inst. Mech. Eng., G J. Aerosp. Eng. 233(14) (2019) 5107–5121.

[51]. Tao, J. and Sun, G., "Application of deep learning based multi-fidelity surrogate model to robust aerodynamic design optimization", Aerospace Science and Technology, vol. 92, pp. 722-737, Sep. 2019.

[52]. G. Sun, S. Wang, A review of the artificial neural network surrogate model-ing in aerodynamic design, Proc. Inst. Mech. Eng., G J. Aerosp. Eng. 233(16) (2019) 5863–5872.

[53]. Li J, Du X, Martins J R R A. Machine learning in aerodynamic shape optimization[J]. Progress in Aerospace Sciences, 2022, 134: 100849.

[54]. G. Sun, Y. Sun, S. Wang, Artificial neural network based inverse design airfoils and wings, Aerosp. Sci. Technol. 42 (2015) 415–428.

[55]. Xiang Z, Bao Y, Tang Z, et al. Deep reinforcement learning-based sampling method for structural reliability assessment[J]. Reliability Engineering & System Safety, 2020, 199: 106901.

[56]. Yasuda H, Yang J. Wingtip Deflection Monitoring and Prediction Based on Digital Image Correlation and Machine Learning Techniques[C]//European Workshop on Structural Health Monitoring. Cham: Springer International Publishing, 2022: 409-416.

[57]. Michael J. Bianco, Peter Gerstoft, James Traer, Emma Ozanich, Marie A. Roch, Sharon Gannot, Charles-Alban Deledalle, Machine learning in acoustics: theory and applications, J. Acoust. Soc. Am. 146(5) (2019) 3590–3628.

[58]. Stéphane Moreau, The third golden age of aeroacoustics, Phys. Fluids 34(3) (2022) 031301.

[59]. Williams J E F. Aeroacoustics[J]. Annual Review of Fluid Mechanics, 1977, 9(1): 447-468.

[60]. Keating A, Beedy J, Shock R. Lattice Boltzmann simulations of the DLR-F4, DLR-F6 and variants[C]//46th AIAA Aerospace Sciences Meeting and Exhibit. 2008: 749.

[61]. Kusano K, Yamada K, Furukawa M. Aeroacoustic simulation of broadband sound generated from low-Mach-number flows using a lattice Boltzmann method[J]. Journal of Sound and Vibration, 2020, 467: 115044.

[62]. Zhenyu Tang, Hsien-Yu Meng, Dinesh Manocha, Learning acoustic scattering fields for dynamic interactive sound propagation, in: 2021 IEEE Virtual Reality and 3D User Interfaces (VR), 2021, pp.835–844.

[63]. Antonio Alguacil, Michaël Bauerheim, Marc C. Jacob, Stéphane Moreau, Pre-dicting the propagation of acoustic waves using deep convolutional neural networks, J. Sound Vib. 512 (2021) 116285.

[64]. Damjan Kužnar, Martin Možina, Marina Giordanino, Ivan Bratko, Improving vehicle aeroacoustics using machine learning, Eng. Appl. Artif. Intell. 25(5) (2012) 1053–1061.

[65]. Mario Rüttgers, Seong-Ryong Koh, Jenia Jitsev, Wolfgang Schröder, Andreas Lintermann, Prediction of acoustic fields using a lattice-Boltzmann method and deep learning, in: Heike Jagode, Hartwig Anzt, Guido Juckeland, Hatem Ltaief (Eds.), High Performance Computing, Springer International Publishing, Cham, 2020, pp.81–101.

[66]. Ghulam Moeen Uddin, Sajawal Gul Niazi, SyedMuhammad Arafat, Muham-madSajid Kamran, Muhammad Farooq, Nasir Hayat, Sher Afghan Malik, Abe Zeid, Sagar Kamarthi, Sania Saqib, IjazAhmad Chaudhry, Neural networks assisted computational aero-acoustic analysis of an isolated tire, Proc. Inst. Mech. Eng., Part D, J. Automob. Eng. 234(10–11) (2020) 2561–2577.

[67]. Jiaqing Kou, Laura Botero-Bolívar, Román Ballano, Oscar Marino, Leandro deSantana, Eusebio Valero, Esteban Ferrer, Aeroacoustic airfoil shape optimization enhanced by autoencoders, 2023.

[68]. Tensorflow documentation, https://www.tensorflow.org/ (accessed 9 May 2020).

[69]. Wu S, Akbarov A. Support Vector Regression for Warranty Claim Forecasting. European Journal of Operational Research 2011; 213(1): 196-204.

[70]. Shin J H, Jun H B. On condition based maintenance policy[J]. Journal of Computational Design and Engineering, 2015, 2(2): 119-127.

[71]. Matuszczak M, Żbikowski M, Teodorczyk A. Predictive modelling of turbofan engine components condition using machine and deep learning methods[J]. Eksploatacja i Niezawodność, 2021, 23(2): 359-370.

[72]. Tayarani-Bathaie S S, Vanini Z N S, Khorasani K. Dynamic neural network-based fault diagnosis of gas turbine engines[J]. Neurocomputing, 2014, 125: 153-165.

[73]. De Giorgi M G, Campilongo S, Ficarella A. A diagnostics tool for aero-engines health monitoring using machine learning technique[J]. Energy Procedia, 2018, 148: 860-867.

[74]. De Giorgi M G, Campilongo S, Ficarella A. Development of a real time intelligent health monitoring platform for aero-engine[C]//MATEC Web of Conf.s. EDP Sciences, 2018, 233: 00007.

[75]. Jayachandran A V T, Omar H H, Tkachenko A Y. Machine learning predictor for micro gas turbine performance evaluation[J]. Aeron Aero Open Access J., 2020, 4(4): 172-180.

[76]. Kuz'michev V S, Tkachenko A Y, Krupenich I N, et al. Composing a virtual model of gas turbine engine working process using the CAE system" ASTRA[J]. Research Journal of Applied Sciences, 2014, 9(10): 635-643.

[77]. Bartolini CM, Caresana F, Comodi G, et al. Application of artificial neural networks to micro gas turbines. Energy Convers Manag. 2011;52(1):781–788.

[78]. Chipperfield A, Fleming P. Multi objective gas turbine engine controller design using genetic algorithms. IEEE Transactions on Industrial Electronics. 1996;43(5):583–587.

[79]. Denton, J., 1997. “Lessons from rotor 37”. Journal of Thermal Science, 6(1), pp. 1–13.

[80]. Joly, M, Sarkar, S, & Mehta, D. "Machine Learning Enabled Adaptive Optimization of a Transonic Compressor Rotor With Pre-Compression." Proc of the ASME Turbo Expo 2018: Turbomachinery Technical Conf. and Exposition. Volume 2C: Turbomachinery. Oslo, Norway. June 11–15, 2018. V02CT42A050. ASME.

[81]. J. Aust, A. Mitrovic, and D. Pons, ‘‘Assessment of the effect of cleanliness on the visual inspection of aircraft engine blades: An eye tracking study,’’ Sensors, vol. 21, no. 18, p. 6135, Sep. 2021

[82]. Joly M, Sarkar S, Mehta D. Machine learning enabled adaptive optimization of a transonic compressor rotor with pre-compression[C]//Turbo Expo: Power for Land, Sea, and Air. American Society of Mechanical Engineers, 2018, 51012: V02CT42A050.

[83]. B. Zhao, L. Xie, H. Li, S. Zhang, B. Wang, and C. Li, ‘‘Reliability analysis of aero-engine compressor rotor system considering cruise characteristics,’’ IEEE Trans. Rel., vol. 69, no. 1, pp. 245–259, Mar. 2020.

[84]. B. Sasi, B. P. C. Rao, and T. Jayakumar, ‘‘Dual-frequency eddy current non-destructive detection of fatigue cracks in compressor discs of aero engines,’’ Defence Sci. J., vol. 54, no. 4, pp. 563–570, Oct. 2004.

[85]. V. Ageeva, T. Stratoudaki, M. Clark, and M. G. Somekh, ‘‘Integrative solution for in-situ ultrasonic inspection of aero-engine blades using endoscopic cheap optical transducers (CHOTs),’’ in Proc. 5th Int. Symp. NDT Aerosp., 2013, pp. 1–9.

[86]. F. Zou, ‘‘Review of aero-engine defect detection technology,’’ in Proc. IEEE 4th Inf. Technol., Netw., Electron. Autom. Control Conf. (ITNEC), vol. 1, Jun. 2020, pp. 1524–1527.

[87]. W. K. Wong, S. H. Ng, and K. Xu, ‘‘A statistical investigation and optimization of an industrial radiography inspection process for aero-engine components,’’ Qual. Rel. Eng. Int., vol. 22, no. 3, pp. 321–334, 2006.

[88]. D. Li, Y. Li, Q. Xie, Y. Wu, Z. Yu, and J. Wang, ‘‘Tiny defect detection in high-resolution aero-engine blade images via a coarse-to-fine framework,’’ IEEE Trans. Instrum. Meas., vol. 70, pp. 1–12, 2021.

[89]. Biglari and W. Tang, ‘‘A review of embedded machine learning based on hardware, application, and sensing scheme,’’ Sensors, vol. 23, no. 4,p. 2131, Feb. 2023.

[90]. H. F. Le, L. J. Zhang, and Y. X. Liu, ‘‘Surface defect detection of industrial parts based on YOLOv5,’’ IEEE Access, vol. 10, pp. 130784–130794,2022.

[91]. Y. D. V. Yasuda, F. A. M. Cappabianco, L. E. G. Martins, and J. A. B. Gripp, ‘‘Aircraft visual inspection: A systematic literature review,’’ Comput. Ind., vol. 141, Oct. 2022, Art. no. 103695.

[92]. X. Tao, X. Gong, X. Zhang, S. Yan, and C. Adak, ‘‘Deep learning for unsupervised anomaly localization in industrial images: A survey,’’ IEEE Trans. Instrum. Meas., vol. 71, pp. 1–21, 2022

[93]. Steven L. Brunton, Bernd R. Noack, Petros Koumoutsakos, Machine learning for fluid mechanics, Annu. Rev. Fluid Mech. 52 (2020) 477–508.

[94]. R.W. Bilger, The role of combustion technology in the 21st century, 2011.

[95]. Stephen B. Pope, Small scales, many species and the manifold challenges of turbulent combustion, Proc. Combust. Inst. 34 (2013) 1–31.

[96]. E. Mastorakos, A. Giusti, Turbulent combustion modelling and experiments: recent trends and developments, Flow Turbul. Combust. 103() (11.2019) 847–869.

[97]. Kamila Zdybał, Mohammad Rafi Malik, Axel Coussement, James C. Sutherland, Alessandro Parente, Reduced-order modeling of reactive flows using data-driven approaches, in: N. Swaminathan, A. Parente (Eds.), Lecture Notes in Energy: Machine Learning and Its Application to Reacting Flows, Springer, 2022. Chapter 9.

[98]. Jacqueline H. Chen, Petascale direct numerical simulation of turbulent combustion -fundamental insights towards predictive models, Proc. Combust. Inst. 33 (2011) 99–123.

[99]. Matthias Ihme, Wai Tong Chung, Aashwin Ananda Mishra, Combustion ma-chine learning: principles, progress and prospects, Prog. Energy Combust. Sci. 91 (2022) 101010.

[100]. I.T. Jolliffe, Principal Component Analysis, Springer, New York, 1986.

[101]. Ulrich Maas, Dominique Thévenin, Correlation analysis of direct numerical simulation data of turbulent non-premixed flames, in: Symp (International) on Combustion, vol.27, 1998, pp.1183–1189.

[102]. C.E. Frouzakis, Y.G. Kevrekidis, J. Lee, K. Boulouchos, A.A. Alonso, Proper orthogonal decomposition of direct numerical simulation data: data reduction and observer construction, Proc. Combust. Inst. 28 (1.2000) 75–81.

[103]. R.S. Barlow, J.H. Frank, Effects of turbulence on species mass fractions in methane/air jet flames, 1998.

[104]. R.S. Barlow, G.J. Fiechtner, C.D. Carter, J.-Y. Chen, Experiments on the scalar structure of turbulent co/h 2 /n 2 jet flames, 2000.

[105]. Evatt R. Hawkes, Ramanan Sankaran, Jacqueline H. Chen, Sebastian A. Kaiser, Jonathan H. Frank, An analysis of lower-dimensional approximations to the scalar dissipation rate using direct numerical simulations of plane jet flames, Proc. Combust. Inst. 32(1) (2009) 1455–1463.

[106]. Naveen Punati, James C. Sutherland, Alan R. Kerstein, Evatt R. Hawkes, Jacque-line H. Chen, An evaluation of the one-dimensional turbulence model: com-parison with direct numerical simulations of co/h2 jets with extinction and reignition, Proc. Combust. Inst. 33 (2011) 1515–1522.

[107]. Naveen Punati, James C. Sutherland, Alan R. Kerstein, Evatt R. Hawkes, Jacque-line H. Chen, An evaluation of the one-dimensional turbulence model: com-parison with direct numerical simulations of co/h2 jets with extinction and reignition, Proc. Combust. Inst. 33 (2011) 1515–1522.

[108]. A.A. Mascarenhas, G. Bansal, J.H. Chen, Identification of intrinsic low dimensional manifolds in turbulent combustion using an isomap based technique, Technical report, Sandia National Lab. (SNL-CA), Livermore, California, United States, 2011.

[109]. Ehsan Fooladgar, Pál Tóth, Christophe Duwig, Characterization of flameless combustion in a model gas turbine combustor using a novel post-processing tool, Combust. Flame 204 (6.2019) 356–367.

[110]. Kamila Zdybał, Giuseppe D’Alessio, Gianmarco Aversano, Mohammad Rafi Malik, Axel Coussement, James C. Sutherland, Alessandro Parente, Advancing reactive flow simulations with data-driven models, in: Miguel A. Mendez, Andrea Ianiro, Bernd R. Noack, Steven L. Brunton (Eds.), Data-Driven Fluid Mechanics: Combining First Principles and Machine Learning, Cambridge University Press, 2022. Chapter 15.

[111]. Kaidi Wan, Sandra Hartl, Luc Vervisch, Pascale Domingo, Robert S. Barlow, Christian Hasse, Combustion regime identification from machine learning trained by Raman/Rayleigh line measurements, Combust. Flame 219 (9.2020) 268–274.

[112]. Kherlen Jigjid, Chitoshi Tamaoki, Yuki Minamoto, Ryota Nakazawa, Nakamasa Inoue, Mamoru Tanahashi, Data driven analysis and prediction of mild combustion mode, Combust. Flame 223 (1.2021) 474–485.

Cite this article

Wang,W.;Ma,J. (2024). A review: Applications of machine learning and deep learning in aerospace engineering and aero-engine engineering. Advances in Engineering Innovation,6,54-72.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Journal:Advances in Engineering Innovation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. European Commission. Directorate-General for Mobility and Transport, Directorate-General for Research and Innovation, Flightpath 2050: Europe’s vision for aviation: maintaining global leadership and serving society’s needs[J]. 2011.

[2]. Åkerman J. Sustainable air transport––on track in 2050[J]. Transportation Research Part D: Transport and Environment, 2005, 10(2): 111-126.

[3]. Goel A, Goel A K, Kumar A. The role of artificial neural network and machine learning in utilizing spatial information[J]. Spatial Information Research, 2023, 31(3): 275-285.

[4]. Grant C. Automated processes for composite aircraft structure[J]. Industrial Robot: An International Journal, 2006, 33(2): 117-121.

[5]. Corrochano, A.F. Neves, B. Khanal, S. Le Clainche, N.J. Lawson, Des of a slingsby firefly aircraft: unsteady flow feature extraction using pod and hodmd, J. Aerosp. Eng. 35(5) (2022) 04022063.

[6]. Brunton S L, Nathan Kutz J, Manohar K, et al. Data-driven aerospace engineering: reframing the industry with machine learning[J]. AIAA Journal, 2021, 59(8): 2820-2847.

[7]. Kani JN and Elsheikh AH. Dr-rnn: a deep residual recurrent neural network for model reduction. arXiv preprint arXiv:170900939, 2017.

[8]. Wu Y, Feng J. Development and application of artificial neural network[J]. Wireless Personal Communications, 2018, 102: 1645-1656.

[9]. Bu H, Huang X, Zhang X. An overview of testing methods for aeroengine fan noise[J]. Progress in Aerospace Sciences, 2021, 124: 100722.

[10]. Filippone A. Aircraft noise prediction[J]. Progress in Aerospace Sciences, 2014, 68: 27-63.

[11]. Liu Y, Dowling A P, Swaminathan N, et al. Prediction of combustion noise for an aeroengine combustor[J]. Journal of Propulsion and Power, 2014, 30(1): 114-122.

[12]. Moore A. A 3D prediction of the wing reflection of aero engine noise[C]//10th AIAA/CEAS Aeroacoustics Conf.. 2004: 2865.

[13]. Jordan M I, Mitchell T M. Machine learning: Trends, perspectives, and prospects[J]. Science, 2015, 349(6245): 255-260.

[14]. El Naqa I, Murphy M J. What is machine learning? [M]. Springer International Publishing, 2015.

[15]. LeCun Y, Bengio Y, Hinton G. Deep learning[J]. nature, 2015, 521(7553): 436-444.

[16]. Goodfellow I, Bengio Y, Courville A. Deep learning[M]. MIT press, 2016.

[17]. Mendez C, Le Clainche S, Moreno-Ramos R, et al. A new automatic, very efficient method for the analysis of flight flutter testing data[J]. Aerospace Science and Technology, 2021, 114: 106749.

[18]. Berke L, Patnaik S N, Murthy P L N. Optimum design of aerospace structural components using neural networks[J]. Computers & structures, 1993, 48(6): 1001-1010.

[19]. Hagan M T, Menhaj M B. Training feedforward networks with the Marquardt algorithm[J]. IEEE transactions on Neural Networks, 1994, 5(6): 989-993.

[20]. Rojas R. Neural networks: a systematic introduction[M]. Springer Science & Business Media, 2013.

[21]. Cunningham P, Cord M, Delany S J. Supervised learning[M]//Machine learning techniques for multimedia: case studies on organization and retrieval. Berlin, Heidelberg: Springer Berlin Heidelberg, 2008: 21-49.

[22]. Le Clainche S, Ferrer E, Gibson S, et al. Improving aircraft performance using machine learning: a review[J]. Aerospace Science and Technology, 2023: 108354.

[23]. Alloghani M, Al-Jumeily D, Mustafina J, et al. A systematic review on supervised and unsupervised machine learning algorithms for data science[J]. Supervised and unsupervised learning for data science, 2020: 3-21.

[24]. Sorzano C O S, Vargas J, Montano A P. A survey of dimensionality reduction techniques[J]. arXiv preprint arXiv:1403.2877, 2014.

[25]. Van Der Maaten L, Postma E, Van den Herik J. Dimensionality reduction: a comparative[J]. J Mach Learn Res, 2009, 10(66-71).

[26]. Pezzotti N, Höllt T, Lelieveldt B, et al. Hierarchical stochastic neighbor embedding[C]//Computer Graphics Forum. 2016, 35(3): 21-30.

[27]. Kaelbling L P, Littman M L, Moore A W. Reinforcement learning: A survey[J]. Journal of artificial intelligence research, 1996, 4: 237-285.

[28]. Hester T, Vecerik M, Pietquin O, et al. Deep q-learning from demonstrations[C]//Proc. of the AAAI Conf. on artificial intelligence. 2018, 32(1).

[29]. Zhang W, Li H, Li Y, et al. Application of deep learning algorithms in geotechnical engineering: a short critical review[J]. Artificial Intelligence Review, 2021: 1-41.

[30]. Glorot X, Bengio Y. Understanding the difficulty of training deep feedforward neural networks[C]//Proc. of the thirteenth international Conf. on artificial intelligence and statistics. JMLR Workshop and Conf. Proc., 2010: 249-256.

[31]. Shrestha A, Mahmood A (2019) Review of deep learning algorithms and architectures. IEEE Access 7:53040–53065

[32]. Rumelhart D E, Durbin R, Golden R, et al. Backpropagation: The basic theory[M]//Backpropagation. Psychology Press, 2013: 1-34.

[33]. Medsker L R, Jain L C. Recurrent neural networks[J]. Design and Applications, 2001, 5(64-67): 2.

[34]. Pascanu R, Gulcehre C, Cho K, et al. How to construct deep recurrent neural networks[J]. arXiv preprint arXiv:1312.6026, 2013.

[35]. Yu Y, Si X, Hu C, et al. A review of recurrent neural networks: LSTM cells and network architectures[J]. Neural computation, 2019, 31(7): 1235-1270.

[36]. Gu J, Wang Z, Kuen J, et al. Recent advances in convolutional neural networks[J]. Pattern recognition, 2018, 77: 354-377.