1 Introduction

To start with, air-based protein production is based on the technology of cellular agriculture, which is an animal-sourced food production method using cells. Cellular agriculture can be a key for food production by reducing the need for land, fertilizer, and other resources that traditional agriculture requires. As a branch of cellular agriculture, the air based protein production, in other words, the use of microorganisms for harvesting single-cell protein (SCP), will mainly rely on three types of bacteria: (i) hydrogen-oxidizing bacteria (hydrogenotrophs), (ii) obligate aerobic methane-oxidizing bacteria (methanotrophs), and (iii) obligate aerobic carbon monoxide-oxidizing bacteria(carboxydotrophs), with the first two being the most promising sources for SCP production [1]. These bacteria will serve as the reaction set, while the reaction will involve several kinds of gas (hydrogen, methane, carbon monoxide) as the energy source. The application of gas as the raw material can effectively reduce the amount of space required, as well as the more costly agricultural ingredient. On the contrary, there will indeed be challenges, which will be discussed in the article. Moreover, this technology has a considerable commercial application, a company called Kiverdi, founded in 2011, produces the SCP products air-based protein, there is even a company called ‘Air Protein’, which specializes in the process of gas fermentation to produce the air-based protein, has established. There are loads of potential economic values for this technology. By studying the presented research and related information, this article will provide a generalized analysis of this novel technology, from the principle of the reactions to the pros and cons as well as the commercializing and future development. In order to provide sufficient background information for others who share a similar interest in this field.

2 Basic working principle of the gas fermentation

There are several prerequisites for the selection of bacteria that are used for the gas fermentation of the air-based protein. (1) The bacteria will generate heat and require oxygen for the fermentation process. (2) The stable gene and morphology during the fermentation process. (3) The final product will be in terms of protein. (4) They not only have relatively easy recovery but also are able to purify themselves on their yield.

This process requires hydrogen-oxidizing bacteria(HOB) hydrogenotrophs, methanotrophs, and carboxydotrophs, as introduced in the introduction. The gas fraction including hydrogen, methane, and carbon monoxide will be the electron donor that provides the energy for the reaction, while oxygen will be the final electron acceptor. During the reaction, carbon dioxide will be fixed, which is pretty essential, since the capability of the carbon dioxide fixing ability has made these bacteria the most plausible method for sustainable protein production. In addition, the preferred bacteria to do this process should be oxygen dependent (aerobic), since their reaction will not have significant byproducts, as the contradiction to anaerobic bacteria. This is due to the energy released by the reaction of H2 with oxygen (O2). Indeed, a mixture of O2 and H2 under optimal conditions can easily react to producing an ear‐piercing bang or ‘Knall’ in German, where the gas mixture is known as Knallgas. Aerobic H2 autotrophs are therefore known as Knallgas bacteria or the H2 oxidizing bacteria[2].

The overall equation of the reaction of H2 oxidizing bacteria (HOB):

H2+O2+CO2 → Biomass + H2O

If one assumes an overall process where H2 and O2 are produced via electrolysis the overall process is analogous to oxygenic photosynthesis:

H2+O2+energy → Biomass + H2O

Most of the industrial applied Knallgas bacteria or the H2 oxidising bacteria (HOB) will use similar metabolic pathway, also, they can survive in a wild range of environments, such as Antarctic subglacial lakes, temperate soils, and hot hydrothermal vents[3]. After fermentation, the cell biomass is harvested for downstream processing, involving cell disruption, washing and protein extraction followed by purification[4]. The final product is concentrated, and the cells are dead and dried. The bacteria has a relatively short generation time is relatively short with 50-80 % protein content, improving the efficiency of the fermentation.

There are mainly three available fermentation technologies. First is submerge fermentation, in which the bacteria always remain in a liquid that contains all the elements necessary for the fermentation. The products will be obtained by filtration or ways by separating the solid and liquid. The second way is the semisolid fermentation. In this process, most of the substrates are in the solid state, while the steps involve different states. The third method is solid state fermentation. The solid substrates are deposited with the microbes seedling on them, then they will be left in the rooms at a controlled temperature for a few days.

3 The benefits and downsides of the Air based protein production

3.1 Benefits

The gas fermentation of bacteria to produce the air-based protein is pretty advanced as well as beneficial for the world. There are several benefits that can be realized:

3.1.1 Reduce the land requirement. The Food and Agriculture Fund of the United Nations (FAO) predicts that by 2050, farmers will have to increase food production by 70% and land area by 5% in order to achieve the expected growth of 10 billion people. The land requirement will also wreak deforestation, more soil erosion, and reduction of biodiversity. Accordingly, the dramatically reduced requirement of land mass has become one of the most essential advantages of air-based protein. Surprisingly, the production of an air-based protein can reduce about 99 percent of the land of traditional agriculture. In addition, there is no concern about the surrounding environment like agriculture. Air fermentation can execute in almost any region, despite the harsh environment. In short, the improved availability of air-based protein production has reduced the need for land.

3.1.2 Reduce the resources requirement. During the processes of traditional agriculture, there is a great amount of need for resources as medium or catalyst, e.g. fertilizer, forage, and pesticide. higher amounts of nitrogen fertilizer are produced and employed in farming to avoid shortages in the limiting nutrient for plant growth. The total conversion of nitrogen into its reactive form through the Haber-Bosch process accounts for approx. 1-2% of the global energy consumption [1]. In this case, there will be plenty of resources consumed during the growth of the crops or livestock. By contrast, most of the raw materials or catalysts of gas fermentation are derived directly from air, most of them are even pollutants, which enables people to effortlessly gain protein with less consumption.

3.1.3 Minimize the pollution. CO2 is one of the major raw materials of gas fermentation. As we all know, currently our world is suffering from global warming, which can wreak the extinction of species, raise sea levels, and create less favorable living conditions. The ultimate cause of global warming is the release of greenhouse gas, specifically, the greatest portion of the greenhouse gas that we release is the CO2. Thus the CO2 consumption of the production process will reduce the CO2 proportion in the atmosphere effectively, reducing the harm of global warming.

Furthermore, there are other pollutions during the traditional agriculture. the worldwide ammonia emissions caused by the use of artificial nitrogen fertilizers in croplands have increased over the last decades, and this results in increased contamination of nitrogen oxide pollutants in the air and nitrate pollution in water.

3.1.4 Reduce the need for transportation. Owing to the requirement of an appropriate environment, the growth of crops and raising of livestock will be restricted by a particular region. As a result, there will be a need for transportation in order to let people receive the available food. But there will be a considerable cost of the transportation process, increasing the price of this food as well.

Air fermentation seems capable of reducing that spending since air fermentation is almost available anywhere, the government can build air fermentation factories around or even inside the urban area. Consequently, the transportation cost of food will be reduced by applying air fermentation.

3.1.5 Variety of utilities. The air-based protein can be produced in lots of forms, there is a type of product called “Solein®” which is pounder state. It contains 65-75 percent of protein, 10-20 percent of carbohydrates, 4-10 percent of fat and 4-10 percent of minerals. The Solein® does not have a distinctive flavor, making it a capable ingredient in a variety of meals. Solein is an ideal substitute for meat products with a flexible juicy texture; Free of gluten, and suitable for use in grains and baking; Although rich in protein, Solein also contains fiber and low fat content, making it a perfect snack substitute, as well as sports nutrition bars and meal substitutes.

3.2 Downsides

3.2.1 The cost of production. Although air protein can be produced in lots of areas, there is a considerable amount of expense. Fermentation is a very sensitive biochemical process and must be performed in fully automated fermenters in a highly controlled manner [3]. Since the main reaction site is bacteria, people have to carefully regulate the bacteria in order to create a constant and safe production process. As a consequence, loads of budget should be allocated to the conservation and regulation of the bacteria, increasing the cost of the production.

On the other hand, Bacteria have small cell sizes and low density, increasing the difficulty of the harvesting process. The harvesting process has increased the cost of gas fermentation despite the easy access to raw materials. A considerable proportion of the budget for this process will be spent on harvesting proteins, making air-based protein production less economically viable.

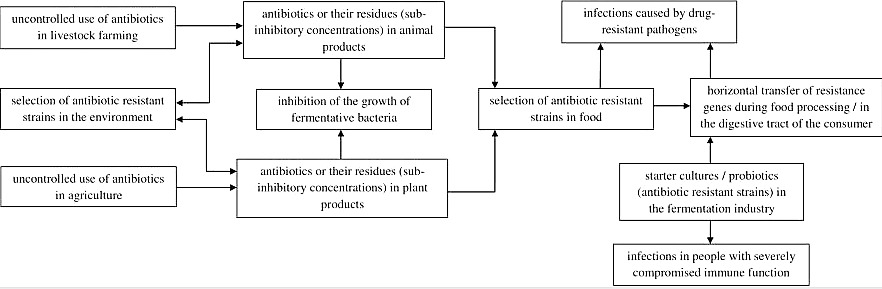

3.2.2 The safety. The potential health hazard is presented. Fermentation needs to be conducted in axenic conditions so as to avoid any unwanted microbial growth. Unwanted growth can contaminate the SCP and could have an adverse impact on human health. The application of some low-quality material will provide a condition favorable for the harmful bacteria to grow. There are risks of the contaminated fermented product increase when low-quality ingredients are used for its production, initially containing a sufficiently high number of bacteria, fungi, or toxins produced by them. in other word, the overall hygiene level of the products tend to be reduced if the companies’ effort on the purification is not enough (see Figure 1).

Figure 1. The potential health hazard

Besides the hazards of the bacteria, the product, which is the protein, has limitations as well. From a nutritional viewpoint, Nucleic Acids (NA) content in SCP is one of the main factors hindering its utilization as food. Excessive intakes of NA lead to uric acid precipitation, causing health disorders, such as gout or kidney stone formation. So, in human, their NA contents must be reduced below 2% [5]. Conversely, the SCP of these bacteria will contain 6-10% of the nucleic acid. This access in quantity results precipitation of uric acid which can cause health problems like the formation of gout and kidney stones [4].

3.2.3 The technology prerequisites. It is relatively difficult for some developing countries with lower economies to apply this technology extensively. Firstly, there is insufficient technology to perform so many productions in order to have enough supply to meet people’s demands. Secondly, the standard of sanitation may not be appropriate for people to eat without the concern of health, as mentioned in the former passage. As a result, for some developing countries, nowadays technology cannot support this technology.

4 The future development

4.1 Commercialization

There is a huge economic potential for the technology of air-based protein production. In recent years, several companies have been aware of the benefits of the air-based protein and started to this approach to produce food. The California-based company Kiverdi, founded in 2011, produces the SCP products Air Protein TM. The Belgium company developed some SCPs from low-value substrates. With the aid of the new development, more advanced methods have been discovered. Deep Branch Biotechnology was founded by a team that has a background in both gas fermentation and synthetic biology in 2018. Their first SCP produced by HOB, Proton TM is a protein source with a tailored amino acid profile. In 2019, Deep Branch Biotechnology partnered with the Drax Group to pilot their SCP production technology using CO2 from Drax flue gas [2]. In the future, owing to the increasing demand for protein, more and more businesses tend to start to be aware of the benefits of this strategy, as a consequence, there will be a promising development in the future.

4.2 Technology development

When air fermentation was first introduced there indeed were lots of problems, however, as this technology becomes more and more mature, some of the disadvantages can possibly be solved.

One way to improve the productivity of the bacteria is to introduce more effective nutrition media. With the aid of the better nutrition media, the bacteria are able to gain more supply of energy in order to keep a higher rate of production of protein as well as other beneficial contents.

There is another way of improvement by using a more efficient harvesting strategy. By having a more effective harvesting method, we are able to save a large amount of cost, which will dramatically improve economic profitability.

The third is the acceptability to the public, due to the source of the food, and the taste, there are some people who do not appreciate food that is made from air-based protein. It is possible for companies to foster sales by improving the taste and reliability of their products, such as enhancing the purification or producing an alternative form of their products.

5 Conclusion

The air-based protein production through air fermentation is gaining attention worldwide, by applying this strategy, loads of the problems can be solved. It is reasonable to apply this strategy extensively in the future, with the aid of more capable technology as well as a better economy. This paper reviewed this strategy from several perspectives, including the processes, advantages, drawbacks, and development. There is a promising future for it to develop and become one of the main sources of protein to feed the fast-growing population. Yet there are some points that are missed in this paper: there is not a specific description of the particular technologies that we can potentially use in the future to improve air-based protein production. Also, the process may not be so specific that every single step is described. In the future, the main focus will about the latest technology used in the processes, hope there will be new cutting-edge technology that will provide assistance toward this strategy.

References

[1]. Carlos Woern, Lutz Grossmann; University of Massachusetts; Microbial gas fermentation technology for sustainable food protein production; 9 September 2023

[2]. Bart Pander, Zahara Mortimer Craig Woods, Callum McGregor, Andrew Dempster, Lisa Thomas, Joshua Maliepaard, Robert Mansfield, Peter Rowe, and Preben Krabben; Hydrogen oxidising bacteria for production of single‐cell protein and other food and feed ingredients; 2020 Jun 25; doi: 10.1049/enb.2020.0005

[3]. Ravindra Kumar, Tirath Raj, Geir Næss, Mette Sørensen, Vibha Dhawan; Opportunities and challenges in single-cell protein production using lignocellulosic material; 19 December 2023

[4]. Abdur Raziq, Muhammad Lateef, Asad Ullah, Hayat Ullah and Muhammad Waseem Khan; Single cell protein (SCP) production and potential substrates: A comprehensive review; September, 2020

[5]. A.T. Nasseri S. Rasoul-Amini M.H. Morowvat Y. Ghasemi Single Cell Protein: Production and Process; 2011; DOI: 10.3923/ajft.2011.103.116

Cite this article

Tang,G. (2024). A review for air fermentation to produce the air-based protein. Applied and Computational Engineering,66,48-52.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Carlos Woern, Lutz Grossmann; University of Massachusetts; Microbial gas fermentation technology for sustainable food protein production; 9 September 2023

[2]. Bart Pander, Zahara Mortimer Craig Woods, Callum McGregor, Andrew Dempster, Lisa Thomas, Joshua Maliepaard, Robert Mansfield, Peter Rowe, and Preben Krabben; Hydrogen oxidising bacteria for production of single‐cell protein and other food and feed ingredients; 2020 Jun 25; doi: 10.1049/enb.2020.0005

[3]. Ravindra Kumar, Tirath Raj, Geir Næss, Mette Sørensen, Vibha Dhawan; Opportunities and challenges in single-cell protein production using lignocellulosic material; 19 December 2023

[4]. Abdur Raziq, Muhammad Lateef, Asad Ullah, Hayat Ullah and Muhammad Waseem Khan; Single cell protein (SCP) production and potential substrates: A comprehensive review; September, 2020

[5]. A.T. Nasseri S. Rasoul-Amini M.H. Morowvat Y. Ghasemi Single Cell Protein: Production and Process; 2011; DOI: 10.3923/ajft.2011.103.116