1 Introduction

Currently, Battery Energy Storage Systems (BESS hereafter) are one of the most crucial components for sustainable energy solutions in the modern power grid. Even though BESS can have several applications from energy storage to load balancing and black start capability, the most important task is to maintain grid’s stability. However, managing a BESS nowadays is a big challenge because of its complex chemical reaction, nonlinear dynamic behaviour and the need for control action within a tight time-scale. This complex dynamic is hard to be effectively managed by traditional approaches still adapting the time-series principles using sliding mode based on static model. They cannot handle the fast-dynamic environment exactly in real time and thus bring about inefficiency and high cost to the system operations. The worst scenario is the system failure. State-of-the-art AI technologies, especially in deep learning, reinforcement learning and neural networks techniques, give us valuable tools for modelling more complicated reaction mechanisms, for adapting to real-time information and for predictive maintenance. With the help of intelligent analytics, we can obtain critical information from abundant datasets from different sources to optimise the charging and discharging of BESS, to prolong the lifetime of batteries, and to enhance the reliability of the overall system. To date, AI-based battery management systems have proven to improve the accuracy of prediction of energy predictions and controls, indicating that most AI technologies can be widely applied to energy management. Additionally, AI can improve system stability in conjunction with distributed energy resources (such as solar and wind), by dynamically adjusting system parameters to best accommodate power supply and demand under varying conditions [1]. For example, reinforcement learning can adjust a system’s parameters to maintain stability and performance levels, which can reduce the likelihood of blackouts while improving the efficiency and resilience of the power grid. These AI advancements represent a new generation of real-world BESS applications that will enable more resilient energy systems. This document brings forward the usage of AI inside BESS by discussing its role in the system stability, the battery use optimisation and its predictive maintenance. Combining theoretical working models and real-life case studies, this research sheds a light on how the AI-based approaches can improve the management of BESS, and ultimately pave the way for more durable and sustainable energy infrastructures for future usage.

2 Application of AI in energy storage technology

2.1 Complex reaction mechanisms in BESS

BESS use highly nonlinear chemical and physical processes to store and release energy, for example, in the case of lithium-ion batteries, ions move between the anode and cathode by reaction with an electrolyte during charging and discharging, respectively. These processes respond very sensitively to temperature, state of charge (SoC), current rates and so on. Standard static models do not capture these subtleties well, hence the control algorithms used to manage these systems often perform sub-optimally. In addition, they can lead to unexpected failures. What if you were to train an AI using a large dataset of operational data, and could make very reactions? This is exactly, can do. In contrast to chemical models that are accurate but impractical to apply or control models that can be applied but lack accuracy, machine-learning models can be applied and are as accurate as good chemical models [2]. The benefit to a systems level approach is that by learning continuously from operational data, AI systems can predict behaviour under varied conditions, more precisely control charging and discharging processes, and optimise energy conversion, thereby extending battery life and making the energy storage system more reliable.

2.2 Enhancing system stability with AI

Stability, a key principle for a BESS, is essential when connected to the grid or used with a distributed energy resource such as solar or wind power. Presently, traditional stability analysis techniques include time-domain simulations and frequency response methods to identify the proper settings that maintain stability. Although these methods are powerful, they tend to be computationally expensive and typically do not scale well for large complex systems. Reinforcement learning AI methods, on the other hand, teach the system how to maintain stability by interacting repeatedly with the environment and adjusting its parameters in real time to maintain desirable performance in the face of dynamic inputs. This is particularly useful in setting the optimal load-sharing between the BESS and primary sources of electricity during peak demand. If the BESS shares too much load with primary sources, the grid voltage will be too high. Conversely, if the BESS provides too little, the voltage will be too low and might cause problems with the connected appliances. With an AI-based system, the grid learns how to dynamically share the load to maintain a consistent voltage [3]. By doing so, it improves the robustness of the BESS against sudden changes in grid conditions, thus minimising the risk of blackouts that may otherwise cause substantial service disruption.

2.3 Cost-effective control strategies

A major factor in BESS being profitable is if operators can control energy in and out effectively and cheaply. Most traditional control strategies, eg rule-based or model predictive control, require significant parameter tuning – and they are not flexible enough to adapt to a changing market or energy demand. By contrast, an AI-based control strategy can evolve dynamically and optimise energy management by analysing data in real time, eg on current or forecast electricity prices, weather conditions and grid conditions, or learn from past failures. For example, if AI is able to predict when electricity demand and price will be high, it can decide to discharge the stored energy during such moments to get the best return. Likewise, during periods when demand and price are low, it can prioritise charging of the BESS to again optimise return. This way of managing energy can go well beyond reducing operational costs, and increase the financial viability of BESS investments, making them a more attractive option for utilities and investors [4].

3 AI in battery management technology

3.1 Monitoring and predicting battery health

Given that battery health is a key factor for BESS operation, it is crucial for all stakeholders to understand the remaining useful life of these batteries so they can optimise their performance and longevity. Traditional battery management systems (BMS) mainly monitor basic parameters such as voltage, current and temperature. While such metrics are necessary, they may not always be sufficient to assess the battery’s health. By leveraging AI, a modern BMS can integrate data from diverse sources, such as electrochemical models, historical usage patterns and real-time sensor data, to build high-sophistication health models that can predict degradation pathways, early signs of capacity loss, and recommend maintenance to avert or mitigate critical failures. For instance, an AI algorithm can detect subtle changes in the internal resistance of lithium-ion batteries, which could be caused by lithium plating and electrolyte decomposition [5]. Such a deeper access to battery health extends the operational life of BESS, reduces downtime, and lowers maintenance costs.

3.2 AI-Enhanced state of charge estimation

The state of charge (SOC) is an important parameter that represents how much energy is available in a battery. SOC estimation is very important to the effective operation of BESS as it is used to make decisions about charging, discharging and overall energy management. For example, underestimating the SOC of a BESS can lead to overcharging and overheating, while underestimating it can lead to the BESS operating near discharge limits, which can be detrimental to the battery and hence to the BESS. The traditional approaches for SOC estimation mostly rely on coulomb counting or open-circuit voltage. These approaches do not consider temperature variations, aging effects or measurement errors, and hence are not very accurate. Consequently, AI approaches, especially deep learning (DL), have shown significant improvement in SOC estimation accuracy. DL models can capture complex, nonlinear relationships among multiple variables (voltages, currents, temperatures and historical use data) to predict SOC with higher accuracy [6]. The same deep neural network trained on large datasets of different battery chemistries can adapt to the characteristics of individual batteries and provide more accurate SOC estimates even under difficult operating conditions. Table 1 compares traditional SOC estimation methods with AI-enhanced approaches.

Table 1. SOC Estimation Method Comparison

Method |

Coulomb Counting |

Open-Circuit Voltage |

Deep Neural Network (AI) |

Accuracy (%) |

85 |

88 |

96 |

Sensitivity to Temperature |

High |

Moderate |

Low |

Impact of Aging |

High |

High |

Low |

Measurement Errors |

Common |

Occasional |

Rare |

Adaptability to Different Chemistries |

Low |

Moderate |

High |

3.3 Optimizing battery usage with AI

The challenge is how to optimise the battery usage in a BESS, balancing performance, efficiency and longevity. The conventional battery management systems are based on static rules or heuristic methods, which often do not account for the dynamic nature of real-world operating conditions. AI-based optimisation techniques such as genetic algorithms or reinforcement learning can dynamically adjust the operating parameters in response to real-time data. For instance, AI can be leveraged to determine the optimal charge/discharge cycles based on load forecasts, grid conditions and electricity prices and utilise the batteries in the most efficient and economic manner. AI can also predict the right time for battery maintenance and reduce the risk of unexpected failures and downtime. The operational data from the batteries can be constantly fed into AI models to refine the optimisation strategies and improve the performance over time, which greatly reduces operational costs [7]. By proactively managing batteries in a BESS, not only the efficiency of the BESS can be improved, but also the return on investment is maximised.

4 AI in system monitoring and control

4.1 Real-time data acquisition and analysis

Continuous monitoring of a BESS is necessary for accurate data collection and analysis involving many active sensors and system components. Current monitoring systems generally create huge amounts of data, and the timely analysis and response to these data during system operation can be difficult and lag behind real-time situations, which might result in an ineffective time-delayed response to certain critical issues in the system. This can be remedied by using AI-enabled monitoring solutions, which can automate data analysis tasks in a real-time manner. Based on certain training, AI can detect patterns, trends and abnormalities, for example if the voltage or the temperature of particular cells or connections of a battery is not normal, which might be a precursor to problems such as thermal runaway or cell imbalance. Once such a task is automated, it greatly reduces the workload of human operators, and enables them to devote more time to high-level decision-making or system control.[8] Table 2 clearly depicts the difference in response times taken by the present-day monitoring devices and AI-based monitoring devices.AI-based systems detect and respond to voltage fluctuation in around 2 seconds, while for traditional monitoring system takes upto 15 seconds to identify the same. Likewise, in temperature abnormality, if conventional systems take upto 20 seconds to identify them, AI-based systems take upto 3 seconds. The most prominent benefit is shwon when we go through the time taken by AI to process the sensor data in case of general anomaly. Traditional systems take around 30 seconds to detect anomaly in sensor data, while AI does it in 5 seconds. Further, it can be seen from table 2 that AI greatly decrease the need of human intervention. The traditional system needs frequent human interventions for thermal runway or cell imbalance management whereas AI systems automate the entire process, which greatly reduce the need of human intervention and increase the efficiency of the operations. The 2 also indicate that AI will improve the total system output. Traditional systems have moderate reliability at voltage fluctuation and temperature anomaly. However, AI systems will make the reliability of all monitoring points higher by identifying and solving issues quicker and more accurately. As a result, these monitoring solutions, based on AI, would improve the safety and efficiency of BESS, preventing the failure before it occurs.

Table 2. Real-Time Data Acquisition and Analysis Comparison

Monitoring Aspect |

Voltage Fluctuations |

Temperature Anomalies |

Sensor Data Processing |

Traditional System Response Time (seconds) |

15 |

20 |

30 |

AI-Driven System Response Time (seconds) |

2 |

3 |

5 |

Potential Issues Detected |

Thermal Runaway |

Cell Imbalances |

General Anomalies |

Human Intervention Required |

High |

Moderate |

Low |

Impact on System Reliability |

Moderate |

Moderate |

High |

4.2 Automated fault detection and response

BESS monitoring, in particular, fault detection, is vital as undetected faults can lead to system failures, costly repair and maintenance efforts, and even safety-related hazards. Traditional fault detection methods often rely on fixed thresholds or rules that are difficult to generalise, whereas machine learning (ML)-powered fault detection models are capable of learning to identify subtler but more meaningful signs of fault from operational data that are difficult to capture using formalised rules and thresholds. With typical battery energy storage system (BESS) faults, for example, a fault detection model can learn to estimate the probability of a fault occurring in a power inverter or battery module based on both historical fault data and real-time readings from sensors. Following detection of a potential fault in a component, the fault detection models can generate responses that isolate the component and/or reduce the system’s loading as appropriate. Such automatic fault detection and response dramatically improves the safety and survival of the system, such as a BESS, against catastrophic failures and excessive downtimes [9].

4.3 Enhancing predictive maintenance with AI

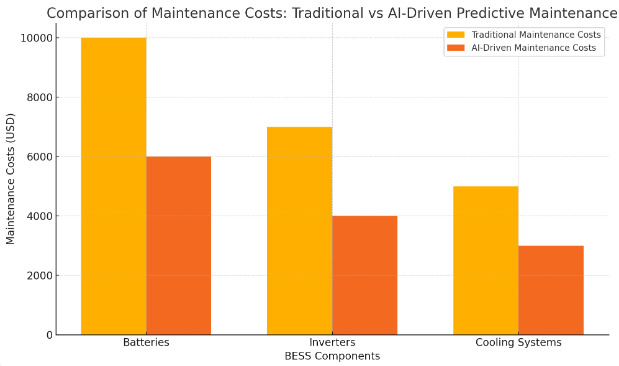

Predictive maintenance is an advanced system management methodology designed to prevent outages or hardware component failures by detecting and addressing early signs of component degradation. In the context of Battery Energy Storage Systems (BESS), predictive maintenance involves continuously monitoring the performance of critical components, such as batteries, inverters, and cooling systems, to predict the remaining useful life of these components and preemptively schedule maintenance activities. AI plays a crucial role in enabling predictive maintenance by analyzing large volumes of operational data to detect wear patterns and degradation early. This allows for more precise maintenance scheduling, reducing the likelihood of unexpected failures and maximizing the operational life of the system. AI algorithms can, for example, monitor battery impedance changes or inverter efficiency over time, providing early warnings before these components fail. This real-time data analysis capability enables operators to plan maintenance during the most optimal windows, thus avoiding disruptive outages and extending the lifespan of the BESS. Figure 1 below illustrates the significant cost savings achieved through AI-driven predictive maintenance compared to traditional maintenance methods across key BESS components. For batteries, the cost of traditional maintenance approaches reaches nearly $10,000, whereas AI-driven maintenance reduces this cost by about 50%. A similar trend is observed with inverters, where AI-enabled maintenance strategies decrease the cost from over $7,000 to less than $5,000. For cooling systems, the maintenance cost drops from approximately $5,000 to below $3,000 when employing AI-based predictive models. This reduction in maintenance costs, as shown in Figure 1, highlights the ability of AI to optimize the scheduling and execution of maintenance tasks, leading to substantial operational savings. Beyond the financial benefits, AI-driven predictive maintenance also enhances the overall reliability of the system by minimizing unplanned downtime and ensuring that components are serviced at the most effective times. These improvements not only boost the efficiency of BESS but also enhance their long-term economic viability.

Figure 1. Comparison of Maintenance Costs: Traditional vs AI-Driven Predictive Maintenance

5 Integrating AI with emerging technologies

5.1 IoT integration for enhanced connectivity

The IoT, which provides enhanced connectivity and data exchange between its components, plays a critical role in the integration of AI in BESS. IoT devices, such as smart sensors and meters, can monitor variables such as energy consumption levels, environmental conditions and system performance at a granular level. AI can process this data to optimise energy flows, anticipate future load demands and enhance the resilience of BES. For instance, AI can utilise data collected from IoT devices to dynamically adjust the charging and discharging schedules of the BESS based on real-time conditions of the grid and current loads. The incorporation of AI in the IoT-enabled BESS helps to enhance the efficiency and reliability of the system, leading to better operations, and allows for more sophisticated energy management strategies such as demand response and peak shaving. Furthermore, as modern grid technology enables the deployment of BESS in BES, such as microgrid and smart grid, the IoT-enabled BESS could even be remotely monitored and controlled by the operator, and be able to rapidly respond to changes in the system performance and environmental conditions.

5.2 Blockchain for secure energy transactions

Blockchain allows for a distributed, Decentralised and secure ledger(database) for storing and managing energy transactions, which is especially beneficial for Distributed energy systems where BESS serves as the foundation. AI can be used to manage and optimise these transactions to serve the energy needs of all participants in the best possible way. For example, AI might be used to analyse real-time supply and demand data to negotiate energy prices and finally settle transactions. This is a possible scenario where AI is used to smoothen and optimise trading in energy markets. Considering blockchain is known for its transparency and security, AI-integrated blockchain can lead to more secure and resilient energy markets where cyberthreats can be reduced and chances of fraud can be prevented. Apart from this, blockchain enablers distributed energy trading platforms where prosumers(producers and consumers) can make deals with each other by trading their excess energy stored inside their BESS with other users [10]. These trades can be optimised by AI-algorithms to match buyers and sellers, with buyers purchasing the energy suited to their needs and preferences, and sellers selling at appropriate times and prices.

5.3 Neural networks for advanced system modeling

Because neural networks are essentially black-box models that do not require a detailed understanding of the system to learn and design, they are ideal for BESS, which often rely on many complex and interconnected variables across a range of spatial scales. BESS can use neural networks to model system behaviour under various scenarios, such as different loading and weather conditions, and grid disturbances. These models can be continuously updated as new data is added incrementally, so models become more accurate over time. This improved accuracy from capturing additional data can enhance the planning and decisionmaking process. It could provide signals to operators about equipment in distress ahead of time, and allow for preemptive action to maintain system stability. The combination of BESS and neural network models isn’t just a clever application; it could drive the kind of innovation we discovered in our research. It enabled us to go beyond simply identifying promising interventions, such as sensor-based monitoring of system performance, and modelling system behaviour under different conditions. We were also able to gain deeper insights into the performance of the system. Neural network-based models are uniquely suited for this purpose, and could provide the kind of insights to enhance decisionmaking in ways that we haven’t yet considered.

6 Conclusions

The integration of Artificial Intelligence into Battery Energy Storage Systems represents a transformative advancement in the field of energy management. AI's ability to model complex systems, enhance predictive maintenance, and optimize battery usage offers substantial benefits, including improved efficiency, reduced costs, and increased system reliability. The case studies presented in this paper demonstrate that AI-driven approaches can significantly enhance the performance and economic viability of BESS, particularly in complex and dynamic environments. As AI technologies continue to evolve, their application in BESS is likely to expand, enabling more sophisticated energy management strategies and contributing to the broader adoption of renewable energy sources. The findings of this research underscore the importance of continuing to develop and implement AI-driven solutions in BESS, paving the way for a more resilient, efficient, and sustainable energy future.

Authors’ Contribution

Ziqi Cai and Nan Ma have made equally significant contributions to the work and share equal responsibility and accountability for it.

References

[1]. Rojek, I., et al. (2023). Machine learning-and artificial intelligence-derived prediction for home smart energy systems with PV installation and battery energy storage. Energies, 16(18), 6613.

[2]. Sharma, S., Chauhan, B. K., & Saxena, N. K. (2023). Artificial neural network grid-connected MPPT-based techniques for hybrid PV-WIND with battery energy storage system. Journal of The Institution of Engineers (India): Series B, 104(6), 1217–1226.

[3]. Giglio, E., et al. (2023). An efficient artificial intelligence energy management system for urban building integrating photovoltaic and storage. IEEE Access, 11, 18673–18688.

[4]. Kurucan, M., et al. (2024). Applications of artificial neural network based battery management systems: A literature review. Renewable and Sustainable Energy Reviews, 192, 114262.

[5]. Mehraban, A., Ghanbari, T., & Farjah, E. (2023). AI-Based Control of Storage Capacity in High-Power-Density Energy Storage Systems, Used in Electric Vehicles. IEEE Transactions on Transportation Electrification, 10(1), 2293–2301.

[6]. Mehdi, H. M., Azeem, M. K., & Ahmad, I. (2023). Artificial intelligence based nonlinear control of hybrid DC microgrid for dynamic stability and bidirectional power flow. Journal of Energy Storage, 58, 106333.

[7]. Patrizi, G., et al. (2024). A Review of Degradation Models and Remaining Useful Life Prediction for Testing Design and Predictive Maintenance of Lithium-Ion Batteries. Sensors, 24(11), 3382.

[8]. Surabhi, S. N. R. D. (2023). Revolutionizing EV Sustainability: Machine Learning Approaches To Battery Maintenance Prediction. Educational Administration: Theory and Practice, 29(2), 355–376.

[9]. Tian, J., et al. (2023). Deep learning framework for lithium-ion battery state of charge estimation: Recent advances and future perspectives. Energy Storage Materials, 102883.

[10]. Paret, P., Finegan, D., & Narumanchi, S. (2023). Artificial Intelligence for Power Electronics in Electric Vehicles: Challenges and Opportunities. Journal of Electronic Packaging, 145(3), 034501.

Cite this article

Cai,Z.;Ma,N. (2024). Artificial intelligence-based integration technology applications in battery energy storage systems. Advances in Engineering Innovation,12,41-46.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Journal:Advances in Engineering Innovation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Rojek, I., et al. (2023). Machine learning-and artificial intelligence-derived prediction for home smart energy systems with PV installation and battery energy storage. Energies, 16(18), 6613.

[2]. Sharma, S., Chauhan, B. K., & Saxena, N. K. (2023). Artificial neural network grid-connected MPPT-based techniques for hybrid PV-WIND with battery energy storage system. Journal of The Institution of Engineers (India): Series B, 104(6), 1217–1226.

[3]. Giglio, E., et al. (2023). An efficient artificial intelligence energy management system for urban building integrating photovoltaic and storage. IEEE Access, 11, 18673–18688.

[4]. Kurucan, M., et al. (2024). Applications of artificial neural network based battery management systems: A literature review. Renewable and Sustainable Energy Reviews, 192, 114262.

[5]. Mehraban, A., Ghanbari, T., & Farjah, E. (2023). AI-Based Control of Storage Capacity in High-Power-Density Energy Storage Systems, Used in Electric Vehicles. IEEE Transactions on Transportation Electrification, 10(1), 2293–2301.

[6]. Mehdi, H. M., Azeem, M. K., & Ahmad, I. (2023). Artificial intelligence based nonlinear control of hybrid DC microgrid for dynamic stability and bidirectional power flow. Journal of Energy Storage, 58, 106333.

[7]. Patrizi, G., et al. (2024). A Review of Degradation Models and Remaining Useful Life Prediction for Testing Design and Predictive Maintenance of Lithium-Ion Batteries. Sensors, 24(11), 3382.

[8]. Surabhi, S. N. R. D. (2023). Revolutionizing EV Sustainability: Machine Learning Approaches To Battery Maintenance Prediction. Educational Administration: Theory and Practice, 29(2), 355–376.

[9]. Tian, J., et al. (2023). Deep learning framework for lithium-ion battery state of charge estimation: Recent advances and future perspectives. Energy Storage Materials, 102883.

[10]. Paret, P., Finegan, D., & Narumanchi, S. (2023). Artificial Intelligence for Power Electronics in Electric Vehicles: Challenges and Opportunities. Journal of Electronic Packaging, 145(3), 034501.