1. Introduction

The relentless pursuit of energy efficiency and storage capacity in the realm of portable electronics, electric vehicles, and grid storage has propelled lithium-ion batteries (LIBs) to the forefront of research and development. Despite their widespread adoption, the quest for higher energy densities, improved safety profiles, and longer lifespans continues to drive innovation within this field. Advanced cathode and anode materials have emerged as pivotal to enhancing LIB performance, with silicon-based anodes and novel cathode compositions offering significant advancements in energy storage capacity. However, these materials introduce new challenges, including thermal management and mechanical degradation, necessitating innovative solutions to ensure long-term stability and safety. Concurrently, the optimization of electrolytes presents a path toward non-flammable and more efficient LIBs, further enhancing their applicability across various domains. Additionally, engineering strategies targeting the microstructure of electrode materials and the integration of smart battery management systems (BMS) offer avenues for optimizing performance and extending battery life. This paper provides an in-depth analysis of these material innovations and engineering strategies, underpinning the current state-of-the-art in LIB technology and shedding light on future directions for research and application [1]. By weaving together advancements in materials science with sophisticated engineering approaches, we aim to chart the course for the next generation of lithium-ion batteries, characterized by unparalleled efficiency, safety, and reliability.

2. Material Innovations for Enhanced Performance

2.1. Advanced Cathode Materials

Lithium-ion batteries (LIBs) have seen substantial advancements in cathode materials to meet the increasing demands for energy storage systems. Among them, lithium nickel manganese cobalt oxide (NMC) and lithium iron phosphate (LFP) stand out due to their superior attributes. NMC, particularly the variants with higher nickel content such as NMC811 (which contains 80% nickel, 10% manganese, and 10% cobalt), offers a higher energy density exceeding 200 Wh/kg. This is achieved through its layered structure, which facilitates more lithium ions to participate in the electrochemical reactions, enhancing the battery’s capacity. However, the high nickel content raises concerns regarding thermal stability and longevity, necessitating complex thermal management systems. On the other hand, LFP presents an attractive alternative with its inherently safe phosphate structure, providing thermal stability and safety over a wide range of temperatures. LFP cathodes exhibit a specific energy density of approximately 90-120 Wh/kg, which is lower than NMC. However, they compensate with a longer cycle life (over 2000 cycles with minimal capacity fade) and enhanced safety characteristics, making them suitable for applications where safety and lifespan are critical, such as electric vehicles and large-scale energy storage systems. Quantitative models focusing on the degradation mechanisms of these cathodes, such as the solid-electrolyte interphase (SEI) layer growth and cathode dissolution, are crucial for predicting and enhancing battery life, as shown in Table 1 [2]. Advanced simulation tools, leveraging both DFT (Density Functional Theory) calculations and continuum models, are employed to study the intercalation kinetics and structural changes during battery operation, guiding the development of materials with optimized performance.

Table 1. Comparative Analysis of Advanced Cathode Materials for Lithium-Ion Batteries: NMC811 vs LFP

Material | Energy Density (Wh/kg) | Cycle Life | Thermal Stability Concerns | Safety Characteristics | Electrochemical Performance Enhancements | Degradation Mechanism Focus | Simulation Tools Used |

NMC811 | 200 | >2000 cycles | High (due to 80% Ni content) | Complex thermal management needed | Layered structure enhances capacity | SEI layer growth and cathode dissolution | DFT calculations and continuum models |

LFP | 110 | >2000 cycles | Low (inherently safe structure) | High thermal stability and safety | Stable over a wide temperature range | SEI layer growth and cathode dissolution | DFT calculations and continuum models |

2.2. Anode Materials for Increased Efficiency

Silicon-based anodes represent a promising avenue for enhancing LIB efficiency due to their high theoretical capacity of about 4200 mAh/g, which is significantly higher than the 372 mAh/g of traditional graphite anodes. The integration of silicon into anodes can potentially triple the energy density of LIBs. However, the application of silicon anodes is hindered by severe volume expansion of up to 300% during lithiation, leading to mechanical degradation and loss of electrical contact, which severely limits their cycle life. Recent advancements have focused on nanostructured silicon, such as silicon nanowires, nanoparticles, and silicon-carbon composites, which can accommodate large volume changes and maintain structural integrity. For instance, embedding silicon nanoparticles in a carbon matrix has shown to mitigate volume expansion and facilitate electron transport, significantly enhancing cycle stability. Quantitative analysis reveals that these nanostructured silicon anodes can sustain capacities of 1500-2000 mAh/g over hundreds of cycles. Moreover, alloying strategies involving silicon with materials like tin or germanium have been explored to form stable compounds during lithiation, which can endure the volume changes more effectively [3]. Theoretical models, such as molecular dynamics simulations, have been instrumental in understanding the lithiation mechanisms in these alloys, providing insights into optimal compositions and structures that balance capacity, stability, and conductivity, as shown in Table 2.

Table 2. Quantitative Analysis of Silicon-Based Anode Materials for Enhanced Efficiency in Lithium-Ion Batteries

Anode Material | Theoretical Capacity (mAh/g) | Practical Capacity (mAh/g) | Volume Expansion | Cycle Life Stability | Key Advantages | Simulation Tools |

Silicon Nanoparticles in Carbon Matrix | 4200 | 1500 | Mitigated through carbon matrix | High (hundreds of cycles) | Mitigates volume expansion, enhances electron transport | Molecular dynamics simulations |

Silicon-Tin Alloy | 4200 | 1600 | Reduced via alloying with tin | Moderate to high | Forms stable compounds during lithiation, endures volume changes | Molecular dynamics simulations |

Silicon-Germanium Alloy | 4200 | 1550 | Reduced via alloying with germanium | Moderate to high | Balances capacity and stability with optimal compositions | Molecular dynamics simulations |

2.3. Electrolyte Optimization for Enhanced Safety

Electrolyte optimization stands as a critical frontier in enhancing the safety and performance of lithium-ion batteries (LIBs), serving as the conduit for lithium ion transport between the cathode and anode. The relentless pursuit of safer electrolyte alternatives has spurred the development of various options, including non-flammable ionic liquids, solid-state electrolytes, and advanced liquid electrolytes fortified with flame retardants. Among these, solid-state electrolytes emerge as a game-changer in the quest for enhanced safety, effectively nullifying the flammability risks associated with traditional organic solvent-based electrolytes.

Materials such as lithium phosphorus oxynitride (LiPON) and garnet-type lithium lanthanum zirconium oxide (LLZO) have emerged as frontrunners in the realm of solid-state electrolytes, boasting ionic conductivities that rival those of their liquid counterparts, surpassing 1 mS/cm at room temperature. A comprehensive quantitative analysis of these electrolytes involves evaluating critical parameters such as ionic conductivity, electrochemical window, and compatibility with electrode materials. For instance, LLZO demonstrates an impressive electrochemical stability window extending up to 6V versus Li/Li+, rendering it highly suitable for deployment alongside high-voltage cathode materials. Nevertheless, challenges persist, particularly regarding the management of interfacial resistance between the solid electrolyte and electrode interfaces. Advanced computational models, including ab initio molecular dynamics simulations, have emerged as indispensable tools in unraveling the complex ion transport mechanisms and interface phenomena governing solid-state electrolytes. By providing nuanced insights into the design of electrolyte compositions and interfaces, these computational models play a pivotal role in advancing the performance and safety of LIBs [4]. Through continued research and refinement, electrolyte optimization promises to catalyze the evolution of lithium-ion battery technology towards safer, more efficient, and more reliable energy storage solutions.

3. Engineering Strategies for Performance Optimization

3.1. Microstructure Design for Enhanced Electrode Performance

In the realm of lithium-ion batteries, the electrode microstructure plays a pivotal role in dictating overall battery performance. Through advanced microstructure design techniques, such as the utilization of three-dimensional (3D) porous electrodes and nanostructuring of active materials, significant improvements in both energy density and cycle stability have been achieved. For instance, 3D porous electrodes facilitate a shorter lithium-ion diffusion path and provide more surface area for electrochemical reactions, which in turn improves the charge and discharge rates. Quantitative analysis shows that electrodes with an optimized porosity of 70-80% can enhance the specific capacity by up to 25% compared to traditional compact electrodes. Nanostructuring, another critical strategy, involves designing electrodes with nano-sized active materials that offer a higher reaction surface area and shorter ion diffusion paths. This approach has been shown to improve the specific capacity and rate capability substantially. Formula 1 offers a theoretical framework to estimate the impact of microstructural optimizations on electrode performance.

\( {C_{specific}}={C_{base}}×(1+\frac{P-{P_{min}}}{{P_{max}}-{P_{min}}}×{∆P_{factor}})×(1+N)\ \ \ (1) \) :

\( {P_{min}} \) and \( {P_{max}} \) represent the minimum and maximum porosity values for optimization, typically 70% and 80% respectively, \( {∆P_{factor}} \) represents the factor of specific capacity improvement due to porosity optimization, assumed as 25% in the best-case scenario as per the text, \( N \) is the nanostructuring improvement factor, which can be derived from experimental data.

For example, silicon nanowires used as anode materials have demonstrated a remarkable increase in lithium-ion storage capacity, achieving up to 3,000 mAh/g, which is significantly higher than the 372 mAh/g offered by conventional graphite anodes. Simulation models, including finite element analysis (FEA), have been extensively applied to study the effects of different microstructural designs on ion diffusion kinetics and mechanical integrity during cycling, guiding the development of electrodes with enhanced performance [5].

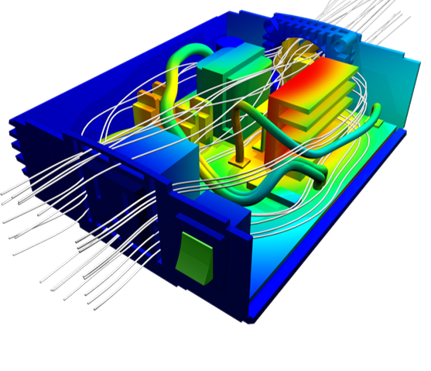

3.2. Thermal Management for Extended Battery Lifespan

Effective thermal management plays a pivotal role in ensuring the longevity and safety of lithium-ion batteries (LIBs), particularly in the face of challenges posed by excessive heat generation during rapid charging or high-load discharging. The detrimental effects of elevated temperatures on LIBs, including accelerated aging, reduced efficiency, and potential safety hazards, underscore the critical importance of implementing robust thermal management strategies [6]. One innovative approach to thermal management involves the integration of phase change materials (PCMs) into battery packs. PCMs possess the unique ability to absorb and release significant amounts of heat during phase transitions, thereby stabilizing temperatures within the battery pack. Quantitative studies have demonstrated that the incorporation of PCMs can effectively mitigate peak temperatures by up to 10°C during extreme operating conditions, thereby substantially reducing the risk of thermal runaway and enhancing the overall safety and reliability of LIBs. Microfluidic cooling systems represent another cutting-edge solution for thermal management in LIBs. These systems utilize microchannels embedded within the battery pack to circulate a coolant, facilitating precise temperature control and efficient heat dissipation. Computational fluid dynamics (CFD) simulations have been instrumental in optimizing the design of these microchannels, ensuring uniform temperature distribution across the battery cells. The insights gleaned from these simulations, as depicted in Figure 1, highlight the efficacy of microfluidic cooling in maintaining operational temperatures within the optimal range of 20°C to 40°C, even under intensive usage scenarios [7].

Overall, the adoption of advanced thermal management techniques, such as PCM integration and microfluidic cooling systems, holds immense promise for extending the lifespan and enhancing the safety of LIBs. By effectively mitigating thermal stresses and maintaining optimal operating temperatures, these strategies contribute significantly to the advancement of battery technology, paving the way for more reliable and durable energy storage solutions.

Figure 1. Computational fluid dynamics (CFD) (Source: npd-solutions.com)

3.3. Smart Battery Management Systems for Enhanced Efficiency

Smart Battery Management Systems (BMS) represent a cutting-edge approach to enhancing the efficiency and reliability of battery systems through the seamless integration of advanced sensing, monitoring, and control technologies. By leveraging sophisticated algorithms, these systems optimize battery performance and safety, ensuring optimal operation under diverse conditions [8]. One of the key functionalities of smart BMS is state-of-charge (SOC) estimation, which plays a critical role in determining the available energy within the battery. Advanced techniques, such as adaptive filtering algorithms like the Extended Kalman Filter (EKF), are employed to achieve precise SOC estimation, with accuracies reaching within 2-3% across varying operational scenarios. This level of accuracy enables better utilization of available energy and enhances the overall efficiency of battery systems. Furthermore, smart BMS incorporates predictive analytics algorithms to analyze historical and real-time battery data, enabling the anticipation of future performance trends and identification of potential issues before they escalate into failures. Machine learning models, trained on extensive datasets comprising charge/discharge cycles, temperature profiles, and voltage fluctuations, empower smart BMS to forecast battery degradation pathways [9]. By preemptively addressing degradation mechanisms, these systems facilitate proactive maintenance and optimization strategies, thereby extending battery lifespan and maximizing operational efficiency.

Quantitative analyses have underscored the substantial benefits of smart BMS, with studies demonstrating improvements in battery efficiency of up to 10% and significant extensions in battery lifespan. Through proactive management and predictive capabilities, smart BMS herald a new era of optimized battery performance, laying the foundation for enhanced energy storage solutions in diverse applications [10].

4. Conclusion

This comprehensive review emphasizes the pivotal role played by material innovations and engineering strategies in propelling lithium-ion battery (LIB) technology forward. By focusing on advancements in cathode and anode materials, along with electrolyte optimization and strategic engineering approaches, significant progress has been achieved in enhancing key aspects such as energy density, safety, and operational efficiency within LIBs. Furthermore, the integration of smart battery management systems has further augmented these advancements, providing capabilities for real-time optimization and predictive maintenance. However, challenges such as volume expansion, thermal management, and cycle life persist, underscoring the need for continued research and development efforts. Insights gleaned from ongoing investigations offer a promising trajectory for future innovations. Interdisciplinary collaboration and the utilization of advanced simulation tools are vital in unlocking the full potential of LIBs. These collaborative efforts hold the key to addressing existing challenges and driving the evolution of LIB technology towards a more sustainable and electrified future. In essence, the journey towards maximizing the capabilities of LIBs is ongoing, with each milestone representing a step forward in achieving higher performance, improved safety, and increased efficiency. By embracing innovation and collaboration, the LIB industry is poised to usher in a new era of energy storage solutions that will power the transition towards a greener and more sustainable world.

References

[1]. Degen, Florian, et al. “Energy consumption of current and future production of lithium-ion and post lithium-ion battery cells.” Nature Energy 8.11 (2023): 1284-1295.

[2]. Ghaeminezhad, Nourallah, Zhisheng Wang, and Quan Ouyang. “A Review on lithium-ion battery thermal management system techniques: A control-oriented analysis.” Applied Thermal Engineering 219 (2023): 119497.

[3]. Quilty, Calvin D., et al. “Electron and ion transport in lithium and lithium-ion battery negative and positive composite electrodes.” Chemical Reviews 123.4 (2023): 1327-1363.

[4]. Bodart, Jérôme, et al. “From Na2FePO4F/CNT to NaKFePO4F/CNT as advanced cathode material for K-ion batteries.” Journal of Power Sources 555 (2023): 232410.

[5]. De, Puja, et al. “Two-Dimensional V2O5 Nanosheets as an Advanced Cathode Material for Realizing Low-Cost Aqueous Aluminum-Ion Batteries.” ACS Applied Energy Materials 6.2 (2023): 753-762.

[6]. Satrughna, Jena Akash Kumar, et al. “Experimental and computational advancement of cathode materials for futuristic sodium ion batteries.” Materials Today (2023).

[7]. Grandjean, Martine, et al. “Matching silicon-based anodes with sulfide-based solid-state electrolytes for Li-ion batteries.” Journal of Power Sources 580 (2023): 233386.

[8]. Karimi, Zahra, Ali Sadeghi, and Ali Ghaffarinejad. “The comparison of different deposition methods to prepare thin film of silicon-based anodes and their performances in Li-ion batteries.” Journal of Energy Storage 72 (2023): 108282.

[9]. Larkin, Roy-John, Shane Clayton Willenberg, and Natasha Ross. “Silicon-Based Anodes towards Enhanced Cycling Efficiencies for Next-Generation Lithium-Ion Batteries.” International Journal of Electrochemical Science (2023): 100158.

[10]. Park, Hyunjung, et al. “A multifunctional network binder enables stable and high performance of silicon-based anode in lithium-ion battery.” Journal of Power Sources 574 (2023): 233159.

Cite this article

Zhao,A.;Hao,G.;Zhang,W. (2024). Innovations and strategies for optimizing lithium-ion battery performance: From material advancements to system management. Applied and Computational Engineering,66,144-149.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Degen, Florian, et al. “Energy consumption of current and future production of lithium-ion and post lithium-ion battery cells.” Nature Energy 8.11 (2023): 1284-1295.

[2]. Ghaeminezhad, Nourallah, Zhisheng Wang, and Quan Ouyang. “A Review on lithium-ion battery thermal management system techniques: A control-oriented analysis.” Applied Thermal Engineering 219 (2023): 119497.

[3]. Quilty, Calvin D., et al. “Electron and ion transport in lithium and lithium-ion battery negative and positive composite electrodes.” Chemical Reviews 123.4 (2023): 1327-1363.

[4]. Bodart, Jérôme, et al. “From Na2FePO4F/CNT to NaKFePO4F/CNT as advanced cathode material for K-ion batteries.” Journal of Power Sources 555 (2023): 232410.

[5]. De, Puja, et al. “Two-Dimensional V2O5 Nanosheets as an Advanced Cathode Material for Realizing Low-Cost Aqueous Aluminum-Ion Batteries.” ACS Applied Energy Materials 6.2 (2023): 753-762.

[6]. Satrughna, Jena Akash Kumar, et al. “Experimental and computational advancement of cathode materials for futuristic sodium ion batteries.” Materials Today (2023).

[7]. Grandjean, Martine, et al. “Matching silicon-based anodes with sulfide-based solid-state electrolytes for Li-ion batteries.” Journal of Power Sources 580 (2023): 233386.

[8]. Karimi, Zahra, Ali Sadeghi, and Ali Ghaffarinejad. “The comparison of different deposition methods to prepare thin film of silicon-based anodes and their performances in Li-ion batteries.” Journal of Energy Storage 72 (2023): 108282.

[9]. Larkin, Roy-John, Shane Clayton Willenberg, and Natasha Ross. “Silicon-Based Anodes towards Enhanced Cycling Efficiencies for Next-Generation Lithium-Ion Batteries.” International Journal of Electrochemical Science (2023): 100158.

[10]. Park, Hyunjung, et al. “A multifunctional network binder enables stable and high performance of silicon-based anode in lithium-ion battery.” Journal of Power Sources 574 (2023): 233159.