Volume 164

Published on May 2025Volume title: Proceedings of the 3rd International Conference on Functional Materials and Civil Engineering

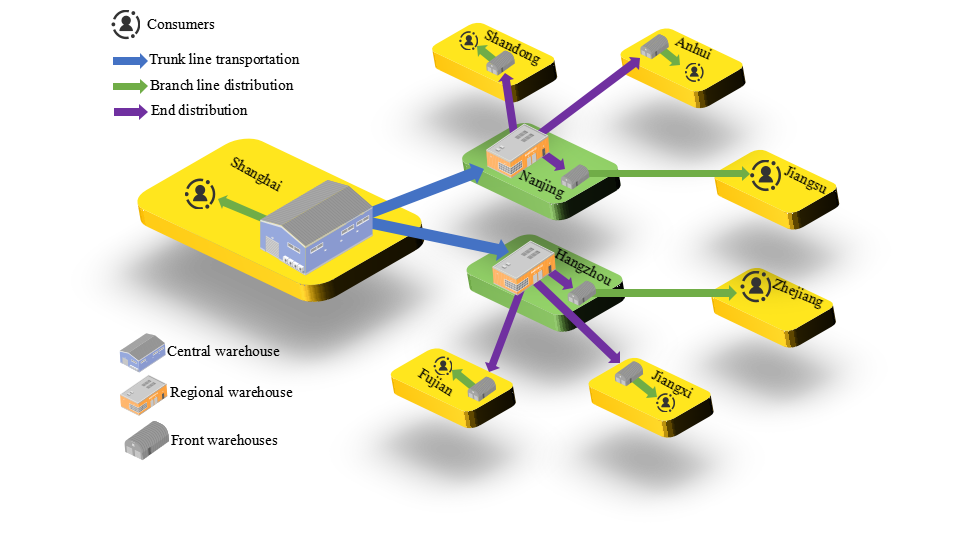

To address the challenge of high carbon emission intensity in China's logistics industry, split warehouse distribution is used as an entry point to construct a transportation-warehousing coupling model to quantify the synergistic effect of multilevel warehousing networks on carbon emission reduction in the logistics industry. Based on the measured data of the industry, the Logarithmic Mean Divisia Index (LMDI) model is used to decompose the carbon emission drivers, and the difference in carbon footprints between the traditional direct distribution mode and the split warehousing mode is compared through the case of home appliance logistics in East China. The results show that the split warehouse model significantly reduces transportation carbon emissions by shortening the average transportation distance, but the warehouse scale expansion partially offsets some of the emission reduction benefits. The sensitivity analysis further reveals that the transportation distance is the core sensitive parameter and the penetration rate of new energy vehicles is the most potential emission reduction parameter among the secondary sensitive parameters, and that shortening the transportation radius and increasing the proportion of electric trucks can respectively increase the total emission reduction efficiency. To provide a systematic optimization path for the logistics industry to achieve the “dual-carbon” goal, intelligent scheduling, warehousing and sharing, and clean energy substitution are suggested to balance the network efficiency and economy of scale.

View pdf

View pdf