1. Introduction

The field of architecture is undergoing a paradigm shift, propelled by the integration of computational design and digital fabrication technologies. This fusion marks a departure from traditional architectural practices, embracing a future where design and construction are informed by algorithmic processes and advanced manufacturing techniques. The advent of computational design has introduced architects to a world of limitless possibilities, where complex forms and structures can be conceptualized and executed with unprecedented precision and efficiency. Digital fabrication, on the other hand, has transformed the way architects materialize their visions, offering new avenues for creating intricate details and bespoke elements previously considered impractical or impossible. This article aims to shed light on the theoretical foundations of computational design and the evolution of digital fabrication techniques, illustrating how these innovations have redefined the architectural process. It delves into the symbiotic relationship between computational algorithms and physical fabrication, a partnership that not only accelerates the design-to-production pipeline but also promotes a more sustainable approach to construction [1]. Through a selection of pioneering projects, we examine the tangible benefits of these technologies, including significant reductions in waste and construction time, as well as the ability to tackle complex design challenges with a new level of sophistication. Furthermore, we explore the broader implications of these advancements, from the environmental impact of adopting more sustainable materials and processes to the future directions that computational design and digital fabrication might take. The discussion extends to the technological frontiers, including material innovation, robotic automation, and the development of specialized software tools, which collectively contribute to the ongoing evolution of architecture.

2. Theoretical Foundations

2.1. Computational Design in Architecture

Computational design in architecture leverages algorithmic and generative methodologies to explore spatial, structural, and aesthetic possibilities beyond conventional design limits. By employing algorithms that simulate natural processes or embody complex mathematical concepts, architects can generate forms and structures that respond to environmental, social, and material parameters with unprecedented precision. For instance, parametric modeling tools allow designers to adjust a set of underlying parameters to explore a wide range of design outcomes, optimizing for factors such as light exposure, thermal comfort, and spatial efficiency [2]. Advanced simulation software further enables the analysis of these designs, assessing their performance in real-world conditions to ensure they meet sustainability standards and occupant comfort requirements. This computational approach not only enhances the designer’s creativity and efficiency but also promotes a more informed and responsive design process, where decisions are made based on comprehensive data analysis and simulations.

2.2. Evolution of Digital Fabrication Techniques

The evolution of digital fabrication techniques marks a significant milestone in the realization of complex architectural designs. Early adoption of technologies such as 3D printing and CNC milling facilitated the production of models and components with intricate details, previously unachievable through conventional fabrication methods. As these technologies matured, their application expanded from small-scale models to full-scale structural elements and buildings. For example, 3D concrete printing has emerged as a viable method for constructing bespoke architectural elements and even entire buildings, offering advantages in terms of material efficiency and design flexibility. Similarly, CNC milling has been instrumental in creating complex formwork for concrete structures, while robotic assembly has been applied in the precise placement and assembly of building components. These digital fabrication techniques are characterized by their ability to produce highly customized solutions, reducing material waste and enabling the construction of designs that align closely with the architect’s vision [4]. The precision and efficiency afforded by digital fabrication not only enhance the aesthetic and functional qualities of buildings but also contribute to more sustainable construction practices by minimizing excess material use and optimizing structural performance.

2.3. Integration of Computation and Fabrication

The integration of computational design and digital fabrication technologies has led to a synergistic workflow that bridges the gap between digital models and physical construction. This integrated approach allows for a seamless transition from design to production, where digital models are directly translated into machine-readable instructions for fabrication. One of the key advantages of this integration is the ability to rapidly prototype and iterate designs, enabling architects and designers to test and refine their ideas in physical form quickly. Furthermore, this process supports the efficient use of materials by precisely calculating the amount required for each component, thereby reducing waste and lowering the environmental impact of construction projects. The digital thread that connects design and fabrication also facilitates the customization of building elements without significantly increasing costs or production times, challenging the traditional economies of scale in construction [5]. Moreover, the data-rich environment of integrated computational design and fabrication enables the collection and analysis of performance data throughout the building’s lifecycle, supporting the ongoing optimization of building performance and the development of more sustainable construction methods. This holistic approach to architecture and construction, driven by advanced computational and fabrication technologies, not only pushes the boundaries of design but also promotes a more sustainable, efficient, and innovative building industry.

3. Case Studies

3.1. Pioneering Projects

Several landmark projects stand out for their innovative use of computational design and digital fabrication, setting benchmarks for the industry. The Guggenheim Museum Bilbao by Frank Gehry is an early example where computational design played a critical role in the realization of its complex, free-form architecture. The project utilized custom software to model the building’s unique titanium cladding, demonstrating how advanced computational tools could manage and execute complex geometries in construction. Another notable project is the Icd/Itke Research Pavilion at the University of Stuttgart, which showcases the potential of biomimetic design combined with digital fabrication. Inspired by the natural constructions of sea urchins, this pavilion was developed using algorithms that mimicked natural processes, and it was fabricated using robotic weaving techniques, highlighting the efficiency and sustainability of using computational design and digital fabrication in tandem [6].

3.2. Impact on Construction Efficiency

Table 1. ETH Zurich DFAB HOUSE and WinSun 3D Printed Houses

Project | Location | Method | Construction Waste Reduction (%) | Construction Time Reduction (%) | Number of Houses | Construction Time | Materials Used |

ETH Zurich DFAB HOUS E | Zurich, Switzerland | 3D Printing, Robotic Assembly, Drone Monitoring | 60 | 70 | 1 | 24 hours | 3D Printed Components |

WinSun 3D Printed Houses | China | 3D Printing with Recycled Materials | 50 | 60 | 10 | 24 hours | Ground Construction/ Industrial Waste with Cement Binder |

Quantitative analysis reveals significant efficiency gains in projects employing digital fabrication methods. For instance, the ETH Zurich DFAB HOUSE represents a milestone in digital fabrication’s application to residential construction. The project reported a 60% reduction in construction waste and a 70% decrease in construction time compared to traditional methods. This was achieved through the integration of 3D printed components, robotic assembly, and drone monitoring, streamlining the construction process and significantly reducing material waste. Furthermore, the WinSun Decoration Design Engineering Co. in China has been pioneering in the use of 3D printing for constructing residential buildings. Table 1 summarizes the data for the ETH Zurich DFAB HOUSE and WinSun 3D Printed Houses projects [7]. They successfully printed 10 houses in 24 hours, using a custom 3D printer that layers a mixture of ground construction and industrial waste with a cement binder. The rapid construction pace and the recycling of materials present a compelling case for the environmental and economic advantages of incorporating digital fabrication in construction projects.

3.3. Future Directions

The future of computational design and digital fabrication lies in further integration and innovation, pushing the boundaries of what is architecturally feasible while emphasizing sustainability and efficiency. Research is increasingly focusing on adaptive and responsive design, where buildings can adjust to environmental conditions in real-time, optimizing energy use and enhancing occupant comfort. An emerging area of interest is the use of artificial intelligence (AI) in computational design, where machine learning algorithms can predict optimal design solutions based on a set of parameters, including structural integrity, material efficiency, and environmental impact [8]. Additionally, the development of new materials suited for digital fabrication, such as advanced polymers and composite materials, promises to further reduce the environmental footprint of construction by offering stronger, lighter, and more sustainable alternatives to traditional building materials.

4. Technological Advancements

4.1. Material Innovation

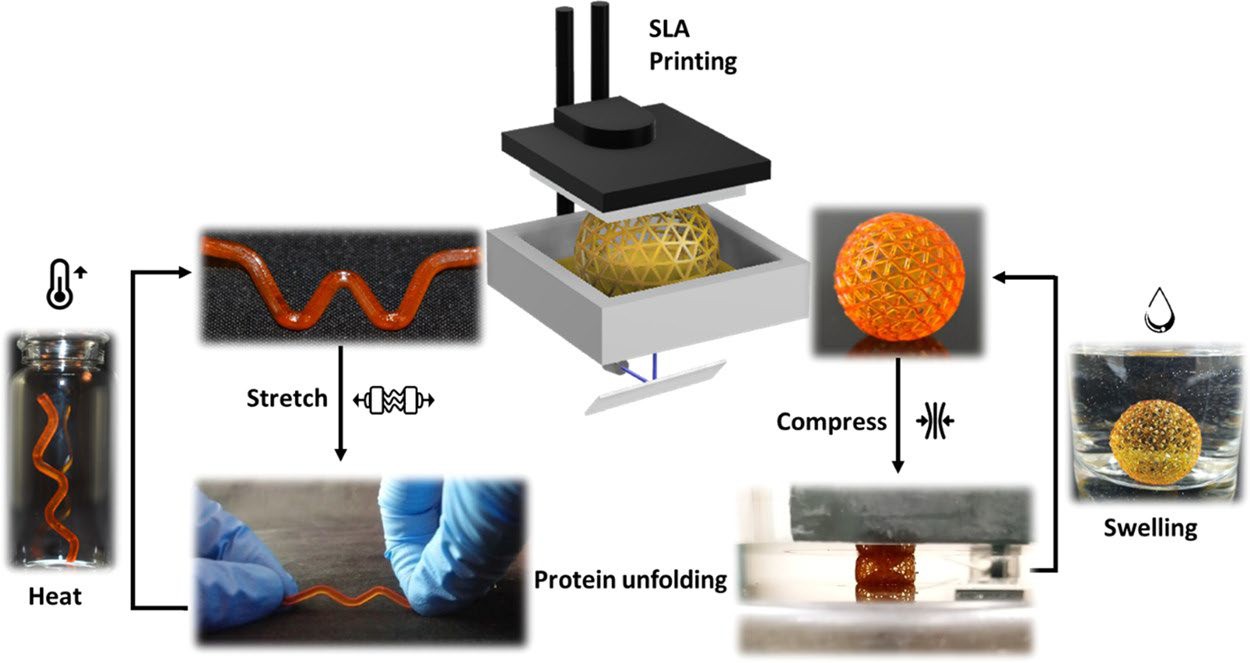

Recent advances in material science, interfaced with digital fabrication techniques, have catalyzed the emergence of novel materials with enhanced sustainability and performance characteristics. For instance, the development of self-healing concrete incorporates microencapsulated healing agents that activate upon the formation of cracks, significantly prolonging the structural lifespan and reducing maintenance needs. Similarly, the integration of nanomaterials, such as graphene, into building materials has led to improvements in strength, thermal and electrical conductivity, and durability. The digital fabrication process, especially through precise additive manufacturing techniques, allows for the material’s properties to be tailored to specific requirements of different parts of a structure, enabling a more efficient use of resources and minimizing waste. A notable example of this application is the use of 3D- printed bioplastics, derived from renewable biomass sources, which are not only biodegradable but also customizable to varying degrees of rigidity and flexibility, catering to diverse architectural needs, as shown in Figure 1. These innovations underscore a paradigm shift towards the development of construction materials that are not just environmentally benign but actively contribute to the sustainability and resilience of built environments.

Figure 1. 3D-Printed Bioplastics with Shape-Memory Behavior (Source: 3D-Printed Bioplastics with Shape-Memory Behavior Based on Native Bovine Serum Albumin)

4.2. Robotic Automation

The incorporation of robotic automation in construction processes has led to significant advancements in precision, efficiency, and the ability to execute complex designs. Robots, equipped with AI and machine learning capabilities, can now perform tasks with a level of accuracy and speed unattainable by human labor. For example, robotic arms are being used for the precise placement of bricks or the assembly of intricate structural components, tasks that require a high degree of accuracy to ensure structural integrity and aesthetic fidelity. The application of swarm robotics, inspired by the collective behavior of insects, is another innovative approach where multiple robots work in concert to complete tasks more efficiently than could be achieved individually. This method has been particularly effective in scenarios requiring the rapid assembly of pre-fabricated components or in environments hazardous for human workers. Moreover, the integration of sensors and real-time data analytics allows these robotic systems to adapt to changes in the environment or design specifications, further enhancing the flexibility and resilience of the construction process [9]. The automation of such tasks not only reduces the time and cost associated with construction projects but also mitigates the risk of human error and improves workplace safety.

4.3. Software Development

The advancement of specialized software tools has been instrumental in bridging the gap between computational design and digital fabrication. These software platforms enable architects and engineers to create detailed digital models that simulate the physical and functional characteristics of proposed designs, facilitating an iterative design process that optimizes for performance, aesthetics, and sustainability. For instance, parametric design software allows designers to input sets of rules that define relationships between design elements, enabling the automatic adjustment of the model in response to changes in parameters, thus expediting the exploration of design alternatives and optimization of structural performance. Environmental simulation tools integrate data on local climate, sunlight, wind patterns, and other factors to predict the energy performance and comfort of building designs, guiding decisions that enhance sustainability and occupant well-being.

5. Environmental Impact

5.1. Reducing Carbon Footprint

The integration of digital fabrication technologies in architectural practices presents a notable opportunity for the reduction of the carbon footprint associated with construction projects. Digital fabrication methods, such as 3D printing and CNC milling, allow for precise control over material use, significantly minimizing waste generated during the construction process. For instance, 3D printing enables the production of components with optimized geometries that use the minimum amount of material necessary for structural integrity, thereby reducing material consumption and the associated carbon emissions from production and transportation.

Moreover, digital fabrication facilitates the fabrication of complex forms and intricate details without the need for additional resources or processes, which traditionally result in excess waste and increased carbon output. A study by the Institute of Advanced Architecture of Catalonia (IAAC) on the application of 3D printing in construction estimated a reduction of up to 30% in material use, highlighting the environmental benefits of precision in digital fabrication.

5.2. Energy Efficiency

Computational design methods stand at the forefront of enhancing building energy efficiency, employing advanced simulations to optimize buildings’ performance from the outset. By analyzing solar orientation, architects can design buildings that maximize natural light and heat, reducing the need for artificial lighting and heating. This strategic approach can significantly lower energy consumption, contributing to a building’s overall energy efficiency. Thermal mass, another critical factor, is optimized through computational design to regulate indoor temperatures. Materials with high thermal mass can absorb and store heat during the day and release it at night, reducing the reliance on HVAC systems. Computational tools enable architects to precisely calculate the optimal distribution and amount of thermal mass, ensuring buildings maintain comfortable temperatures with minimal energy input. Ventilation is yet another area where computational design methods yield energy efficiency gains. By simulating air flow, architects can create buildings that naturally ventilate, reducing the need for mechanical ventilation systems.

6. Conclusion

The convergence of computational design and digital fabrication represents a significant milestone in the evolution of architecture. This integration not only challenges traditional construction methodologies but also opens up new possibilities for innovation, efficiency, and sustainability in the built environment. The examination of theoretical foundations, technological advancements, and case studies within this article underscores the transformative impact of these technologies on architectural design and construction processes. As we move forward, the continued development and application of computational and digital fabrication techniques will undoubtedly play a crucial role in shaping the future of architecture. Embracing these technologies not only enables architects to push the boundaries of design but also contributes to a more sustainable and environmentally conscious construction practice. The journey towards fully integrating these technologies into mainstream architectural practices is ongoing, and it requires a collaborative effort among architects, engineers, researchers, and policymakers. By fostering an environment that encourages innovation and sustainability, the architectural field can continue to evolve, reflecting the changing needs and values of society.

References

[1]. Gahbauer, Stefan, et al. “Iterative computational design and crystallographic screening identifies potent inhibitors targeting the Nsp3 macrodomain of SARS-CoV-2.” Proceedings of the National Academy of Sciences 120.2 (2023): e2212931120.

[2]. Hassan, Abrar U., et al. “Novel pull–push organic switches with D–π–A structural designs: computational design of star shape organic materials.” Structural Chemistry 34.2 (2023): 399- 412.

[3]. Kyratsis, Panagiotis, Athanasios Manavis, and J. Paulo Davim, eds. Computational design and digital manufacturing. Springer Nature, 2023.

[4]. Rehman, Ashfaq Ur, et al. “Computational approaches for the design of modulators targeting protein-protein interactions.” Expert opinion on drug discovery 18.3 (2023): 315-333.

[5]. Mou, Tianyou, et al. “Bridging the complexity gap in computational heterogeneous catalysis with machine learning.” Nature Catalysis 6.2 (2023): 122-136.

[6]. Tuvayanond, Wiput, and Lapyote Prasittisopin. “Design for Manufacture and Assembly of Digital Fabrication and Additive Manufacturing in Construction: A Review.” Buildings 13.2 (2023): 429.

[7]. Graser, Konrad. From Invention to Innovation: Socio-technical Processes in the Adoption of Digital Fabrication to Architecture, Engineering and Construction Praxis. Diss. ETH Zurich, 2023.

[8]. Ng, Ming Shan, Konrad Graser, and Daniel Mark Hall. “Digital fabrication, BIM and early contractor involvement in design in construction projects: A comparative case study.” Architectural Engineering and Design Management 19.1 (2023): 39-55.

[9]. Rane, Nitin. “Potential Role and Challenges of ChatGPT and Similar Generative Artificial Intelligence in Architectural Engineering.” Available at SSRN 4607767 (2023).

Cite this article

Fu,M.;Yang,Y.;Xing,J. (2024). Revolutionizing architecture: The synergy of computational design and digital fabrication. Applied and Computational Engineering,62,1-6.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Mechatronics and Smart Systems

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Gahbauer, Stefan, et al. “Iterative computational design and crystallographic screening identifies potent inhibitors targeting the Nsp3 macrodomain of SARS-CoV-2.” Proceedings of the National Academy of Sciences 120.2 (2023): e2212931120.

[2]. Hassan, Abrar U., et al. “Novel pull–push organic switches with D–π–A structural designs: computational design of star shape organic materials.” Structural Chemistry 34.2 (2023): 399- 412.

[3]. Kyratsis, Panagiotis, Athanasios Manavis, and J. Paulo Davim, eds. Computational design and digital manufacturing. Springer Nature, 2023.

[4]. Rehman, Ashfaq Ur, et al. “Computational approaches for the design of modulators targeting protein-protein interactions.” Expert opinion on drug discovery 18.3 (2023): 315-333.

[5]. Mou, Tianyou, et al. “Bridging the complexity gap in computational heterogeneous catalysis with machine learning.” Nature Catalysis 6.2 (2023): 122-136.

[6]. Tuvayanond, Wiput, and Lapyote Prasittisopin. “Design for Manufacture and Assembly of Digital Fabrication and Additive Manufacturing in Construction: A Review.” Buildings 13.2 (2023): 429.

[7]. Graser, Konrad. From Invention to Innovation: Socio-technical Processes in the Adoption of Digital Fabrication to Architecture, Engineering and Construction Praxis. Diss. ETH Zurich, 2023.

[8]. Ng, Ming Shan, Konrad Graser, and Daniel Mark Hall. “Digital fabrication, BIM and early contractor involvement in design in construction projects: A comparative case study.” Architectural Engineering and Design Management 19.1 (2023): 39-55.

[9]. Rane, Nitin. “Potential Role and Challenges of ChatGPT and Similar Generative Artificial Intelligence in Architectural Engineering.” Available at SSRN 4607767 (2023).