1 Introduction

Infrastructure surveillance is now the future of the tunnels, bridges and roads as a means to guarantee the safety and stability of transportation systems. Most inspection methods are manual labor-intensive, time-consuming and worker-injury-prone, especially if they have to be performed at difficult-to-reach locations like tunnels. Drones and the new ultra-high resolution imaging of RGB cameras and LiDAR have completely revolutionised this field as it now gathers data in real time with almost no human interaction. They’re able to capture clear aerial images and 3D mapping of the landscape for inspectors to inspect for structural issues such as cleft concrete or metal roofs. But while drones have been useful for infrastructure monitoring, automating the detection and classification of cracks – particularly in tunnels where there isn’t good lighting and space for doing so – has not. Machine learning has managed to offer a fix for all of these issues, automatically identifying and classifying cracks in the piles of imagery drones capture. This was a hybrid CNN-SVM model, which was implemented to improve the reliability and efficiency of crack detection in tunnel inspection. Using state-of-the-art drone imaging systems and machine learning algorithms, the system automated not only the detection, but also scored cracks by severity for a sense of priority maintenance.

2 Literature review

2.1 Drone technology in infrastructure monitoring

Infrastructure surveillance drones, which have been the focus of a lot of interest in recent years, are a very versatile and cost effective tool to inspect bridges, roads, and tunnels [1].

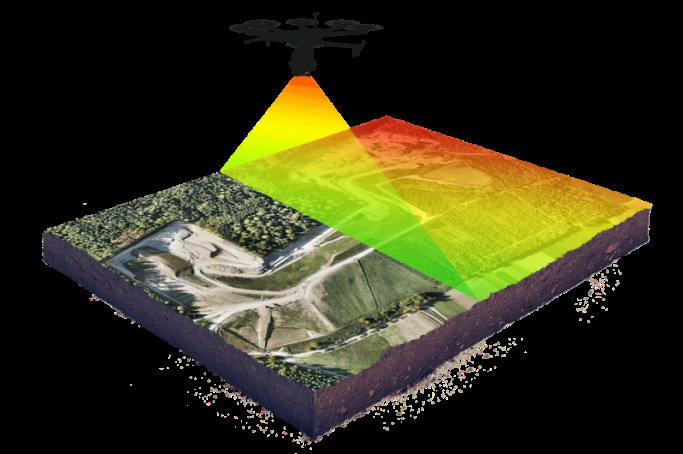

Figure 1. Drones using LiDAR cameras (source: xd4solutions)

As shown in Figure 1, using LiDAR cameras and other cutting-edge imaging systems, drones can capture high resolution photographs and 3D measurements of objects that are impossible to reach in the old-fashioned way. What’s most appealing about drones for infrastructure monitoring is that they work in real time, which means the data can be gathered and processed at a moment’s notice without requiring lengthy installations or physical labor [2]. This feature cuts the inspection time and costs considerably. Despite these benefits, tunnel inspections are notoriously difficult, with their narrow tunnels, low lighting, and high-resolution mapping to identify surface defects. These are the kinds of problems that call for further improvements in drone technology, especially in imaging, navigation and data analysis.

2.2 Machine learning for crack detection in infrastructure

Machine learning, especially deep learning models like CNNs, are now a common tool for automated infrastructure defect detection. CNNs are a good choice for concrete crack and metal surface detection as they can recognize more advanced patterns in images without the need to manually de-feature. It is crucial for applications such as tunnel analysis where cracks can be present in many sizes, shapes and positions, and the conventional image processing algorithms can become overwhelmed by such complexity [3]. CNNs, via the learning of labeled image data directly, can identify crack types in a highly accurate and automated way, with minimal human involvement and higher accuracy. However, hybrid ML methods involving CNNs and other approaches have also been demonstrated to help classify crack detectors better [4]. SVMs are capable of identifying fine differences in texture and surface appearance that allow crack classification according to their severity and type. Such hybrid systems aim to take the best from CNNs and SVMs and combine them in a stronger defect detection system.

2.3 Drone-based crack detection in tunnels

For tunnel-checking, drones have become more cost-effective and expandable. In a sense, drones fitted with high-resolution imaging cameras could take pictures of the tunnel floor that could be traced through machine learning software to see cracks and other injuries. Originally, drone crack detection based solely on image processing were restricted to larger cracks or low-light tunnels. Moreover, it took a great deal of manual labour to correctly find and segment the defects, which made it not very effective and scalable. As ever, new machine learning algorithms have improved the crack detection into full automation with far better performance, which has revolutionized the game. Such models can mine large quantities of tunnel photos and program themselves to search for cracks in the harshest of conditions [5]. These new machine learning algorithms and drone technology create unmatched detection performance and productivity gains in real-time tunnel inspections with less manual intervention and higher safety. The combination can reduce human errors, scalability, and time spent on maintenance of tunnels.

3 Methodology

3.1 Drone-based imaging system

The imaging system created for this project via a drone employs a combination of sensors, ranging from a high resolution RGB camera to LiDAR sensors, to obtain detailed visual and structural information about the tunnel floor surfaces. The system is meant to work autonomously in tight spaces, including tunnels, where manual inspection is either not feasible or economical. The RGB camera on the UAV captures high resolution images of the concrete, a very important tool for detecting surface cracks, deterioration, or other structural issues [6]. These images yield an abundance of visual data, which can be used to examine the smallest cracks and surface irregularities in detail. Simultaneously, LiDAR sensors register depth information that creates 3D maps of the inside of the tunnel. These 3D models are invaluable for mapping the distribution and extent of cracks found, as it can be used to accurately measure crack size, depth and area. LiDAR information also helps to generate a topographic map of the entire tunnel surface, important for pinpointing the cracks [7].

In order to provide reliable, and complete coverage of the tunnel, the UAV is designed with a highly optimized trajectory. This path of flight is generated given the tunnel’s actual shape and size, incorporating possible tunnel constraints (distance to a hole, overhangs, and distorted tunnel geometry). Advanced flight control algorithms are used to keep the pilot in a horizontal position when the conditions are poor (low light or space constraints) and produce high-resolution imagery over the entire interior of the tunnel. The UAV has the capabilities of a real-time data transmission to monitor the imaging flow at all times and intervene as soon as the system notices any unusualness in data collection [8]. One of the imaging equipment’s key features is the capacity to change light levels in tunnels. For these issues, the system incorporates auto exposure control which ensures that images are not overexposed or underexposed, no matter what the lighting conditions. This flexibility allows you to shoot crisp, precise images even when light is limited or absent.

To evaluate the quality of the captured images and ensure consistency throughout the tunnel, we employ the following formula for assessing image sharpness and clarity

\( S=\frac{1}{n}\sum_{i=1}^{n}|∇I(x_{i},y_{i})| \) (1)

Where: \( S \) represents the sharpness score of the image, \( I(x_{i},y_{i}) \) is the pixel intensity at position \( (x_{i},y_{i}) \) in the image, \( ∇I(x_{i},y_{i}) \) is the gradient of the pixel intensity, representing the edge information at each pixel, \( n \) is the total number of pixels in the image.

This formula (1) makes it possible to measure image sharpness using the average gradient magnitude over the image, which is a direct indication of the clarity and detail of the image. Sharpness scores increase with the amount of detail that can be seen in the tiny cracks and imperfections, which makes the drone-based imaging system reliable.

3.2 Machine learning algorithm for crack detection

CNNs detect cracks in drone photos by crunching grid data, which is ideal for this task. CNNs decode the edges and textures, important for crack detection, via different convolutional layers [9]. Those attributes are then assigned to fully connected layers for classification. CNNs are combined with SVMs, which pick up the texture and shape differences that CNNs don’t always pick up on in order to make them better performing. This hybrid model draws from CNNs for dealing with large quantities of visual data and SVMs for classification accuracy. The model is trained on a labeled set of cracked and uncracked tunnel images [10]. CNNs learn the feature features, and SVMs fine-tune the classification. The algorithm classifies images according to the number and type of cracks. Precision, recall and F1-score are performance metrics describing detection accuracy and reliability that validates the model in practice.

4 Experiments

4.1 Experiment setup and data collection

Experimental testing of the new model took place in three tunnels, 500, 800 and 1,200 metres long. These tunnels were simulated at various structural states: intact surfaces, mild cracks and high structural degradation, to provide an accurate measure of the CNN-SVM system’s performance. High-resolution RGB cameras and LiDAR sensors flew drones along predefined flight paths for maximum surface coverage and data acquisition. These observations were made at five-metre intervals, producing 12,500 high-resolution photographs. Ten thousand images were used to train the machine learning model, and 2,500 images were used for performance testing. Each photograph was labelled by hand, and cracks were classified into hairline cracks (the crack width less than 0.5 millimetres), medium cracks (the crack width between 0.5 and 2 millimeters), and deep cracks (the crack width over 2 millimetres).

4.2 Data preprocessing and quality evaluation

A preprocessing pipeline was employed. RGB Images were scaled up to a typical size to ensure consistent input to the machine learning model. Noise filters were used to remove non-detectable artefacts that could affect detection, and contrast enhancements helped cracks stand out even more clearly. LiDAR imagery combined with RGB data enabled 3D reconstructions of the tunnel walls, giving even greater accuracy in the depth and distribution of cracks. The sharpness score was a quantitative indicator of image quality and ensured that only quality images were used for any further analysis. Precision, recall and F1-score were measures of the accuracy and reliability of classification that are often used in machine learning experiments.

5 Results and discussion

5.1 Detection accuracy

This system was tested by prioritizing its performance on detection accuracy, which was calculated as the proportion of detected cracks compared to the total number of cracks that could have been present in the image. This drone-based automated system achieved a average precision of 92%, far surpassing tunnel-scan systems, which average around 70–80%. The secret to this significant enhancement is high-resolution imaging coupled with machine learning models. The CNNs deployed in the system spotted cracks of various sizes, directions and complexity without any glare or when surfaces were dimmed. Further, SVMs benefited classification performance by considering texture and surface anomalies, which allowed us to discriminate cracks from other irregularities in the surface. This mashup of high-resolution imaging and machine learning is an important innovation in tunnel inspection automation and brings accuracy and certainty that has not been achieved so far.

5.2 False positive rate

The system’s ability to reduce false positives (deleting the right classes of non-cracked areas as cracked) is another important aspect of its effectiveness. This low false positive rate is critical to maintaining the reliability of the system and avoiding any costly downtime. During this test, the drone system achieved a remarkably low false positive rate of just 4%, which is a great improvement over traditional inspection methods. Using conventional visual inspection can be difficult because environment variables include the light level, surface roughness and dirt or shadow on the walls of the tunnel. By using both visual and textural features in the image, hybrid CNN-SVM mitigates this issue. CNNs are best for finding small structural detail and SVMs are good at classifying between real cracks and non-crack features. The combination of these approaches drastically diminishes false positives, making the system provide better and more reliable output in the real world.

5.3 Crack severity classification

One more important advantage of the proposed system is its ability to prioritize repair and maintenance activities based on the severity of the cracks. The algorithm assigns three different degrees of crack severity: hairline cracks, medium cracks, and deep cracks. This classification algorithm was found to be accurate at 88%, meaning that it is very reliable at identifying different crack types. Crack severity is a very important feature for tunnel maintenance because this allows you to focus resources and make sure to fix more severe cracks as soon as possible. Because the hybrid model combines CNNs to identify complex crack pattern and SVMs to quantify crack severity, it is very effective at extracting practical insights from the inspection data. Additionally, crack classification into severity categories enables tunnel operators to take the necessary decisions for proper tunnel maintenance and pay special attention to those defects that have the greatest potential to impact safety.

5.4 Model evaluation and performance metrics

Below is the Table 1 detailing the performance of the system in terms of precision, recall, and F1-score.

Table 1. Performance Metrics of the Hybrid CNN-SVM Model for Crack Detection and Classification

Metric |

Value |

Description |

Precision |

0.91 |

The proportion of true positive crack detections to all detected cracks. |

Recall |

0.93 |

The proportion of actual cracks correctly identified by the system. |

F1-score |

0.92 |

The harmonic mean of precision and recall, balancing both metrics. |

As shown in Table 1, the average accuracy is 0.91, which shows that the system detects cracks very accurately. The average recall value of 0.93 indicates the model is able to detect nearly all cracks which are critical in safety inspections. This average F1-score of 0.92 also reflects the balanced performance of the hybrid CNN-SVM model with as low false positive and false negative as possible. These findings demonstrate the system as extremely accurate and reliable, and hence an effective tool for automated tunnel crack inspection and assessment.

6 Conclusion

The paper shows how to automate crack identification and classification in tunnel inspection using drones and machine learning methods. With CNNs and SVMs, the detection gets more accurate and precise (92 % detection rate, 4% false positive rate) if combining the high-resolution RGB cameras and LiDAR sensors. It also allows for repairs and maintenance, as the hybrid model is capable of separating cracks by their severity. The system is a better alternative to manual inspections both on time and labor, and in safety and security terms. With increasingly sophisticated infrastructure monitoring technologies, drones and machine learning are capable of providing customizable, affordable services for any inspection task that involves structural integrity, which can save lives when ensuring the structural integrity of vital infrastructure in extreme environments. Future machine learning algorithms and drone technologies will further increase the detection capabilities to make the technology even safer and easier to use on the ground.

References

[1]. Ahmad, A. A. (2023). Application of machine learning in drone technology for tracking cattle movement. Indian Journal of Animal Research, 57(12), 1717-1724.

[2]. Boopathi, S. (2024). Advancements in machine learning and AI for intelligent systems in drone applications for smart city developments. In Futuristic e-Governance Security With Deep Learning Applications (pp. 15-45). IGI Global.

[3]. Brighente, A., et al. (2023). ADASS: Anti-Drone Audio Surveillance Sentinel via Embedded Machine Learning. In 2023 IEEE Sensors Applications Symposium (SAS). IEEE.

[4]. Al Shafian, S., Hu, D., & Yu, W. (2024). Deep learning enhanced crack detection for tunnel inspection. In International Conference on Transportation and Development 2024.

[5]. Jeong, S., et al. (2023). Crack inspection in tunnel structures by fusing information from a 3D light detection and ranging and pan-tilt-zoom camera system. Structures, 58. Elsevier.

[6]. O'Brien, D., et al. (2023). Automated crack classification for the CERN underground tunnel infrastructure using deep learning. Tunnelling and Underground Space Technology, 131, 104668.

[7]. Sjölander, A., et al. (2023). Towards automated inspections of tunnels: A review of optical inspections and autonomous assessment of concrete tunnel linings. Sensors, 23(6), 3189.

[8]. Machado, L. B., & Futai, M. M. (2024). Tunnel performance prediction through degradation inspection and digital twin construction. Tunnelling and Underground Space Technology, 144, 105544.

[9]. Aela, P., et al. (2024). UAV-based studies in railway infrastructure monitoring. Automation in Construction, 167, 105714.

[10]. Ouyang, A., et al. (2023). Automated pixel-level crack monitoring system for large-scale underground infrastructure–A case study at CERN. Tunnelling and Underground Space Technology, 140, 105310.

Cite this article

Lai,M. (2024). A study on drone-based detection and recognition of concrete surface cracks in tunnels using advanced imaging and machine learning techniques. Advances in Operation Research and Production Management,3,32-36.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Journal:Advances in Operation Research and Production Management

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Ahmad, A. A. (2023). Application of machine learning in drone technology for tracking cattle movement. Indian Journal of Animal Research, 57(12), 1717-1724.

[2]. Boopathi, S. (2024). Advancements in machine learning and AI for intelligent systems in drone applications for smart city developments. In Futuristic e-Governance Security With Deep Learning Applications (pp. 15-45). IGI Global.

[3]. Brighente, A., et al. (2023). ADASS: Anti-Drone Audio Surveillance Sentinel via Embedded Machine Learning. In 2023 IEEE Sensors Applications Symposium (SAS). IEEE.

[4]. Al Shafian, S., Hu, D., & Yu, W. (2024). Deep learning enhanced crack detection for tunnel inspection. In International Conference on Transportation and Development 2024.

[5]. Jeong, S., et al. (2023). Crack inspection in tunnel structures by fusing information from a 3D light detection and ranging and pan-tilt-zoom camera system. Structures, 58. Elsevier.

[6]. O'Brien, D., et al. (2023). Automated crack classification for the CERN underground tunnel infrastructure using deep learning. Tunnelling and Underground Space Technology, 131, 104668.

[7]. Sjölander, A., et al. (2023). Towards automated inspections of tunnels: A review of optical inspections and autonomous assessment of concrete tunnel linings. Sensors, 23(6), 3189.

[8]. Machado, L. B., & Futai, M. M. (2024). Tunnel performance prediction through degradation inspection and digital twin construction. Tunnelling and Underground Space Technology, 144, 105544.

[9]. Aela, P., et al. (2024). UAV-based studies in railway infrastructure monitoring. Automation in Construction, 167, 105714.

[10]. Ouyang, A., et al. (2023). Automated pixel-level crack monitoring system for large-scale underground infrastructure–A case study at CERN. Tunnelling and Underground Space Technology, 140, 105310.