1.Introduction

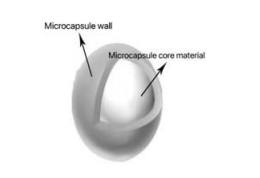

Microencapsulation, also known as microencapsulating, refers to a type of microcontainer or packaging with a polymeric shell. It is a technique that uses microencapsulation technology to enclose small particles or droplets in a film-forming material, thereby creating micro- or nano-sized capsules with a core-shell structure and uniform dimensions [1], typically ranging from 1-250 μm in diameter [2]. The composition consists of a core material and a wall material. The core material refers to the substance being encapsulated, while the wall material refers to the external coating. The wall material is typically a highly stable substance, while the core material contains functional components. The wall material surrounds the core material, providing protection to the core. Based on the properties of the core and wall materials, and the different microencapsulation technologies, microencapsulates can be categorized into multilayer single-core, single-layer multi-core, single-layer single-core, and irregular single-layer single-core types [1]. Microencapsulation technology refers to a novel technique in which the core material (such as polysaccharides, peptides, probiotics, additives, etc.) is emulsified with a wall material chosen according to the nature of the core, and then tightly encapsulated in the wall material under specific conditions. The resulting product is a powder-like microencapsulate after drying [33]. This article primarily discusses the classification, preparation processes, and applications of microencapsulation in drug formulations, providing reference materials for research and development in the field of microencapsulation.

Figure 1. Concept Diagram of Microencapsulation Figure 2. Main Types of Microencapsulation

2.Preparation materials of microencapsulation

In the synthesis and preparation of microencapsulates, the core material can be solid, liquid, or gas, or it can be a mixture of solid and liquid, liquid and liquid, solid and gas, or liquid and gas [33]. For example, volatile ingredients or additives such as flavorings and fragrances in food can serve as “gas” core materials. The selection of the wall material is also critical. Choosing the right wall material can significantly improve the encapsulation efficiency, encapsulation rate, and stability of the microencapsulate. The nature of the wall material largely determines the physicochemical properties of the product. An ideal wall material should have the following characteristics: the core material can be effectively encapsulated without affecting the core material’s properties or functions; it should have appropriate mechanical strength, solubility, flowability, emulsifying ability, permeability, and stability; it should not chemically react with the core material; it should enable controlled release of the core material under specific conditions; it should be reasonably priced and easy to obtain [3]. The wall material can be a single material or a mixture of multiple materials. If one wall material is insufficient to protect the encapsulated core, a combination of different wall materials can be used to enhance the protective effect, thereby improving the core material’s performance [4]. The selection of the wall material depends on the nature and function of the core material, the encapsulation method, and the ideal properties of the final product. Each wall material has distinct advantages and disadvantages in terms of chemical, physical, and biological performance, and the choice should be made based on the specific situation [5].

2.1.Classification and characteristics of microencapsulation wall materials

2.1.1.Carbohydrate-based wall materials

Resistant Starch: Resistant starch is a component of starch that is resistant to digestion in the small intestine. It is found in higher concentrations in plant-based starches. By applying microencapsulation technology and adding plant starch as a wall material, the lyophilization protection rate and storage performance of Lactobacillus microencapsulates can be enhanced, allowing the probiotics to reach the intestines and exert their effects [6]. As an insoluble dietary fiber, resistant starch has beneficial physiological effects. It has a synergistic effect with Lactobacillus, and the resulting synbiotics help regulate the intestinal microbiota and prevent or assist in the treatment of diseases [7].

Cyclodextrins: β-Cyclodextrin, used as a wall material to prepare compound nano-microencapsulates of Artemisia annua, maintains the core material’s original activity, providing a good controlled-release effect and cognitive-enhancing properties [8]. Using hydroxypropyl-β-cyclodextrin as a wall material to encapsulate the lipid-soluble rosemary extract as the core material significantly enhances the antioxidant capacity of the extract and provides controlled release [9].

Alginate Salts: Alginate salts have several advantages, including wide availability, low cost, non-toxicity, high biocompatibility, resistance to digestion, good solubility, and controllable release properties. These characteristics make them ideal for encapsulating probiotics and maintaining stable viable bacterial counts in the microcapsules, increasing the encapsulation rate of probiotics. Alginate is the most commonly used wall material for probiotic microencapsulation [10]. Alginate’s ability to form microgels is used to protect probiotics. Due to its heat resistance and lyophilization tolerance, alginate is widely applied in studies of co-microencapsulation with various probiotics. Further research [11] shows that when sodium alginate hydrogel shells are formed, adding appropriate amounts of cellulose, nanofibers, and lecithin can enhance the binding on the porous surface of the hydrogel, significantly improving its isolation strength and reducing the interaction between the core material and the outside environment. Using sodium alginate as a wall material to prepare tea tree oil microencapsulates not only preserves the original properties of tea tree oil but also provides a good controlled-release effect [12].

Chitosan: Chitosan, which is cross-linked through ionic interactions, has good biocompatibility and high sensitivity to changes in pH, leading to excellent swelling properties [13]. Chitosan can also enhance the gel structure of alginate. One study [14] used chitosan to perform a secondary encapsulation of sodium alginate microcapsules that encapsulate bifidobacteria. The results showed that chitosan encapsulation improved the sealability of the microcapsules and increased the survival rate of the probiotics. Another experiment [15] prepared chitosan microcapsules with a controllable nanofilm for the controlled release of tea tree oil. These chitosan microcapsules exhibited good rapid release performance and antibacterial properties.

Other Carbohydrates: Arabic gum has good film-forming and plasticizing properties, and during the drying process, it can quickly form a hard shell to encapsulate probiotics and reduce their loss. Arabic gum, as a wall material, has been used to prepare arabic gum-Lactobacillus peptides microcapsules, significantly improving antimicrobial stability and durability [16]. Modified cellulose, which has been chemically or physically altered, introduces new functional groups that can greatly enhance its mechanical properties and thermal plasticity, making it an ideal choice for microencapsulation preparation [17]. Marine polysaccharides possess unique gelling and film-forming properties. Not only do they provide excellent emulsifying, gelling, and film-forming functions, but they also form three-dimensional gel networks, matrices, or protective films that protect and stabilize encapsulated probiotics. They also exhibit anti-inflammatory effects and improve intestinal microbiota, demonstrating a synergistic promotion effect with probiotics, as well as some targeted delivery and release capabilities [18].

2.1.2.Protein-based wall materials

Whey protein, when used as a wall material for microencapsulating probiotics, can reduce the loss of probiotics during the drying process and protect them from the adverse effects of the gastrointestinal tract and other harsh environments, improving their tolerance and stability in the digestive system. Whey protein isolate, used as a wall material for microencapsulating natural chlorophyll in bread preparation, can enhance the stability of natural chlorophyll, increase the hardness, elasticity, and chewiness of the bread, and improve the bread’s crude fat content, total amino acids, and essential amino acids content [19]. Wheat peptides, derived from wheat proteins through enzymatic hydrolysis, exhibit various biological activities such as antioxidant, immune regulation, blood sugar regulation, gastrointestinal protection, and antitumor properties. Wheat peptides, which contain multiple amino acids, can be used as wall materials to encapsulate vitamin D, improving its stability, extending storage time, and preserving the activity of vitamin D [20]. Casein combined with cassava dextrin as wall materials, and olive oil and coconut oil as core materials, was used to prepare microcapsules with high oil content and excellent encapsulation efficiency [21].

2.1.3.Composite wall materials

Microcapsules prepared using sodium alginate-pectin-whey protein isolate composites as wall materials exhibit extremely high encapsulation rates for probiotics. These microcapsules are able to survive in the stomach and release the probiotics in intestinal fluids [22]. Sodium alginate and carrageenan composites, used as microencapsulation wall materials with fructooligosaccharides as a protectant, were used to encapsulate Bifidobacteria, resulting in significantly improved encapsulation and survival rates of the probiotics, with good tolerance in harsh environments such as simulated gastric fluid [23]. Xanthan gum and chitosan polyelectrolyte complex gels protect probiotic cells from adverse environmental conditions and increase their survival rates [24]. Oxidized high-amylose starch and sodium alginate composite microcapsules provide protective effects for probiotics [26]. Glyceryl monostearate (GMS), a common food emulsifier and additive, and sodium starch octenyl succinate (SSO), a highly safe emulsifying thickener and an excellent microencapsulation wall material, can be used to encapsulate water-insoluble and volatile substances. GMS and SSO composite wall materials, with L-menthol as the core material, were used to prepare thermosensitive L-menthol microcapsules. The resulting microcapsules exhibited complete structures, high encapsulation rates, strong stability, and the ability to release slowly at specific temperatures [27]. Sodium caseinate, a natural pH-dependent protein with good biocompatibility and biodegradability, can withstand acidic conditions and dissolve in neutral environments, making it an excellent enteric-coated carrier material [28]. Sodium caseinate-gelatin composite wall materials were used to prepare diclofenac sodium microcapsules, reducing dissolution in simulated gastric fluid, increasing dissolution in simulated intestinal fluid, and improving stability and drug bioavailability [30]. Experimental studies have shown that sodium alginate-chitosan oligosaccharide microcapsules encapsulating immunoglobulin Y can protect the immunoglobulin from gastric acid, preserving its immunological activity and stability [29].

2.2.Principles for selecting wall materials

Wall materials determine the encapsulation efficiency, stability, and controlled release properties of microcapsules. Their protective effects primarily manifest in the following three aspects: preventing radiation and corrosion from strong light, high temperatures, and strong acids and bases, thus increasing storage time; similar to drug capsules, they enable the sustained, slow, and prolonged release of active ingredients, extending the duration of their effect; and masking undesirable flavors or unpleasant sensory characteristics [25]. The wall material mainly serves to isolate the core material from the environment, preventing the core material from being affected by external factors.

A good wall material should have excellent stability, be able to encapsulate active internal substances and protect their activity, be cost-effective, form films easily, have good emulsifying properties, possess good biocompatibility and non-toxicity [31] , and provide a physical protective barrier against external environmental changes and pressure [32]. In addition to influencing the shaping and encapsulation effects of microcapsules, the wall material should also have suitable viscosity, plasticity, permeability, solubility, and stability [31]. Furthermore, wall materials should be selected based on the physicochemical properties of the core material, ensuring they do not chemically react with the core material, thereby achieving the intended research and application objectives [33].

3.Microencapsulation preparation process

Microencapsulation technology can entrap unstable solids, liquids, or gases within a semi-permeable or sealed wall membrane to protect the core material [34]. Currently, there are over 200 effective methods for preparing microcapsules, such as spray drying, extrusion, freeze-drying, interfacial polymerization, ion crosslinking, layer-by-layer self-assembly, and coacervation. The advantages and disadvantages of these methods are detailed in Table 1.

Spray Drying Method: This method involves the use of hot air to concentrate and dry liquid substances into solid particles [35]. Xinzhen Fu et al. [39] used spray drying to prepare butter microcapsules. Under optimal processing conditions, the encapsulation efficiency was high, and the resulting butter microcapsules were in dry powder form, light yellow, with a butter fragrance, good dispersibility, and no clumping. NAMBIAR R. B. et al. [40] used spray drying to prepare tender coconut water microcapsules. Under optimal process parameters, the resulting microcapsules had strong antioxidant capacity and good bioactivity.

Table 1. Commonly Used Microencapsulation Methods and Their Advantages and Disadvantages [1][33-38]

|

Preparation Method |

Advantages |

Disadvantages |

|

Spray Drying |

Simple operation, high encapsulation efficiency, uniform particle size |

Not suitable for heat-sensitive compounds, difficult particle size control |

|

Extrusion |

Simple operation, low cost, suitable for coating heat-unstable core materials |

Capsules must be separated from the liquid bath and dried, unsuitable for high-viscosity polymers |

|

Freeze Drying |

High stability, suitable for encapsulating heat-sensitive substances |

High cost, complex operation, product surface shrinkage |

|

Interfacial Polymerization |

Simple preparation process, easy operation |

Organic solvents used are somewhat toxic, waste liquids may cause environmental pollution |

|

Ion Crosslinking |

Mild reaction conditions, simple operation, high controllability, variety of combinations |

Uneven particle size distribution, poor stability of microcapsules |

|

Layer-by-Layer Self-Assembly |

Strong controllability, high encapsulation efficiency, and stability |

Complex preparation process, requires specific and appropriate templates |

|

Coacervation |

Wide variation in core material loading and microcapsule size, high encapsulation efficiency, diverse core materials |

Complex process, high cost |

Freeze-Drying Method: This method involves combining the core material with an emulsifier, then further combining it with the wall material to form an emulsion. The emulsion is then subjected to sublimation under low temperature and low pressure in a vacuum drying chamber, allowing water to sublimate and dehydrate the emulsion, resulting in high-quality dried microcapsules [33]. Li Zhou et al. [41] enhanced the survival rate and stress resistance of Lactobacillus acidophilus by preparing freeze-dried microcapsules. The results showed good release characteristics and acid resistance in artificial intestinal and gastric fluid tests, with improved storage stability and viability. Rajam et al. [42] encapsulated Lactobacillus plantarum MTCC5422 using freeze-drying. The resulting microcapsules were spherical, had good flow properties, and exhibited low hygroscopicity.

Interfacial Polymerization Method: This is a commonly used method for preparing microcapsules. In this process, the wall material and core material are dissolved in two or more immiscible solvents, and polymerization occurs at the interface between the phases, forming microcapsules. A suitable polymer must be chosen for the core material, and an appropriate wall material should be selected to achieve the desired properties and functions [36]. Vidal et al. [43] used interfacial polymerization to prepare microcapsules of maqui berry extract. The study showed that the encapsulation enhanced the stability of the extract, providing good protection and a high antioxidant capacity. Liu et al. [44] prepared osmanthus essential oil microcapsules using this method, and the results showed that microencapsulation effectively improved the stability of the essential oil and reduced its volatility. Wu Baiheng et al. [45] used interfacial polymerization to prepare polydopamine-nanoparticle-stabilized oxygen microcapsules as effective oxygen carriers. These microcapsules exhibited biocompatibility and could improve the hypoxic microenvironment of tumors, inhibiting tumor growth.

Other Methods: Ion Crosslinking Method uses ionic crosslinking agents to link various charged polymers, forming a microcapsule structure [36]. Jiang Tianyan et al. [46] used chitosan as the wall material and sodium tripolyphosphate as the anionic crosslinking agent to prepare CS/TPP fragrance microcapsules, which demonstrated good stability and effectively protected lemon fragrance, prolonging its scent. Layer-by-Layer Self-Assembly Method forms multilayer thin-wall structures encapsulating core substances by sequential deposition of polyelectrolytes and reversible crosslinkers at the nanoscale. To ensure compatibility and stability between the core and wall materials, surface modifications such as functional group introduction can be applied to the core material [36]. Ana Cadete et al. [47] used self-assembly techniques to prepare hyaluronic acid nanocapsules for delivering anticancer drugs into cells. Extrusion is the most common and traditional method for preparing microcapsules. It requires no heating and exerts minimal pressure on the core material, ensuring high activity of the encapsulated cells [48]. Zhou et al. [49] used extrusion to prepare thermophilic Streptococcus thermophilus 6038 microcapsules, which showed enhanced stability and acid resistance after microencapsulation. Coacervation Method involves the electrostatic interaction between two or more oppositely charged polymers to form microcapsules [35]. Eratte et al. [50] used whey protein and arabic gum as wall materials to coencapsulate Lactobacillus casei 431 and tuna oil. The results showed that microencapsulation improved the oxidative stability of both Lactobacillus casei 431 and tuna oil.

3.1.Application of microcapsules in improving drug stability

Chinese herbal essential oils are volatile and prone to oxidation, making them unstable. Cyclodextrins are widely used in the encapsulation of herbal essential oils. Yue Zhongqun et al. [8] prepared microcapsules with β-cyclodextrin as the wall material. The optimal conditions were determined to be a core-to-wall ratio of 1:5, encapsulation temperature of 60°C, and homogenization speed of 12,000 r/min. The resulting microcapsules showed strong stability, and the compound Aina essential oil exhibited a sustained release effect. Sodium diclofenac, a commonly used non-steroidal anti-inflammatory drug, is widely used to treat acute pain and chronic inflammation [51]. It has good antipyretic and analgesic properties but has a short biological half-life and can cause severe irritation to the gastric mucosa. Guo Honghui et al. [30] used sodium caseinate and gelatin as wall materials and employed spray drying to prepare enteric-coated drug-loaded microcapsules. The release of the drug was minimal in simulated gastric fluid, but the microcapsules gradually dissolved in simulated intestinal fluid, achieving effective release. These drug-loaded microcapsules serve as an oral enteric drug delivery system, protecting sensitive drugs under acidic conditions, reducing gastric irritation, and enhancing drug stability and bioavailability. Vitamin A is a group of compounds with retinol activity that plays an important role in vision, bone growth, cell differentiation and proliferation, and immune function [52]. However, vitamin A is easily affected by light, heat, oxygen, and peroxides, leading to polymerization, oxidation, and dissociation, which degrade its stability [53]. Zhou Di et al. [54] prepared a vitamin A acetate microcapsule with a bilayer encapsulation system, which enhanced the stability and retention rate of vitamin A.

3.2.Application of microcapsules in novel drug formulations

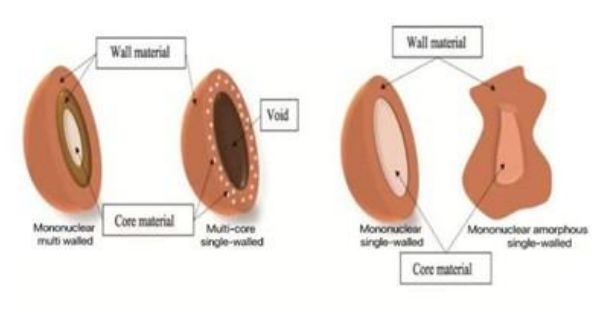

Microcapsules in drug formulations have functions such as controlled release, targeting, and improved oral bioavailability. Under conditions of 20°C and RH 85%, the change in tea tree oil content in both tea tree oil and tea tree oil microcapsules over 144 hours is shown in the figure below. Compared to tea tree oil, the tea tree oil microcapsules released the oil more slowly and steadily, indicating that the prepared microcapsules can significantly reduce the release rate of tea tree oil and have good sustained-release properties [12].

Figure 3. Sustained Release Properties of Tea Tree Oil Microcapsules

Some marine polysaccharides can encapsulate and protect probiotics while targeting their delivery and rapid release at the target site, improving treatment efficacy. Huang et al. [55] used methacrylated hyaluronic acid and thiolated thiolaldehyde to encapsulate probiotics. Their negative charge allows them to preferentially adhere to inflammatory sites in the intestines, where they release probiotics to treat colitis. Sodium diclofenac microcapsules showed minimal release in simulated gastric fluid, but gradually dissolved in simulated intestinal fluid, allowing for effective drug release. As an oral enteric drug delivery system, these microcapsules reduce gastric irritation, improve drug targeting, and enhance controlled release properties [30]. Li [56] prepared salicylic acid microcapsules and tested their antimicrobial activity against Propionibacterium acnes and Staphylococcus aureus. The results showed that salicylic acid microcapsules had stronger antimicrobial activity than commercial salicylic acid, and their sustained release was also effective in reducing irritation. Li [57] used sodium alginate and chitosan to construct a microcapsule delivery system to improve intestinal dysbiosis and enhance antitumor treatment. The study showed that the microcapsules exhibited good gastrointestinal tolerance and significantly improved oral bioavailability.

4.Conclusion

Currently, the materials and technologies for preparing microcapsules are continuously developing and innovating. Commonly used wall materials for microcapsules include carbohydrates such as resistant starch, cyclodextrins, alginates, and chitosan; proteins such as whey protein, wheat peptides, and casein; and composite materials like sodium alginate-pectin-whey protein isolates, xanthan gum-chitosan composites, and sodium caseinate-gelatin complexes. The choice of wall material depends on its compatibility with the core material and its physicochemical properties. Preparation methods include spray drying, freeze-drying, and interfacial polymerization. Microcapsules have shown important application value in improving drug stability, controlled release, targeting, and oral bioavailability. Future research can further explore the preparation materials, process optimization, and the broader application of microcapsules in drug formulations.

References

[1]. Zuo, Z., Song, S., Bai, X., et al. (2021). Application of natural polymers in microcapsule wall materials. Packaging Engineering, 42(15), 10. https://doi.org/10.19554/j.cnki.1001-3563.2021.15.013

[2]. Ning, D., Luo, Q., Chen, Y., et al. (2024). Research progress on microencapsulation of bioactive substances. Food Research and Development, 45(14), 193-200.

[3]. Li, W., Zhao, Y. J., Zhao, Y., et al. (2023). Improving the viability of Lactobacillus plantarum LP90 by carboxymethylated dextran-whey protein conjugates: The relationship with glass transition temperature. Food Hydrocolloids, 134, 108102. https://doi.org/10.1016/j.foodhyd.2022.108102

[4]. Halwani, M., Yebio, B., Suntres, Z. E., Alipour, M., Azghani, A. O., & Omri, A. (2008). Co-encapsulation of gallium with gentamicin in liposomes enhances antimicrobial activity of gentamicin against Pseudomonas aeruginosa. Journal of Antimicrobial Chemotherapy, 62(6), 1291-1297. https://doi.org/10.1093/jac/dkn388

[5]. Razavi, S., Janfaza, S., Tasnim, N., et al. (2021). Microencapsulating polymers for probiotics delivery systems: Preparation, characterization, and applications. Food Hydrocolloids, 120, 106882. https://doi.org/10.1016/j.foodhyd.2021.106882

[6]. Zhang, X., Zhong, M., Cui, L., et al. (2024). Effect of plant starch on the freeze-drying protection and storage performance of Lactobacillus casei microcapsules. Chinese Journal of Animal Husbandry and Veterinary Medicine.

[7]. Zhou, Z., Wang, J., & Li, Y. (2016). Protective effect of green banana starch on the activity of lactic acid bacteria during freeze-drying and storage. Food Science, 37(15), 5. https://doi.org/10.7506/spkx1002-6630-201615024

[8]. Yue, Z., Zhu, Y., Chen, T., et al. (2024). Preparation and evaluation of compound Ainaxiang brain-refreshing slow-release nano-microcapsules. Guangdong Chemical Industry, 51(8), 128-131.

[9]. Shao, S., Yan, S., Li, C., et al. (2024). Preparation and antioxidant activity of lipid-soluble rosemary extract microcapsules. Food Industry, 45(3), 68-73.

[10]. Zhang, Q., Liu, S., Wang, Z., et al. (2019). Applications of polysaccharides and their derivatives in food microcapsule wall materials. Chinese Food Additives, 30(11), 6. https://doi.org/10.19804/j.issn1006-2513.2019.11.014

[11]. Li, Z., Behrens, A. M., Ginat, N., et al. (2018). Biofilm-inspired encapsulation of probiotics for the treatment of complex infections. Advanced Materials, 30(51), 1803925. https://doi.org/10.1002/adma.201803925

[12]. Zhang, Y., Ni, H., Wu, Q., et al. (2024). Optimization and characterization of tea tree essential oil microcapsule encapsulation process. Journal of Henan University of Technology (Natural Science Edition), 3.

[13]. Li, R., Zhang, Y., Li, Y., et al. (2024). Progress in microencapsulation of probiotics and prebiotics. Bioprocessing, 22(2), 204-212.

[14]. Wang, Q., Zhong, F., & Li, Y. (2014). Study on the preparation of bifidobacteria microcapsules by the endogenous emulsification method. Jiangnan University.

[15]. Mu, X., Ju, X., Zhang, L., et al. (2019). Chitosan microcapsule membranes with nanoscale thickness for controlled release of drugs. Journal of Membrane Science, 590, 117275.

[16]. Feng, G., Junqing, Q., Yan, C., et al. (2018). Preparation and properties of gum arabic cross-link binding nisin microparticles. Carbohydrate Polymers, 197, S0144861718306349-. https://doi.org/10.1016/j.carbpol.2018.05.080

[17]. He, Q., Huang, L., Chen, W., et al. (2024). Research progress on microcapsule technology in protein encapsulation. Contemporary Chemical Engineering Research, 11, 9-12.

[18]. Zhou, Y., Guo, H., Hong, Z., et al. (2024). Research progress on the preparation and application of marine polysaccharide-based probiotic microcapsules. Food Industry Technology, 45(11), 351-360. https://doi.org/10.13386/j.issn1002-0306.2023050111

[19]. Huang, X., Yang, Y., Wang, H., et al. (2024). Natural chlorophyll microcapsules improve bread quality. Food Research and Development, 45(21), 18-24.

[20]. Liu, R., Wang, H., Wu, H., et al. (2024). Stability and structural identification of wheat peptide-vitamin D microcapsules. Food Technology, 49(5), 258-265.

[21]. Chen, L., Liu, J., Jia, Y., et al. (2024). Optimization of olive oil/coconut oil microcapsule nanoemulsion formulation by response surface methodology. Grain and Oil Science and Technology, 37(10), 48-54.

[22]. Luo, X., Fan, S. Q., He, Z. S., et al. (2022). Preparation of alginate-whey protein isolate and alginate-pectin-whey protein isolate composites for protection and delivery of Lactobacillus plantarum. *Food Research International, 161*, 111794. https://doi.org/10.1016/j.foodres.2022.111794

[23]. Deng, Y., Huo, A., Li, S., et al. (2019). Process optimization, characterization, and functional properties analysis of bifidobacteria composite microcapsules. Food Industry Technology, 40(6), 10. https://doi.org/10.13386/j.issn1002-0306.2019.06.025

[24]. Argin, S. (2007). Microencapsulation of probiotic bacteria in xanthan-chitosan polyelectrolyte complex gels (Doctoral dissertation). University of Maryland. https://hdl.handle.net/1903/7826

[25]. Zhong, Q., Li, W., Sun, W., et al. (2024). Preparation and stability analysis of spirulina polyphenol composite nanomicrocapsules. Food Industry Technology, 45(10), 198-206. https://doi.org/10.13386/j.issn1002-0306.2023070075

[26]. Xiang, N. (2023). Construction and performance evaluation of oxidized high amylose starch-sodium alginate composite probiotic microcapsules (Master’s thesis). Southern Medical University. https://doi.org/10.27003/d.cnki.gojyu.2023.001217

[27]. Cheng, S., Xie, W., Jiang, B., et al. (2024). Preparation and properties of thermosensitive L-menthol microcapsules. Food Research and Development, 1-15. http://kns.cnki.net/kcms/detail/12.1231.TS.20241112.0923.002.html

[28]. Kavousi, H. R., Fathi, M., & Goli, S. A. H. (2018). Novel cress seed mucilage and sodium caseinate microparticles for encapsulation of curcumin: An approach for controlled release. Food and Bioproducts Processing, S0960308518302839. https://doi.org/10.1016/j.fbp.2018.05.004

[29]. Zhang, J., Li, H. H., Chen, Y. F., et al. (2020). Microencapsulation of immunoglobulin Y: Optimization with response surface morphology and controlled release during simulated gastrointestinal digestion. Journal of Zhejiang University Science B, 21(8), 611-627. https://doi.org/10.1631/jzus.B2000172

[30]. Guo, H., Xie, Q., Hong, Z., et al. (2023). Preparation and in vitro drug release performance of diclofenac sodium microcapsules. Chinese Pharmaceutical Journal, 58(19), 1752-1758. https://doi.org/10.11669/cpj.2023.19.005

[31]. Zhang, Z., Zhong, S., Peng, F., et al. (2020). Research progress on microcapsule wall materials and preparation techniques. Food Science, 41(9), 8. https://doi.org/10.7506/spkx1002-6630-20190625-320

[32]. Fishery Animal Medicine. (2023). Chitosan-sodium alginate microcapsule delivery of Lactobacillus casei expressing VP56310-500 vaccine for the prevention of hemorrhagic disease in grass carp (Doctoral dissertation).

[33]. Zhu, Z., Cheng, J., Du, Y., et al. (2024). Preparation methods of microcapsules and their application in encapsulating three major nutrients. Food Technology, 49(2), 48-56.

[34]. Chen, J., Meng, L., Wang, W., et al. (2024). Research and application progress of yeast encapsulation microcapsule technology in the food industry. Food and Fermentation Industry, 1-11. https://doi.org/10.13995/j.cnki.11-1802/ts.040160

[35]. Gao, X. (2023). Preparation and characterization of Bifidobacterium microcapsules (Master’s thesis). Inner Mongolia Agricultural University. https://doi.org/10.27229/d.cnki.gnmnu.2023.000465

[36]. Huang, S., Yi, Y., Zhang, X., et al. (2024). Reversible thermochromic nanomicrocapsule materials for tumor photothermal therapy. Journal of Dongguan University of Technology, 31(3), 73-80.

[37]. Zhang, W. J., Gilstrap, K., Wu, L. Y., et al. (2010). Synthesis and characterization of thermally responsive pluronic F127-chitosan nanocapsules for controlled release and intracellular delivery of small molecules. ACS Nano, 4(11), 6747.

[38]. Li, Y., Chen, Y., Zeng, X., et al. (2023). Progress in food-grade wall materials for probiotic microcapsule technology. Food Industry, 44(10), 185-190.

[39]. Fu, X., Ye, S., Wu, Y., et al. (2022). Research on the application of porous sweet potato starch in spray drying of powdered butter. Grain and Oil Science and Technology, 35(2), 5.

[40]. Nambiar, R. B., Selvam, S. P., & Perumal, A. B. (2017). Microencapsulation of tender coconut water by spray drying: Effect of moringa oleifera gum, maltodextrin concentrations, and inlet temperature on powder qualities. Food & Bioprocess Technology, 10(4), 1-17. https://doi.org/10.1007/s11947-017-1934-z

[41]. Zhou, L., Zhang, L., Guan, B., et al. (2021). Preparation and tolerance study of freeze-dried microcapsules of Lactobacillus acidophilus. *Food Science and Technology.*

[42]. Rajam, R., & Anandharamakrishnan, C. (2015). Spray freeze drying method for microencapsulation of Lactobacillus plantarum. *Journal of Food Engineering, 166*, 95-103. https://doi.org/10.1016/j.jfoodeng.2015.05.029

[43]. Leslie, V. J., Marcia, A. L., Cristina, L. C., et al. (2013). Microencapsulation of maqui (Aristotelia chilensis Molina Stuntz) leaf extracts to preserve and control antioxidant properties. *Chilean Journal of Agricultural Research, 73*(1), 17-23. https://doi.org/10.4067/S0718-58392013000100003

[44]. Liu, Y. H., Liu, M. Y., Zhao, J., et al. (2021). Microencapsulation of osmanthus essential oil by interfacial polymerization: Optimization, characterization, release kinetics, and storage stability of essential oil from microcapsules. Journal of Food Science, 86(12), 5397-5408.

[45]. Wu, B., Sun, Z., Wu, J., et al. (2021). Nanoparticle-stabilized oxygen microcapsules prepared by interfacial polymerization for enhanced oxygen delivery. Angewandte Chemie (International ed. in English), 60(17), 9284-9289. https://doi.org/10.1002/anie.202100752

[46]. Jiang, T. Y. (2024). Preparation of cellulose nanocrystal-chitosan composite microcapsules (Master’s thesis). Light Industry Technology and Engineering.

[47]. Cadete, A., Olivera, A., Besev, M., et al. (2019). Self-assembled hyaluronan nanocapsules for the intracellular delivery of anticancer drugs. Scientific Reports, 9(1). https://doi.org/10.1038/s41598-019-47995-8

[48]. Chen, B. (2023). Dual-layer microcapsules for encapsulating probiotics and evaluating in vitro and in vivo effects (Master’s thesis). Shanghai Ocean University.

[49]. Zhou, H. B., Chen, J., Li, S., et al. (2017). Preparation of acid-resistant microcapsules with shell-matrix structure to enhance stability of Streptococcus thermophilus IFFI 6038. *Journal of Food Science, 82*(8). https://doi.org/10.1111/1750-3841.13774

[50]. Dowling, K., Barrow, L., et al. (2016). Survival and fermentation activity of probiotic bacteria and oxidative stability of omega-3 oil in co-microcapsules during storage. Journal of Functional Foods.

[51]. Silva, C. N. S. D., Di-Medeiros, M. C. B., Lio, L. M., et al. (2021). Cashew gum polysaccharide nanoparticles grafted with polypropylene glycol as carriers for diclofenac sodium. Materials, 14(9). https://doi.org/10.3390/MA14092115

[52]. Blomhoff, R., & Blomhoff, H. K. (2006). Overview of retinoid metabolism and function. Journal of Neurobiology. https://doi.org/10.1002/neu.20242

[53]. Yu, A., Yin, H., Chen, Z., et al. (2013). Research progress on factors affecting the stability of vitamin A. Chinese Journal of Food Science, 1, 8. DOI:CNKI:SUN:ZGSP.0.2013-01-030.

[54]. Zhou, D., Yao, K., Yu, Q., et al. (2024). Compression performance and stability of dual-layer encapsulated vitamin A microcapsules. Chinese Food Additives, 35(9), 188-196. https://doi.org/10.19804/j.issn1006-2513.2024.9.023

[55]. Huang, L., Wang, J., Kong, L., Wang, X., Zhang, Q., Shi, L., Duan, J., Mu, J., & Haibo, S. (2022). ROS-responsive hyaluronic acid hydrogel for targeted delivery of probiotics to relieve colitis. International Journal of Biological Macromolecules: Structure, Function and Interactions, 222(Pt. A), 1476-1486.

[56]. Li, L. X. (2023). Study on the preparation process of salicylic acid microcapsules (Master’s thesis). Beijing University of Chemical Technology.

[57]. Li, N. N. (2023). Oral delivery of Lactobacillus reuteri using sodium alginate-chitosan microcapsules for anti-colon cancer research (Master’s thesis). Dalian Medical University.

Cite this article

Zhou,X. (2025). Microencapsulation materials, processes, and their applications in drug formulations. Journal of Food Science, Nutrition and Health,3,42-48.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Journal:Journal of Food Science, Nutrition and Health

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Zuo, Z., Song, S., Bai, X., et al. (2021). Application of natural polymers in microcapsule wall materials. Packaging Engineering, 42(15), 10. https://doi.org/10.19554/j.cnki.1001-3563.2021.15.013

[2]. Ning, D., Luo, Q., Chen, Y., et al. (2024). Research progress on microencapsulation of bioactive substances. Food Research and Development, 45(14), 193-200.

[3]. Li, W., Zhao, Y. J., Zhao, Y., et al. (2023). Improving the viability of Lactobacillus plantarum LP90 by carboxymethylated dextran-whey protein conjugates: The relationship with glass transition temperature. Food Hydrocolloids, 134, 108102. https://doi.org/10.1016/j.foodhyd.2022.108102

[4]. Halwani, M., Yebio, B., Suntres, Z. E., Alipour, M., Azghani, A. O., & Omri, A. (2008). Co-encapsulation of gallium with gentamicin in liposomes enhances antimicrobial activity of gentamicin against Pseudomonas aeruginosa. Journal of Antimicrobial Chemotherapy, 62(6), 1291-1297. https://doi.org/10.1093/jac/dkn388

[5]. Razavi, S., Janfaza, S., Tasnim, N., et al. (2021). Microencapsulating polymers for probiotics delivery systems: Preparation, characterization, and applications. Food Hydrocolloids, 120, 106882. https://doi.org/10.1016/j.foodhyd.2021.106882

[6]. Zhang, X., Zhong, M., Cui, L., et al. (2024). Effect of plant starch on the freeze-drying protection and storage performance of Lactobacillus casei microcapsules. Chinese Journal of Animal Husbandry and Veterinary Medicine.

[7]. Zhou, Z., Wang, J., & Li, Y. (2016). Protective effect of green banana starch on the activity of lactic acid bacteria during freeze-drying and storage. Food Science, 37(15), 5. https://doi.org/10.7506/spkx1002-6630-201615024

[8]. Yue, Z., Zhu, Y., Chen, T., et al. (2024). Preparation and evaluation of compound Ainaxiang brain-refreshing slow-release nano-microcapsules. Guangdong Chemical Industry, 51(8), 128-131.

[9]. Shao, S., Yan, S., Li, C., et al. (2024). Preparation and antioxidant activity of lipid-soluble rosemary extract microcapsules. Food Industry, 45(3), 68-73.

[10]. Zhang, Q., Liu, S., Wang, Z., et al. (2019). Applications of polysaccharides and their derivatives in food microcapsule wall materials. Chinese Food Additives, 30(11), 6. https://doi.org/10.19804/j.issn1006-2513.2019.11.014

[11]. Li, Z., Behrens, A. M., Ginat, N., et al. (2018). Biofilm-inspired encapsulation of probiotics for the treatment of complex infections. Advanced Materials, 30(51), 1803925. https://doi.org/10.1002/adma.201803925

[12]. Zhang, Y., Ni, H., Wu, Q., et al. (2024). Optimization and characterization of tea tree essential oil microcapsule encapsulation process. Journal of Henan University of Technology (Natural Science Edition), 3.

[13]. Li, R., Zhang, Y., Li, Y., et al. (2024). Progress in microencapsulation of probiotics and prebiotics. Bioprocessing, 22(2), 204-212.

[14]. Wang, Q., Zhong, F., & Li, Y. (2014). Study on the preparation of bifidobacteria microcapsules by the endogenous emulsification method. Jiangnan University.

[15]. Mu, X., Ju, X., Zhang, L., et al. (2019). Chitosan microcapsule membranes with nanoscale thickness for controlled release of drugs. Journal of Membrane Science, 590, 117275.

[16]. Feng, G., Junqing, Q., Yan, C., et al. (2018). Preparation and properties of gum arabic cross-link binding nisin microparticles. Carbohydrate Polymers, 197, S0144861718306349-. https://doi.org/10.1016/j.carbpol.2018.05.080

[17]. He, Q., Huang, L., Chen, W., et al. (2024). Research progress on microcapsule technology in protein encapsulation. Contemporary Chemical Engineering Research, 11, 9-12.

[18]. Zhou, Y., Guo, H., Hong, Z., et al. (2024). Research progress on the preparation and application of marine polysaccharide-based probiotic microcapsules. Food Industry Technology, 45(11), 351-360. https://doi.org/10.13386/j.issn1002-0306.2023050111

[19]. Huang, X., Yang, Y., Wang, H., et al. (2024). Natural chlorophyll microcapsules improve bread quality. Food Research and Development, 45(21), 18-24.

[20]. Liu, R., Wang, H., Wu, H., et al. (2024). Stability and structural identification of wheat peptide-vitamin D microcapsules. Food Technology, 49(5), 258-265.

[21]. Chen, L., Liu, J., Jia, Y., et al. (2024). Optimization of olive oil/coconut oil microcapsule nanoemulsion formulation by response surface methodology. Grain and Oil Science and Technology, 37(10), 48-54.

[22]. Luo, X., Fan, S. Q., He, Z. S., et al. (2022). Preparation of alginate-whey protein isolate and alginate-pectin-whey protein isolate composites for protection and delivery of Lactobacillus plantarum. *Food Research International, 161*, 111794. https://doi.org/10.1016/j.foodres.2022.111794

[23]. Deng, Y., Huo, A., Li, S., et al. (2019). Process optimization, characterization, and functional properties analysis of bifidobacteria composite microcapsules. Food Industry Technology, 40(6), 10. https://doi.org/10.13386/j.issn1002-0306.2019.06.025

[24]. Argin, S. (2007). Microencapsulation of probiotic bacteria in xanthan-chitosan polyelectrolyte complex gels (Doctoral dissertation). University of Maryland. https://hdl.handle.net/1903/7826

[25]. Zhong, Q., Li, W., Sun, W., et al. (2024). Preparation and stability analysis of spirulina polyphenol composite nanomicrocapsules. Food Industry Technology, 45(10), 198-206. https://doi.org/10.13386/j.issn1002-0306.2023070075

[26]. Xiang, N. (2023). Construction and performance evaluation of oxidized high amylose starch-sodium alginate composite probiotic microcapsules (Master’s thesis). Southern Medical University. https://doi.org/10.27003/d.cnki.gojyu.2023.001217

[27]. Cheng, S., Xie, W., Jiang, B., et al. (2024). Preparation and properties of thermosensitive L-menthol microcapsules. Food Research and Development, 1-15. http://kns.cnki.net/kcms/detail/12.1231.TS.20241112.0923.002.html

[28]. Kavousi, H. R., Fathi, M., & Goli, S. A. H. (2018). Novel cress seed mucilage and sodium caseinate microparticles for encapsulation of curcumin: An approach for controlled release. Food and Bioproducts Processing, S0960308518302839. https://doi.org/10.1016/j.fbp.2018.05.004

[29]. Zhang, J., Li, H. H., Chen, Y. F., et al. (2020). Microencapsulation of immunoglobulin Y: Optimization with response surface morphology and controlled release during simulated gastrointestinal digestion. Journal of Zhejiang University Science B, 21(8), 611-627. https://doi.org/10.1631/jzus.B2000172

[30]. Guo, H., Xie, Q., Hong, Z., et al. (2023). Preparation and in vitro drug release performance of diclofenac sodium microcapsules. Chinese Pharmaceutical Journal, 58(19), 1752-1758. https://doi.org/10.11669/cpj.2023.19.005

[31]. Zhang, Z., Zhong, S., Peng, F., et al. (2020). Research progress on microcapsule wall materials and preparation techniques. Food Science, 41(9), 8. https://doi.org/10.7506/spkx1002-6630-20190625-320

[32]. Fishery Animal Medicine. (2023). Chitosan-sodium alginate microcapsule delivery of Lactobacillus casei expressing VP56310-500 vaccine for the prevention of hemorrhagic disease in grass carp (Doctoral dissertation).

[33]. Zhu, Z., Cheng, J., Du, Y., et al. (2024). Preparation methods of microcapsules and their application in encapsulating three major nutrients. Food Technology, 49(2), 48-56.

[34]. Chen, J., Meng, L., Wang, W., et al. (2024). Research and application progress of yeast encapsulation microcapsule technology in the food industry. Food and Fermentation Industry, 1-11. https://doi.org/10.13995/j.cnki.11-1802/ts.040160

[35]. Gao, X. (2023). Preparation and characterization of Bifidobacterium microcapsules (Master’s thesis). Inner Mongolia Agricultural University. https://doi.org/10.27229/d.cnki.gnmnu.2023.000465

[36]. Huang, S., Yi, Y., Zhang, X., et al. (2024). Reversible thermochromic nanomicrocapsule materials for tumor photothermal therapy. Journal of Dongguan University of Technology, 31(3), 73-80.

[37]. Zhang, W. J., Gilstrap, K., Wu, L. Y., et al. (2010). Synthesis and characterization of thermally responsive pluronic F127-chitosan nanocapsules for controlled release and intracellular delivery of small molecules. ACS Nano, 4(11), 6747.

[38]. Li, Y., Chen, Y., Zeng, X., et al. (2023). Progress in food-grade wall materials for probiotic microcapsule technology. Food Industry, 44(10), 185-190.

[39]. Fu, X., Ye, S., Wu, Y., et al. (2022). Research on the application of porous sweet potato starch in spray drying of powdered butter. Grain and Oil Science and Technology, 35(2), 5.

[40]. Nambiar, R. B., Selvam, S. P., & Perumal, A. B. (2017). Microencapsulation of tender coconut water by spray drying: Effect of moringa oleifera gum, maltodextrin concentrations, and inlet temperature on powder qualities. Food & Bioprocess Technology, 10(4), 1-17. https://doi.org/10.1007/s11947-017-1934-z

[41]. Zhou, L., Zhang, L., Guan, B., et al. (2021). Preparation and tolerance study of freeze-dried microcapsules of Lactobacillus acidophilus. *Food Science and Technology.*

[42]. Rajam, R., & Anandharamakrishnan, C. (2015). Spray freeze drying method for microencapsulation of Lactobacillus plantarum. *Journal of Food Engineering, 166*, 95-103. https://doi.org/10.1016/j.jfoodeng.2015.05.029

[43]. Leslie, V. J., Marcia, A. L., Cristina, L. C., et al. (2013). Microencapsulation of maqui (Aristotelia chilensis Molina Stuntz) leaf extracts to preserve and control antioxidant properties. *Chilean Journal of Agricultural Research, 73*(1), 17-23. https://doi.org/10.4067/S0718-58392013000100003

[44]. Liu, Y. H., Liu, M. Y., Zhao, J., et al. (2021). Microencapsulation of osmanthus essential oil by interfacial polymerization: Optimization, characterization, release kinetics, and storage stability of essential oil from microcapsules. Journal of Food Science, 86(12), 5397-5408.

[45]. Wu, B., Sun, Z., Wu, J., et al. (2021). Nanoparticle-stabilized oxygen microcapsules prepared by interfacial polymerization for enhanced oxygen delivery. Angewandte Chemie (International ed. in English), 60(17), 9284-9289. https://doi.org/10.1002/anie.202100752

[46]. Jiang, T. Y. (2024). Preparation of cellulose nanocrystal-chitosan composite microcapsules (Master’s thesis). Light Industry Technology and Engineering.

[47]. Cadete, A., Olivera, A., Besev, M., et al. (2019). Self-assembled hyaluronan nanocapsules for the intracellular delivery of anticancer drugs. Scientific Reports, 9(1). https://doi.org/10.1038/s41598-019-47995-8

[48]. Chen, B. (2023). Dual-layer microcapsules for encapsulating probiotics and evaluating in vitro and in vivo effects (Master’s thesis). Shanghai Ocean University.

[49]. Zhou, H. B., Chen, J., Li, S., et al. (2017). Preparation of acid-resistant microcapsules with shell-matrix structure to enhance stability of Streptococcus thermophilus IFFI 6038. *Journal of Food Science, 82*(8). https://doi.org/10.1111/1750-3841.13774

[50]. Dowling, K., Barrow, L., et al. (2016). Survival and fermentation activity of probiotic bacteria and oxidative stability of omega-3 oil in co-microcapsules during storage. Journal of Functional Foods.

[51]. Silva, C. N. S. D., Di-Medeiros, M. C. B., Lio, L. M., et al. (2021). Cashew gum polysaccharide nanoparticles grafted with polypropylene glycol as carriers for diclofenac sodium. Materials, 14(9). https://doi.org/10.3390/MA14092115

[52]. Blomhoff, R., & Blomhoff, H. K. (2006). Overview of retinoid metabolism and function. Journal of Neurobiology. https://doi.org/10.1002/neu.20242

[53]. Yu, A., Yin, H., Chen, Z., et al. (2013). Research progress on factors affecting the stability of vitamin A. Chinese Journal of Food Science, 1, 8. DOI:CNKI:SUN:ZGSP.0.2013-01-030.

[54]. Zhou, D., Yao, K., Yu, Q., et al. (2024). Compression performance and stability of dual-layer encapsulated vitamin A microcapsules. Chinese Food Additives, 35(9), 188-196. https://doi.org/10.19804/j.issn1006-2513.2024.9.023

[55]. Huang, L., Wang, J., Kong, L., Wang, X., Zhang, Q., Shi, L., Duan, J., Mu, J., & Haibo, S. (2022). ROS-responsive hyaluronic acid hydrogel for targeted delivery of probiotics to relieve colitis. International Journal of Biological Macromolecules: Structure, Function and Interactions, 222(Pt. A), 1476-1486.

[56]. Li, L. X. (2023). Study on the preparation process of salicylic acid microcapsules (Master’s thesis). Beijing University of Chemical Technology.

[57]. Li, N. N. (2023). Oral delivery of Lactobacillus reuteri using sodium alginate-chitosan microcapsules for anti-colon cancer research (Master’s thesis). Dalian Medical University.