1. Research and Preparation of Reactive Powder Concrete

With the advancement of science and technology, new materials and processes are continuously being used in the research and development of concrete, leading to a new approach to concrete development. The formulations and materials for various types of reactive powder concrete vary, but they mainly consist of cement, quartz sand, silica fume, steel fibers, and high-efficiency water reducers, and are prepared using appropriate molding and curing processes. The basic formulation principle of reactive powder concrete is to minimize defects such as microcracks and pores in the material.

1.1. Design Principles of RPC

The basic design principle of RPC is to enhance the fineness and activity of the raw materials, reduce internal defects (including pores and microcracks), achieve high strength and durability, and then improve its toughness by adding steel fibers [1]. According to this principle, the average particle size of the raw materials used in RPC ranges from 0.1μm to 1mm, aiming to minimize the distance between micro-pores in the concrete mixture and thus improve its compactness.

1.2. Properties and Proportions of RPC Raw Materials

The basic raw materials used in preparing RPC include cement, sand, silica fume, water, quartz powder, high-efficiency water reducers, and steel fibers. Typically, both cement and silica fume in RPC have high fineness, and the proper gradation of quartz powder has a significant impact on the strength and flowability of RPC. When preparing RPC, the cement slurry fills voids and coats the surface of quartz powder. Well-graded quartz powder is conducive to preparing denser concrete, improving the workability of the concrete mixture, thereby enhancing the strength and durability of the concrete.

Table 1 shows the mix proportions of several types of domestic and foreign reactive powder concrete and one type of high-performance concrete. From Table 1, it can be seen that compared to high-performance concrete, RPC contains a higher proportion of silica fume and a lower water-to-binder ratio. In fact, the higher the silica fume content, the lower the water-to-binder ratio, resulting in rapid early development of concrete, with more pronounced cracking and shrinkage phenomena. Therefore, in RPC with higher silica fume content, to compensate for the adverse effects of cracking on concrete, the steel fiber content is also higher. Therefore, to obtain RPC with excellent performance, it is crucial to select high-quality concrete raw materials.

Table 1. Mix Proportions of Various Types of Concrete

No. | Cement | Sand | Stone | Silica Fume | Water | Water Reducer | Quartz Powder | Steel Fiber |

1 | 1.000 | 1.100 | — | 0.230 | 0.190 | 0.019 | 0.390 | 0.175 |

2 | 1.000 | 1.432 | — | 0.325 | 0.280 | 0.280 | 0.300 | 0.200 |

3 | 1.000 | 1.000 | — | 0.350 | 0.200 | 0.200 | 0.300 | 0.030 |

4 | 1.000 | 1.352 | 2.403 | 0.137 | 0.365 | 0.365 | — |

2. Current Research Status of Reactive Powder Concrete Domestic and Abroad

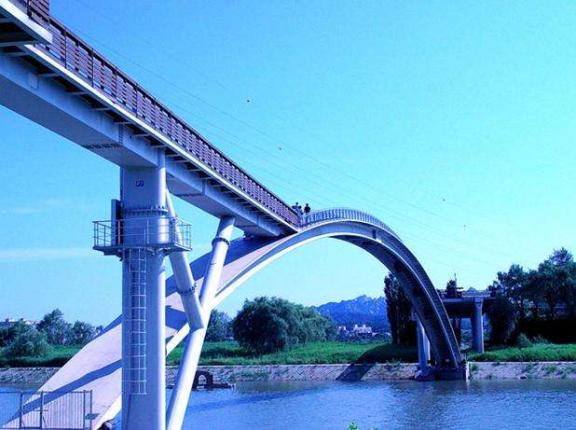

Currently, research on RPC preparation techniques abroad has become relatively mature, with extensive experimental studies conducted on materials, mix proportions, curing conditions, durability, and strength of RPC. The results indicate that due to RPC’s good homogeneity and compactness, both compressive strength and durability have been significantly improved. Moreover, the influence of curing conditions on the mechanical properties of RPC has been investigated to determine appropriate curing conditions. As shown in Figure 1, the Xianyou Bridge is located in Seoul, South Korea, and is the first pedestrian bridge on Xianyou Island, a small island in the Han River.

Figure 1. Xianyou Bridge

China started relatively late in the research and application of ultra-high-performance concrete, but progress has been rapid. In recent years, universities such as Tsinghua University, Hunan University, Central South University, Southeast University, and Wuhan University of Technology have successively conducted research on RPC materials [2]. In addition to Portland cement and silica fume, materials such as ultrafine fly ash, ultrafine slag, and quartz powder are also used in the mixture, successfully producing RPC materials with excellent performance. Furthermore, experimental research has been conducted on the mixing facilities, high-frequency vibration, and demolding agents of RPC, developing material selection, preparation technology, and production processes for RPC, creating conditions for its application in the field of engineering construction. Research in China on RPC indicates that using domestic materials and ordinary forming and curing processes, the strength of plain RPC (without steel fibers) can reach over 140 MPa. In addition to maintaining the high strength and durability characteristics of high-performance concrete, RPC also exhibits better deformability.

3. Classification and Properties of Reactive Powder Concrete

Reactive powder concrete (RPC) can be divided into two categories: RPC for on-site casting (designated as RC) and RPC for factory prefabricated products (designated as RP). Due to the low water-cement ratio and high flowability requirements of RPC, quality control is easier in factory production. Steam curing can be employed in factories, where higher steam curing temperatures can accelerate the hydration and hardening process of cementitious materials, resulting in higher strength development rates and ultimately achieving higher strengths.

For some non-standard structures, on-site casting of RPC can also be used. In such cases, curing conditions are poorer, resulting in lower performance compared to prefabricated RPC products. Table 2 presents the mechanical performance grades of reactive powder concrete.

Table 2. Mechanical Performance Grades of Reactive Powder Concrete

Grade | Compressive Strength (MPa) | Flexural Strength (MPa) | Elastic Modulus (GPa) |

RPC100 | >=100 | >=12 | >=40 |

RPC200 | >=120 | >=14 | >=40 |

RPC140 | >=140 | >=18 | >=40 |

RPC160 | >=160 | >=22 | >=40 |

RPC180 | >=180 | >=24 | >=40 |

3.1. Material Properties

Long Peiheng [3] et al. applied reactive powder concrete (RPC) to new composite structures. They concluded that plate tests and shear stud push-out tests were used to analyze the ultimate bearing capacity of RPC local components. The increase in plate thickness had a significant effect on the ultimate bearing capacity and stiffness of bridge decks, and the initial cracking load strength increased with the increase in plate thickness. Other studies have shown that the compressive strength of RPC materials can reach up to 800 MPa, whereas the compressive strength of high-performance concrete only reaches 100 MPa, and its flexural strength is only 1/10 of that of reactive powder concrete. It can be seen that reactive powder concrete has ultra-high material performance.

3.2. Mechanical Properties

The mechanical properties of reactive powder concrete are excellent. Qi Kaineng [4] et al. studied the mechanical properties of RPC through static load-bearing capacity tests of prestressed RPC crane beams. Table 3 illustrates the mechanical properties of RPC:

Table 3. Mechanical Properties of RPC

Cuboid Compressive Strength | Peak Stress Corresponding to Strain | Compressive Elastic Modulus | Tensile Strength | Poisson’s Ratio v |

119.5 | 3780 | 43600 | 8.95 | 0.192 |

The conclusion drawn from this is that the contribution of the concrete in the tensile zone of RPC to the load-bearing capacity cannot be ignored. For prestressed RPC T-beams, the equivalent coefficient k of the stress diagram in the tensile zone can be approximately taken as 0.34. This indicates the excellent mechanical performance of reactive powder concrete.

As shown in Table 4:

Table 4. Comparison of Main Mechanical Properties between RPC and HSC

Performance | RPC200 | RPC800 | HSC |

Compressive Strength/Mpa | 170-230 | 500-800 | 60-100 |

Flexural Strength/Mpa | 30-60 | 45-140 | 6-10 |

Fracture Energy/J*m-2 | 20000-40000 | 1200-2000 | 140 |

Elastic Modulus/Gpa | 50-60 | 65-75 | 30-40 |

Hence, it can be seen that the mechanical performance of RPC is superior to that of HSC.

3.3. Durability Performance

RPC has low porosity and small pore size, with a chloride ion permeability coefficient of only 2.17×10-14m2/s [5]. Research has shown that after undergoing 1500 cycles of 15% salt crystallization, RPC’s mass loss rate is only 0.62%. These findings are sufficient to illustrate RPC’s extremely low porosity and exceptionally high impermeability.

A certain study designed an accelerated carbonization experiment on RPC, comparing the carbonization performance of RPC materials, ordinary concrete, and high-strength concrete at 28 days. It was found that the carbonization depth of RPC was 0, compared to an average carbonization depth of 1.37mm for C80 concrete, leading to the conclusion that RPC exhibits optimal resistance to carbonization [6]. Subsequent research also consistently indicated that the carbonization depth of RPC is close to 0 [7],demonstrating its excellent resistance to external carbonization.

Regarding RPC’s resistance to chemical corrosion, He Feng [8] et al. studied the effect of sulfuric acid and hydrochloric acid solutions on RPC strength, and found that with prolonged immersion time, RPC exhibited good resistance to acid erosion.

3.4. Environmental Performance

Table 5 provides the ecological performance of 30MPa air-entrained concrete, 60MPa HPC, and 200MPa RPC under the same load-bearing conditions. It can be observed that the cement usage and carbon dioxide emissions of 200MPa RPC are nearly half of those of 30MPa air-entrained concrete and 60MPa HPC, while the aggregate usage is a quarter of that of 30MPa air-entrained concrete and a third of that of 60MPa HPC. This indicates that the superior performance of RPC can significantly reduce raw material input, conserve ecological resources, and protect the environment.

Table 5. Ecological Performance of Different Types of Concrete under the Same Load-bearing Conditions

Type | 30MPa Air-entrained Concrete | 60MPa HPC | 200MPa RPC |

Equivalent Volume (m3) | 126 | 100 | 33 |

Cement Usage (t) | 44 | 40 | 23 |

Carbon Dioxide Emissions | 44 | 40 | 23 |

Aggregate Usage (t) | 230 | 170 | 60 |

4. Advantages of Reactive Powder Concrete

Reactive powder concrete (RPC) has the advantages of high specific strength, high durability, high seismic and impact resistance, good resistance to high temperature and fire, as well as ease of factory prefabrication and on-site assembly.

4.1. High Seismic and Impact Resistance

In 2018, Yang Yiting et al. [9] conducted a simulation analysis of the mechanical properties of 7 steel-concrete columns under low-cycle repeated loads. The results showed that high-strength steel-concrete columns with large shear-to-span ratios, low axial compression ratios, high hoop reinforcement ratios, and high steel content tend to exhibit fuller hysteresis loops, indicating stronger ultimate deformation capacity of the specimens. With the increase of hoop reinforcement ratio and steel content, both the ultimate bearing capacity and ductility of the specimens improved, with relatively small variations.

In 2020, Li Sha and Jia Xiaopan [10] used a combination of numerical simulation and theoretical analysis to study the seismic performance of two new types of steel-concrete column sections, significantly improving the seismic performance of the structure.

In 2021, Zhang Qi et al. [11] conducted comparative tests on 6 steel-concrete columns with different regionally confined concrete under quasi-static reciprocating loads. The results showed that the steel-concrete columns with regionally confined concrete bear force uniformly, effectively suppressing the occurrence of penetrating diagonal cracks and avoiding brittle shear failure. Additionally, steel-concrete columns with regionally confined concrete exhibit good mechanical and seismic performance under high axial compression ratios, suggesting that they should be widely promoted and used.

For reactive powder concrete, its high toughness and high specific strength contribute to improving the seismic and impact resistance of structures.

4.2. Excellent High-Temperature Resistance and Fire Resistance

Studies have shown that the high-temperature resistance, fire resistance, and corrosion resistance of reactive powder concrete are much higher than that of steel.

Harbin Institute of Technology’s Luo Baifu [12] verified the performance of RPC under high temperatures from multiple aspects, while Lin Jian et al. [13] confirmed RPC’s excellent high-temperature resistance through the study of RPC’s pore structure.

4.3. Excellent Toughness

The water absorption characteristics of reactive powder concrete result in a lower chloride ion diffusion rate compared to high-performance concrete and ordinary concrete, indicating RPC’s high resistance to environmental media erosion and good abrasion resistance. RPC exhibits high resistance to corrosion, high permeability coefficients, and has excellent toughness and durability.

5. Maintenance Requirements for Reactive Powder Concrete

Concrete curing refers to the process of accelerating the hydration of concrete under appropriate temperature and humidity conditions to promote its hardening and continuous strength development. During the curing process, various conditions are created to ensure thorough hydration of cement and accelerate the hardening of concrete, while also preventing abnormal shrinkage, cracking, and other damage that may occur due to changes in external environmental conditions after concrete formation. The quality of curing will affect the physical and mechanical properties as well as the durability of concrete, and may even impact its appearance and usability. Currently, research on curing methods for reactive powder concrete (RPC) is limited to standard curing, hot water curing, and steam curing [14].

5.1. Standard Maintenance

According to the “Standard Test Methods for Mechanical Properties of Ordinary Concrete” GB/T50081, standard curing is defined as placing the specimens in a standard curing room with a temperature of 20±2°C and a relative humidity of over 95% immediately after demolding for 24 hours of static placement at a temperature of 20±5°C.

5.2. Hot Water Curing

Hot water curing involves placing the specimen in hot water for curing after demolding, followed by standard maintenance.

5.3. Steam Curing

Steam curing involves curing the specimen using steam after demolding. Steam curing can increase the 28-day strength of concrete by 10%-40%.

6. Applications of Reactive Powder Concrete

Reactive powder concrete (RPC), as a new type of cement-based composite material, is characterized by its ultra-high compressive and tensile strength, high durability, and toughness. It finds applications in various fields such as high-rise buildings, concrete product engineering, port and marine engineering, protective engineering, tunnels and underground engineering, and hydraulic engineering, achieving significant economic and social benefits. Compared to conventional high-strength concrete, it has greater advantages and a wider range of applications.

6.1. Prefabricated Structural Products

Due to its excellent ductility, RPC is widely used in the field of prefabricated products, such as bridge prefabricated components, pile prefabricated components, sidewalks, railways, pavement panels, retaining walls, and integral sound barriers. The fracture energy of RPC is 15-20 kJ/m2, exceeding that of cast iron, making RPC prefabricated products suitable replacements for cast iron products (such as manhole covers, underground pipelines, molds, etc.), significantly reducing the weight of cast iron products while achieving the same performance.

6.2. Prestressed Structure Field

High compressive strength, high modulus of elasticity, and high tensile strength are characteristics of Reactive Powder Concrete (RPC), which allow for the full utilization of the strength of prestressed tendons. While traditional concrete often incorporates prestressed tendons to prevent cracking, in most cases, their strength is still not fully utilized. However, when using RPC with prestressed tendons, not only can excessive compression deformation beneath the anchorages be avoided, but also prestress loss can be significantly reduced. Due to the minimal creep and shrinkage of RPC, the prestress loss caused by material shrinkage and creep in prestressed members is minimized. Therefore, it is evident that RPC holds promising prospects in the field of prestressed structures.

6.3. Hydraulic Engineering and Underground Engineering

Due to its superior performance in frost resistance, carbonation resistance, chloride ion erosion resistance, sulfate erosion resistance, and chemical solution erosion resistance, reactive powder concrete (RPC) has become an excellent alternative to ordinary concrete for improving hydraulic structures. RPC’s high impermeability enhances the water resistance of dam surfaces, allowing it to remain submerged in water for extended periods while maintaining its strength. In areas subject to high-speed water flow, such as spillways, drainage holes, and dam bottoms, RPC materials can also be used to enhance crack resistance. Currently, RPC is also being used abroad in various applications, including sealing of underwater gas pipelines, support structures, sealing of prestressed pipeline holes behind offshore oil platforms, and repairing corroded areas exposed to seawater.

Additionally, RPC’s excellent performance makes it applicable in various fields such as bridges, pavement engineering, construction engineering, hydraulic engineering, and special structures.

6.4. Bridge Field

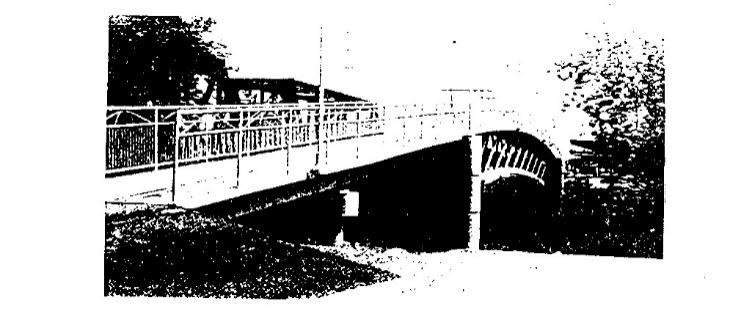

The world’s first bridge constructed with RPC as the material was the Sherbrooke Pedestrian Bridge in Quebec, Canada, completed in 1997 (see Figure 1.1). The upper structure of the bridge is a post-tensioned hollow space truss composed of 6 matched prefabricated segments. The segments are assembled on-site and tensioned into a bridge with internal and external prestressed tendons. The bridge deck and upper and lower chord rods are made of reactive powder concrete, with a compressive strength of 200 MPa. The diagonal braces of the bridge are made of stainless steel tubes filled with RPC, with a compressive strength of 350 MPa. The inter-segment length of the diagonal braces of the Sherbrooke pedestrian bridge, which spans the Magog River in Sherbrooke, Quebec, is 3 m. The bridge has a span of 60 m, a vertical curve radius of 326 m, and is accessible to bicycles and pedestrians.

Figure 2. Sherbrooke Pedestrian Bridge [15]

Regarding its application value:

RPC material can effectively reduce the cross-sectional dimensions and self-weight of bridge structures, enhancing their spanning capacity.

It will play an important role in prestressed and steel-concrete bridge engineering.

RPC material will significantly improve the durability and service life of bridges.

It will effectively reduce the construction cost of bridges and achieve significant social and economic benefits.

6.5. Railway Engineering Field

A certain study analyzed and compared the performance of ballastless track structure track slabs made of NC and RPC, finding that RPC track slabs have higher technical and economic advantages than NC solid slabs [16].

Table 6. Comparison of the mechanical properties of RPC and ordinary concrete NC (Normal Concrete):

Concrete Type | RPC | NC | RPC/NC |

Compressive Strength | 170~230 | 20~50 | Approximately 4 times |

Flexural Strength | 30~60 | 2~5 | Approximately 10 times |

Elastic Modulus | 40~60 | 30~40 | Approximately 1.2 times |

Material Fracture | 20~40 | 0.12 | Approximately 200 times |

Creep Coefficient | 0.29~0.31 | 1.3~2.1 | Approximately 20% |

Chloride Ion Diffusion | 0.02 | 1.1 | Approximately 2% |

Freeze-Thaw Peeling | 7 | >100 | <7% |

Wear Coefficient | 1.3 | 4 | Approximately 30% |

Compressive Strength / Material Density | 7.4~10 | 0.87~2.2 | Approximately 7 times |

It can be seen that RPC not only has a higher compressive strength, reaching 230 MPa, which is about 4 times that of ordinary concrete, but also has a high flexural strength, with an RPC flexural strength of 30~60 MPa, which is one order of magnitude higher than that of ordinary concrete. At the same time, the average fracture energy of RPC reaches about 30 kJ/m2, which is about 200 times that of ordinary concrete, and even comparable to aluminum metal (>10 kJ/m2). Its compressive strength-to-density ratio (compressive strength/material density) is about 7 times that of ordinary concrete and 2 times that of ordinary steel.

6.6. Pipeline Field

In the United States, various RPC sewer system construction technologies and methods have been developed to adapt to different characteristics and uses of pressure pipelines. Domestically, some have established RPC buried water pipeline models to demonstrate its applicability in municipal engineering and have provided considerations for pipeline construction requirements [16].

6.7. Other Fields

Based on product design, mold development, and construction technology, new RPC eaves boards for the Beijing Sihui Overpass East-to-North Ramp Bridge were designed and successfully applied in the replacement project [18].

In France, during the renovation of a nuclear power plant’s cooling tower, RPC materials were used to replace severely corroded truss beams, indicating RPC as an ideal material for preparing new generation nuclear waste storage containers [19].

Due to the extremely low porosity of Reactive Powder Concrete (RPC), it can prevent radioactive substances from leaking internally and resist the corrosion of external aggressive media. Therefore, using RPC as a material for nuclear power plants is a reasonable choice. RPC, with its strong compressive strength and wear resistance, is suitable for structural ground bearing heavy loads, such as industrial and warehouse floors. Additionally, in strengthening materials, seismic reinforcement materials, and refractory product manufacturing, its effects are also significant.

As a high-tech concrete, Reactive Powder Concrete (RPC) has excellent mechanical properties, indicating significant development prospects. Compared with ordinary concrete and existing high-performance concrete, RPC has undergone a qualitative leap.

7. Conclusion

(1) The higher the silica fume content in RPC, the higher the steel fiber content needs to be increased to compensate for its adverse effects on concrete cracking.

(2) To meet the mechanical properties and fluidity requirements of RPC, the water-cement ratio is generally set at 0.16 to 0.24. Excessive or insufficient water-cement ratio will reduce the compressive strength of RPC.

(3) RPC exhibits good acid erosion resistance with the prolongation of immersion time in sulfuric acid and hydrochloric acid solutions.

(4) RPC has a near-zero carbonization depth, which enables it to resist the carbonization effect of the external environment effectively.

In summary, despite the many advantages of RPC such as high specific strength, durability, seismic resistance, and impact resistance, rational design and construction are still necessary based on specific requirements and engineering conditions in practical applications.

References

[1]. Liu, H., Chen, J., Jia, Y., Ju, Y., & Ye, G. (2008). Study on preparation technology and mechanical properties of reactive powder concrete. Industrial Construction, 74-78.

[2]. Qin, W. (2002). Research on reactive powder concrete. Petroleum Engineering Construction, 1-3+2.

[3]. Long, P., Liu, K., Song, H., Qiao, H., & Wang, Q. (2020). Application and analysis of reactive powder concrete on new composite structures. In Proceedings of the 2020 Industrial Construction Academic Exchange Conference (Vol. 2, pp. 728-733). Publisher Not Available. DOI:10.26914/c.cnkihy.2020.024296.

[4]. Jin, L., Qi, K., Liu, P., Zhao, X., & Wu, X. (2013). Experimental study on static load-bearing capacity of prestressed RPC crane beams in positive section. Architectural Science, 29(03), 40-45. DOI:10.13614/j.cnki.11-1962/tu.2013.03.015.

[5]. Wang, D. (2015). Research on the application of reactive powder concrete pipes in water conveyance projects (Doctoral dissertation, Hebei Agricultural University).

[6]. Song, S., & Wei, C. (2006). Study on durability of reactive powder concrete. Concrete, 72-73+80.

[7]. Wang, Z. (2011). Study on chloride ion erosion and permeability of reactive powder concrete (Doctoral dissertation, Beijing Jiaotong University).

[8]. He, F., Huang, Z., & Yi, W. (2011). Acid resistance of reactive powder concrete. Journal of Natural Disasters, 20(02), 44-49. DOI:10.13577/j.jnd.2011.0207.

[9]. Yang, Y., Hou, Z., Gong, C., & Wang, Y. (2018). Research on influencing factors of seismic performance of high-strength steel-concrete columns. Advances in Structural Engineering, 20(05), 11-21. DOI:10.13969/j.cnki.cn31-1893.2018.05.002.

[10]. Li, S., & Jia, X. (2020). Seismic performance of new type of steel-concrete columns. Journal of Shenyang University (Natural Science), 32(05), 423-430. DOI:10.16103/j.cnki.21-1583/n.2020.05.011.

[11]. Zhang, Q., Cao, X., Xiao, L., Chang, Y., Mu, R., & Cao, J. (2021). Experimental study on seismic performance of steel-constrained concrete columns. Building Structure, 51(02), 85-91. DOI:10.19701/j.jzjg.2021.02.014.

[12]. Luo, B. (2014). Study on bursting law and mechanical properties of reactive powder concrete under high temperature (Doctoral dissertation, Harbin Institute of Technology).

[13]. Lin, J., Gao, S., Yin, S., Lu, L., Chang, Y., & Wang, J. (2019). Study on pore structure of reactive powder concrete under high temperature. Journal of Hainan University (Natural Science), 37(02), 172-179. DOI:10.15886/j.cnki.hdxbzkb.2019.0025.

[14]. Zhou, X., Zhang, S., & Xie, Y. (2010). Influence of curing system on strength and dry shrinkage performance of RPC. Concrete, 42-44.

[15]. Zhou, Y., & Du, Y. (2000). The world’s first prefabricated prestressed reactive powder concrete structure - Sherbrooke pedestrian bridge. Foreign Bridges, 18-23.

[16]. Yang, J., Wang, J., & Peng, X. (2015). Research and prospect of RPC application in ballastless track. Journal of Railway Science and Engineering, 12(01), 53-58. DOI:10.19713/j.cnki.43-1423/u.2015.01.009.

[17]. Wang, D. (2015). Research on the application of reactive powder concrete pipes in water conveyance projects (Doctoral dissertation, Hebei Agricultural University).

[18]. Fan, L., Li, D., Lu, S., Peng, M., Cao, Z., Li, R., & Zhang, Y. (2014). Development and engineering application of RPC eaves boards. Concrete and Cement Products, 44-46. DOI:10.19761/j.1000-4637.2014.04.012.

[19]. Li, X., Wu, F., Shou, Q., & Feng, J. (2012). Analysis of engineering performance and application prospects of reactive powder concrete (RPC). China Water Transport (Second Half of the Month), 12(07), 225-227.

Cite this article

Zhao,Y. (2024). Performance analysis and application fields of reactive powder concrete. Applied and Computational Engineering,63,137-145.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Liu, H., Chen, J., Jia, Y., Ju, Y., & Ye, G. (2008). Study on preparation technology and mechanical properties of reactive powder concrete. Industrial Construction, 74-78.

[2]. Qin, W. (2002). Research on reactive powder concrete. Petroleum Engineering Construction, 1-3+2.

[3]. Long, P., Liu, K., Song, H., Qiao, H., & Wang, Q. (2020). Application and analysis of reactive powder concrete on new composite structures. In Proceedings of the 2020 Industrial Construction Academic Exchange Conference (Vol. 2, pp. 728-733). Publisher Not Available. DOI:10.26914/c.cnkihy.2020.024296.

[4]. Jin, L., Qi, K., Liu, P., Zhao, X., & Wu, X. (2013). Experimental study on static load-bearing capacity of prestressed RPC crane beams in positive section. Architectural Science, 29(03), 40-45. DOI:10.13614/j.cnki.11-1962/tu.2013.03.015.

[5]. Wang, D. (2015). Research on the application of reactive powder concrete pipes in water conveyance projects (Doctoral dissertation, Hebei Agricultural University).

[6]. Song, S., & Wei, C. (2006). Study on durability of reactive powder concrete. Concrete, 72-73+80.

[7]. Wang, Z. (2011). Study on chloride ion erosion and permeability of reactive powder concrete (Doctoral dissertation, Beijing Jiaotong University).

[8]. He, F., Huang, Z., & Yi, W. (2011). Acid resistance of reactive powder concrete. Journal of Natural Disasters, 20(02), 44-49. DOI:10.13577/j.jnd.2011.0207.

[9]. Yang, Y., Hou, Z., Gong, C., & Wang, Y. (2018). Research on influencing factors of seismic performance of high-strength steel-concrete columns. Advances in Structural Engineering, 20(05), 11-21. DOI:10.13969/j.cnki.cn31-1893.2018.05.002.

[10]. Li, S., & Jia, X. (2020). Seismic performance of new type of steel-concrete columns. Journal of Shenyang University (Natural Science), 32(05), 423-430. DOI:10.16103/j.cnki.21-1583/n.2020.05.011.

[11]. Zhang, Q., Cao, X., Xiao, L., Chang, Y., Mu, R., & Cao, J. (2021). Experimental study on seismic performance of steel-constrained concrete columns. Building Structure, 51(02), 85-91. DOI:10.19701/j.jzjg.2021.02.014.

[12]. Luo, B. (2014). Study on bursting law and mechanical properties of reactive powder concrete under high temperature (Doctoral dissertation, Harbin Institute of Technology).

[13]. Lin, J., Gao, S., Yin, S., Lu, L., Chang, Y., & Wang, J. (2019). Study on pore structure of reactive powder concrete under high temperature. Journal of Hainan University (Natural Science), 37(02), 172-179. DOI:10.15886/j.cnki.hdxbzkb.2019.0025.

[14]. Zhou, X., Zhang, S., & Xie, Y. (2010). Influence of curing system on strength and dry shrinkage performance of RPC. Concrete, 42-44.

[15]. Zhou, Y., & Du, Y. (2000). The world’s first prefabricated prestressed reactive powder concrete structure - Sherbrooke pedestrian bridge. Foreign Bridges, 18-23.

[16]. Yang, J., Wang, J., & Peng, X. (2015). Research and prospect of RPC application in ballastless track. Journal of Railway Science and Engineering, 12(01), 53-58. DOI:10.19713/j.cnki.43-1423/u.2015.01.009.

[17]. Wang, D. (2015). Research on the application of reactive powder concrete pipes in water conveyance projects (Doctoral dissertation, Hebei Agricultural University).

[18]. Fan, L., Li, D., Lu, S., Peng, M., Cao, Z., Li, R., & Zhang, Y. (2014). Development and engineering application of RPC eaves boards. Concrete and Cement Products, 44-46. DOI:10.19761/j.1000-4637.2014.04.012.

[19]. Li, X., Wu, F., Shou, Q., & Feng, J. (2012). Analysis of engineering performance and application prospects of reactive powder concrete (RPC). China Water Transport (Second Half of the Month), 12(07), 225-227.