1. Introduction

The traditional fuel vehicle industry in China has developed rapidly. The rapid development of the fuel vehicle industry has brought significant changes to the domestic climate and environment [1-2]. Every day, a large number of vehicles are running on the roads in China, and the fuel exhaust they produce has a relatively serious impact on the domestic environment. At the same time, the energy demand of vehicles has also led to a relatively serious energy shortage problem in China. The emergence of new energy vehicles plays a crucial role in solving the current situation. After their application, they can alleviate the domestic energy problem to a certain extent. Moreover, since their energy supply is basically from green and environmentally friendly materials, the wastewater and exhaust gas they emit will be greatly reduced compared to traditional fuel vehicles [3]. In short, new energy vehicles are the main development direction of the automotive industry in the future. They can help us reduce our excessive dependence on petroleum resources and enable China to better follow the path of sustainable development [4]. Therefore, promoting the development of the new energy vehicle industry in China is both necessary and essential. Only by establishing a firm foothold in this industry can China achieve better development and faster progress in the future.

2. Main types of batteries for new energy vehicles

The following are the main types of batteries commonly used in new energy vehicles in China.

2.1. Lead-acid battery

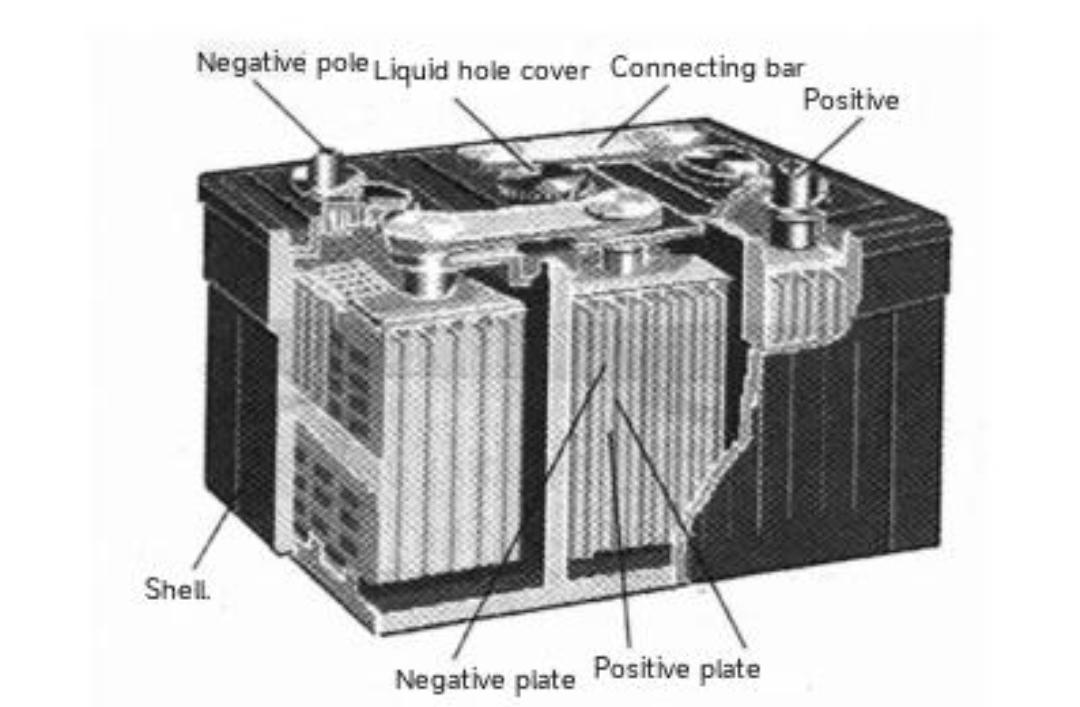

This type of battery has a long history of use and is mainly applied in large vehicles such as mining trucks. Its technical level is relatively mature [5]. It has the characteristic of large storage capacity. However, in terms of environmental protection standards, it fails to meet the national requirements. Meanwhile, its service life is not long, and it requires a considerable amount of time for replacement. Additionally, many manufacturers consider this technology outdated, prone to causing environmental pollution, and lacking competitive advantages compared to other batteries, thus gradually ceasing the production of lead-acid batteries [6]. In general, lead-acid batteries have high stability, low production costs, and a high penetration rate. The basic structure of a lead-acid battery is shown in Figure 1.

Figure 1. Basic structure diagram of lead-acid battery

2.2. Nickel-metal hydride batteries

Among alkaline batteries, nickel-metal hydride batteries are the most widely used. They have a long service life, high output power in energy storage technology, relatively high working power, and high charging and discharging efficiency. However, they are relatively expensive in practical use. In the production history of nickel-metal hydride batteries, the batteries produced by Toyota have the highest specific energy, which can reach up to 90 Wh/kg. Moreover, after recycling, the remaining number of uses of such batteries can still be maintained at over 500 times, offering a relatively high cost-performance ratio and a wide range of applications [7].

2.3. Fuel cells

This type of battery is a highly integrated medium and small-sized power generation device, with its main energy source coming from clean energy. After reactions occur inside the battery, they are converted into electricity [8]. They are less likely to cause environmental pollution. Currently, they have received extensive attention and application from new energy vehicle enterprises. The external structure of the fuel cell is shown in Figure 2.

Figure 2. Outline structure diagram of fuel cell

3. Analysis of problems and causes of power batteries in new energy vehicles

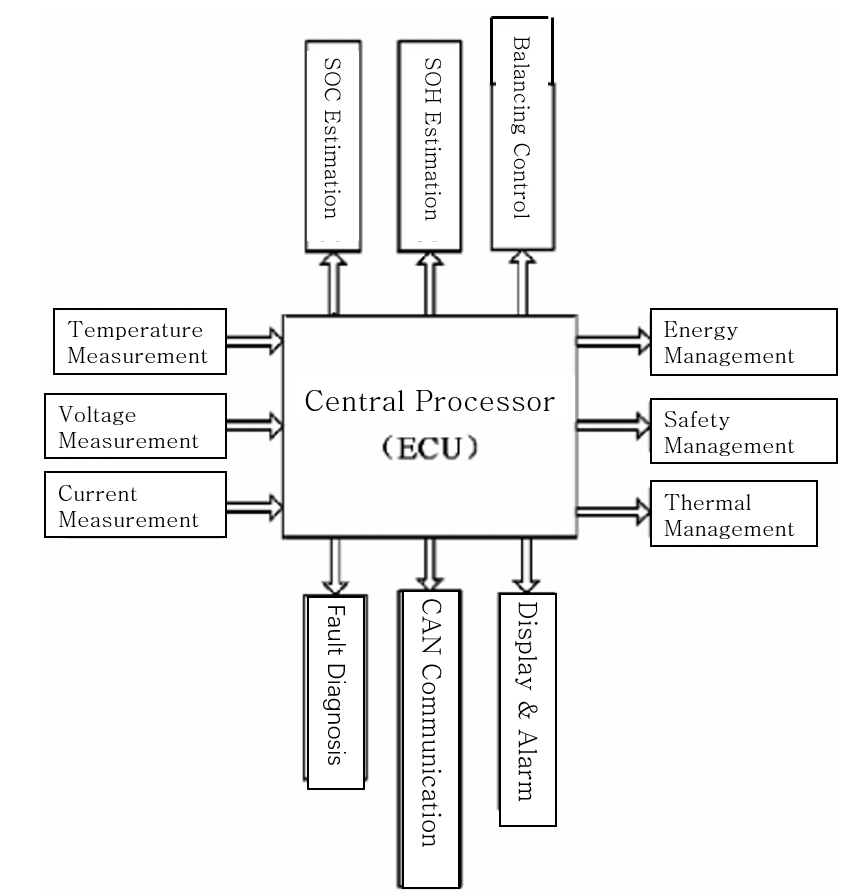

In the battery management system (BMS) of new energy vehicles, common faults include CAN system communication faults, voltage anomaly faults, BMS anomaly faults, abnormal temperature collection faults, insulation faults, pre-charging faults, internal and external voltage measurement faults, and inability to charge faults, etc. [9]. The functions of the battery management system are shown in Figure 3.

Figure 3. Function diagram of battery management system

3.1. Battery capacity density

Although the technology of new energy vehicles has gradually matured, the issue of battery capacity density in many vehicles has not been well addressed. Currently, the reason why new energy vehicles fail to gain consumers' trust is that their battery range is relatively poor and the number of charging piles set up on the roads is too small to meet the growing charging demands of new energy vehicles, which is caused by the low battery density [10].

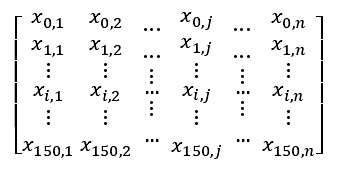

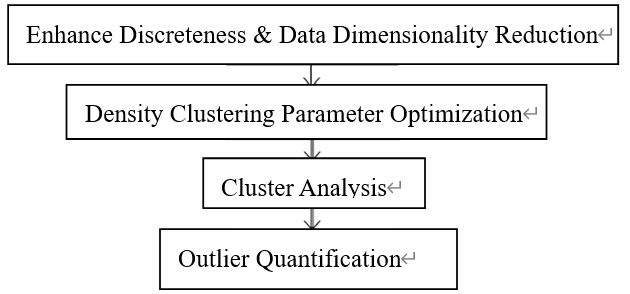

Extract the voltage data of a certain vehicle within a relatively short period of time, count the frequency of the voltage, and construct a matrix with the same distribution of power battery voltage data. The only difference is that the time segment of the data set is shorter. The matrix is shown as in Figure 4. The matrix contains n batteries, that is, each column represents one battery, and it includes 151 voltage scale values, that is, each voltage scale value is (3000mv + i * 10mv). The density clustering process is shown in Figure 5.

Figure 4. Battery voltage data matrix diagram

Figure 5. Flowchart of density clustering

The first step is to discretize and reduce the dimension of the voltage frequency data. The steps are as follows:

(1) Convert the frequency data values of each battery into frequency values.

(2) Filter the frequency data with voltage state to increase the discreteness between battery data.

(3) Screen out the data with large weights, and construct a new matrix in reverse order to achieve matrix dimension reduction.

In step (1), considering that the duration of vehicles on the platform within the extracted time period has a significant impact on the magnitude of the data values, to enhance the calculation speed, the frequency data values are converted into frequency values. In step (2), the voltage values will be used as a filter to amplify the frequency values of each battery, further increasing the discreteness between them, and at the same time, the voltage attribute value is removed, reducing the complexity of the data. In step (3), although the voltage value range is between 3V and 4.5V, the actual voltage value will further narrow within this range, resulting in a large number of 0-value data in the data set distribution; meanwhile, one of the disadvantages of density clustering is the curse of dimensionality. To address these issues, data dimension reduction can be performed. The most commonly used method is PCA (Principal Component Analysis), but this method will change the distribution of the original matrix and also cause scale scaling and rotation of the data. Therefore, in this step, a new matrix is reconstructed in reverse order based on the data weight size, successfully extracting the effective data and further reducing the data dimension, while preserving the effective data set to the greatest extent [11].

The second step is to calculate the standard deviation for each battery. Select the 3σvalue with the highest frequency of occurrence and the battery voltage dimension as parameters respectively, and perform density clustering to obtain the datasets of normal and abnormal batteries.

Thirdly, for the selected set of abnormal batteries, calculate the Euclidean distance between each abnormal battery and each normal battery in the normal battery set. The battery with the maximum distance is identified as the most abnormal battery.

Fourthly, extract the voltage data of the most distinctive abnormal and normal batteries, and plot the voltage curve to obtain the voltage difference variation.

3.2. Battery inspection technology

Firstly, battery assembly is the core process in battery production and requires high precision. However, due to technical and other limitations, some automotive batteries often have significant dimensional deviations during assembly. As the number of integral outer rotor blades of the cooling fan for new energy vehicle batteries is relatively large, typically 41 pieces, the specific manufacturing and installation process is prone to cause the outer rotor to deviate due to non-standard installation dimensions, resulting in fan vibration. Over time, this leads to increased energy consumption, reduced battery life, and additional maintenance and repair costs.

Secondly, due to inadequate supervision during the production process and the weak quality awareness of relevant maintenance personnel, there are loopholes in the battery inspection process, causing axial vibration of the battery cooling fan. Additionally, there is a shortage of professional talents in the new energy vehicle field. Many maintenance personnel do not clearly understand the differences in quality inspection methods and troubleshooting approaches between traditional and new energy vehicles. They still use relatively traditional inspection techniques in battery fan inspections instead of conducting tests in a simulation environment. As a result, new energy vehicles are prone to vibration due to external environmental factors in actual use, affecting their normal operation and potentially causing various safety issues.

3.3. Impact on the safety of power batteries

In terms of the development of new energy vehicles in China, we are still in the early and intermediate stages, and new energy vehicles have not been fully popularized. Therefore, many technologies are not as perfect as those in Western countries. The consistency of battery manufacturing and the safety of battery assembly cannot be fully guaranteed, and safety hazards will seriously affect the use of users and new energy vehicles. Generally speaking, the safety of batteries mainly lies in whether the thermal conductivity of common raw materials is good or not; otherwise, it will lead to battery heat accumulation, combustion, and even explosion. In this regard, relevant technicians must pay attention to the heat dissipation problem of batteries and the service life problem caused by battery aging.

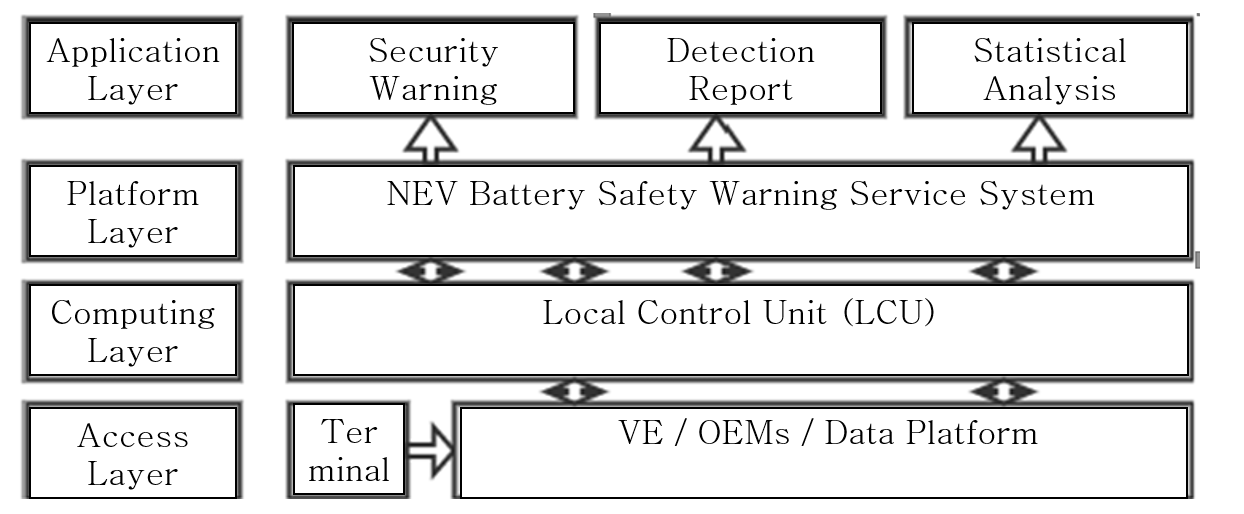

As shown in Figure 6, the overall architecture of the new energy vehicle battery safety early warning service system mainly consists of four layers: the data access layer, the local computing layer, the platform system layer, and the application layer.

(1) Data Access Layer

The data access in the data access layer is multi-data source access. The main data sources include vehicle data sources, vehicle manufacturer data sources, charging pile data sources, national platforms, and data sources from various local platforms. During the actual operation of vehicles, a large amount of real and valid data is generated. These data are directly transmitted to the corresponding vehicle manufacturers, local new energy vehicle supervision centers, and the national supervision platform through the network. In addition, during the charging process of vehicles, the charging piles also generate battery charging data [12].

(2) Local Computing Layer

Local data computing mainly refers to the preprocessing of the received raw data under the local control unit, converting the data into structured data and storing it. It mainly includes five parts: data access, data cleaning, data decomposition, data anomaly detection, and data storage.

(3) System Platform Layer

The preprocessed data is stored in the platform database, and the corresponding functions are realized through these data. Ultimately, with the help of system visualization, the system can better monitor the batteries of new energy vehicles and serve the safety of new energy vehicle batteries.

(4) Application Layer

The system platform offers various basic functions and visual displays, including specific features such as abnormal battery detection for new energy vehicles, management of detection models, battery data analysis, and comparisons of batteries from different manufacturers, all tailored to practical application scenarios.

Figure 6. Overall architecture diagram of the battery safety early warning service system for new energy vehicles

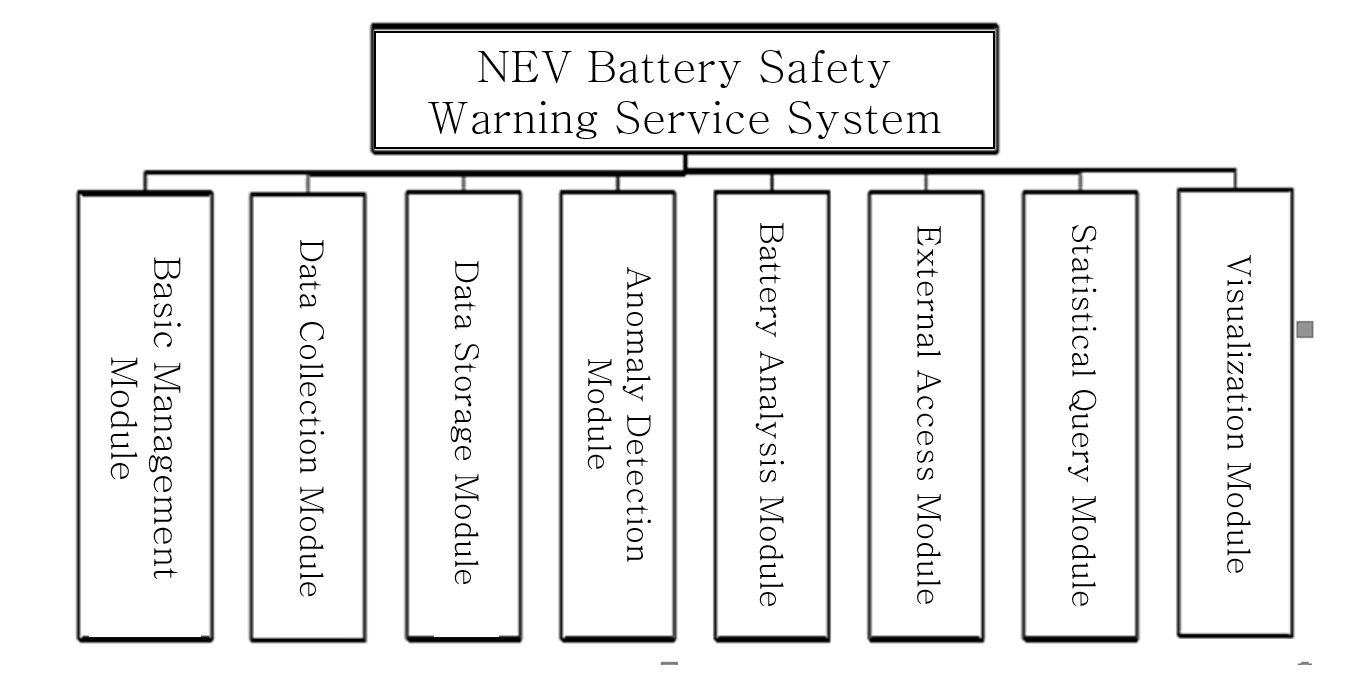

The new energy vehicle battery safety early warning service system mainly consists of the basic management module, data collection module, data storage module, anomaly detection module, battery analysis module, external access module, statistical query module, and visualization module. Among them, the battery anomaly detection module and the battery analysis module both perform analysis and processing on the battery. The application of battery anomaly detection in this paper is mainly designed and implemented through the new energy vehicle battery safety early warning service system. The functional structure of the new energy vehicle battery safety early warning service system is shown in Figure 7.

Figure 7. Control flow chart and screenshot of main program

4. Analysis of common faults in new energy vehicle batteries

4.1. Faults of lithium batteries in pure electric vehicles

The power of electric vehicles comes from lithium batteries inside the vehicle. Nowadays, many electric vehicles have unstandardized performance because there is no unified standard specification for batteries. Under such circumstances, various faults are prone to occur. For instance, after a certain period of use, some new energy vehicles often encounter problems of overcharging and overdischarging. New energy vehicles also have different technical requirements for the performance of lithium batteries inside the vehicle. On the one hand, they need to have the characteristics of high efficiency and recyclability; on the other hand, their capacity must meet the demands of electric vehicles. However, the circuit systems of new energy vehicles are often composed of multiple small lithium batteries as a whole, and the performance of these small lithium batteries varies greatly, which easily leads to system incompatibility, damages the lithium batteries, thereby reducing their service life and operational capacity, and increasing safety risks.

4.2. Faults of batteries in hybrid vehicles

Apart from pure battery-driven models, hybrid vehicles are more common in the market nowadays. Their working mode combines electrical energy with fossil energy. Hybrid vehicles not only overcome the problem of insufficient range of new energy vehicles but also have lower energy consumption than traditional vehicles, presenting obvious advantages. However, at the initial stage of operation, the battery can provide relatively sufficient electrical energy. However, as the vehicle is used for a longer time, the internal circuits, magnetic circuits, and mechanical parts may malfunction due to incompatibility. When operating under poor environmental conditions, the probability of problems occurring in the control system and motor drive of hybrid vehicles will increase significantly, and parts will age and wear out, thereby increasing the difficulty of maintenance and repair for new energy vehicles.

5. Measures to enhance the detection technology and maintenance methods of power batteries for new energy vehicles

5.1. Detection methods for new energy vehicle batteries

(1) Utilizing X-ray Inspection

To address the current challenges faced by new energy vehicles, the first step is to improve the battery detection methods. By inspecting the batteries of new energy vehicles, the overall driving conditions of the vehicles can be accurately grasped. As domestic electric new energy vehicles become increasingly integrated into people's daily lives, the core technologies of electric vehicles are motors, batteries, and electronic control systems. Therefore, higher requirements are placed on the batteries of new energy vehicles, including their energy storage capacity, volume energy density, temperature tolerance range, cycle life, discharge capacity, performance reliability, and density. For instance, using an electronic computer X-ray tomography machine to measure the original batteries of new energy vehicles can distinguish their different density structures.

Secondly, the detector converts the received analog signals into digital signals, and the computer detects the internal structure and electrode plates of the undamaged battery to initially confirm the initial normal state of the new energy vehicle battery. Then, accurately calculate the state of the electrode plates and the internal linear distance, as well as the wear and misalignment issues near the electrode plates. Finally, the computer calculates the attenuation coefficient of each pixel of the battery and reconstructs the image based on the battery's cross-sectional structure, thereby identifying the subtle differences in the internal components of the battery. Detecting the batteries of new energy vehicles is beneficial for optimizing battery design and energy storage capacity.

(2) Detection Methods for Battery Modules and Cells of New Energy Vehicles

The safety and reliability of new energy vehicle batteries are important criteria for people when choosing a vehicle. Detecting the battery modules and cells of new energy vehicles is a prerequisite for vehicle maintenance. Through the arduous efforts of the automotive R&D team, China has achieved remarkable results in the new energy vehicle industry, both in terms of R&D methods and market acceptance, enhancing the competitiveness of the new energy vehicle industry and improving the industrial structure. Different driving modes of new energy vehicles require corresponding battery detection methods. Battery test cabinets can be used to record the discharge capacity of new energy vehicle batteries under standard charging and discharging conditions at room temperature to check the electrical performance of the batteries. Battery charge and discharge machines can be used to conduct battery condition cycle tests on the batteries and record their capacity rates to check the cycle performance of the batteries in different power-driven new energy vehicles. Battery reliability can be tested using battery test cabinets and explosion-proof boxes. Limiting devices and protection circuits can be designed on the PCB board outside the battery or in the charger to prevent over-discharge. Short-circuit testers can be used to detect whether there are short circuits in the battery's internal circuits.

5.2. Maintenance methods for new energy vehicle batteries

(1) Establish a sound battery charging and swapping mechanism and build large-scale charging platforms. After four years of development, China has made significant progress in the new energy vehicle industry. China has ranked first in the world for five consecutive years in terms of the production, sales, and ownership of new energy vehicles. The maintenance of new energy vehicle batteries requires the support of a sound battery charging and swapping mechanism. The battery drive system accounts for 30% to 45% of the cost of new energy vehicles, and batteries account for 70% to 85% of this drive system. Strengthening the maintenance of new energy vehicle batteries can reduce the production cost of new energy vehicles. Familiarize with the battery gradient use system screening principles and regularly inspect and replace the multi-purpose converters of large-scale charging platforms. Establish an integrated monitoring system for large-scale charging platforms and energy storage stations; an integrated multi-functional charging platform that combines battery swapping stations and energy storage stations. Establish a complete battery recycling mechanism to enhance the value of battery recycling and reduce battery costs through the reuse of power batteries. The charging demand characteristics of electric vehicles and the impact of large-scale electric vehicle charging on the power grid; (1) Orderly charging control and management system for electric vehicles, orderly charging test system for new energy vehicles. Familiar with the operation characteristics of new energy vehicle charging piles, key technologies and control strategies for integrating charging stations as distributed energy storage units into the power grid. Built intelligent charging and discharging machines, intelligent on-board terminals, and interactive and coordinated control systems for new energy vehicles and the power grid. Battery replacement technology, billing and metering methods, and asset management technology for large-scale new energy electric vehicles; strive to promote the establishment of a business model for the operation of large-scale charging equipment platforms; and build an operation management system for intelligent charging and battery swapping service networks based on the Internet of Things and the Internet.

(2) Enhance the awareness of new energy vehicle owners to maintain batteries. Prevent overcharging and overdischarging of new energy vehicles. Based on the feedback from the verification system of the interaction experiment between new energy vehicles and the power grid, combined with the inspection and testing technology of new energy vehicle charging and discharging facilities, calculate the battery charging time and strictly prevent overcharging to avoid battery overheating and accidents. Check the car's power supply at any time. Driving in a state of low battery power causes significant damage to the battery. Regularly charge the stored batteries to keep them in a healthy state. New energy vehicles should start slowly and avoid sudden operation of the accelerator, as this can cause significant changes in current and lead to the formation of lead sulfate crystals, causing physical damage to the battery plates. At the same time, pay attention to sun exposure and extreme cold. If an electric vehicle is exposed to strong sunlight for a long time, the internal pressure of the battery will increase, causing battery water loss, reduced battery activity, and accelerated aging. During the charging process, pay close attention to the battery temperature. When the battery temperature of a new energy vehicle reaches 65℃, immediately unplug the power supply. In daily use, charge and discharge the battery correctly to prevent damage caused by improper operation. Generally, the charging time for a battery is ten hours. Reasonable and standardized charging of the battery and continuous charging to enter a cycle state can extend the battery's lifespan.

6. Future development direction of new energy vehicle battery detection and maintenance technology

Compared with the new energy vehicle technologies of some developed countries, China's new energy vehicles are still in the development stage, with significant differences in asset investment and time development. Therefore, China's new energy vehicles currently have no obvious competitiveness in the international market. This situation is encouraging for the development of new energy vehicles in China. The Chinese government has successively introduced a series of policies to support the development of new energy vehicles, providing abundant technical and financial support for the specific development work of new energy vehicles. However, as China's research on new energy vehicle technology deepens, the traditional dependence on automotive energy has significantly decreased, and the highly praised new energy vehicle era will arrive earlier. Therefore, more attention must be paid to the daily maintenance and care of new energy vehicle batteries.

7. Conclusions

As the new energy vehicle industry gradually develops and matures, the quality of battery detection and maintenance technology is receiving increasing attention. It is not only closely related to the energy consumption and performance of the vehicle but also directly affects the safety of new energy vehicles. Improving the level of battery detection and maintenance for electric new energy vehicles can continuously promote the industrialization process of new energy electric vehicles in China and drive energy conservation and emission reduction in the transportation sector and the low-carbon and sustainable development of the automotive industry. Vigorously improving the methods of battery detection and maintenance for new energy vehicles, promoting the substitution of electricity for oil, and increasing the utilization rate of energy can reduce the automotive industry's dependence on petroleum energy and lower air pollution. This not only suits China's national conditions but also aligns with the development requirements of environmentally friendly vehicles in the low-carbon era. Researching the detection and maintenance methods of new energy vehicle batteries can not only enhance the innovation ability of automotive maintenance technology teaching and research personnel, promote the development of China's automotive manufacturing and maintenance technology, and facilitate the adjustment of the automotive industry structure, but also be conducive to revitalizing China's automotive repair technology and promoting social and economic construction.

References

[1]. Ma, J., Liu, X., Chen, Y., Wang, G., Zhao, X., He, Y., Xu, S., Zhang, K., & Zhang, Y. (2018). Current Situation and Countermeasures of China's New Energy Vehicle Industry and Technology Development. China Journal of Highway and Transport, 31(08), 1-19.

[2]. She, C., Zhang, Z., Liu, P., & Sun, F. (2019). Review on the Application of Big Data Analysis Technology in the New Energy Vehicle Industry - Based on the Big Data of New Energy Vehicle Operation. Journal of Mechanical Engineering, 55(20), 3-16.

[3]. hang, H. (2017). Research on Thermal Management System of Lithium Batteries for New Energy Vehicles. Shandong University.

[4]. Zhang, W. (2021). Analysis of Development Bottlenecks and Countermeasures of Battery Technology for New Energy Vehicles. Journal of Functional Materials, 28(01), 78-84.

[5]. Yao, Y. (2015). Comparative Study on the Development Strategies of New Energy Vehicle Industry in China and the United States. Shanxi University of Finance and Economics.

[6]. Liang, H., & Lin, M. (2020). Discussion on Battery Detection and Maintenance Technology for New Energy Vehicles. Western Transportation Technology, (09), 166-168.

[7]. Guo, C. (2020). Maintenance and Care of Batteries for New Energy Vehicles. Hubei Agricultural Machinery(13), 123-124.

[8]. Deng, J., Chen, M., & Ming, Z. (2019). Review on Detection and Development Direction of Power Batteries for New Energy Vehicles. Guangdong Science and Technology, 28(11), 41-43.

[9]. Tian, X. (2019). Analysis of Maintenance and Care Strategies for Power Batteries of New Energy Vehicles. Bonding, 40(11), 60-62.

[10]. Wang, Y. (2019). Analysis of Common Fault Diagnosis and Maintenance Technology for New Energy Vehicles. Southern Agricultural Machinery, 50(20), 34.

[11]. Liu, J. (2022). Performance Analysis and Maintenance of Lithium-ion Batteries for Pure Electric Vehicles. Southern Agricultural Machinery, 53(08), 144-146.

[12]. Yang, S., Zhang, J., Qian, Z., & Cui, D. (2022). Research and Prospect of Multi-domain Integration in Automotive Safety. Journal of Automotive Safety and Energy, 13(01), 29-47.

Cite this article

Liu,L.;Mao,Y.;Song,Y.;Wang,L.;Cheng,C.;Xi,L.;Yi,X. (2025). Research on detection and maintenance methods for power batteries of new energy vehicles. Advances in Engineering Innovation,16(5),28-35.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Journal:Advances in Engineering Innovation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Ma, J., Liu, X., Chen, Y., Wang, G., Zhao, X., He, Y., Xu, S., Zhang, K., & Zhang, Y. (2018). Current Situation and Countermeasures of China's New Energy Vehicle Industry and Technology Development. China Journal of Highway and Transport, 31(08), 1-19.

[2]. She, C., Zhang, Z., Liu, P., & Sun, F. (2019). Review on the Application of Big Data Analysis Technology in the New Energy Vehicle Industry - Based on the Big Data of New Energy Vehicle Operation. Journal of Mechanical Engineering, 55(20), 3-16.

[3]. hang, H. (2017). Research on Thermal Management System of Lithium Batteries for New Energy Vehicles. Shandong University.

[4]. Zhang, W. (2021). Analysis of Development Bottlenecks and Countermeasures of Battery Technology for New Energy Vehicles. Journal of Functional Materials, 28(01), 78-84.

[5]. Yao, Y. (2015). Comparative Study on the Development Strategies of New Energy Vehicle Industry in China and the United States. Shanxi University of Finance and Economics.

[6]. Liang, H., & Lin, M. (2020). Discussion on Battery Detection and Maintenance Technology for New Energy Vehicles. Western Transportation Technology, (09), 166-168.

[7]. Guo, C. (2020). Maintenance and Care of Batteries for New Energy Vehicles. Hubei Agricultural Machinery(13), 123-124.

[8]. Deng, J., Chen, M., & Ming, Z. (2019). Review on Detection and Development Direction of Power Batteries for New Energy Vehicles. Guangdong Science and Technology, 28(11), 41-43.

[9]. Tian, X. (2019). Analysis of Maintenance and Care Strategies for Power Batteries of New Energy Vehicles. Bonding, 40(11), 60-62.

[10]. Wang, Y. (2019). Analysis of Common Fault Diagnosis and Maintenance Technology for New Energy Vehicles. Southern Agricultural Machinery, 50(20), 34.

[11]. Liu, J. (2022). Performance Analysis and Maintenance of Lithium-ion Batteries for Pure Electric Vehicles. Southern Agricultural Machinery, 53(08), 144-146.

[12]. Yang, S., Zhang, J., Qian, Z., & Cui, D. (2022). Research and Prospect of Multi-domain Integration in Automotive Safety. Journal of Automotive Safety and Energy, 13(01), 29-47.