1. Introduction

Cement-based composite materials with high strength high durability and high workability is called Ultra-high performance concrete (UHPC) [1]. UHPC packs its constituent materials (cement, silica fume, fly ash, quartz sand, etc.) closely together with particles of different particle sizes to obtain higher strength, so the design theory is also known as the closest packing theory [2]. At the same time, the extra different fiber can further enhance the toughness of UHPC and enhance its engineering applicability. Engineering practices have shown that the application of UHPC in building structures can optimize the structural size of components and enhance the durability of components, providing effective solutions to many problems in building structures [3]. At present, UHPC has seen extensive usage in the fields of long-span pedestrian bridge, highway and railway bridge, cable anchorage reinforcement plate, etc.

Axial compression is one of the common load conditions in building structures. On the other hand, UHPC columns aren't earthquake-proof because their brittle failure mechanism occurs under axial compression. To this end, the researchers applied transverse constraint around the UHPC column to enhance axial compression performance. The forms of transverse restraint mainly include transverse steel bar, steel tube and fiber-reinforced-polymer (FRP) sheet. Research has shown that by using transverse steel bars, steel tubes, and FRP sheets to constrain concrete in the core area, UHPC columns can improve their bearing capacity and peak strain, reduce the likelihood of crack development, perform better after peak, and eliminate the issue of brittle failure [4, 5]. Therefore, imposing horizontal constraints on UHPC has become one of the hot spots of scholars, which is conducive to promoting the application of UHPC in practical engineering.

The research results of this paper on UHPC columns constrained by transverse steel bar, steel tube and FRP sheet are summarized, and UHPC columns that are limited by steel tubes or transverse bars have their axial compression characteristics examined and contrasted. This paper's research can serve as a starting point for further exploration of UHPC applications.

2. ACB of UHPC confined by transverse reinforcement

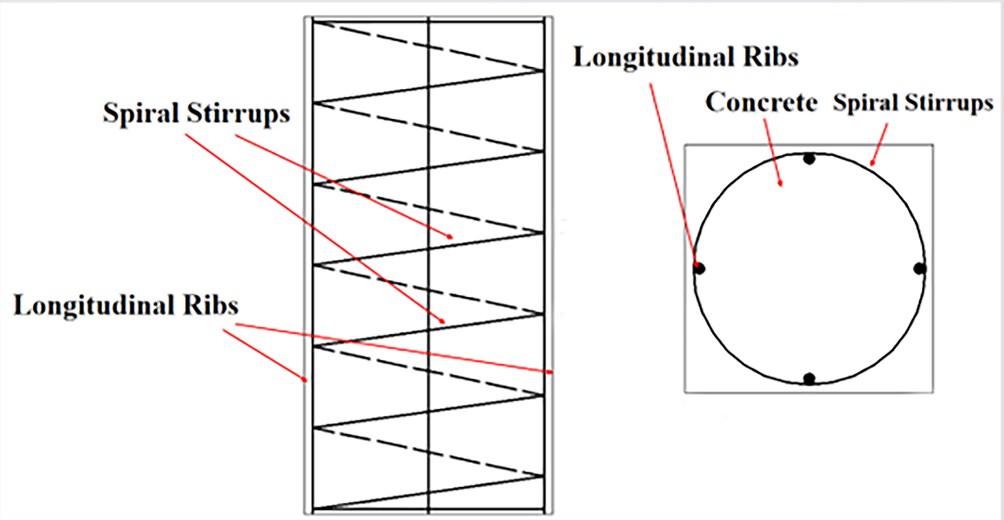

Transverse reinforcement confinement involves the use of reinforcement bars arranged transversely in the outer regions of a UHPC column, typically in the form of stirrups or spiral stirrups, to provide lateral restraint against concrete expansion. This concept is illustrated in Figure 1. Assa et al. [6] performed axial compression test (ACT) on 24 concrete columns reinforced with spiral stirrups. The compressive strengths of the concrete cylinders ranged from 25.04 MPa to 85.03 MPa, while the spiral stirrups exhibited yield strengths between 900 MPa and 1296 MPa. The results demonstrated that spiral stirrups offer significant lateral confinement to the concrete, enhancing peak strain, peak stress, and ductility, which all increase with the stirrup volume reinforcement ratio. Similarly, Wang et al. [7] conducted ACT on 13 square concrete columns confined by stirrups. These square columns had concrete strength grades of C45 and C65, with stirrups graded as HTRB630 and HRB400. The experiments confirmed that, given identical longitudinal arrangements, stirrup configurations, spacing, and the compressive strength of unconfined concrete, columns with stronger stirrups exhibit greater resistance to axial compression and deformation. Yang et al. [8] carried out ACT on UHPC cylinders reinforced with 21 spiral stirrups. In this case, the compressive strength of the concrete axis was 151 MPa, and the yield strength of the spiral stirrups was 404 MPa. The findings indicated that spiral stirrups not only provide effective lateral confinement for UHPC columns but also enhance their peak strain, peak stress, and ductility. Li et al. [9] compared 7 plain concrete cylinders with 14 UHPC cylinders confined by spiral stirrups, noting that while the compressive strengths of the concrete cylinders ranged from 126.6 MPa to 141.2 MPa, the yield strengths of the stirrups varied between 401 MPa and 723 MPa. Their results showed that as the yield strength of the stirrups increased from 401 MPa to 723 MPa, the ductility index of the UHPC columns enhanced by 22.5%. Chang et al. [10] conducted ACT on UHPC cylinders using twelve spiral stirrups for confinement. The concrete cubes' compressive strengths ranged from 99.86 MPa to 120.92 MPa, while the yield strengths of the spiral stirrups were between 661.5 MPa and 992.6 MPa. The tests demonstrated that increasing external confinement significantly enhances the ACB of UHPC cylinders, and both concrete strength and the ratio of transverse reinforcement volume have a pronounced impact on the cylinders' load-bearing capacity.

In conclusion, transverse reinforcement around UHPC columns can provide effective lateral restraint. Increases in the range are proportional to increases in the transverse steel bar reinforcement ratio and the UHPC column's bearing capacity and ductility. Therefore, in engineering applications, it is necessary to rationally allocate transverse reinforcement according to the strength of UHPC.

Figure 1. Spiral stirrups and Longitudinal ribs.

3. UHPC's axial compression efficiency limited by steel tubing

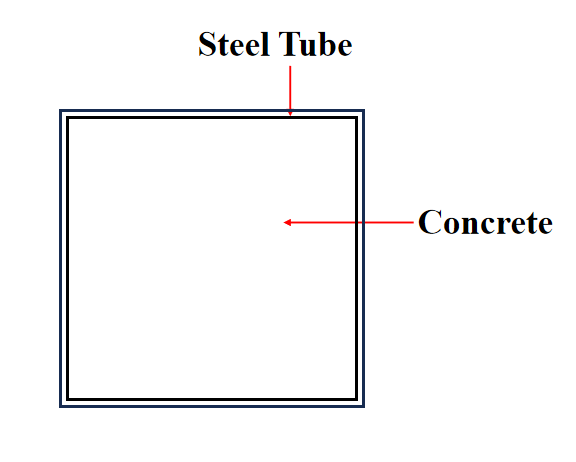

As described in Figure 2, steel tube confinement is encircling a UHPC column with a steel tube to impose lateral constraint to the concrete. Usually, the exterior steel tube provides the main transverse confinement while steel bars are arranged inside the UHPC column based on building or design criteria. Hoang et al. [11] conducted ACTs on eighteen UHPC cylinders housed in steel tubes. These concrete cylinders had compressive strength ranging from 178.9 MPa to 198.0 MPa; the steel tubes had yield strength ranging from 392.6 MPa to 445.9 MPa. The transverse confinement provided by the steel tubes clearly enhanced the load-bearing capability and ductility of the UHPC columns. Li et al. [12] similarly tested axial compression on 12 square UHPC columns housed in steel tubes and examined data from 28 more columns. The concrete in these square columns had compressive strength ranging from 81.4 MPa to 128.1 MPa; the yield strengths of the steel tubes fell between 444.6 MPa and 517.6 MPa. The study revealed that high-strength steel tubes enhanced transverse constraint to the UHPC core, therefore boosting both bearing capacity and ductility. With 12 cylindrical UHPC columns encased in steel tubes, Wei et al. [13] performed ACTs where the concrete cube compressive strength was 137.1 MPa and the steel tube yield strength was 389.4 MPa. With the improvement more evident as the hoop factor rose, the results revealed that the steel tube raised the bearing capacity of the UHPC cylinders by 20% to 40%. Chen et al. [14] studied under axial compression the confinement effects on 22 UHPC cylinders encased in steel tubes with cylindrical and square concrete cube compressive strengths ranging from 123.5 MPa to 137.3 MPa and steel tube yield strengths between 628.6 MPa and 703.0 MPa. Their investigation found that UHPC column bearing capacity rose as steel tube thickness rose. Under axial compression, Zhao et al. [15] investigated 27 UHPC cylinders encapsased in stainless steel tubes. Whereas the concrete cylinders had a compressive strength of 108.92 MPa, the yield strength of these stainless steel tubes ranged from 272.14 MPa to 375.51 MPa. The results revealed that although a decrease in the area proportion of the stainless steel tube resulted in lower axial peak stress and decreased axial bearing capacity, stainless steel tubes also gave efficient transverse confinement for UHPC columns.

To sum up, the placement of steel tubes around the UHPC column can also provide effective transverse constraint for the UHPC column. In addition to improving the UHPC cylinder's bearing capacity and ductility, increasing the steel tube's thickness and strength correlates with an amplitude of increase. In order to improve the ACB of UHPC columns with high-cost performance, engineers should logically build the steel tubes according to the strength of UHPC.

Figure 2. Steel tube constraints.

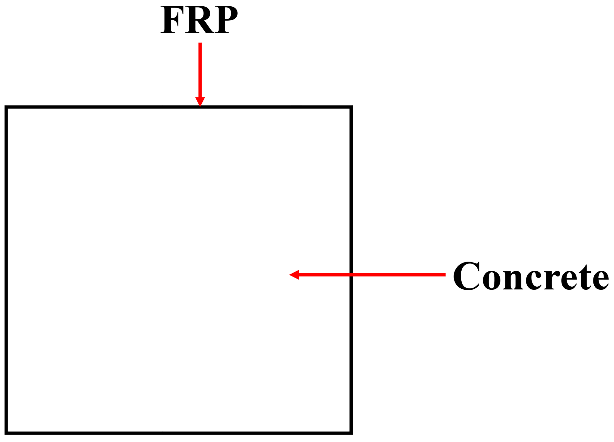

4. ACB of UHPC confined by FRP sheet

The FRP sheet constraint refers to the technique where a FRP sheet is tightly wrapped around the exterior of a UHPC column to provide transverse constraint to the concrete, as described in Figure 3. Typically, the interior of the UHPC column is reinforced with steel bars based on construction or design specifications, and the exterior is subsequently wrapped with FRP sheets to further enhance the ACB of column. In their study, Dang et al. [16] conducted ACT on 4 standard UHPC cylinders and 12 UHPC cylinders confined by FRP sheets. The compressive strength of the concrete cylinders was measured at 142.1 MPa, with the restrained FRP sheets exhibiting elastic moduli of 91.1 GPa and 236.9 GPa, and breaking strains of 2.19% and 1.78%, respectively. The results indicated that the external FRP sheet wrapping significantly enhanced both the compressive performance and failure mode of the UHPC columns. The effectiveness of the FRP sheet in confining the UHPC is directly related to the strength of the FRP material. Liao et al. [17] performed similar ACT s on 12 unconfined UHPC cylinders and 52 UHPC cylinders wrapped in FRP sheets. The axial compressive strength of the concrete ranged from 127.85 MPa to 156.44 MPa, with the FRP sheets having elastic moduli of 227.3 GPa and 43.3 GPa, and breaking strains of 1.5% and 1.0%, respectively. Their findings demonstrated that thicker FRP sheets provided more effective confinement for the UHPC columns. In another study, Wang et al. [18] tested 12 UHPC cylinders and 40 FRP-constrained UHPC cylinders under axial compression. The cylindrical concrete exhibited compressive strengths between 119.0 MPa and 158.1 MPa, with the FRP sheets displaying elastic moduli of 249.58 GPa and 121.76 GPa, and breaking strains of 1.2% and 2.27%, respectively. Their results showed that adding steel fibers helped mitigate the reduction in performance of UHPC confined by FRP sheets and enhanced the uniformity of expansion. Li et al. [19] investigated the ACB of 36 UHPC cylinders that were either fully or partially confined by FRP sheets. The cylindrical concrete exhibited compressive strengths ranging from 108.5 MPa to 122.2 MPa, while the FRP sheets used had an elastic modulus of 33.4 GPa and a breaking strain of 1.4%. The study concluded that even partially confined UHPC cylinders showed notable enhancements in compressive properties compared to fully confined ones, with the degree of improvement closely related to the level of FRP confinement. In a subsequent study, Chang et al. [9] performed ACTs on 12 UHPC cylinders that were reinforced with both spiral stirrups and FRP sheets. The compressive strengths of the concrete cylinders ranged from 99.86 MPa to 120.92 MPa, while the yield strengths of the spiral stirrups were between 661.5 MPa and 992.6 MPa. The FRP sheets exhibited an elastic modulus of 268 GPa and a breaking strain of 1.77%. The experimental results showed that increasing the degree of external confinement significantly improved the toughness, ductility, peak strain, and peak stress of the UHPC columns.

Therefore, wrapping UHPC columns with FRP sheets has proven to be a highly effective method for providing lateral restraint. Additionally, this technique significantly boosts the ductility and load-bearing capacity of the UHPC columns, with the extent of this enhancement being directly proportional to the mechanical properties, thickness, and wrapping method of the FRP sheets. For optimizing the ACB of UHPC columns in a cost-effective manner, engineers are advised to apply FRP sheets judiciously, taking into account the specific strengths of the UHPC.

Figure 3. Constraints of FRP sheet.

5. ACB comparison of UHPC under different constraints

This paper individually discusses the axial compression performance of UHPC columns confined by a transverse steel bar, a steel tube, and an FRP sheet. The results showed that the transverse steel bar, steel tube, and FRP sheet can provide good transverse constraint on the UHPC column and effectively improve its axial compressive performance. Besides improving axial compression performance, the confinement provided by the combination of transverse steel rebars and steel tubes with FRP sheets can also increase the seismic capacity of the UHPC columns and support UHPC engineering applications.

Compared with different forms of constraint, steel tube UHPC has the following advantages: (1) The construction of steel tube UHPC does not require formwork; thus, it saves time. (2) A peripheral steel tube in the steel tube UHPC can enhance the corrosion resistance of UHPC components. Advantages of the transverse steel bar restrained UHPC are as follows: The dosage of steel used in the transverse steel bar restrained UHPC is less than that of the steel tube restrained UHPC, and the cost is low. If the strength grade and reinforcement ratio meet the requirements, then the transverse steel bar constraint UHPC can satisfy the fundamental requirements. In general, the FRP sheet is wrapped on the UHPC column after the configuration of transverse reinforcement to enhance its ACB. The FRP sheet is of low density, corrosion-resistant, and has relatively good adiabatic performance, but it is poorly resistant to long-term heat resistance. Meanwhile, the application of FRP sheet shall be conducted with the construction process and engineering cost.

In summary, the transverse steel bar, steel tube, and FRP sheet all can improve the effectiveness of UHPC columns under axial compression. Different kinds of constraint have their own advantages and disadvantages. The constraints of transverse reinforcement can meet the engineering applications of UHPC columns. When the section size of the UHPC column is too large, it can be considered to configure steel tubes or FRP sheets around the UHPC column to meet the design requirements. Therefore, when applying UHPC in practical engineering, it is necessary to select reasonable constraint forms according to the engineering situation.

6. Conclusions

(1) With the help of lateral limitations, it is possible to raise the ACB of the UHPC column. Transverse steel bars, steel tubes and FRP plates can provide effective transverse constraints for UHPC columns. The mechanical properties, thickness and winding mode of FRP sheets determine the degree of transverse confinement. The strength and volume ratio of transverse steel bar determine the transverse constraint degree of steel pipe. The mechanical properties of FRP sheets determine the degree of transverse restraint of steel sheets.

(2) Transverse steel bar, steel tube and FRP sheet have their own characteristics and advantages. When UHPC is used in practical engineering, reasonable constraint forms should be selected according to actual needs to meet the design requirements with high-cost performance.

(3) Compared with ordinary strength grade concrete, UHPC has achieved a greater leap in civil engineering materials, and the promotion of UHPC has become inevitable. At the same time, transverse constraint can effectively solve the brittle failure problem of UHPC and realize the engineering application of UHPC. Therefore, the reasonable arrangement of transverse steel bars, steel tubes and FRP sheets should be further discussed in the follow-up study, and the corresponding design method should be established. At the same time, it is necessary to explore the form of transverse constraint to further enhance the performance of UHPC and promote the engineering application of UHPC.

References

[1]. Yu Z., Wu L., Yuan Z., et al. (2022) Mechanical Properties, Durability and Application of Ultra-high-performance Concrete Containing Coarse Aggregate (UHPC-CA): A Review. Construction and Building Materials, 334, 127360.

[2]. Dushimimana A, Niyonsenga A.A, Nzamurambaho F. (2021) A Review on Strength Development of High Performance Concrete. Construction and Building Materials, 307, 124865.

[3]. Hu A.X. (2019) Research on Mechanical Performance of Ultra-High Performance Concrete. Xi 'an: Xi 'an University of Science and Technology.

[4]. Wang Y.B, Song C, Zhao X.Y, et al. (2022) Experimental Study on Behavior of Circular Concrete-filled High Strength Steel Tubular Stub Columns under Compression. Journal of Building Structures, 43(11), 221-234.

[5]. Xu C. (2022) Experimental Study on UHPC Short Columns Confined by High Strength Stirrups under Axial Compressive Loadings. Changsha: Hunan University.

[6]. Assa B, Nishiyama M, Watanabe F. (2011) New Approach for Modeling Confinement Concrete. I: Circular Columns. Journal of Structural Engineering, 127(7), 743-750.

[7]. Wang Z.B, Shi J.Y, Liu J.C, et al. (2021) Axial Compression Performance Test of Concrete Columns Confined by HTRB630 Stirrups. Jiangsu Architecture, 2, 23-26.

[8]. Yang X, Zohrevand P, Mirmiran A. (2016) Behavior of Ultrahigh-Performance Concrete Confined by Steel. Journal of Materials in Civil Engineering, 28(10), 04016113.

[9]. Li J, Deng Z, Yao J. (2020) Research on Uniaxial Compressive Behavior of High‐strength Spiral Stirrups Confined Circular Ultra‐high Performance Concrete Columns. Structural Concrete, 21(6), 2584-2600.

[10]. Chang W, Hao M, Zheng W. (2020) Compressive Behavior of UHPC Confined by both Spiral Stirrups and Carbon Fiber-reinforced Polymer (CFRP). Construction and Building Materials, 230, 117007.

[11]. Hoang A.L, Fehling E, Lai B, et al. (2019) Experimental Study on Structural Performance of UHPC and UHPFRC Columns Confined with Steel Tube. Engineering Structures, 187, 457-477.

[12]. Li J, Deng Z. (2022) Performance of Square UHPC Filled High-strength Steel Tubular Columns under Axial Compression: Experiment and Theory Analysis. Structures, 46, 1395-1406.

[13]. Wei J.G, Xie Z.T, Luo X, et al. (2022) Mechanical Behavior of Circular Steel Tube Confined Ultra High Performance Concrete Stub Columns under Axial Compressive Loading. Journal of Building Structures, 43(06), 34-42.

[14]. Chen J, Wang Q.Z, Guo MG, et al. (2024) Experimental Study on Axial Compressive Load Capacity Performance of UHPC Columns with High-strength Steel Pipes. Journal of Xiangtan University (Natural Science Edition), 46(2), 20-34.

[15]. Zhao Z, Wei Y, Wang G, et al. (2024) Axial Compression Performance of Circular UHPC-filled Stainless-steel Tubular Columns. Engineering Structures, 302, 117430.

[16]. Dang Z, Li Z, Feng P. (2022) Axial Compressive Behavior of UHPC Confined by FRP. Composite Structures, 300, 116110.

[17]. Liao J, Yang K, Zeng J, et al. (2021) Compressive Behavior of FRP-confined Ultra-high Performance Concrete (UHPC) in Circular Columns. Engineering Structures, 249, 113246.

[18]. Wang J, Zhang S, Nie X, et al. (2023) Compressive Behavior of FRP-confined Ultra-high Performance Concrete (UHPC) and Ultra-high Performance Fiber Reinforced Concrete (UHPFRC). Composite Structures, 312, 116879.

[19]. Li W, Li W, Lu Y, et al. (2024) Axial Compressive Behavior and Failure Mechanism of CFRP Partially Confined Ultra-high Performance Concrete (UHPC). Construction and Building Materials, 426, 136104.

Cite this article

Jiang,Y. (2024). Analysis on the transversely constricted axial compression behaviour of UHPC columns. Advances in Engineering Innovation,12,7-11.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Journal:Advances in Engineering Innovation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Yu Z., Wu L., Yuan Z., et al. (2022) Mechanical Properties, Durability and Application of Ultra-high-performance Concrete Containing Coarse Aggregate (UHPC-CA): A Review. Construction and Building Materials, 334, 127360.

[2]. Dushimimana A, Niyonsenga A.A, Nzamurambaho F. (2021) A Review on Strength Development of High Performance Concrete. Construction and Building Materials, 307, 124865.

[3]. Hu A.X. (2019) Research on Mechanical Performance of Ultra-High Performance Concrete. Xi 'an: Xi 'an University of Science and Technology.

[4]. Wang Y.B, Song C, Zhao X.Y, et al. (2022) Experimental Study on Behavior of Circular Concrete-filled High Strength Steel Tubular Stub Columns under Compression. Journal of Building Structures, 43(11), 221-234.

[5]. Xu C. (2022) Experimental Study on UHPC Short Columns Confined by High Strength Stirrups under Axial Compressive Loadings. Changsha: Hunan University.

[6]. Assa B, Nishiyama M, Watanabe F. (2011) New Approach for Modeling Confinement Concrete. I: Circular Columns. Journal of Structural Engineering, 127(7), 743-750.

[7]. Wang Z.B, Shi J.Y, Liu J.C, et al. (2021) Axial Compression Performance Test of Concrete Columns Confined by HTRB630 Stirrups. Jiangsu Architecture, 2, 23-26.

[8]. Yang X, Zohrevand P, Mirmiran A. (2016) Behavior of Ultrahigh-Performance Concrete Confined by Steel. Journal of Materials in Civil Engineering, 28(10), 04016113.

[9]. Li J, Deng Z, Yao J. (2020) Research on Uniaxial Compressive Behavior of High‐strength Spiral Stirrups Confined Circular Ultra‐high Performance Concrete Columns. Structural Concrete, 21(6), 2584-2600.

[10]. Chang W, Hao M, Zheng W. (2020) Compressive Behavior of UHPC Confined by both Spiral Stirrups and Carbon Fiber-reinforced Polymer (CFRP). Construction and Building Materials, 230, 117007.

[11]. Hoang A.L, Fehling E, Lai B, et al. (2019) Experimental Study on Structural Performance of UHPC and UHPFRC Columns Confined with Steel Tube. Engineering Structures, 187, 457-477.

[12]. Li J, Deng Z. (2022) Performance of Square UHPC Filled High-strength Steel Tubular Columns under Axial Compression: Experiment and Theory Analysis. Structures, 46, 1395-1406.

[13]. Wei J.G, Xie Z.T, Luo X, et al. (2022) Mechanical Behavior of Circular Steel Tube Confined Ultra High Performance Concrete Stub Columns under Axial Compressive Loading. Journal of Building Structures, 43(06), 34-42.

[14]. Chen J, Wang Q.Z, Guo MG, et al. (2024) Experimental Study on Axial Compressive Load Capacity Performance of UHPC Columns with High-strength Steel Pipes. Journal of Xiangtan University (Natural Science Edition), 46(2), 20-34.

[15]. Zhao Z, Wei Y, Wang G, et al. (2024) Axial Compression Performance of Circular UHPC-filled Stainless-steel Tubular Columns. Engineering Structures, 302, 117430.

[16]. Dang Z, Li Z, Feng P. (2022) Axial Compressive Behavior of UHPC Confined by FRP. Composite Structures, 300, 116110.

[17]. Liao J, Yang K, Zeng J, et al. (2021) Compressive Behavior of FRP-confined Ultra-high Performance Concrete (UHPC) in Circular Columns. Engineering Structures, 249, 113246.

[18]. Wang J, Zhang S, Nie X, et al. (2023) Compressive Behavior of FRP-confined Ultra-high Performance Concrete (UHPC) and Ultra-high Performance Fiber Reinforced Concrete (UHPFRC). Composite Structures, 312, 116879.

[19]. Li W, Li W, Lu Y, et al. (2024) Axial Compressive Behavior and Failure Mechanism of CFRP Partially Confined Ultra-high Performance Concrete (UHPC). Construction and Building Materials, 426, 136104.