1. Introduction

The movement of solid particles in curved channels is more common in environments such as the energy industry, pharmaceutical and food industries, as well as in ventilation and heat exchange channels. Particularly in indoor ventilation systems, where curved ducts are common, the deposition and dispersion behaviour of aerosol particles in ventilation ducts can affect the air quality of the indoor environment, thus impairing the health of workers [1]. Variable cross-section ducts, such as expansion and contraction, are often used in HVAC (heating, ventilation and air conditioning) systems. Due to the large changes in geometry and flow field structure, the particle deposition rate and deposition mechanism in ducts with different cross-sections may be very different from those in uniform ducts [2], however, there are fewer studies on particle deposition and diffusion in these types of ducts, and therefore a careful study is necessary.

This paper examines the deposition behaviour of monodisperse particles in homogeneous pipes. The deposition behaviour of monodisperse particles has been extensively studied over the past few decades through experimental studies, theoretical analyses, and numerical simulations [3-5]. Due to the development of computer technology, the use of numerical methods has become an effective way of providing information on particle and gas flow. Models can be divided into continuum models and discrete body models based on the treatment of the particle phase. [6, 7]. Among them, the discrete-phase approach is usually used in ventilation ducts because the continuum model cannot solve the problem of motion trajectories and particle accumulation on the particle scale. When using discrete methods in the particle phase, it is common to track each particle using the Lagrangian method. The discrete element method (DEM) or discrete phase model (DPM) can be employed for this purpose. The DEM framework effortlessly considers the discrete nature of granular systems. DEM is a powerful numerical simulation technique for modelling and reproducing discrete media flows, especially dense granular flows, based on Newton's laws of motion. The use of DEM in CFD-DEM simulations enables the tracking of individual particles in a particle-fluid system, providing valuable particle-level information for understanding the underlying mechanisms of particle-fluid flow. In their study, Chaumeil and Crapper [8] examined the process of aggregation and deposition of colloidal particles on shrink-tube collectors in immersed liquids using the discrete element method. Li et al. [9] investigated the aggregation and growth behaviours of fluid-driven fine particles on the pore scale based on CFD-DEM in the field of efficient oil and gas development. The study considered the continuous injection and transport process of fluid-driven fine particles and obtained the aggregation and growth behaviours of particles in porous media. The study also explored the effects of particle aggregation and growth on hydraulic properties. There are more review studies related to DEM, for example In 2020, Wang [10] conducted a comprehensive pedagogical review of various state-of-the-art CFD-based methods for simulating fluid dynamics in gas-solid fluidisation techniques, with CFD-DEM as a component. A review of CFD simulations of fluidised beds was provided by Alobaid et al. [11]. The CFD-DEM method is commonly used to study dense particles in fluidised beds. Although the CFD-DEM method can perform the coupled particle-fluid simulation better, for the simulation of particle deposition in ventilation ducts, the DPM method is usually used because the particle density is much lower than the fluid phase. Shang and Tao [12] investigated the effect of different cross-sectional types of pipes (circular, semi-circular, and square) on the deposition and diffusion of aerosolised particulate matter in supercritical CO2 using the DPM model for the study of colloidal particulate matter. Particle deposition in large-scale roughness bend turbulence was probed by Ladino et al. [13] using k-ε RNG and DPM methods. Lu and Lu [14] employed DPM and modified RSM models to investigate particle deposition in smooth rib-walled turbulent duct flows. The study revealed that the primary mechanisms for the increased deposition of small particles are rib-induced turbulent vortex trapping and entrainment of turbulent kinetic energy to the wall. The DPM model is primarily used to study aerosol particulate matter in pipelines due to the lower density of aerosol particulate matter compared to gas density. Therefore, the DPM model will also be used to calculate the particle phase in this study.

This study employs numerical calculations to investigate particle deposition in 90-degree curved pipes with different scaling factors, focusing on monodisperse particles. The method used is based on the Lagrange method and a discrete phase model, which is consistent with previous studies. The aim is to provide design ideas for related projects.

2. Calculation method

The RNG k - ε model and DPM coupling are used in this study. This is because it was used by previous researchers in their studies on bends, such as Sun et al. [15] and Zhang et al. [16]. As particle deposition is highly dependent on wall treatment, the accuracy of the wall treatment affects both the accuracy of particle deposition and the fidelity of the separation flow under high backpressure gradients. Therefore, this study employs enhanced wall treatment (EWT), a validated method used by other researchers. (Guo et al. [17] and Lu and Lu [18]).

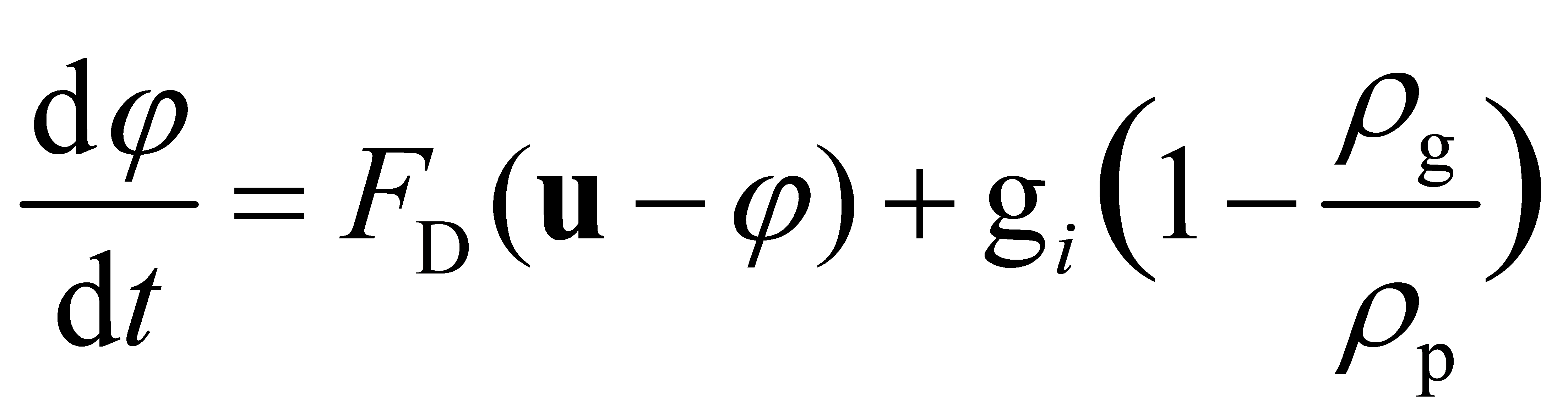

The Lagrange method is utilised for particle tracking, and the forces acting on the particles comply with the second law of Newton, a discrete random walk (DRW) model has been developed, and the force balance equation for a single particle is as follows:

(1)

(1)

Stokes number is more important in this study and Stokes number  is:

is:

(2)

(2)

The numerical solution is based on a semi-implicit method (SIMPLE) for the coupled pressure-velocity pressure-connection equations, with second-order windward discretisation of the advection terms of the momentum and turbulence equations. The absolute residual convergence criterion for all variables is set to 10-5.

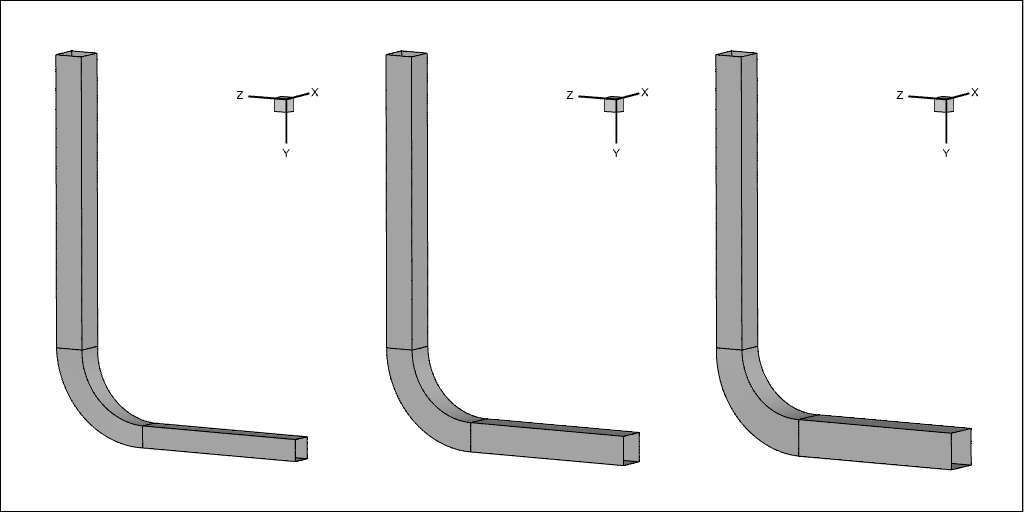

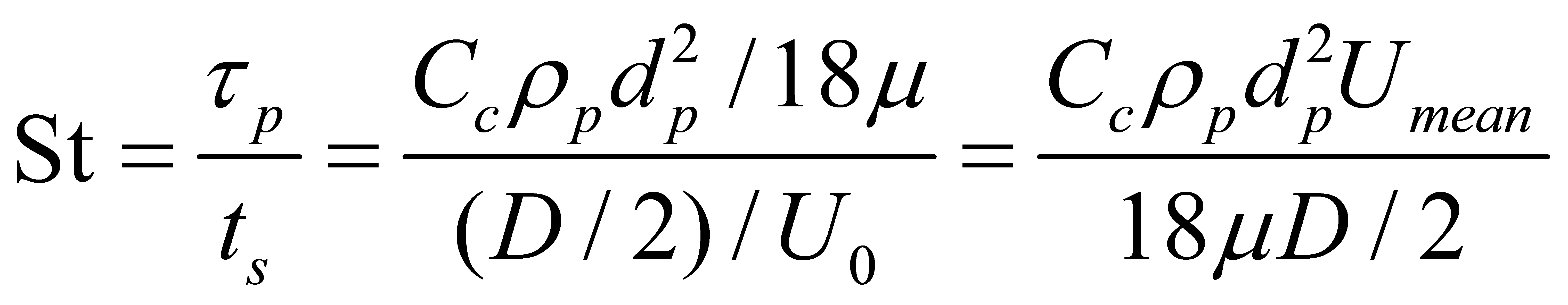

3. Geometrical model

The boundary conditions in this study use velocity inlet and pressure outlet, and the walls are non-slip walls. The computational domain is displayed in Figure 1, where D1 has a value of 8.51 mm and the Reynolds number is 10,000. The front and rear sections of the bend use 10 D1 and 6 D1, respectively, to eliminate the effects of the inlet and outlet on the bend section. At the duct inlet, monodisperse particles are uniformly released comprising of around 25,000 particles, with a particle velocity equivalent to the air velocity. The particle size range studied was between 2-9.5 μm with the corresponding Stokes numbers ranging from 0.049-1.03, as shown in Table 1. The particle density of 895 kg/m3 is in agreement with the experimental conditions of Pui et al [19], as well as the existing numerical simulation study [17]. This study builds on previous work. The air density is 1.225 kg/m3 and the dynamic viscosity is 1.7894 × 10−5 kg·(m·s)-1, The turbulence intensity is 5%, and the walls are subject to a no-slip boundary condition.

Figure 1. Three-dimensional 90° bend geometry model.

Table 1. Parameters of the particle phase

Particle diameter(μm) | 2.00 | 3.00 | 4.10 | 4.82 | 6.32 | 7.20 | 8.09 | 9.00 | 9.50 |

Stokes number | 0.049 | 0.107 | 0.197 | 0.270 | 0.461 | 0.596 | 0.750 | 0.926 | 1.030 |

Dimensionless deposition time | 2.584 | 5.695 | 10.415 | 14.307 | 24.395 | 31.558 | 39.739 | 49.077 | 54.627 |

Define the asymptotic coefficient K = D2/D1, this study calculates three different bends, respectively, when K = 0.75, 1.0, 1.25. The specific calculation model is shown in Figure 2.

| ||

(a)K=0.75 | (b)K=1.0 | (c)K=1.25 |

Figure 2. Geometric Modelling of Calculations

4. Calculated results

4.1. Validation of numerical results

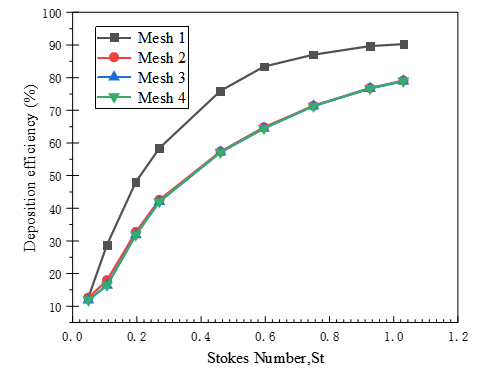

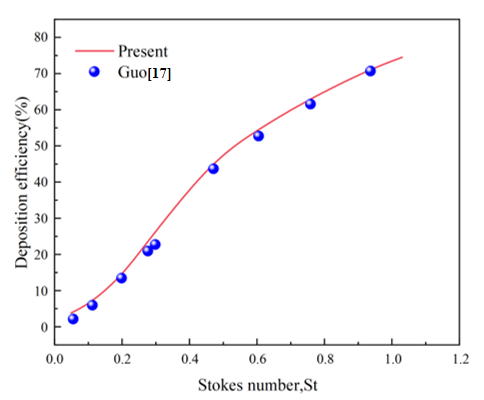

To ensure the accuracy of the simulation results, we first verified the grid. We used four groups of grids with 600,000, 800,000, 1,000,000, and 1,200,000 grids. Based on Figure 3(a), we selected the third group of grids (1,000,000) for the calculation. To validate the methodology used in this study, we compared the results with those of Guo et al. [17], as shown in Figure 3(b). The results were well-fitted, indicating the validity of our study.

|

|

(a) Grid independence verification | (b) Particle deposition validation |

Figure 3. Numerical verification.

4.2. Effect of different K on particle deposition

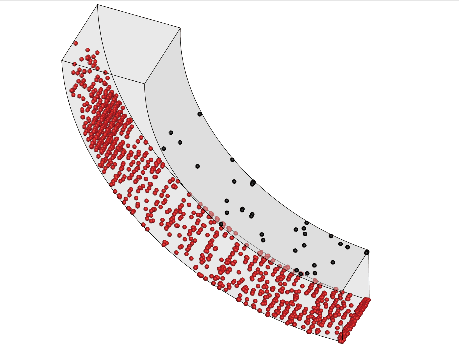

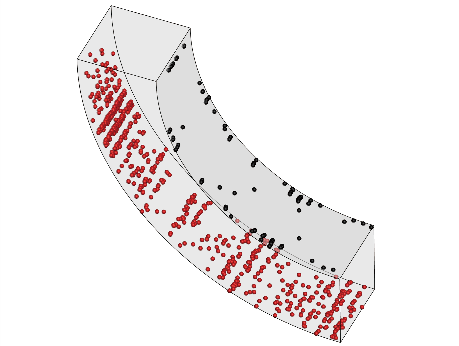

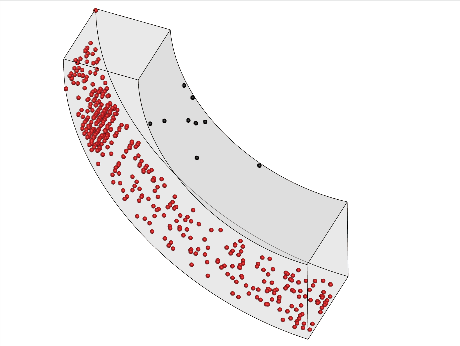

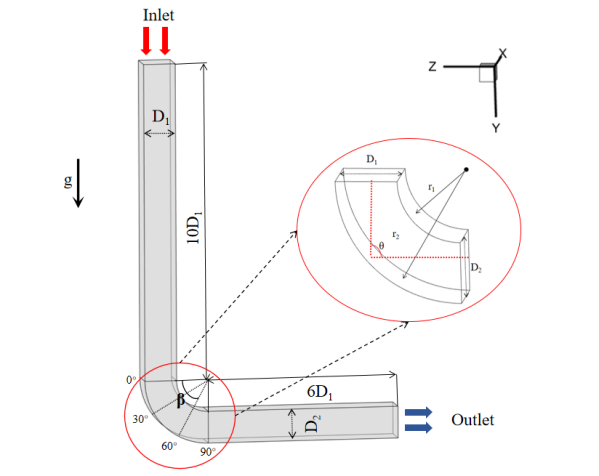

The particle deposition efficiency increases gradually with increasing particle size. As particle size increases, particle deposition is primarily affected by gravity. This effect reduces the velocity of the particles inside the bend, making it easier for them to deposit on the bend's wall. Changes in the pipe's cross-section have a more significant impact on particle deposition. The deposition of particles becomes significantly worse as K increases. As K increases, the velocity gradient in the pipe decreases significantly, resulting in a lower fluid viscous force. This causes small particles to be subjected to turbulence, making them less likely to be deposited on the pipe wall. Additionally, the wider channel results in lower resistance to flow, reducing the chance of particle deposition. Figure 4 illustrates the effect of specific Stokes number and K on particle deposition efficiency. The deposition of particles on the inside and outside of the bend is shown schematically in Figure 5.

Figure 4. Effect of different asymptotic coefficients on particle deposition

|

|

|

(a)K=0.75 | (b)K=1.0 | (c)K=1.25 |

Figure 5. Schematic of particle deposition at 2 μm particle size

5. Conclusions

This study investigates the deposition-diffusion characteristics of aerosol particles in a 90-degree elbow pipe with a shrinking or expanding cross-sectional area through numerical simulation. The study examines the effects of different Stokes numbers and pipe cross-sectional variation coefficients (K) on the deposition efficiency and location of particles.

1. Particle deposition in bends is strongly influenced by the Stokes number and the deposition efficiency increases with increasing Stokes number.

2. The asymptotic coefficient K affects particle deposition in the bend. As K increases, the efficiency of particle deposition decreases. When the particle size is 2 μm, the deposition efficiency of the pipe with K = 0.75 is five times larger than that of K = 1.25.

3. The location of particle deposition is influenced by K. Gravity causes the particles to be primarily deposited on the outer curved wall of the bend. On the inner curved wall, the largest number of particles with a size of 2 μm are deposited at K = 1.0, and they are more concentrated at the connection with the side wall. At K = 1.25, the number of particles deposited on the inner curved wall is the smallest, and the location is mainly concentrated in the inlet section. As the value of K increases, the number of particles deposited on the outer curved wall decreases, and there is a significant decrease in the number of particles deposited in the exit portion. Consequently, the particle deposition efficiency of the entire bend decreases.

Acknowledgments

The authors appreciate the financial supports provided by National Oversea High-level Talents Program of China, National Natural Science Foundation of China (No. 52266017) and the Major Project of the National Social Science Foundation of China (No. 21&ZD133). It is also supported by the Xinjiang Natural Science Fund for Distinguished Young Scholars (No.2021D01E08), the Xinjiang Regional Coordination Special Project-International Science and Technology Cooperation Program (No.2022E01026), the Xinjiang Major Science and Technology Special Project (No.2022401002-2,2022A01007-1,2022A01007-4), the Xinjiang Key Research and development Project (No.2022B03028-2, No.2022B01033-2, No.2022B01022-1), the Central Guidance on Local Science and Technology Development Project (No.ZYYD2022C16), the Innovation Team Project of Xinjiang University (500122006021) and High-level Talents Project of Xinjiang University (No.100521001).

References

[1]. M.H. Gielen, S. Van Der Zee, J. Van Wijnen, C. Van Steen, B. Brunekreef, Acute effects of summer air pollution on respiratory health of asthmatic children, American journal of respiratory and critical care medicine, 155 (1997) 2105-2108.

[2]. H. Lu, L. Lu, Y. Jiang, Numerical study of monodispersed particle deposition rates in variable-section ducts with different expanding or contracting ratios, Applied Thermal Engineering, 110 (2017) 150-161.

[3]. B.Y. Liu, J.K. Agarwal, Experimental observation of aerosol deposition in turbulent flow, Journal of Aerosol Science, 5 (1974) 145-155.

[4]. B. Zhao, J. Wu, Modeling particle deposition onto rough walls in ventilation duct, Atmospheric Environment, 40 (2006) 6918-6927.

[5]. N. Gao, J. Niu, Q. He, T. Zhu, J. Wu, Using RANS turbulence models and Lagrangian approach to predict particle deposition in turbulent channel flows, Building and Environment, 48 (2012) 206-214.

[6]. H. Zhu, Z. Zhou, R. Yang, A. Yu, Discrete particle simulation of particulate systems: a review of major applications and findings, Chemical Engineering Science, 63 (2008) 5728-5770.

[7]. N. Mangadoddy, T.R. Vakamalla, M. Kumar, A. Mainza, Computational modelling of particle-fluid dynamics in comminution and classification: a review, Mineral Processing and Extractive Metallurgy, 129 (2020) 145-156.

[8]. F. Chaumeil, M. Crapper, Using the DEM-CFD method to predict Brownian particle deposition in a constricted tube, Particuology, 15 (2014) 94-106.

[9]. H. Li, S. Wang, X. Chen, L. Xie, B. Shao, Y. Ma, CFD-DEM simulation of aggregation and growth behaviors of fluid-flow-driven migrating particle in porous media, Geoenergy Science and Engineering, 231 (2023) 212343.

[10]. J. Wang, Continuum theory for dense gas-solid flow: A state-of-the-art review, Chemical Engineering Science, 215 (2020) 115428.

[11]. F. Alobaid, N. Almohammed, M.M. Farid, J. May, P. Rößger, A. Richter, B. Epple, Progress in CFD simulations of fluidized beds for chemical and energy process engineering, Progress in Energy and Combustion Science, 91 (2022) 100930.

[12]. S. Mao, T. Zhou, Y. Liao, J. Tang, X. Liu, Thermal-hydraulic and particle deposition analysis of supercritical CO2 in different tubes, Powder Technology, 413 (2023) 118076.

[13]. Ladino, C.A. Duque-Daza, S. Lain, Effect of walls with large scale roughness in deposition efficiency for 90-degree square bend configurations, Journal of Aerosol Science, 167 (2023) 106093.

[14]. H. Lu, L. Lu, Numerical investigation on particle deposition enhancement in duct air flow by ribbed wall, Building and Environment, 85 (2015) 61-72.

[15]. K. Sun, L. Lu, H. Jiang, A numerical study of bend-induced particle deposition in and behind duct bends, Building and Environment, 52 (2012) 77-87.

[16]. P. Zhang, R.M. Roberts, A. Bénard, Computational guidelines and an empirical model for particle deposition in curved pipes using an Eulerian-Lagrangian approach, Journal of Aerosol Science, 53 (2012) 1-20.

[17]. J. Guo, Z. Chen, B. Shen, J. Wang, L. Yang, Numerical study on characteristics of particle deposition efficiency on different walls of 90° square bend, Powder Technology, 364 (2020) 572-583.

[18]. H. Lu, L. Lu, CFD investigation on particle deposition in aligned and staggered ribbed duct air flows, Applied Thermal Engineering, 93 (2016) 697-706.

[19]. D.Y. Pui, F. Romay-Novas, B.Y. Liu, Experimental study of particle deposition in bends of circular cross section, Aerosol Science and Technology, 7 (1987) 301-315.

Cite this article

Wang,Y.;Lu,H. (2024). Numerical study of deposition rates of monodisperse particles in curved pipes with different expansion or shrinkage variables. Applied and Computational Engineering,63,146-152.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. M.H. Gielen, S. Van Der Zee, J. Van Wijnen, C. Van Steen, B. Brunekreef, Acute effects of summer air pollution on respiratory health of asthmatic children, American journal of respiratory and critical care medicine, 155 (1997) 2105-2108.

[2]. H. Lu, L. Lu, Y. Jiang, Numerical study of monodispersed particle deposition rates in variable-section ducts with different expanding or contracting ratios, Applied Thermal Engineering, 110 (2017) 150-161.

[3]. B.Y. Liu, J.K. Agarwal, Experimental observation of aerosol deposition in turbulent flow, Journal of Aerosol Science, 5 (1974) 145-155.

[4]. B. Zhao, J. Wu, Modeling particle deposition onto rough walls in ventilation duct, Atmospheric Environment, 40 (2006) 6918-6927.

[5]. N. Gao, J. Niu, Q. He, T. Zhu, J. Wu, Using RANS turbulence models and Lagrangian approach to predict particle deposition in turbulent channel flows, Building and Environment, 48 (2012) 206-214.

[6]. H. Zhu, Z. Zhou, R. Yang, A. Yu, Discrete particle simulation of particulate systems: a review of major applications and findings, Chemical Engineering Science, 63 (2008) 5728-5770.

[7]. N. Mangadoddy, T.R. Vakamalla, M. Kumar, A. Mainza, Computational modelling of particle-fluid dynamics in comminution and classification: a review, Mineral Processing and Extractive Metallurgy, 129 (2020) 145-156.

[8]. F. Chaumeil, M. Crapper, Using the DEM-CFD method to predict Brownian particle deposition in a constricted tube, Particuology, 15 (2014) 94-106.

[9]. H. Li, S. Wang, X. Chen, L. Xie, B. Shao, Y. Ma, CFD-DEM simulation of aggregation and growth behaviors of fluid-flow-driven migrating particle in porous media, Geoenergy Science and Engineering, 231 (2023) 212343.

[10]. J. Wang, Continuum theory for dense gas-solid flow: A state-of-the-art review, Chemical Engineering Science, 215 (2020) 115428.

[11]. F. Alobaid, N. Almohammed, M.M. Farid, J. May, P. Rößger, A. Richter, B. Epple, Progress in CFD simulations of fluidized beds for chemical and energy process engineering, Progress in Energy and Combustion Science, 91 (2022) 100930.

[12]. S. Mao, T. Zhou, Y. Liao, J. Tang, X. Liu, Thermal-hydraulic and particle deposition analysis of supercritical CO2 in different tubes, Powder Technology, 413 (2023) 118076.

[13]. Ladino, C.A. Duque-Daza, S. Lain, Effect of walls with large scale roughness in deposition efficiency for 90-degree square bend configurations, Journal of Aerosol Science, 167 (2023) 106093.

[14]. H. Lu, L. Lu, Numerical investigation on particle deposition enhancement in duct air flow by ribbed wall, Building and Environment, 85 (2015) 61-72.

[15]. K. Sun, L. Lu, H. Jiang, A numerical study of bend-induced particle deposition in and behind duct bends, Building and Environment, 52 (2012) 77-87.

[16]. P. Zhang, R.M. Roberts, A. Bénard, Computational guidelines and an empirical model for particle deposition in curved pipes using an Eulerian-Lagrangian approach, Journal of Aerosol Science, 53 (2012) 1-20.

[17]. J. Guo, Z. Chen, B. Shen, J. Wang, L. Yang, Numerical study on characteristics of particle deposition efficiency on different walls of 90° square bend, Powder Technology, 364 (2020) 572-583.

[18]. H. Lu, L. Lu, CFD investigation on particle deposition in aligned and staggered ribbed duct air flows, Applied Thermal Engineering, 93 (2016) 697-706.

[19]. D.Y. Pui, F. Romay-Novas, B.Y. Liu, Experimental study of particle deposition in bends of circular cross section, Aerosol Science and Technology, 7 (1987) 301-315.