1. Introduction

The traditional brewing techniques of Chinese baijiu have been passed down through generations, embodying a rich historical and cultural heritage. However, with advancements in technology and the increasing globalization of cultural exchanges, foreign distilled spirits have begun to impact the domestic baijiu market share. Additionally, as consumer demand for baijiu continues to grow, traditional brewing methods are struggling to meet market needs. In this context, the intelligent innovation of traditional baijiu brewing processes has become increasingly significant. Enhancing the accuracy and efficiency of baijiu brewing through intelligent electronic devices has emerged as a critical issue that the industry must address [1].

In the baijiu brewing process, ingredient preparation serves as the foundation of the craft. The primary factor in ingredient preparation is temperature conditions, which require determining an optimal formula based on seasonal variations, climate, ground temperature fluctuations, and fermentation temperature changes. Traditional baijiu is brewed using the di gang solid-state fermentation method, where the temperature of the raw materials entering the fermentation pit must align with ambient room temperature and humidity. The fermentation process lasts for 28 days, during which heat is generated. Brewmasters rely on temperature fluctuations to assess fermentation quality. The mainstream traditional approach to determining raw material ratios is based on “experience and intuition.” During the initial mixing and cooling process, raw material temperature is measured using conventional thermometers. During fermentation, temperature measurements are typically conducted only on the seventh and fifteenth days to evaluate the fermentation status, making the assessment somewhat limited. Due to the constraints of traditional temperature monitoring methods in baijiu brewing, precise temperature control is often difficult to achieve, leading to product inconsistency and low production efficiency [5].

This study analyzes temperature control in the baijiu brewing process and proposes a real-time temperature monitoring system tailored to baijiu production. First, temperature sensors are used to capture temperature variations in the brewing materials during fermentation. The data is then uploaded and stored on the Alibaba Cloud IoT platform, enabling real-time monitoring and historical temperature data storage. Furthermore, advanced sensor and wireless communication technologies are employed to achieve real-time collection, transmission, and analysis of key temperature parameters in the brewing process of Fenjiu. Finally, field experiments validate the effectiveness of this approach in improving baijiu quality and yield. This research offers new insights and methodologies for the intelligent transformation of traditional baijiu brewing processes, driving technological progress and industrial upgrades in the baijiu sector.

2. Baijiu brewing process and temperature control requirements

The primary raw material for baijiu production is sorghum, which is crushed into small granules in a “4-6-8” ratio, known as shan (cracked sorghum). Hot water is gradually added to the shan while stirring, a process referred to as he shan (mixing the cracked sorghum). The mixture formed after stirring is called hong shan (red shan), which serves as the main raw material for baijiu brewing. In the brewing process, hong shan is first placed in a steaming pot for atmospheric steaming for 40 minutes. After steaming, the hong shan is removed and cooled with cold water, allowing the sorghum granules to absorb moisture and expand, providing the necessary water content for subsequent fermentation. After standing for five minutes, the hong shan is transferred in batches onto a cooling conveyor, where a blower is used to reduce its temperature. Once cooled to the appropriate temperature, a precise amount of daqu (a type of fermentation starter) is added and evenly mixed. The mixture is then placed into underground fermentation pits (di gang), where it undergoes sealed fermentation for 28 days. This primary fermentation process is known as da cha fermentation. During da cha fermentation, the temperature of the material gradually increases as fermentation progresses, then stabilizes before eventually decreasing. By monitoring temperature fluctuations at key time points, brewmasters can assess yeast activity, evaluate fermentation efficiency, and make necessary adjustments to optimize the brewing process.

After the completion of da cha fermentation, the fermented mash (jiupei) is removed from the fermentation pit and distilled to extract the baijiu. Once distillation is complete, water is directly added to the spent mash, which is then transferred to the cooling conveyor for further cooling. A suitable amount of daqu is then added again before being placed back into the fermentation pit for a second round of fermentation, known as er cha fermentation. This secondary fermentation also lasts 28 days, after which the material undergoes distillation to produce light-aroma baijiu (qingxiang baijiu). Throughout the er cha fermentation process, temperature fluctuations must also be closely monitored to ensure optimal yeast activity. Proper temperature control promotes the formation of ethanol and various aromatic compounds while preventing the production of harmful substances that could compromise the quality of Fenjiu. Thus, temperature monitoring is critical throughout the entire baijiu brewing process. Traditional manual temperature measurement methods are labor-intensive, time-consuming, and often inaccurate. In contrast, modern wireless monitoring systems enable real-time and precise temperature measurement and control, significantly enhancing the automation and efficiency of baijiu production.

3. Design of the real-time temperature monitoring system

3.1. Temperature sensor

The DHT11 digital temperature sensor was selected as the temperature sensing module for the real-time temperature monitoring system due to its low cost, low power consumption, and built-in factory-calibrated signal output capability. It outputs temperature data as a digital signal via a single-wire serial interface, making it easy to integrate with most microcontrollers [4]. Additionally, the DHT11 sensor requires minimal peripheral circuitry, simplifying the design process. The basic specifications of the DHT11 sensor are shown in Table 1.

Table 1. Specifications of sensor DHT11

Temperature Range | Humidity Range | Temperature Accuracy | Humidity Accuracy | Resolution | Package Type |

0-50℃ | 20%-90%RH | ±2℃ | ±5%RH | 1 | DIP4 |

3.2. Data transmission and storage module for real-time temperature display

Considering the environmental factors of the brewing process and the need for real-time data transmission, the ESP8266 module was chosen as the communication module. The ESP8266 development board is a highly integrated wireless communication module that can either connect directly to other microcontrollers via a transparent transmission mode or function as an independent processing device. It features a built-in high-speed cache, which enhances its computational performance and system efficiency [11]. The module is compact, highly reliable, and suitable for embedding in various environments.

In this system, the ESP8266 is primarily responsible for receiving and transmitting temperature data. It operates in station mode (STA), allowing it to send data collected by the sensors to the cloud [6]. The system uses the MQTT (Message Queuing Telemetry Transport) protocol for data transmission [9, 12], which is implemented over a TCP/IP network. By layering the MQTT protocol on top of TCP/IP, the system meets the specific requirements of the Internet of Things (IoT). The temperature sensor collects temperature data, which is then transmitted to the ESP8266 module. The ESP8266 reports the data to the cloud, where it is categorized, stored, analyzed, and used for threshold-based alerts, thereby significantly reducing the computational burden on client devices [3].

This study employs the Alibaba Cloud IoT platform as the MQTT broker. The cost-effective ESP8266 module serves as the client to facilitate data transmission and interaction with the cloud platform [11]. In addition to functioning as a Wi-Fi module, the ESP8266 has a certain degree of programmability. After receiving data from the temperature sensor, the ESP8266 converts it into MQTT message format before sending it to the Alibaba Cloud IoT platform [2]. The cloud platform then forwards the message to the cloud database and relevant smart devices that have subscribed to the topic. Additionally, the ESP8266 subscribes to specific remote control topics, allowing it to receive commands from smart devices and display relevant temperature data remotely [8].

4. Experiment and analysis

To ensure the reliability and accuracy of the data, a real-world test environment was set up. This study conducted on-site experiments at a distillery equipped with comprehensive brewing facilities and monitoring equipment to support the required experimental conditions. A large volume of temperature data was collected during the baijiu brewing process using the DHT11 digital temperature sensor, ESP8266 development board, and Alibaba Cloud IoT platform [7]. The experiment was divided into two fermentation stages: secondary fermentation and primary fermentation. Temperature data was recorded every 30 minutes and uploaded to the cloud for analysis.

The experiment aimed to verify the effectiveness and accuracy of the real-time temperature monitoring system in the baijiu brewing process. The specific setup steps for the experimental environment were as follows:

1. Selection of the experimental site: A detailed assessment of the fermentation environment in the distillery’s brewing workshop was conducted. After careful screening, a specific fermentation workshop was chosen. Temperature sensors were placed at the edge and center of the fermentation pit.

2. Installation of hardware equipment: The DHT11 digital temperature sensor was connected to the ESP8266 development board via a single-wire serial interface. The sensors were installed at the edge and center of the fermentation pits.

3. Sensor data transmission: The ESP8266 development board transmitted data to the Alibaba Cloud IoT platform using the MQTT protocol, enabling real-time data transmission and storage.

4. Configuration of host computer and display devices: A host computer was connected to the display equipment for real-time monitoring and data analysis.

4.1. Analysis of Temperature Variations in the Secondary Fermentation Process

To monitor the full fermentation cycle of secondary fermentation, the temperature sensor probe was inserted into the fermentation pit to track the temperature variations of the fermenting grain mash. To ensure accurate temperature recording, data collection started one hour after placing the mash into the pit, and the sensor recorded and uploaded temperature readings every 30 minutes until the 28-day fermentation process was completed, at which point the materials were removed from the pit.

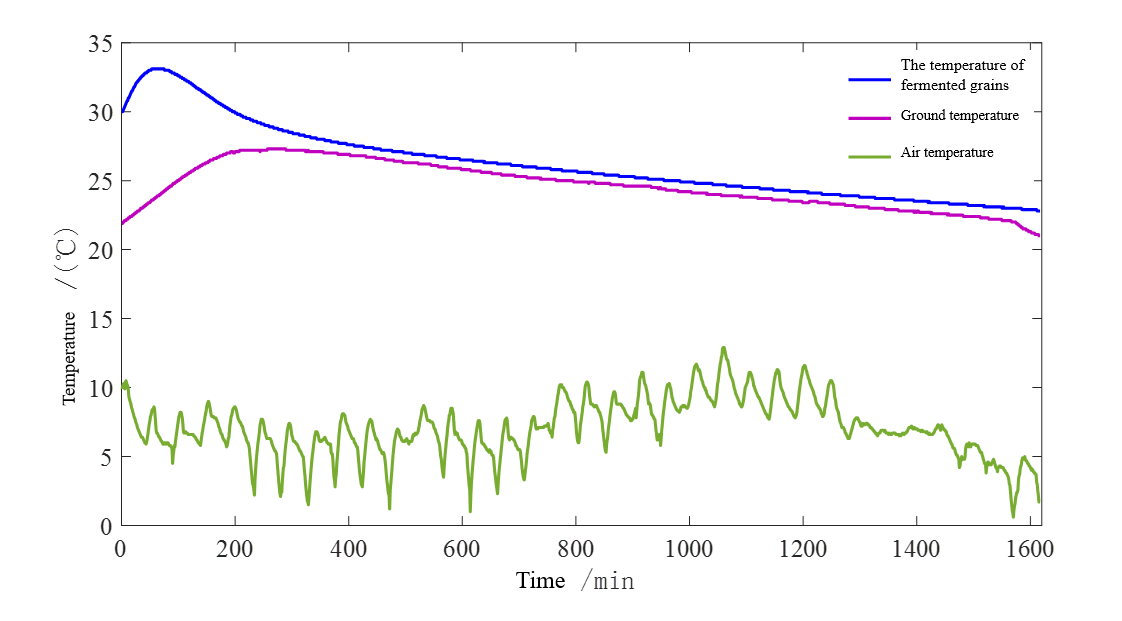

Figure 1. Temperature change of fermented grains in secondary fermentation

As shown in Figure 1, the temperature variations during secondary fermentation follow a clear pattern. After the cooling and aeration process, the mash was placed into the fermentation pit, initiating alcoholic fermentation. Initially, the temperature decreased to a range suitable for microbial reproduction, then gradually increased due to the fermentation process. As fermentation activity diminished over time, the temperature declined and stabilized. From the recorded data, it was observed that under the given environmental conditions, the optimal initial temperature of the mash before being placed into the pit was 28°C, which facilitated the best fermentation start.

4.2. Analysis of temperature variations in the primary fermentation process

To monitor the temperature variations during primary fermentation, the temperature sensor’s external probe was pre-inserted into the fermentation pit before adding the mash. Once the mash was added, temperature readings were recorded every 30 minutes until the 28-day fermentation cycle was completed and the materials were removed from the pit.

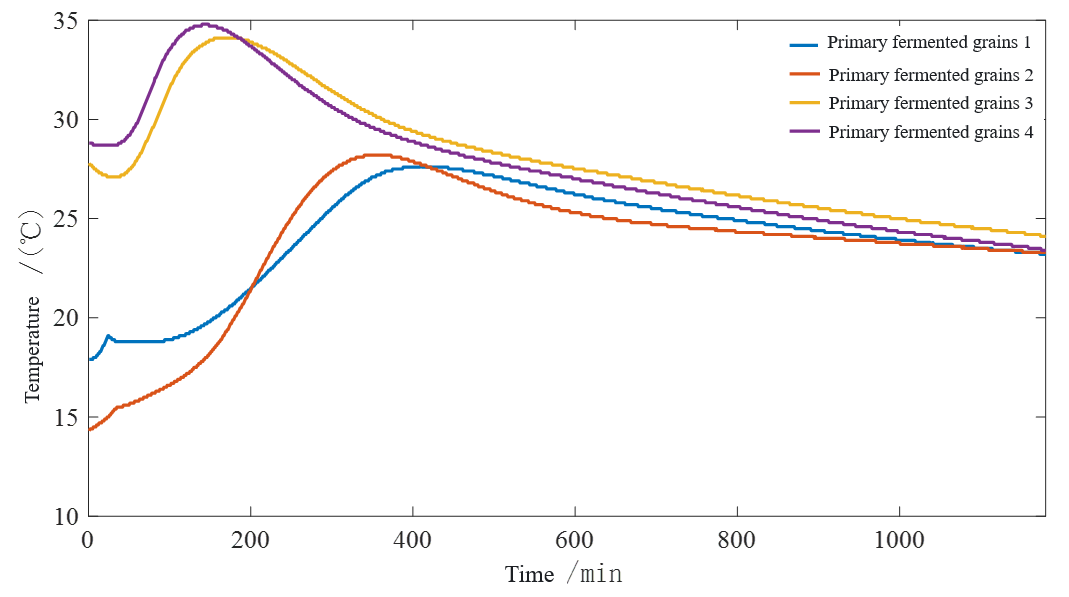

Figure 2. Temperature change of fermented grains in primary fermentation

Figure 2 shows the temperature changes of dacha fermented grains during the fermentation process. As shown in the figure, the temperature curve follows a pattern characterized by "a slow rise in the early stage, a stable peak in the middle stage, and a gradual decline in the late stage." To allow sufficient time for the slow rise phase in the early stage and considering the external environmental factors during testing, the optimal approach is to control the initial fermentation material temperature at 12℃ to 16℃. The temperature should then rise gradually, reaching its peak on the seventh day, after which it should gradually decrease and eventually stabilize above 23℃.

5. Conclusion

Based on an analysis of the liquor brewing process and the requirements for temperature control, this paper proposes a real-time temperature monitoring system suitable for liquor brewing. The system uses a DHT11 digital temperature sensor and an ESP8266 development board, with real-time data transmission and storage achieved through the Alibaba Cloud IoT platform, thereby obtaining real-time temperature data during the brewing process. Through on-site experiments conducted at a distillery, the system was shown to accurately reflect the temperature variation patterns during secondary fermentation and dacha fermentation, providing a scientific basis for ingredient production and fermentation process control. The results indicate that the system can improve monitoring efficiency, reduce human error and labor costs, prevent air leakage from fermentation tanks and contamination by foreign bacteria, enhance the intelligence level of the liquor brewing process, and promote the modernization of traditional brewing techniques. With technological advancements and expanding application scenarios, the advantages of this system in liquor brewing and other fermentation industries are expected to increase further.

References

[1]. Luo, J. (2018). Research on the current situation and development of intelligent home brewing machines based on microcontrol technology. Wireless Internet Technology, 15(13), 142–143, 146.

[2]. Zhou, B. (2023). Design of a smart agricultural greenhouse monitoring and control system based on the Internet of Things (Master’s thesis). Xidian University.

[3]. Hou, D. (2024). Back-end design of a digital chip communication module for smart agriculture (Master’s thesis). Zhejiang Ocean University.

[4]. Wang, M. (2024). Research on an intelligent greenhouse environment monitoring system based on multi-sensor integration (Master’s thesis). Wuhan Institute of Technology.

[5]. Xu, S. (2024). Application and research of artificial intelligence technology in brewing. China Liquor, (08), 42–43.

[6]. Zhang, J., Wang, L., & Zhou, Y. (2025). Design and implementation of an intelligent irrigation control system. Agricultural Equipment & Vehicle Engineering, 1–11. Advance online publication.

[7]. Xiong, F., Yang, C., & Li, Y. (2025). Research progress on electronic textile sensors for temperature monitoring. New Chemical Materials, 1–8.

[8]. Zhang, L. (2025). Design and implementation of an agricultural soil regulation system based on LoRa technology. Internet of Things Technology, 15(05), 91–95.

[9]. Wen, S., & Su, J. (2025). Design of an ECG monitoring system based on STM32. Integrated Circuit Applications, 42(01), 55–57.

[10]. Zhang, L. (2025). Design of an intelligent cold chain logistics system for agricultural products based on the Internet of Things. Integrated Circuit Applications, 42(01), 356–357.

[11]. Liao, D. (2024). Analysis of real-time data transmission and monitoring methods for intelligent terminal devices. Integrated Circuit Applications, 41(12), 100–101.

[12]. Liu, P., Zhou, Y., & Zhou, G. (2024). Design of a cable terminal joint temperature monitoring system based on STM32. Integrated Circuit Applications, 41(12), 10–12.

Cite this article

Yu,W. (2025). Design of real-time temperature monitoring system in liquor brewing process. Advances in Engineering Innovation,16(3),44-48.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Journal:Advances in Engineering Innovation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Luo, J. (2018). Research on the current situation and development of intelligent home brewing machines based on microcontrol technology. Wireless Internet Technology, 15(13), 142–143, 146.

[2]. Zhou, B. (2023). Design of a smart agricultural greenhouse monitoring and control system based on the Internet of Things (Master’s thesis). Xidian University.

[3]. Hou, D. (2024). Back-end design of a digital chip communication module for smart agriculture (Master’s thesis). Zhejiang Ocean University.

[4]. Wang, M. (2024). Research on an intelligent greenhouse environment monitoring system based on multi-sensor integration (Master’s thesis). Wuhan Institute of Technology.

[5]. Xu, S. (2024). Application and research of artificial intelligence technology in brewing. China Liquor, (08), 42–43.

[6]. Zhang, J., Wang, L., & Zhou, Y. (2025). Design and implementation of an intelligent irrigation control system. Agricultural Equipment & Vehicle Engineering, 1–11. Advance online publication.

[7]. Xiong, F., Yang, C., & Li, Y. (2025). Research progress on electronic textile sensors for temperature monitoring. New Chemical Materials, 1–8.

[8]. Zhang, L. (2025). Design and implementation of an agricultural soil regulation system based on LoRa technology. Internet of Things Technology, 15(05), 91–95.

[9]. Wen, S., & Su, J. (2025). Design of an ECG monitoring system based on STM32. Integrated Circuit Applications, 42(01), 55–57.

[10]. Zhang, L. (2025). Design of an intelligent cold chain logistics system for agricultural products based on the Internet of Things. Integrated Circuit Applications, 42(01), 356–357.

[11]. Liao, D. (2024). Analysis of real-time data transmission and monitoring methods for intelligent terminal devices. Integrated Circuit Applications, 41(12), 100–101.

[12]. Liu, P., Zhou, Y., & Zhou, G. (2024). Design of a cable terminal joint temperature monitoring system based on STM32. Integrated Circuit Applications, 41(12), 10–12.