1. Introduction

With the rapid development of satellite technology, control systems are becoming increasingly dependent on fluid mechanics applications. In the unique microgravity environment of space, fluid behavior exhibits significant differences from terrestrial conditions, presenting both challenges and development opportunities for satellite propulsion systems, thermal control systems, and attitude control. Fluid mechanics plays an irreplaceable role in key satellite subsystems, including propellant management, heat transfer processes in thermal control systems, and liquid sloshing issues affecting stability. In microgravity, surface tension and capillary forces supplant inertia and gravity as the governing influences, necessitating bespoke theoretical models, purpose-built numerical schemes, and dedicated experimental validation.

Over the past decades, organizations such as National Aeronautics and Space Administration (NASA), European Space Agency (ESA), and China Aerospace Science and Technology Corporation have conducted extensive research to address fluid mechanics challenges in satellites. Computational fluid dynamics has become a powerful tool for simulating microgravity flows, while ground experiments like drop towers and parabolic flights provide partial verification methods. However, many unsolved mysteries remain regarding fluid behavior, multi-physics coupling effects, and the reliability of emerging technologies such as electrowetting propulsion and smart fluids. This paper systematically surveys advances in applying fluid mechanics to satellite control, covering microgravity propellant dynamics, thermal-fluid management, and fluidic attitude-control techniques. By offering an interdisciplinary reference for mechanical and aerospace researchers, it seeks to accelerate the integration of fluid-mechanical solutions into next-generation satellite systems.

2. Main application areas of fluid mechanics in satellite control systems

With the increasing global demand for aerospace activities, excluding military satellites operated by various nations, the annual launch demand for civilian small satellites has exceeded 1,000 units. As satellite launches become increasingly accessible to the public, the bar for launch technology is rising—and fluid mechanics is emerging as an indispensable pillar of every mission. This chapter will focus on discussing and outlining the key applications of fluid mechanics in propulsion systems, thermal control systems, and attitude control systems, while clarifying the current development status and the core technologies they rely on.

2.1. Fluid mechanics in propulsion systems

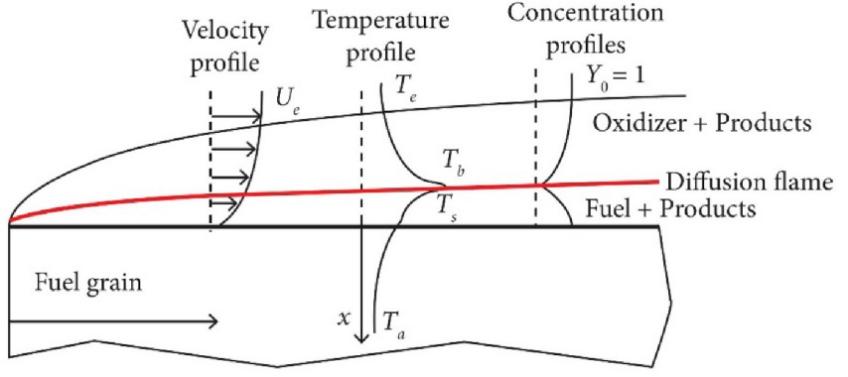

Solid-liquid hybrid propellants represent the most common and widely used form of rocket fuel, with two primary technical approaches: the first combines solid fuel directly with liquid oxidizer, while the second, less conventional approach employs liquid fuel with solid oxidizer. The latter method is less prevalent and more complex, as solid oxidizers demand higher manufacturing precision and incur greater costs compared to their liquid counterparts. Consequently, most contemporary satellite launch vehicles adopt the classic combination of solid fuel with liquid oxidizer in their propulsion systems, making the study of these propellants' mechanical properties critically important. Figure 1 illustrates the regression rate model proposed by Marxman.

The regression rate "γ" refers to the inward propagation velocity of the combustion surface during burning. This parameter directly influences the thrust generation of satellite launch vehicles and depends critically on both the oxidizer injection method and uniform combustion design. Currently, there exist two primary approaches for enhancing the regression rate: the fluid mechanics-based method discussed in this paper and alternative chemical methods.

The model presented in Figure 1 has been widely applied in hybrid-propellant rocket and satellite systems. The regression rate can be mathematically expressed as:

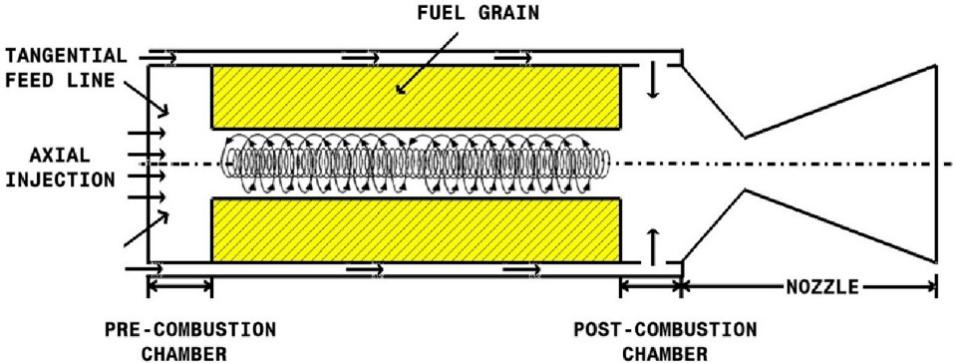

Figure 2 illustrates the vortex oxidizer injection technology developed by Knuth et al. [2] at Orbital Technologies. Numerical simulations demonstrate that this technology enables oxidizer to be injected into vortex flow and subsequently ejected at extremely high velocities. This process enhances turbulent effects, ensuring thorough contact between the oxidizer and solid fuel surface. Consequently, it increases the combustion reaction surface area, effectively elevating the regression rate.

In addition, several other oxidizer injection contact methods have emerged. For instance, Enrico et al. [3] also proposed a vortex oxidizer injection approach. They employed numerical simulation methods using commercial computational fluid dynamics (CFD) codes, focusing on adjusting and examining scaling parameters for vortex injection motors. This effectively enhanced oxidizer injection efficiency and indirectly improved combustion contact efficiency with solid fuel, thereby contributing to increased regression rates.

Another approach to augment regression rates involves chemical methods, which essentially entail selecting and testing suitable oxidizers while investigating their relevant chemical properties. For example, C. Oommen et al. [4] discovered that ammonium nitrate—not just a widely used ammonium compound in modern life with applications limited to industrial explosives, fertilizers, and gas generators—also has potential in propellant systems. However, its utilization in this field remains significantly underdeveloped compared to civilian applications. Their paper provides detailed analysis of ammonium nitrate's phase transition characteristics, chemical properties, and mechanical behavior, demonstrating its capability to handle more complex and efficient combustion tasks. Experimental high-intensity testing has already been conducted using ammonium nitrate as an oxidizer for satellite rockets, proving it to be a highly promising aerospace oxidizer.

2.2. Fluid mechanics in Thermal Control Systems

The Thermal Control System (TCS) ensures all spacecraft components maintain proper operating temperatures under extreme conditions. Satellite thermal control systems are mainly divided into two categories: active thermal control systems and passive thermal control systems. Active systems include heat pipes, fluid heat exchangers, and phase-change cooling modules, while passive systems consist of thermal insulation materials and various high-performance surface coatings.

In active thermal control systems, fluid mechanics plays a vital role, with its core functions including heat exchange (using gases or liquids, similar to computer air-cooling and liquid-cooling systems), temperature homogenization, and real-time monitoring with dynamic fluid regulation capabilities.

2.2.1. Liquid cooling loop

Such systems typically employ pump-driven liquid circulation for heat dissipation, commonly using coolants like ammonia or water-glycol mixtures. The coolant flows through dedicated piping systems to absorb heat from high-temperature components or areas, then releases the heat through radiation. The main challenges in these thermal control systems lie in the design and layout of cooling pipelines, as well as optimizing fluid propulsion efficiency (requiring simulation tests to account for internal pipe resistance). For evaporation-based cooling systems, phase-change dynamics must also be considered.

The International Space Station's (ISS) active thermal control system utilizes an ammonia cycle to cool electronic equipment [5]. Ammonia's advantages—including high latent heat of vaporization, superior thermal conductivity, and low viscosity— make it an exceptionally efficient coolant. Compared to water-cooling systems, ammonia-based systems require less pump power. Additionally, ammonia's lower density results in reduced mass requirements, minimizing its impact on the spacecraft's overall weight.

2.2.2. Heat pipe

Heat pipe cooling primarily relies on working fluids such as ammonia or methanol to achieve passive heat dissipation through evaporation-condensation cycles without requiring pump-driven circulation. The main challenge of this cooling system lies in optimizing the wick structure to prevent dry-out issues. China's Chang'e-4 lunar probe employed such a heat pipe system to cope with extreme temperature variations on the Moon's surface [6].

The advantages of heat pipes include being a completely passive thermal control system without any active components while achieving thermal conductivity exceeding 10,000 times that of copper. Furthermore, given the constrained space available on spacecraft like satellites, heat pipes offer lightweight design solutions that can be customized to fit different spacecraft's compact configurations. Their piping layouts allow relative flexibility, and compared to alternative methods, they demonstrate longer service life with lower maintenance costs.

2.2.3. Other relevant Thermal Control Systems

Jet cooling is a gas flow injection technique that enables direct, high-efficiency cooling by using fans or compressed gas to target specific components requiring thermal regulation. This method is typically employed in deep-space satellites or probes, as atmospheric interference at lower altitudes may disrupt gas flow dynamics. The James Webb Space Telescope (JWST) utilizes this system to cool its infrared detectors [7].

2.3. Fluid-based attitude control technologies

Satellite Attitude Control Systems are designed to precisely regulate a satellite's orientation and maintain stable orbital operation. Fluid mechanics plays an indispensable role in these critical technologies, primarily in attitude propulsion systems and damping systems.

2.3.1. Active attitude control technology based on fluid propulsion

These propulsion methods can be categorized into three types: cold gas propulsion, liquid fuel propulsion, and electric propulsion.

Cold gas thrusters typically utilize high-pressure gas ejected in the opposite direction of the desired orientation, relying on the resulting reaction force to adjust the satellite's attitude. Due to their low cost, this method is commonly used in small satellites or spacecraft for attitude control.

Liquid propellant systems are conventional propulsion technologies that employ liquid fuel. The thrust generated by catalytic decomposition or combustion is used to adjust the satellite's attitude.

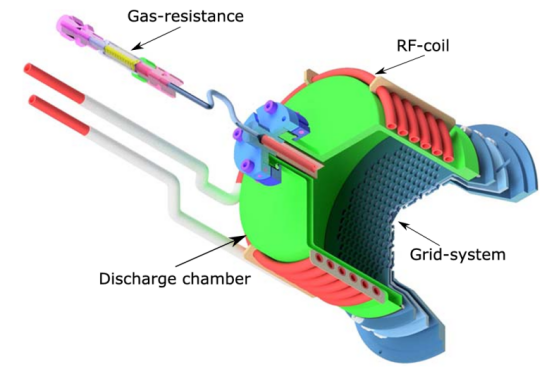

Electric propulsion is a method that ionizes gases (e.g., xenon) and accelerates them using electric fields to produce thrust. Its advantage lies in providing sustained, minute thrust, making it ideal for long-term, fine attitude adjustments. NASA's Deep Space 1 probe, launched in 1998, utilized this technology with an advanced xenon feed system for continuous propulsion in deep space [8]. Figure 3 illustrates the propulsion structure.

2.3.2. Passive attitude control based on fluid dynamics

Liquid dampers utilize viscous fluid dissipation to suppress or attenuate rotational vibrations in satellites. In early satellite launches, numerous failure cases occurred due to unaccounted liquid sloshing effects. Such dampers are now widely implemented in modern satellites.

Magnetohydrodynamic (MHD) attitude control represents a more novel passive stabilization approach. The core concept relies on Lorentz forces generated by conductive fluids within magnetic fields to adjust orientation, requiring preemptive calculations of Maxwell's and Navier-Stokes (N-S) equations to model electromagnetic effects. While not yet deployed at scale, Japan's H-II Transfer Vehicle (HTV) experimentally validated this concept [10]. Figure 4 illustrates this Japanese spacecraft's configuration.

3. Research methods and technologies

Based on the three major application areas of fluid mechanics in satellite control systems discussed above, this section summarizes and categorizes the primary research methods and technologies to provide fundamental theories and methodologies for future scientific investigations. These approaches can generally be divided into three components: theoretical analysis, numerical simulation (CFD), and ground and space-based experiments.

3.1. Theoretical analysis

Equation Validation and Model Establishment

Navier-Stokes (N-S) equations: These fundamental equations are widely used to describe and compute fluid dynamics and heat transfer, making them applicable to scenarios such as propellant flow and thermal transport in satellite systems.

Boltzmann equation: Typically applied to rarefied gas flow dynamics, such as in cold gas thruster operations.

Magnetohydrodynamic (MHD) equations: A coupled system integrating Maxwell's equations with the Navier-Stokes (N-S) equations to model electrically conductive fluid behavior under magnetic fields.

Differential Form of Maxwell's Equations:

3.2. Computational Fluid Dynamics (CFD)

The dominant numerical route in fluid mechanics relies on commercial solvers—most notably ANSYS Fluent [11]—to execute Finite-Volume Method (FVM) simulations of pipeline flows and combustion processes. For simpler scenarios, direct numerical simulation (DNS) can achieve high accuracy in turbulence prediction but requires significant computational resources, making it unsuitable for large-scale applications.

Multiphysics coupling is another widely used method, which accounts for the combined effects of different physical fields to jointly model and predict fluid behavior.

For example, the Volume of Fluid (VOF) [12] method tracks free fluid surface boundaries by calculating fluid volume fractions. This capability makes it particularly useful for simulating liquid sloshing of propellants in storage tanks under microgravity conditions. Therefore, selecting and establishing appropriate simulation methods is critical for accurate results.

3.3. Ground and space experiments

3.3.1. Ground testing technologies

Vacuum chamber testing: Vacuum chambers can simulate space environments, facilitating propellant testing, cold gas jet experiments, etc.

Microgravity simulation: Simulates the motion of fluids such as fuels and propellants in microgravity environments, aiding in the design of thermal control pipelines.

Strength testing: Simulates extreme launch conditions to verify the feasibility and reliability of related fluids under high temperatures and other stresses.

3.3.2. Orbital experiments

In-orbit space experiments are an indispensable means of validating fluid mechanics and thermal control systems in satellites, offering irreplaceable advantages. These experiments provide sustained research conditions, enabling the study of multi-physics coupling effects under simultaneous high vacuum, intense solar radiation, and microgravity. Platforms like the International Space Station (ISS) offer opportunities for testing cutting-edge technologies. Additionally, data feedback from unmanned orbital satellites is equally critical.

In the fall of 2009, an experiment [13] conducted aboard the ISS tested the effects of vibration on liquid diffusion in a multi-physics-coupled space environment. Leveraging the unique conditions, the experiment—enhanced over ground-based tests—ran continuously for 18 hours with astronaut assistance, demonstrating the timeliness and significance of space-based experiments.

4. Conclusion

This paper systematically and comprehensively reviews the application of fluid mechanics in satellite control systems, providing an in-depth analysis of key applications and research progress. Research shows that in microgravity environments, surface tension-dominated fluid behavior critically impacts core functions such as propellant management, thermal control, and attitude stabilization. Current studies employing theoretical modeling, numerical simulations (e.g., the VOF method), and ground-based experiments have achieved significant results, including optimized propellant tank designs, improved two-phase loop performance, and innovative liquid sloshing suppression technologies. However, challenges remain in long-term on-orbit fluid stability, multi-physics coupling effects, and engineering applications of new smart fluid technologies.

Based on current research status and challenges, future studies should focus on three directions: first, developing higher-precision multiscale coupling simulation methods to enhance microgravity fluid prediction capability; second, exploring applications of artificial intelligence technology in fluid system optimization and control; third, developing new fluid devices adapted to extreme deep-space exploration environments. With the rapid development of commercial space activities and ongoing deep-space exploration missions, innovative applications of fluid mechanics in satellite control systems will play an increasingly critical role, providing strong technical support for aerospace development. As commercial space continues to advance and deep-space missions progress, the innovative application of fluid mechanics in satellite control systems will demonstrate even more crucial importance, offering powerful technical support for the advancement of space endeavors.

References

[1]. Marxman G. A., Wooldridge C. E., Muzzy R. J. (1964) Fundamentals of hybrid boundary-layer combustion [M]// Progress in astronautics and rocketry. Elsevier, 15: 485-522.

[2]. Knuth W. H., Chiaverini M. J., Sauer J. A., et al. (2002) Solid-fuel regression rate behavior of vortex hybrid rocket engines [J]. Journal of Propulsion and power, 18(3): 600-609.

[3]. Paccagnella E., Barato F., Pavarin D., et al. (2017) Scaling parameters of swirling oxidizer injection in hybrid rocket motors [J]. Journal of Propulsion and Power, 33(6): 1378-1394.

[4]. Oommen C., Jain S. R. (1999) Ammonium nitrate: a promising rocket propellant oxidizer [J]. Journal of hazardous materials, 67(3): 253-281.

[5]. Patel V. P., Barido R., Johnson B., et al. (2001) Development of the internal thermal control system (ITCS) for international space station (ISS) [R]. SAE Technical Paper.

[6]. Guo Y., Wang L., Miao J., et al. (2022) Design and validation of closed two-phase thermosyphon loop in lunar gravity environment during China lunar project CE-4 [J]. Microgravity Science and Technology, 34(3): 38.

[7]. Sabelhaus P. A., Decker J. E. (2004) An overview of the James Webb space telescope (JWST) project [J]. Optical, Infrared, and Millimeter Space Telescopes, 5487: 550-563.

[8]. Sovey J., Hamley J., Haag T., et al. (1997) Development of an ion thruster and power processor for New Millennium's Deep Space 1 Mission. [C]// 33rd Joint Propulsion Conference and Exhibit, 778.

[9]. Dietz P., Gärtner W., Koch Q., et al. (2019) Molecular propellants for ion thrusters [J]. Plasma Sources Science and Technology, 28(8): 084001.

[10]. Fukushima Y. I. (1994) Development of the H-II Rocket [J]. IEEJ Transactions on Electronics, Information and Systems, 115(1): 69-72.

[11]. Manual U. (2009) ANSYS FLUENT 12.0 [J]. Theory Guide, 67.

[12]. Hirt C. W., Nichols B. D. (1981) Volume of fluid (VOF) method for the dynamics of free boundaries [J]. Journal of computational physics, 39(1): 201-225.

[13]. Shevtsova V. (2010) IVIDIL experiment onboard the ISS [J]. Advances in space research, 46(5): 672-679.

Cite this article

Lu,J. (2025). A Review of Fluid Mechanics Applications in Satellite Control Systems. Applied and Computational Engineering,180,63-71.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-MCEE 2026 Symposium: Advances in Sustainable Aviation and Aerospace Vehicle Automation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Marxman G. A., Wooldridge C. E., Muzzy R. J. (1964) Fundamentals of hybrid boundary-layer combustion [M]// Progress in astronautics and rocketry. Elsevier, 15: 485-522.

[2]. Knuth W. H., Chiaverini M. J., Sauer J. A., et al. (2002) Solid-fuel regression rate behavior of vortex hybrid rocket engines [J]. Journal of Propulsion and power, 18(3): 600-609.

[3]. Paccagnella E., Barato F., Pavarin D., et al. (2017) Scaling parameters of swirling oxidizer injection in hybrid rocket motors [J]. Journal of Propulsion and Power, 33(6): 1378-1394.

[4]. Oommen C., Jain S. R. (1999) Ammonium nitrate: a promising rocket propellant oxidizer [J]. Journal of hazardous materials, 67(3): 253-281.

[5]. Patel V. P., Barido R., Johnson B., et al. (2001) Development of the internal thermal control system (ITCS) for international space station (ISS) [R]. SAE Technical Paper.

[6]. Guo Y., Wang L., Miao J., et al. (2022) Design and validation of closed two-phase thermosyphon loop in lunar gravity environment during China lunar project CE-4 [J]. Microgravity Science and Technology, 34(3): 38.

[7]. Sabelhaus P. A., Decker J. E. (2004) An overview of the James Webb space telescope (JWST) project [J]. Optical, Infrared, and Millimeter Space Telescopes, 5487: 550-563.

[8]. Sovey J., Hamley J., Haag T., et al. (1997) Development of an ion thruster and power processor for New Millennium's Deep Space 1 Mission. [C]// 33rd Joint Propulsion Conference and Exhibit, 778.

[9]. Dietz P., Gärtner W., Koch Q., et al. (2019) Molecular propellants for ion thrusters [J]. Plasma Sources Science and Technology, 28(8): 084001.

[10]. Fukushima Y. I. (1994) Development of the H-II Rocket [J]. IEEJ Transactions on Electronics, Information and Systems, 115(1): 69-72.

[11]. Manual U. (2009) ANSYS FLUENT 12.0 [J]. Theory Guide, 67.

[12]. Hirt C. W., Nichols B. D. (1981) Volume of fluid (VOF) method for the dynamics of free boundaries [J]. Journal of computational physics, 39(1): 201-225.

[13]. Shevtsova V. (2010) IVIDIL experiment onboard the ISS [J]. Advances in space research, 46(5): 672-679.