1. Introduction

Razor clams are deliciously flavored and are extensively cultivated in coastal areas of our country [1], with a production reaching 847,600 tons and a cultivation area of 42,800 hectares in 2022 [2]. Currently, razor clam cultivation relies on manual seedling dispersion during the spring and autumn seasons, characterized by harsh working conditions, low efficiency, poor uniformity, and high labor costs, urgently necessitating a mechanized razor clam seedling dispensing device.

Scholars both domestically and internationally have conducted numerous studies on seeding and jet pumps. Wang Yongmei et al. [3] replaced the straight-groove wheel with a spiral-groove wheel, which cushions the seed group and increases the uniformity of seed distribution. Gai Miaomiao et al. [4] designed a guide-type horizontal disc precision seeder that takes full advantage of the long seeding stroke of the horizontal disc seeder. A guide groove formed by a guide plate on the outer side of the mold hole was designed to achieve orderly seeding of multiple seeds. Liu Chunbo et al. [5] studied the correlation between the seed discharge shaft's rotational speed and the seeding amount, and conducted experiments on the impact of spiral angle on seeding uniformity, the impact of the opening degree of the spiral seed discharge wheel on the seeding amount, and the impact of rice seeds on the seeding amount. Internationally, the development of seeding machinery in agriculturally advanced countries such as the United States, the United Kingdom, and Germany has been the main focus [6]. The United States has successfully developed a series of seed filling with both type-hole discs and round-hole discs. Italy improved the suction holes on the seed discharge disc into pedestal shapes, enhancing seed fluidity, reducing the probability of friction between seeds and the seed discharge disc, and decreasing the variability among seeds. Elger et al. [7] analyzed the situation of jet pump placement under different areas and concluded that the formation of the recirculation zone is closely related to the momentum ratio. Gazzar et al. [8] used CFX-TASC to simulate the flow characteristics inside the pump. Shimizu et al. [9] found through experiments that annular jet pumps have advantages over central jet pumps in terms of performance and structure. Kwon et al. [10] based on numerical simulations, determined that the pump efficiency of the annular jet pump is highest when the suction chamber's contraction angle is 12°. Yamazaki et al. [11] established through research that the relationship between energy loss and surface roughness is linear.

This paper designs an annular jet-type razor clam seedling dispensing device based on the technical requirements for tidal flat razor clam seedling cultivation, establishes a three-dimensional model of the device, optimizes the parameters of the jet pump through Fluent simulation, and verifies the accuracy of the simulation results through experiments.

2. Design of a Hydraulic Razor Clam Seedling Dispensing Device

2.1. Overall Structure of the Hydraulic Razor Clam Seedling Dispensing Device

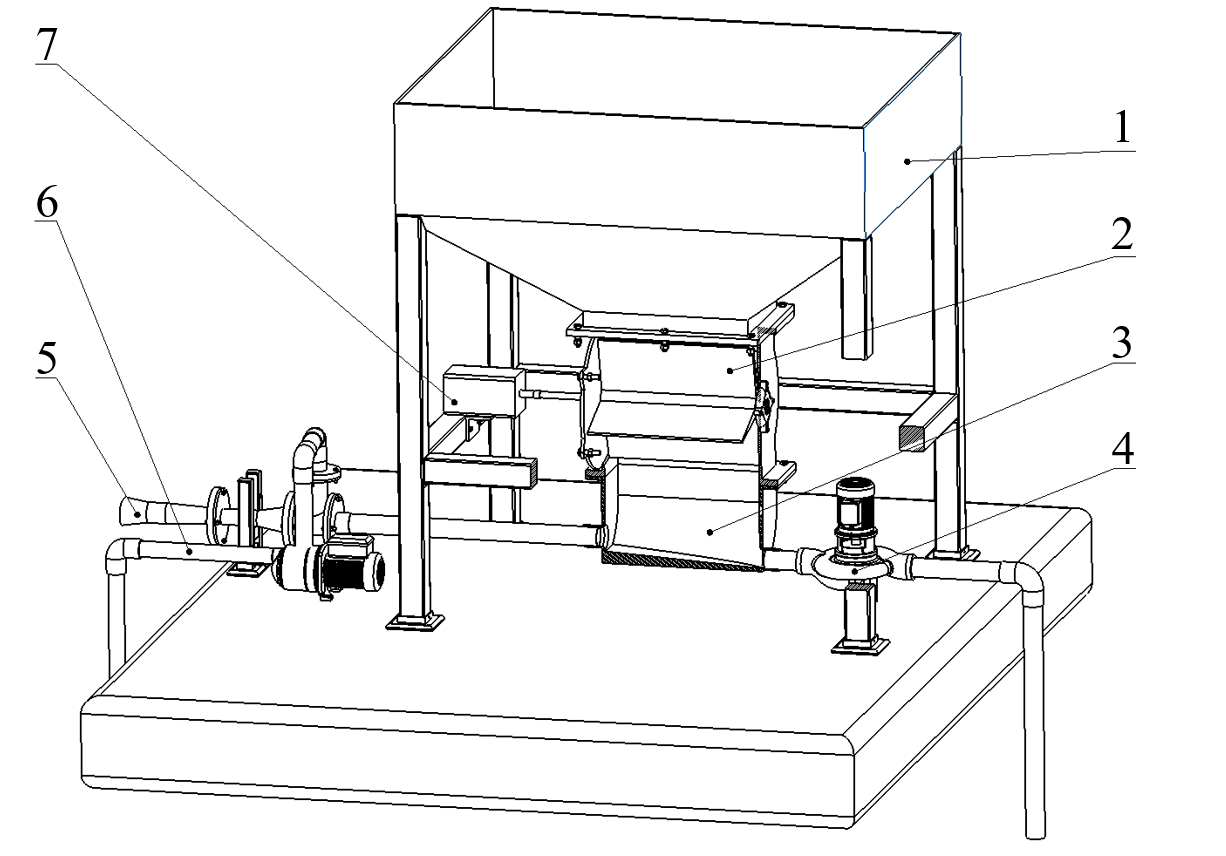

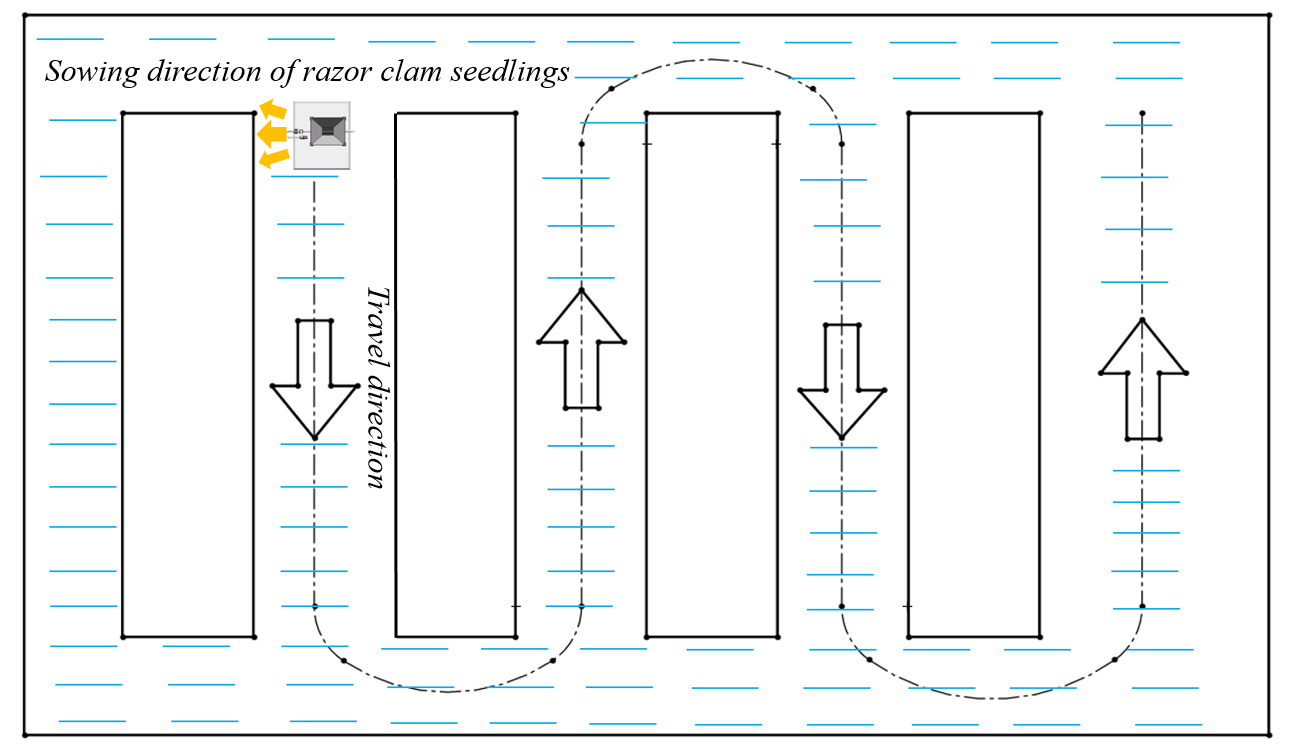

The razor clam seedling dispensing device designed in this paper is shown in Figure 1. When in operation, the device is placed on the water surface and manually propelled. It mainly includes a hopper, frame, trough wheel falling mechanism, jet pump, DC motor, etc. The surfaces of the hopper, trough wheel falling mechanism, and premix chamber are wrapped in a flexible material to prevent the seedlings from being damaged upon impact. The hopper is fixed to the trough wheel falling mechanism, the upper end of the falling mechanism is connected to the hopper, and the lower end is connected to the premix chamber. The DC motor is securely mounted on the frame, and the jet pump is fixed to one side of the overall device alongside the water pipe through a rack. During seeding, the razor clam seedlings are poured into the hopper, the DC motor is powered on, and the seedlings, under the effect of their own gravity, enter the premix chamber through the falling mechanism. Inside the premix chamber, under the effect of the internal fluid, they are taken into the jet pump and finally sprayed into the designated area, completing the seeding process as shown in Figure 2.

Figure 1. Overall Structure Diagram of the Seedling Dispensing Device (1. Hopper 2. Trough Wheel Falling Mechanism 3. Premix Chamber 4. Centrifugal Pump 5. Jet Pump 6. Inlet Pipe 7. DC Motor)

Figure 2. Schematic Diagram of the Seeding Operation

2.2. Jet Seeding Mechanism Design

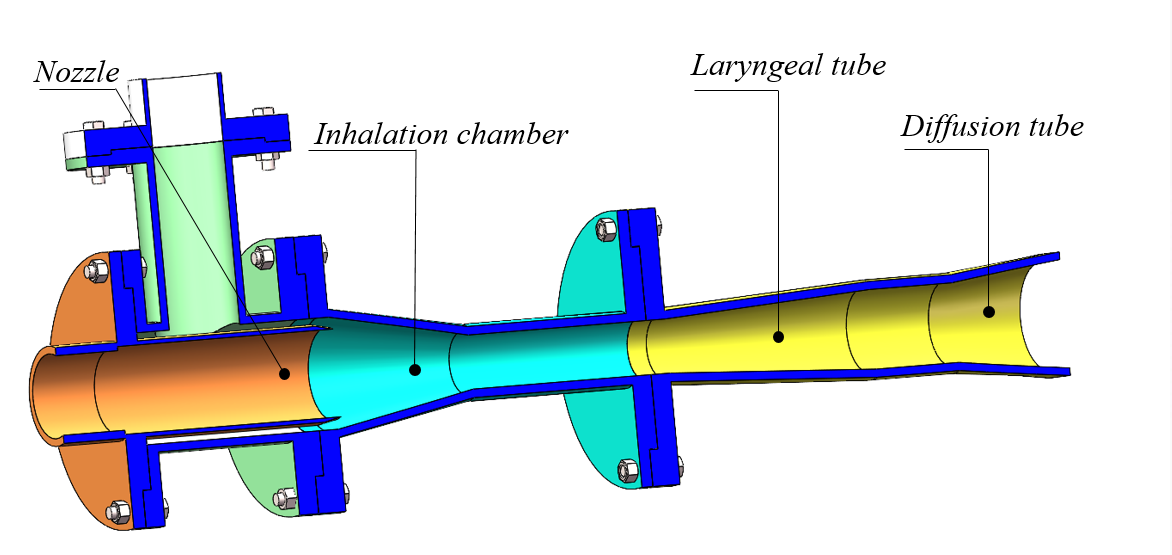

The jet seeding mechanism primarily consists of a nozzle, suction chamber, throat tube, and diffusion tube, with the three-dimensional model shown in Figure 3. The nozzle of the annular jet pump is placed at the inlet pipe of the sucked fluid, creating an unobstructed channel throughout the pump body, suitable for conveying a mixture of razor clam seedlings and water [12], providing conditions for hydraulic transportation.

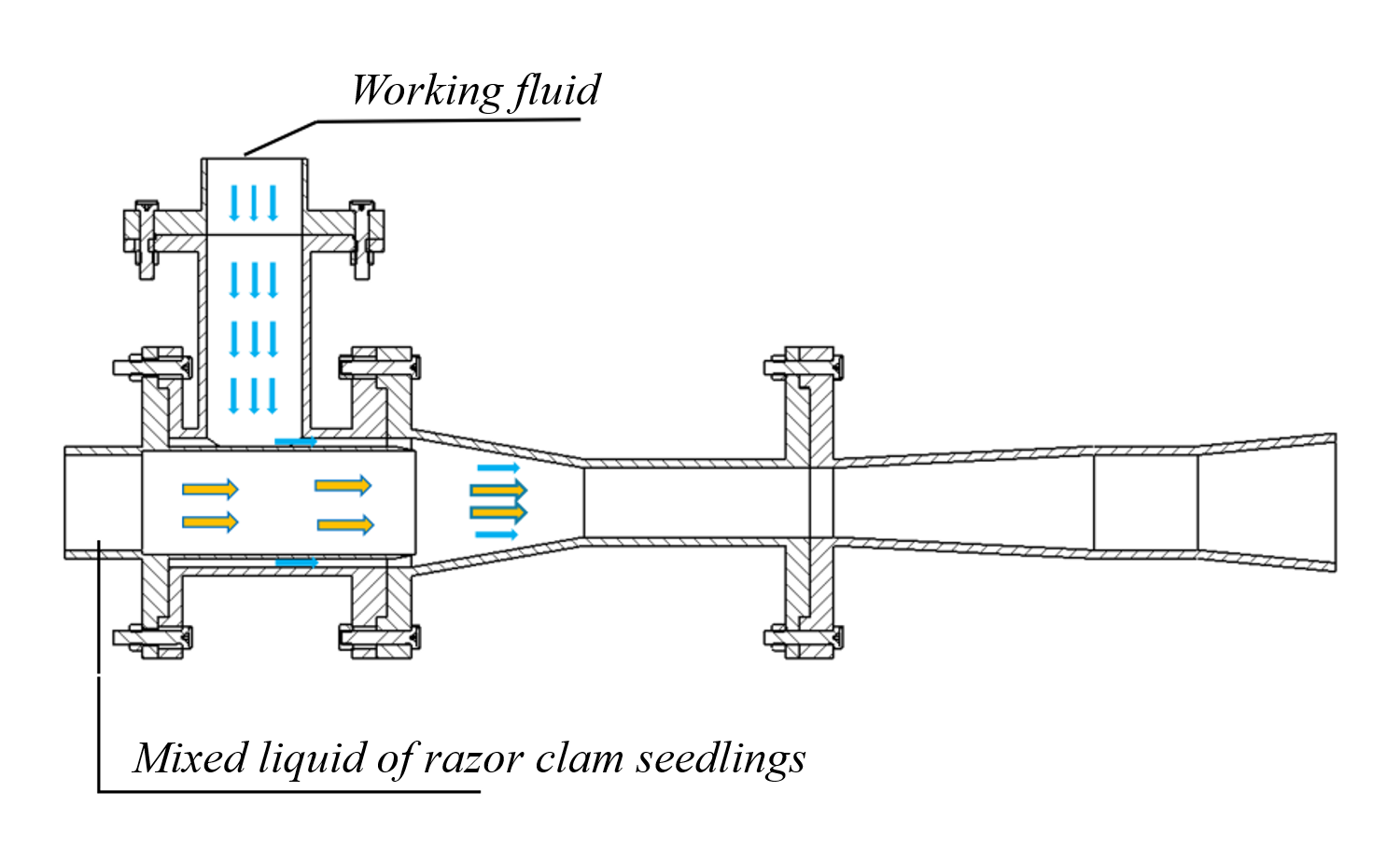

During seeding, the mixture of razor clam seedlings and water is the sucked fluid, while high-pressure water serves as the working fluid. When high-pressure water rapidly passes through the suction chamber, a negative pressure is generated between the suction chamber and the nozzle, extracting the mixture of water and seedlings. After being ejected from the nozzle, the mixture passes through the throat tube and is then sprayed out through the diffusion tube.

Figure 3. Three-Dimensional Diagram of the Jet Pump

When using a jet pump for seeding, it is essential to ensure that the razor clam seedlings can pass through the nozzle and throat tube; otherwise, it would cause blockage, making seeding impossible. Therefore, based on the above operational conditions, an annular jet pump structure was designed with specific dimensions and structure as shown in Table 1.

Table 1. Specific Dimensions of the Jet Pump

Main Structure | Dimensions |

Inlet Diameter Contraction Angle | 33mm 7° |

Seedling Entrance Diameter Nozzle Diameter | 33mm 16mm |

Suction Chamber Length Throat Tube Diameter | 103mm 20mm |

Diffusion Angle | 7° |

Diffusion Tube Diameter | 37mm |

Total Length | 455mm |

3. Fluent Simulation Optimization

3.1. Experimental Design

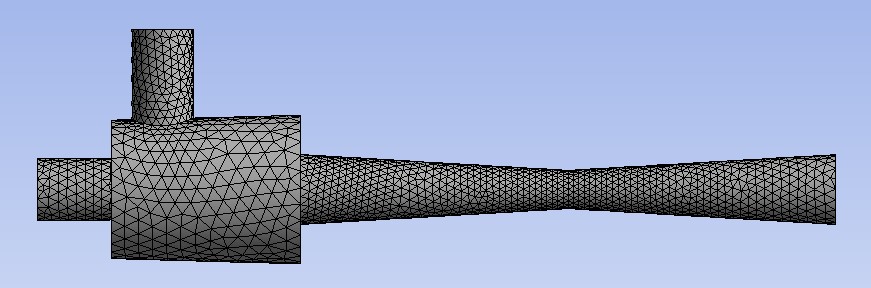

(1) Mesh Division

The mesh division adopts an automated method, requiring a higher density of mesh in complex stress areas. Therefore, the mesh size was chosen to be 3mm, as shown in Figure 4. The average quality of the mesh division is 0.84, with the lowest quality displayed in the mesh quality assessment panel being 0.27. The best quality of the mesh is 1, indicating that the mesh division quality is good when the average mesh quality is greater than 0.7.

Figure 4. Jet Pump Mesh Diagram

(2) Boundary Conditions

Both the working fluid and the sucked fluid inlets of the jet pump are set as velocity inlets, the outlet is set as a pressure outlet, and the remaining boundaries are set as no-slip walls. The inlet flow rates for both the water inlet and seedling inlet are set, increasing from 1m/s to 5 m/s, with an increment of 0.5 m/s; the flow rate of the water-seedling mixture is fixed at 0.5 m/s.

3.2. Results Analysis

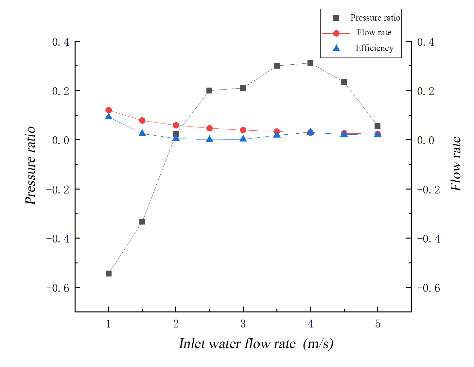

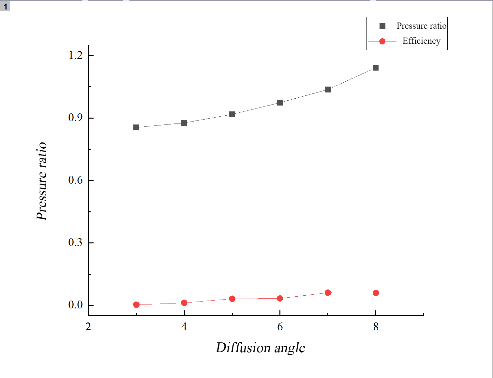

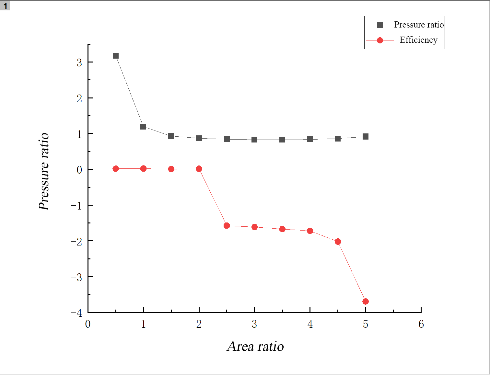

The pressure ratio h is the ratio of the jet pump pressure to the working pressure, and the efficiency η is the ratio of the useful power obtained by the pumped fluid to the power expended by the working fluid. Both reflect the changes in energy within the pump and the impact of the main components on the performance of the jet pump. Therefore, the pressure ratio h and efficiency η of the jet pump are used as evaluation indicators to measure the relationship curves between the flow rate ratio q, diffusion angle β, area ratio m, and pressure ratio h, efficiency η.

Figure 5. Relationship between Flow Rate Ratio q and Pressure Ratio, Efficiency

Figure 6. Relationship between Diffusion Angle β and Pressure Ratio, Efficiency

Figure 7. Relationship between Area Ratio m and Pressure Ratio, Efficiency

From Figure 5, it is known that the flow rate ratio decreases with an increase in the working fluid's velocity, eventually stabilizing, with a maximum value of 0.12. The pressure ratio shows a trend of first increasing and then decreasing with the increase in water flow velocity (working fluid) at the inlet, with a maximum value of 0.31 at around 4m/s. Efficiency shows a trend of first increasing and then decreasing with the increase in working fluid velocity, with a maximum value of 3% at around 4 m/s.

From Figure 6, with the inlet flow velocity set at 4m/s and the flow rate ratio set at 0.03, as the diffusion angle increases, the pressure ratio shows a gradual increasing trend, reaching a maximum value of 1.14 at a diffusion angle of 8°. Efficiency increases with the increase of the diffusion angle, with a maximum value of 9.60% at a diffusion angle of 8°.

From Figure 7, with the inlet flow velocity set at 4m/s and the flow rate ratio set at 0.03, as the area ratio increases, the pressure ratio shows a decreasing trend, with a maximum value of 3.18 at an area ratio of 0.50. Efficiency decreases with the increase of the area ratio, with a maximum value of 1.58% at an area ratio of 2.

The above three sets of experiments conducted a Fluent fluid dynamics simulation study on the relationship between the flow rate ratio, diffusion angle, area ratio, pressure ratio, and efficiency in the structure of the jet seeding pump. It was found that when the working fluid velocity is 4m/s, the flow rate ratio is 0.03, the diffusion angle is 8°, and the area ratio is 2, the efficiency of the jet pump can reach 9.60%, which can meet the actual production needs.

3.3. Experimental Verification

To validate the operational performance of the designed razor clam seedling dispensing device, a jet seeding mechanism was fabricated based on simulation results and subjected to seeding experiments. The experimental setup and process are shown in Figure 8. The experiment was conducted on September 7, 2023, at the Innovation Workshop of Dalian Ocean University. The day of the experiment was clear and windless, and the razor clam seedlings used were of the specification 4800 seedlings/kg. During the experiment, the seedling dispensing device was fixed to the ground, and the working water pressure was set to 10Mpa. The experiment was repeated three times. The results show that the efficiency of the jet pump can reach 10.40%, and the furthest scattering distance can reach about 2.5m, meeting the operational requirements for seeding.

Figure 8. Experimental Components and Effects

4. Conclusions

(1) The flow rate ratio decreases with an increase in the velocity of the working fluid, reaching a maximum value of 0.12. The pressure ratio increases and then decreases with an increase in the working fluid, reaching a maximum value of 0.31; at this point, efficiency increases and then decreases with an increase in the velocity of the working fluid, reaching a maximum of 3%. When the flow rate ratio is set at 0.03, the larger the diffusion angle, the greater the pressure ratio, with a maximum value of 1.14 at a diffusion angle of 8°; at this point, efficiency increases with an increase in the diffusion angle, reaching a maximum of 9.60%, also at a diffusion angle of 8°. With the flow rate ratio set at 0.03, as the area ratio increases, the pressure ratio shows a decreasing trend, with a maximum value of 3.18 at an area ratio of 0.50; efficiency decreases with an increase in the area ratio, reaching a maximum of 1.58% at an area ratio of 2.

(2) The efficiency of the jet pump for the razor clam seeding device during testing was 10.40%, with a deviation from the simulation results of 8.33%, indicating that the finite element simulation analysis method can be used for the design and parameter optimization of the razor clam seeding device. The designed razor clam seeding device can provide a reference for the mechanization and scale development of the shellfish industry.

This research was funded by National Key R&D Program of China (2023YFD2400800); Azure Blue Scholar Project of Dalian Ocean University (Research on key technology of in-situ cleaning of nets based on cavitation jet and flexible impact).

References

[1]. Huang, R., & Zhang, Y. F. (2007). A new seedling of the clam genus. Taiwan Strait, 2007(2), 115-119.

[2]. Fisheries Administration of the Ministry of Agriculture and Rural Affairs. (2023). China Fisheries Statistical Yearbook. Beijing: China Agriculture Press.

[3]. Wang, Y. M., Yang, W. Z., & Wang, X. G. (2006). Research on the spiral groove wheel type seeder. Journal of Xinjiang Agricultural University, 2006(01), 67-70.

[4]. Gai, M. M., Yang, J., Li, X. H., et al. (2023). Design and test of guided horizontal disc precision soybean planter. Jiangsu Agricultural Sciences, 2023, 51(22), 200-206.

[5]. Liu, C. B., Zang, Y., Luo, X. W., et al. (2016). Design and test of rice direct-seeding machine spiral groove wheel planter. Journal of Shenyang Agricultural University, 2016, 47(06), 734-739.

[6]. Liu, B. (2006). Application analysis and development prospect of mechanical shallow tillage and deep loosening cultivation technology. Agricultural Mechanization Research, 2006(1), 63-65.

[7]. Kwon O B, Kim M K, Kwon H C and Bae D S. Two-dimensional Numerical Simulations on the Performance of anAnnular Jet Pump[J]. Journal of Visualization,2001,5(1).

[8]. Liu X, Zhan Q, Lia Y. The application analysis of jet pump in heating system[J]. Procedia Engineering,2017,pp2208-14.

[9]. Bayley R W , Biggs C A. Remediation of contaminated media using a jet pump[J]. Chemical Engineering Journal,2006,118(1).

[10]. Xu J N, Lv W J, Zhu D Y, Gao Y X. Laboratory Experimental Research on Basic Characteristics of Back Pressure Jet Pump[J]. Applied Mechanics and Materials,2013,pp438-42.

[11]. Mao W Y, Zhang Y, Hu M F, Bie Y and Chang J H. Numerical Simulation of the Optimum Geometry Parameters of a New Type Jet Pump[J]. Advanced Materials Research,2014,pp2248-53.

[12]. Zou, J. L. (2019). Study on the characteristics of conveying fruits and vegetables by annular jet pump (Master's thesis). Wuhan University.

Cite this article

Xiong,Y.;Luan,Y.;Liu,Z.;Yuan,X.;Wang,Y.;Zhang,H. (2024). Design and component simulation study of a hydraulic razor clam seedling dispensing device. Applied and Computational Engineering,65,326-332.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of Urban Intelligence: Machine Learning in Smart City Solutions - CONFSEML 2024

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Huang, R., & Zhang, Y. F. (2007). A new seedling of the clam genus. Taiwan Strait, 2007(2), 115-119.

[2]. Fisheries Administration of the Ministry of Agriculture and Rural Affairs. (2023). China Fisheries Statistical Yearbook. Beijing: China Agriculture Press.

[3]. Wang, Y. M., Yang, W. Z., & Wang, X. G. (2006). Research on the spiral groove wheel type seeder. Journal of Xinjiang Agricultural University, 2006(01), 67-70.

[4]. Gai, M. M., Yang, J., Li, X. H., et al. (2023). Design and test of guided horizontal disc precision soybean planter. Jiangsu Agricultural Sciences, 2023, 51(22), 200-206.

[5]. Liu, C. B., Zang, Y., Luo, X. W., et al. (2016). Design and test of rice direct-seeding machine spiral groove wheel planter. Journal of Shenyang Agricultural University, 2016, 47(06), 734-739.

[6]. Liu, B. (2006). Application analysis and development prospect of mechanical shallow tillage and deep loosening cultivation technology. Agricultural Mechanization Research, 2006(1), 63-65.

[7]. Kwon O B, Kim M K, Kwon H C and Bae D S. Two-dimensional Numerical Simulations on the Performance of anAnnular Jet Pump[J]. Journal of Visualization,2001,5(1).

[8]. Liu X, Zhan Q, Lia Y. The application analysis of jet pump in heating system[J]. Procedia Engineering,2017,pp2208-14.

[9]. Bayley R W , Biggs C A. Remediation of contaminated media using a jet pump[J]. Chemical Engineering Journal,2006,118(1).

[10]. Xu J N, Lv W J, Zhu D Y, Gao Y X. Laboratory Experimental Research on Basic Characteristics of Back Pressure Jet Pump[J]. Applied Mechanics and Materials,2013,pp438-42.

[11]. Mao W Y, Zhang Y, Hu M F, Bie Y and Chang J H. Numerical Simulation of the Optimum Geometry Parameters of a New Type Jet Pump[J]. Advanced Materials Research,2014,pp2248-53.

[12]. Zou, J. L. (2019). Study on the characteristics of conveying fruits and vegetables by annular jet pump (Master's thesis). Wuhan University.