1. Introduction

With the increasing global demand for clean energy, the new energy vehicle industry is showing an explosive growth trend. As the core component of new energy vehicles, the application scale of power batteries is rapidly expanding. However, the generation of a large number of retired power batteries has brought potential problems such as resource waste and environmental pollution, making the importance of the power battery recycling industry increasingly prominent. The recycling of power batteries can not only achieve efficient recycling of resources, alleviate the supply pressure of key raw materials, but also effectively reduce environmental pollution risks, which is in line with the strategic needs of sustainable development. But currently, the shortage of professional talents seriously restricts the development process of the industry. High quality talents with professional knowledge and practical skills are urgently needed in key processes such as battery disassembly, material sorting, and hierarchical utilization [1, 2].

In this context, it is of great significance to conduct in-depth research on the international advanced talent cultivation paradigm for power battery recycling. International countries and regions have accumulated rich experience in this field, which provides reference for Chinese universities to explore suitable talent training paths. As an educational institution actively engaged in talent cultivation in the field of new energy, Geely College has explored a series of innovative talent cultivation methods by combining its own “three campuses” strategy and drawing on international experience. Its exploration and practice in talent cultivation have certain representativeness and reference value, and are expected to provide useful references for the improvement of China's power battery recycling talent cultivation system, promoting the healthy and rapid development of the industry [3].

2. Comparison of international talent cultivation paradigms for power battery recycling

2.1. EU: legislative mandatory path

2.1.1. Policy system

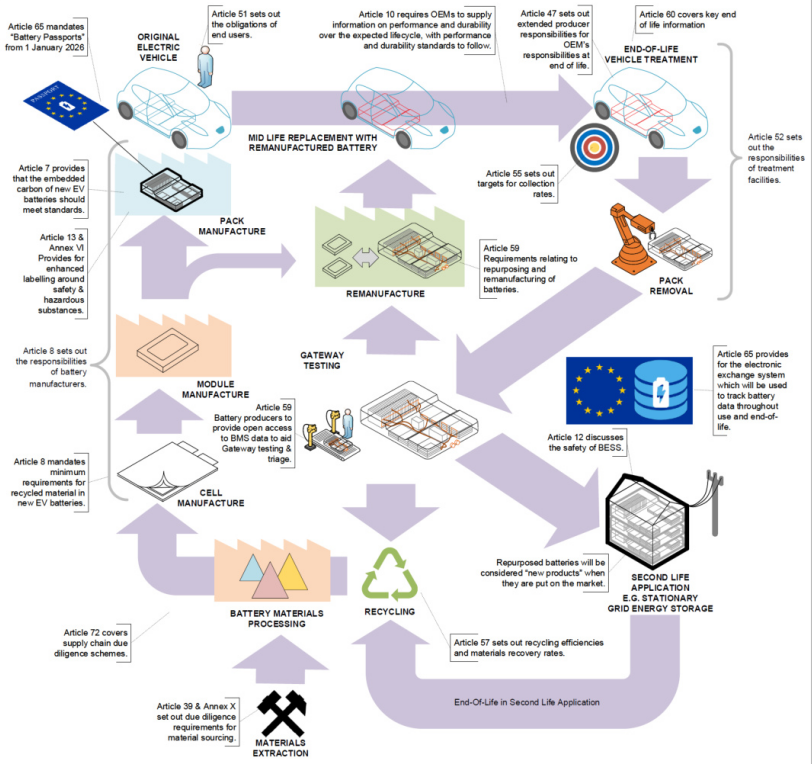

On August 17, 2023, the European Union officially promulgated and implemented the “New Battery Law” (Regulation (EU) 2023/1542), which came into full effect on February 18, 2024, and put forward strict and comprehensive requirements for the full lifecycle management of power batteries [4]. Among them, the recycling rate target for light vehicle batteries is clearly stipulated: it needs to reach 51% by 2028 and climb to 61% by 2031. At the same time, regulations have set specific and phased recovery rate targets for key metals such as lithium, cobalt, and nickel. For example, by 2027, the recovery rate for lithium needs to reach 50%, while the recovery rate for metals such as cobalt, nickel, and copper needs to be as high as 90%. In addition, the regulations have innovatively introduced a “battery passport” system, requiring the gradual disclosure of battery carbon footprint data from July 2025 and the full achievement of material recycling rate standards by 2026. The construction of this series of policy systems provides a clear direction and path for talent cultivation in the field of power battery recycling, requiring practitioners to have a deep understanding of core technologies such as carbon footprint accounting, data traceability, and multi metal sorting, as shown in Figure 1.

Figure 1. A circular economy for electric vehicle batteries, key articles from the proposed EU battery regulation [4]

2.1.2. Educational practice

The EU actively promotes talent cultivation practices in the field of power battery recycling through deep collaboration between industry, academia, and research. Bosch and BMW have collaborated on an energy storage project and successfully developed an AR disassembly training system, allowing students to undergo skill training in a virtual simulation environment and then enter the practical training stage for actual combat exercises. Belgium's Umicore Group has established a training base for pyrometallurgical recycling technology, providing students with a large-scale, industrial level practical platform to personally experience and master the entire process of recycling technology. In addition, the European Battery Institute plans to train 800,000 battery industry workers by 2025, covering multiple modules such as disassembly safety, recycling processes, and material sorting, providing the industry with a large number of professionals with professional skills and practical experience.

2.2. Germany: extended path of producer responsibility

2.2.1. Innovation in dual system education innovation

Based on the EU Waste Framework Directive (2008/98/EC) and the Battery Recycling Directive (2006/66/EC), Germany has clearly defined the specific responsibilities and obligations of producers, sellers, and consumers in the recycling chain. The GRS Foundation, jointly established by battery manufacturers and electronics associations, operates the largest lithium-ion battery recycling network in Europe. The foundation has established an advanced virtual simulation training room for live dismantling through school enterprise cooperation, and equipped it with a KUKA robotic arm programming workstation, providing students with a fully realistic simulation practical environment. At the same time, the “Battery Recycling Safety Engineer” micro certificate course certified by T Ü V S Ü D closely aligns its assessment standards with VDI 2343 technical specifications, ensuring that students can comprehensively master the safety knowledge and skills in the battery recycling process.

2.2.2. Building a reverse logistics system

Volkswagen has established a battery bank system, achieving traceability and recycling of over 95% of battery packs, setting an industry benchmark. The system provides talent with a full process practical scenario from battery traceability diagnosis, cascading utilization to final recycling through a manufacturer led closed-loop management mode. This full process practical model not only enhances the professional skills of talents, but also strengthens their overall understanding and grasp of the battery recycling industry.

2.3. Japan: 3R manufacturing concept driven model

2.3.1. Curriculum system reform

Japan has deeply integrated the 3R concept of “Reduce, Reuse, and Recycle” into its education system, committed to cultivating professional talents with environmental awareness and innovative capabilities [5, 6]. Nissan and Sumitomo have jointly developed a tiered utilization certification system and incorporated relevant technical standards into 12 courses, including “Battery Regeneration Engineering”, enabling students to comprehensively master the knowledge and skills of battery tiered utilization during the learning process. Meanwhile, well-known companies such as Toyota and Panasonic have adopted advanced technologies such as AI visual sorting, significantly improving the recycling efficiency of precious metals and setting a model for technological innovation in the industry. The private recycling network established by the Japan Battery Industry Association (BBA) covers over 93% of consumer terminals, providing colleges with rich practical scenarios such as battery sorting and wet metallurgy, enabling students to continuously improve their professional skills and practical experience in practice.

2.3.2. Social participation mechanism

Since 1994, Japan has implemented a producer recycling program, relying on reverse networks such as retailers and gas stations to collect used batteries. The government requires companies to publicly disclose their recycling data and enhance public awareness of participation through laws and regulations such as the “Promotion of Effective Resource Utilization Law”. This favorable atmosphere of government guidance, corporate entities, and public participation provides strong social support for the development of the power battery recycling industry.

2.4. United States: industry university research alliance model

2.4.1. Driven by technological innovation

The United States strongly supports industry university research cooperation through federal funds to promote technological innovation and development in the field of power battery recycling. Tesla and Redwood Materials have jointly established an industry academy and developed an AR disassembly training system, which has received government funding and support. The ultrasonic separation technology developed by Massachusetts Institute of Technology (MIT) has achieved a recovery purity of 99.9% for positive electrode materials. This technology utilizes the high-frequency vibration of ultrasound to efficiently separate positive electrode materials from other components without damaging the material structure. It has the advantages of high separation efficiency, high purity, and low energy consumption. Currently, it has been applied in some high-end battery recycling enterprises, but it still faces challenges such as high equipment costs and limited processing capacity in large-scale industrial promotion. At the same time, the close cooperation between universities and enterprises has effectively promoted the docking and transformation of scientific research achievements in universities with industrial demands.

2.4.2. Standard system construction

The Portable Rechargeable Battery Association (PRBA) has developed a comprehensive closed-loop recycling standard, covering over 85% of recycling companies in the United States and leading the development of industry standards. In addition, the construction and improvement of laws and regulations such as the Mercury and Rechargeable Battery Management Act and the California Rechargeable Battery Recycling Act have formed a three-level regulatory system from federal to state, providing solid legal protection and support for talent cultivation in the field of power battery recycling. This sound standard system not only standardizes the industry's code of conduct, but also enhances the overall level and competitiveness of the industry. Among them, NORSOK (Norwegian Petroleum Industry Standard) is mainly used in the evaluation system for talent cultivation in power battery recycling to standardize and evaluate safety management, quality control, and other aspects of the battery recycling process. The introduction of this standard helps to enhance the professionalism and standardization of talent cultivation, ensuring that the trained talents have a high level of recognition internationally, and enhancing students' international competitiveness and employment advantages [7].

Based on a comprehensive analysis of the international talent cultivation paradigm for power battery recycling, the EU's legislative mandatory promotion model suggests that Geely College should closely focus on policy guidance to align talent cultivation with industry standards; The dual education system and reverse logistics system construction in Germany demonstrate the importance of deep cooperation between schools and enterprises; The integration of Japan's 3R concept into curriculum and social participation mechanisms emphasizes the value of cultivating students' awareness of environmental protection and innovation, as well as social collaboration; The construction of industry university research alliances and standard systems in the United States highlights the key role of technological innovation and normative standards in talent cultivation. Based on the “Three Campuses” strategy and drawing on these experiences, Geely College has formulated the following talent development plan.

3. Talent cultivation plan of Geely College based on the “three campuses” strategy

3.1. Cross disciplinary campus: building a school enterprise collaborative education ecology with deep integration of industry and education

Geely College actively responds to the “cross-border campus” strategy and collaborates with Geely Holding Group and its leading enterprises in the industry chain (such as Volvo, Jike, etc.) to jointly establish a “dual subject” education mechanism. On campus, the college has set up a Power Battery Recycling and Recycling Industry College, introducing standardized production lines for enterprises, covering core equipment such as battery disassembly and hierarchical utilization. The training projects are strictly reshaped according to the “Enterprise Job Capability Map” to ensure a 1:1 accurate connection between teaching scenarios and production processes. The technical backbone of the enterprise is deeply integrated into the teaching system as a “resident engineer”, and jointly develops loose leaf teaching materials such as “New Energy Battery Testing Technology” and “Intelligent Connected Vehicle Operation and Maintenance” with college teachers. The real cases of the enterprise are transformed into modular courses to ensure that the teaching content is synchronized with the iteration of industrial technology. By implementing the “work study alternation” model, students can enter key positions in enterprises for rotational internships in their junior year and participate in horizontal research and development projects, forming a virtuous cycle of “learning practice innovation”.

3.2. Cross district campus: building a “dual circulation” educational resource network

3.2.1. Integration of international resources

Relying on the “Core Education” digital platform, Geely College has jointly established the China Europe Joint Laboratory for New Energy Vehicles with well-known European universities such as Berlin Institute of Technology in Germany and Chalmers University of Technology in Sweden, and jointly launched a dual mentorship master's program. In 2024, the college has selected 32 outstanding teachers to study battery recycling technology standards in EU enterprises and successfully introduced international certification courses such as ISO 14040 life cycle assessment. At the same time, the college has also established the “ASEAN Vocational Education Alliance”, jointly building a cross-border credit recognition system with Southeast Asian universities such as Thailand's Xianhuang Institute of Technology and Vietnam's Hanoi University of Technology, to achieve the sharing and win-win of course resources and faculty.

3.2.2. Domestic regional industrial linkage

Geely College is deeply embedded in regional development strategies such as the G60 Science and Technology Innovation Corridor in the Yangtze River Delta and the Chengdu Chongqing Economic Circle, and collaborates with new energy industry giants such as Ningde Times (Ningde) and BYD (Shenzhen) to build a new energy industry innovation center. By implementing a “migratory bird” teaching mechanism, students can complete courses such as “High Voltage Electronic Control System Fault Diagnosis” and “Powertrain Matching Technology” in stages at Geely Research Institute (Ningbo), Lingang Intelligent Automobile Industry Park (Shanghai), and other places, forming a characteristic training path of “multi location collaboration and segmented advancement”.

3.3. Parallel campus: building a “digital twin” teaching system

3.3.1. Construction of intelligent teaching platform

Based on the “parallel campus” strategy, Geely College has successfully developed the Geely Education Metaverse Platform, integrating cutting-edge technologies such as blockchain credit banks and AI learning analysis engines to achieve real-time cross campus access to teaching resources. The platform has launched 328 virtual simulation projects, including the VR Power Battery Disassembly Simulation System and AR Motor Assembly Training Module. It supports students to complete high-risk operation training through digital avatars and generate personalized ability radar charts based on learning behavior data, providing accurate guidance for students' growth and development.

3.3.2. Innovation of blended learning mode

Geely College adopts the “O2O Double Spiral” teaching method, conducting theoretical teaching and virtual training online through the metaverse platform, and conducting practical training on “real equipment, real products, and real orders” offline at Geely Automobile Smart Factory (Chengdu), forming a virtual real linkage ability training chain. The 2024 students have successfully completed the NIO ET5 motor assembly project through this model, and their achievements have been directly applied to the enterprise production line, achieving seamless integration between teaching and production.

4. Innovative ideas on curriculum system and integration of industry and education

4.1. Curriculum system restructuring: building a modular system of “three chains connection”

With the rapid development of the global new energy vehicle industry, the demand for high-quality and innovative new energy vehicle talents is becoming increasingly urgent. In order to meet this demand, based on the “three campuses” internationalization strategy of “main campus + overseas campus + cloud campus”, closely in line with the strategic orientation of “Made in China 2025” for talents in the field of new energy vehicles, an innovative modular curriculum system of “basic chain - capability chain - innovation chain” is constructed, which is interconnected and organically integrated.

4.1.1. Basic chain course module

The basic chain course module is the cornerstone of the curriculum system, aimed at consolidating students' knowledge of fundamental disciplines such as automotive construction, materials science, electronics and electrical engineering, and computer science. This article selects classic courses such as “Fundamentals of Automotive Engineering”, “Mechanics of Materials”, and “Principles of Circuits” to ensure that students have a solid theoretical foundation. At the same time, integrating cutting-edge courses such as “New Energy Vehicles and Intelligent Connected Vehicle Technology”, guiding students to understand the latest technologies and development trends in the field of new energy vehicles. Through the study of basic chain courses, students will have a comprehensive understanding of the new energy vehicle industry, laying a solid foundation for subsequent professional learning and practical innovation.

4.1.2. Advanced module of capability chain

The advanced module of the ability chain further enhances students' professional skills and practical abilities on the basis of the basic chain course. This article designs three sub modules: international cooperation module, cross-border practice module, and intelligent technology module.

1. International Cooperation Module

Introduce international standards such as the UN ECE R100 electric vehicle safety standard to enable students to understand and master advanced new energy vehicle technologies and standards internationally. Deeply embedded in Volvo's global technology certification system, enhancing students' international perspective and cross-cultural communication skills through cooperation with internationally renowned enterprises. Offering international exchange courses, inviting foreign experts to give lectures at the school, organizing students to participate in international academic conferences and competitions, and broadening students' international perspectives.

2. Cross border Practice Module

Implement a three-level progressive teaching mechanism of “curriculum project competition”, transform practical cases of Geely Automobile battery dismantling technology and other enterprises into teaching projects, and enable students to learn and master professional skills through practice. Establishing cooperative relationships with multiple new energy vehicle companies and setting up off campus internship bases to provide students with more practical opportunities. Encourage students to participate in innovation and entrepreneurship projects, apply their learned knowledge to solve practical problems, and cultivate their innovative spirit and practical ability.

3. Intelligent technology module

Keeping up with industry development trends, we will develop characteristic courses such as “AI Battery Residual Value Assessment” and “Big Data Traceability Management” to cultivate students' intelligent technology application abilities and innovative thinking. Introduce cutting-edge technologies such as artificial intelligence and big data, combine them with the actual needs of the new energy vehicle field, and offer interdisciplinary courses such as “Intelligent New Energy Vehicle Technology” and “Battery Management System and Big Data Analysis”. Establish an intelligent technology laboratory equipped with advanced experimental equipment and software tools to provide students with a good experimental environment and practical platform.

4.1.3. Innovation chain expansion module

The innovation chain expansion module aims to cultivate students' innovative spirit and research ability, and promote the deep integration of industry, academia, research and application. We have set up the innovative project of “unveiling the list and leading the way” to encourage students to actively participate in scientific research projects and technological breakthroughs. At the same time, close cooperation has been established with research institutions such as Geely Research Institute to jointly carry out cutting-edge technology research and application development.

1. Set up innovative topics

Based on the hot issues and practical needs in the field of new energy vehicles, a series of innovative topics have been set up, such as “Research on Power Battery Cascade Utilization Technology” and “Development of Intelligent Connected Vehicle Safety Technology”. Encourage students to form teams freely, choose topics independently for research and exploration, and cultivate their self-learning ability and teamwork spirit.

2. Establish a dynamic update mechanism

Every semester, based on authoritative materials such as the Global Battery Material Recycling Industry Report, 30% of the practical teaching content is adjusted to ensure the timeliness and cutting-edge nature of the curriculum system. Invite industry experts and technical personnel from enterprises to give lectures and exchange ideas at the school, integrating the latest technological trends and industry trends into the course teaching.

3. Promote the deep integration of industry, academia, research and application

Establish close cooperative relationships with research institutions such as Geely Research Institute to jointly apply for scientific research projects and technological breakthroughs. Transforming scientific research achievements into teaching cases and experimental projects, involving students, and cultivating their research and practical innovation abilities. Promote the industrial application of scientific research achievements, and facilitate the deep integration and development of industry, academia, research and application.

4.2. Industry education integration mechanism: building a “six dimensional collaborative” industry education integration ecosystem

The integration of industry and education, as an important way to deeply integrate higher education with industrial development, plays a crucial role in cultivating high-quality talents and promoting industrial innovation. This article adheres to the collaborative concept of “dual subjects and four commonalities”, that is, schools and enterprises as dual subjects, jointly formulate standards, build facilities, educate people, and evaluate, deepen school enterprise cooperation, and strive to build a “six dimensional collaborative” industry education integration ecosystem. In this ecosystem, the joint construction mechanism of industrial colleges and the research feedback teaching mechanism are closely connected and work together. It is necessary to clarify the boundary between the two. The joint construction mechanism of industrial colleges focuses on the construction of talent training models, while the research feedback teaching mechanism focuses on the transformation of teaching content and research achievements.

4.2.1. Joint construction mechanism of industrial colleges: deep integration, joint cultivation of talents

The joint construction mechanism of industrial colleges is one of the core contents of the integration of industry and education. Through deep cooperation between schools and enterprises, we can jointly create a new talent training model that meets the needs of industrial development.

1.Co construction standards

The school and enterprise jointly formulated the “Capability Standards for Power Battery Recycling Engineers”, which is based on the job qualifications of companies such as Geely Group, and is refined into seven capability matrices. It clarifies the talent training goals and directions from multiple dimensions such as battery disassembly, material analysis, hierarchical utilization, and safety regulations, ensuring that talent training meets market demand and providing accurate guidance for talent training in industrial colleges. It refers to the ideas of the International Organization for Standardization (ISO) in developing standards in relevant fields to ensure the consistency and standardization of talent training quality.

2. Co construction of facilities

Both parties will work together to establish physical teaching platforms such as the “Disassembly Process Simulation Laboratory” and the “Material Analysis and Testing Center”, equipped with advanced teaching equipment such as Volvo V60 plug-in hybrid battery packs. These facilities simulate real production environments, expose students to advanced industry technologies, provide them with rich practical opportunities, enhance their practical operation abilities and skill levels, and enable them to quickly adapt to the job requirements of enterprises after graduation. They draw on the practice of EU enterprises providing practical platforms for education.

3. Educational Model

Implement the “3+1” engineering alternation training program, where students systematically study theoretical knowledge in school for the first three years and build a solid professional foundation; In the final year, I delved into corporate internship practice, where my mentor taught core courses and closely integrated theory with practical production. This model allows students to deepen their theoretical understanding, master practical operational skills, comprehensively cultivate comprehensive qualities and professional abilities, and achieve a smooth transition from campus to the workplace, which is in line with the German dual education model.

4. Evaluation system

Introduce international certification systems such as NORSOK (Norwegian Petroleum Industry Standards) and establish a mechanism for the exchange of course credits and enterprise skills certification. The NORSOK standard strictly regulates the safety management and quality control of battery recycling, and introduces this standard to enhance the internationalization level of talent cultivation. Through this evaluation mechanism, students can obtain both school course credits and internationally recognized enterprise skill certifications, enhancing their international competitiveness and employment advantages, making them more competitive in the global talent market. This refers to the practice of introducing international certifications in international vocational education to improve talent quality.

4.2.2. Research feedback teaching mechanism: mutual promotion between research and teaching

The mechanism of scientific research feeding back teaching is an important way to achieve mutual promotion and a virtuous cycle between scientific research and teaching. This article establishes a research feedback teaching system that links the “project pool talent pool achievement pool” three pools.

1. Horizontal project collaboration

Actively undertake technological transformation projects from companies such as Geely Automobile, such as “non-destructive disassembly of Jike 001 battery housing”. By transforming these practical projects into teaching cases and integrating them into daily teaching, students can understand the actual technical problems and solutions of enterprises, enrich the teaching content, enhance their engineering practice and problem-solving abilities, and better apply theoretical knowledge to practice. This refers to the project driven teaching approach in industry university research cooperation in the United States.

2. Longitudinal research topic

Jointly apply for provincial and ministerial level scientific research projects, such as “Research and Development of Intelligent Sorting Equipment for Retired Power Batteries”. Transform scientific research achievements into teaching software, such as “Virtual Simulation of Power Battery Recycling Process”, and apply it to the teaching process. These teaching software display complex recycling processes in an intuitive and interactive way, enhancing the technological content and innovation of teaching, cultivating students' scientific research ability and innovative thinking, stimulating students' interest in scientific research and exploration spirit, and drawing on the concept of Japanese enterprise technology innovation achievements feeding back education.

3. Innovation platform construction

Establish innovative platforms such as the “Battery Material Recycling Innovation Workshop” and implement the CDIO teaching model (ideation design implementation operation) of “enterprise problem solving teacher-student problem solving market testing”. Enterprises raise questions based on actual production needs, teachers and students participate in solving them together, and finally the results are verified by the market. This model promotes the deep integration of industry, academia, research and application, making scientific research results more in line with market demand. At the same time, it enables students to enhance their comprehensive abilities in solving practical problems, and cultivates talents with innovative ability and practical experience for industrial development. It refers to the EU's model of collaborative innovation between industry, academia and research.

5. Conclusion

This article comprehensively summarizes the international talent cultivation paradigm for power battery recycling, including mandatory EU legislation, extended German producer responsibility, Japan's 3R concept driven approach, and the American industry university research alliance, each with its own characteristics, providing valuable experience for China. Geely College actively innovates based on the “Three Campuses” strategy. Intelligent technology empowers the curriculum system, modular design enhances flexibility, virtual real integration teaching enhances practical abilities, and technology standards are aligned to ensure the quality of talent cultivation. In terms of industry education integration, the “four chain synergy” promotes the deep integration of education and industry, and the integration of “job, course, competition, and certification” comprehensively enhances students' comprehensive competitiveness. In the future, China should deepen international exchanges, draw on advanced experience, continuously improve the talent training system, strengthen cooperation among all parties, increase investment, provide sufficient talent support for the power battery recycling industry, help China seize the opportunity in the global competition in the new energy industry, and promote sustainable development of the industry.

Funded project

the “One College, One Brand” characteristic project of Geely College's educational reform project: Research on the Construction and Teaching Reform Practice of Power Battery Recycling Technology Course Group (2024JG30015);

the “Youth Research Fund” general project of Geely College: Research on Intelligent Decision Support System in Power Battery Recycling and Reuse (2024xzkqP016).

References

[1]. Shi, L. (2022). Teaching Reform and Exploration of “Lithium ion Battery and Recycling” Course in Resource Comprehensive Utilization Technology. Modern Salt Chemical Industry, 49(04), 109-111.

[2]. Always on. (2024). The talent cultivation path for new energy battery professionals under the background of “dual carbon”. Battery, 54(03), 432-434.

[3]. Lin, C., Qin, T., & You, S. (2024). Exploration on the cultivation of practical talents in the field of new energy vehicles in application-oriented undergraduate universities: taking the School of Automotive and Transportation Engineering at Guangdong Normal University as an example. Times Automotive(07), 34-36.

[4]. Melin, H. E., Rajaeifar, M. A., Ku, A. Y., et al. (2021). Global implications of the EU battery regulation. Science, 373(6553), 384-387.

[5]. Zhao, Y., Pohl, O., & Bhatt, A. I. (2021). A review on battery market trends, second-life reuse, and recycling. Sustainable Chemistry, 2(1), 167-205.

[6]. Pesaran, A., Roman, L., & Kincaide, J. (2023). Electric Vehicle Lithium-Ion Battery Life Cycle Management. National Renewable Energy Laboratory (NREL), Golden, CO (United States). https://doi.org/10.2172/1924236

[7]. Dawson, L., Ahuja, J., & Lee, R. (2021). Steering extended producer responsibility for electric vehicle batteries. Environmental Law Review, 23(2), 128-143.

Cite this article

Xi,L.;Xu,W.;Zhang,L.;Zhao,C.;Wang,L. (2025). Exploration of talent cultivation for power battery recycling based on Geely College's "Three Campus" strategy. Advances in Social Behavior Research,16(4),25-32.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Journal:Advances in Social Behavior Research

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Shi, L. (2022). Teaching Reform and Exploration of “Lithium ion Battery and Recycling” Course in Resource Comprehensive Utilization Technology. Modern Salt Chemical Industry, 49(04), 109-111.

[2]. Always on. (2024). The talent cultivation path for new energy battery professionals under the background of “dual carbon”. Battery, 54(03), 432-434.

[3]. Lin, C., Qin, T., & You, S. (2024). Exploration on the cultivation of practical talents in the field of new energy vehicles in application-oriented undergraduate universities: taking the School of Automotive and Transportation Engineering at Guangdong Normal University as an example. Times Automotive(07), 34-36.

[4]. Melin, H. E., Rajaeifar, M. A., Ku, A. Y., et al. (2021). Global implications of the EU battery regulation. Science, 373(6553), 384-387.

[5]. Zhao, Y., Pohl, O., & Bhatt, A. I. (2021). A review on battery market trends, second-life reuse, and recycling. Sustainable Chemistry, 2(1), 167-205.

[6]. Pesaran, A., Roman, L., & Kincaide, J. (2023). Electric Vehicle Lithium-Ion Battery Life Cycle Management. National Renewable Energy Laboratory (NREL), Golden, CO (United States). https://doi.org/10.2172/1924236

[7]. Dawson, L., Ahuja, J., & Lee, R. (2021). Steering extended producer responsibility for electric vehicle batteries. Environmental Law Review, 23(2), 128-143.