1. Background

In recent years, environmental issues such as the greenhouse effect have posed threats to the human living environment. There has been an increasing occurrence of extreme weather events and destruction of biodiversity, even negatively impacting human pro- duction and lifestyle. In response to this, environmental issues like the greenhouse effect have become a global focus, and people are contemplating how to address or mitigate these problems. Identifying the causes of greenhouse effect and implementing measures to mitigate it is a strategy for reducing greenhouse effect.

The use of fossil fuels is a major contributor to the exacerbation of these environ- mental problems.[1] The combustion of fossil fuels generates large amounts of green- house gases, such as carbon dioxide, which accelerates global warming and climate change. In order to address these global environmental issues, the international com- munity is gradually shifting towards renewable energy.

Compared to fossil fuels, renewable energy has the advantage of being green and environmentally friendly, as it significantly reduces greenhouse gas emissions and mitigates the greenhouse effect. However, despite these clear advantages, the high cost of renewable energy systems has hindered their widespread adoption and implementation.

In renewable energy systems, energy storage is considered an important component for energy conservation and cost reduction. Storing energy, especially during periods of excess generation, avoids energy waste and allows for energy supply during peak demand. Therefore, optimization and improvement of the energy storage component in renewable energy systems are of great significance.

This project is based on a system that includes wind power generation, energy storage, and ultimately supplying electric buses. The aim is to optimize and improve renewable energy systems. To simulate and evaluate the performance of the system more realistically, Baoding has been chosen as the simulated location. In the simulation process, factors such as wind energy, battery performance, and battery maintenance costs will be comprehensively considered to achieve a comprehensive analysis and optimization of the system. The use of Matlab for system modeling has several advantages, including providing rich computational, optimization, and simulation tools, which enable accurate analysis of system performance.

Our research team has noticed that battery life is of great importance in an energy storage system. The battery serves as the primary storage medium for electrical energy, and its lifespan directly impacts the overall performance, reliability, and economic viability of the energy storage system. Therefore, simulating and optimizing battery life is crucial for the entire system.

Furthermore, machine learning has unique advantages in improving battery life in renewable energy systems. By exploring extensive historical data and learning patterns, machine learning can provide intelligent predictions and optimization strategies for battery life. In this project, machine learning methods will be employed to improve the battery life in renewable energy systems, thereby enhancing system reliability and stability.

In summary, this paper aims to optimize and improve the system of wind power generation, energy storage, and electric bus supply, in order to reduce dependence on fossil fuels. Matlab modeling and machine learning methods will be utilized to enhance system performance and efficiency. This research will provide valuable insights and references for the field of renewable energy, contributing to the development of clean and sustainable energy solutions.[2]

2. Literature Review

The challenges of global climate change and fossil fuel depletion have been pushing humanity to seek sustainable energy solutions [3]. Among renewable sources, wind energy has gained prominence for its reliability and low carbon footprint. Simultaneously, the rise in electric vehicles (EVs) presents an unprecedented demand for clean energy [3-5]. This literature review critically examines the research landscape surrounding the use of Matlab algorithms to simulate wind power plants feeding electricity to electric vehicles, and the integration of energy storage devices to optimize this system

2.1. Wind Power Generation

2.1.1. Background and Technologies. Wind energy utilization has undergone significant advancements, with technologies evolving from traditional sail wings to more efficient Horizontal-Axis Wind Turbines (HAWTs) and Vertical-Axis Wind Turbines (VAWTs) [6, 7]. HAWTs have been extensively used for their efficiency, while VAWTs are more suitable for urban settings but suffer from lower efficiency.

2.1.2. Matlab Simulation of Wind Energy. Research has utilized Matlab/Simulink for simulating various aspects of wind energy production. Chong et al. performed in-depth simulations and analyzes using Matlab to evaluate the efficiency of different types of wind energy conversion systems under specific climatic conditions in Sarawak, Malaysia [8]. Another study by Run Qin et al. focused on using MATLAB/Simulink to in-depth simulate and analyze the important role of FESS in assisting wind energy power systems to improve frequency stability, especially in power grids with wind energy penetration. This provides valuable experimental data and analysis for frequency control of power systems [9].

2.1.3. Challenges and Future Directions. Although wind power generation has abundant resources, it still has certain limitations and instability due to the influence of weather. This intermittency has been studied extensively, with solutions ranging from grid balancing to energy storage. Offshore wind farms offer more consistent wind speeds but introduce new logistical and maintenance challenges [10].

2.2. Electric Vehicle Powering

2.2.1. Rapid Expansion and Importance. Electric vehicles (EVs) are becoming the cornerstone of future transportation. EVs not only decrease fossil fuel consumption but also provide an opportunity for clean energy utilization. The use of clean energy for power generation and the supply of electricity to electric vehicles through the generated electricity has become a direction for the development of electric vehicle energy supply, which is an exploratory research path

2.2.2. Issues in Real-time Charging. Many studies have highlighted the challenge of real-time charging of EVs using renew- able energy, as there is a mismatch between energy availability and charging demand. Soomin Woo used extensive data to examine how optimizing when and where electric vehicles charge could bring the greatest potential benefits to the grid, both economically and environmentally [11].

2.3. Energy Storage Systems

Among energy storage solutions, Lithium-ion batteries are most commonly used due to their high energy density. However, flow batteries and supercapacitors are also studied for their quick charging capabilities and longer cycle lives [12].

In a study by Mingshen Wang [13], a smoothing control strategy is proposed to address the rapid power fluctuations in the grid due to wind energy integration. This strategy utilizes the battery energy storage systems of electric vehicles (EVs) arranged into aggregators. These aggregators, defined by varying response parameters, contribute to smoothing out power fluctuations. On the other hand, Hossam S. Salama’s research investigates the impact of incorporating EVs into renewable energy-powered grids, with an emphasis on wind energy. The study employs a superconducting magnetic energy storage system (SMES) and fuzzy logic controllers to optimize various grid operation metrics, including power losses and voltage stability. Collectively, these studies under- score the significant role that EVs can play in enhancing the robustness and efficiency of renewable energy-integrated utility grids [5].

2.4. MATLAB Algorithms in Renewable Energy Simulations

Susana Alegre’s research focuses on reducing environmental pollution and energy consumption in the Spanish transport sector through the use of parallel hybrid electric vehicles. The study utilizes Matlab/Simulink for vehicle modeling and GIS-based algorithms to optimize charging station locations, demonstrating potential cost savings and improved service reliability. A case study in Zaragoza, Spain, verified the effective- ness of this model and significantly reduced costs [14]. The role of Matlab algorithms in simulating and optimizing wind power systems to feed electric vehicles is pivotal. Yet, gaps remain in addressing issues like energy intermittency, storage inefficiencies, and real-time energy allocation. Future work should explore advanced Matlab algorithms that can operate under real-time constraints and integrate machine learning for predictive analytics.

3. Methodology

3.1. Introduction

A system of wind power generation, lithium-ion battery storage and power for electric buses is designed, taking Baoding as an example. We collected hourly wind speed and air density data in Tianjin in 2019 [15,16]. Using

\( P = 0.5 *ρ *A*{V^{3}} *Cp \) (1)

(P is the power, ρ is the air density, A is the windmill swept area, V is the wind speed, Cp is the efficiency of the windmill), it’s easy to find out how much electricity a Vestas V90-3.0MW windmill can supply per hour in 2019.

Table 1. Key parameters of Vestas V90-3.0MW windmills

Name | Symbol | Magnitude | Unit |

Power Coefficient | Cp | 0.48 | |

Blade Diameter | D | 90 | m |

Cut-in Wind Speed | Vcut | 4 | m/s |

Rated Wind Speed | Vrated | 15 | m/s |

Stop Wind Speed Windmill Swept Area | Vstop A | 25 6362 | m/s m2 |

The electricity generated from the windfarm will be transferred into and stored in the lithium battery immediately, considering the efficiency. However, electricity would be transferred into the electric bus charging station from the windmills directly when buses need to be charged due to the higher efficiency (the time electricity is required is from 0:00 a.m. to 6:00 a.m.). If electricity from windfarm is not enough to meet the demand [17], battery would also provide electricity. Meanwhile, the redundant electricity will be sold out.

3.2. Cost

Our aim is to meet the needs of electricity for charging the electric buses and minimize the cost of windfarm and lithium-ion battery which the cost of windfarm is decided by the number of windmill and the cost of lithium-ion battery is generally the cost of production of lithium-ion battery per year (The data of money required to make 1kWh of lithium-ion battery are from the data provided by firms in related industry.) So, optimization in MATLAB is used, that is finding out the minimum value of a nonlinear function, which in this case is the money required to build windmills in Baoding to meet the needs of charging the buses and the money to build the lithium-ion battery in order to find out the minimum cost while ensuring the demand is met.

Generally, it’s not easy to calculate the money to build a lithium-ion battery, but through analyzing open data of some of firms in related industry, the money needed to make 1kWh of battery is $148. Since we could also simply find that a Vestas V90- 3.0MW windmill cost $20,000, the total cost is basically the cost of construction of battery and the windfarm minus the revenue earnt by selling electricity.

Table 2. Key parameters in the system

Name | Symbol | Magnitude | Unit |

Transfer Efficiency (Windfarm to Station) | Y1 | 0.975 | |

Transfer Efficiency (Windfarm to Battery) | Y2 | 0.99 | |

Transfer Efficiency (Battery to Station) | Y3 | 0.975 | |

Cost per Windmill | S1 | 20 | k$ |

Cost per kWh of Battery | S2 | 0.148 | k$ |

Price per kWh of Electricity | S3 | 0.00015 | k$ |

3.3. Aging

Talking about the lithium-ion battery, aging or the SOH (State of Health) which is the percentage of remaining capacity, can be a crucial factor. In this case, another model is constructed to predict the SOH line of the lithium-ion battery which requires the machine learning in MATLAB that is producing a line that is most suitable for the trend of a group of sample data. In this case, sets of data of degradation of SOH of lithium-ion battery are required. After big range of searching, collecting and selecting [18], a group of sample data is prepared to be put into the aging model.

4. Results

4.1. Cost

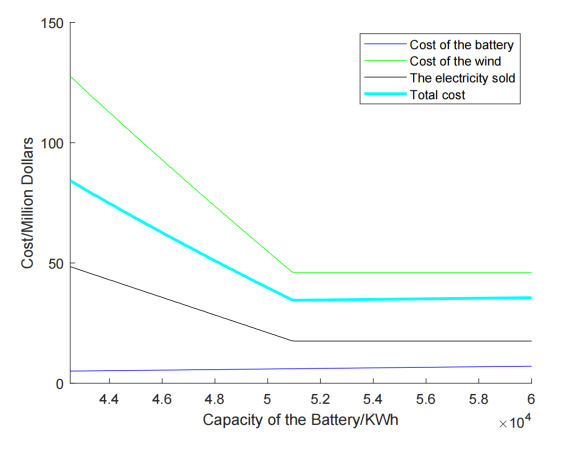

Generally, after running the model of optimization of costs, it’s easy to find out that the minimum total cost would be 43.273178 million dollars, considering the cost of both windfarm and battery and the revenue earnt from selling electricity. Partially, the cost of construction of lithium-ion battery is 6.038919 million dollars and cost of windmills is 46 million dollars. Meanwhile, the revenue earnt is 8.765741 million dollars.

Table 3. Results for Cost

Name | Magnitude | Unit |

Battery Cost Windmills Cost Revenue Earnt from Selling Electricity Total Cost Battery Capacity Number of Windmills | 6.038919 46 8.765741 43.273178 51004.380476 184 | Million Dollars Million Dollars Million Dollars Million Dollars kWh |

Figure 1. Costs and Revenue Change due

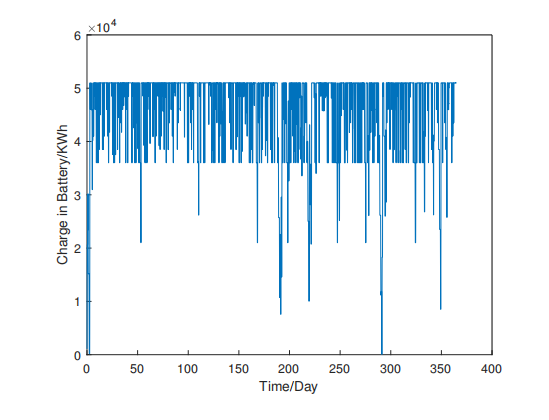

Figure 2. Change in Battery Capacity due to Capacity Change to time

4.2. Aging

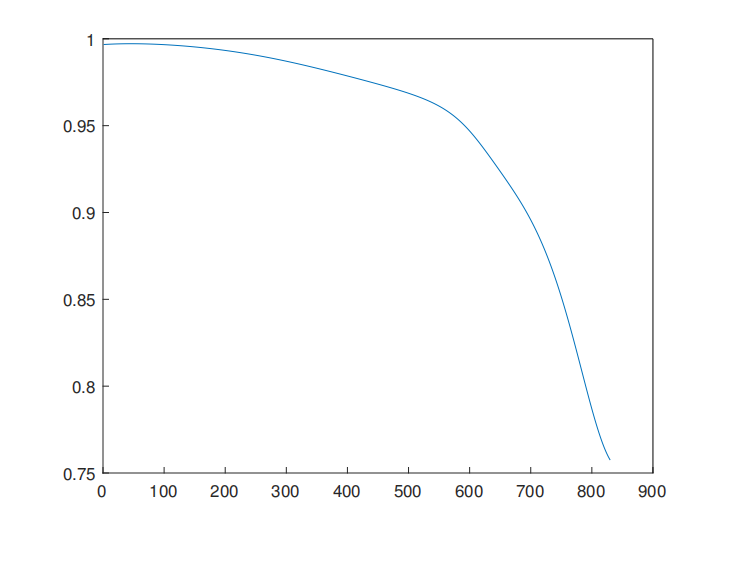

Figure 3. SOH Change with the Cycle Number

Based on data collected, the graph first goes down slightly and then drop significantly when reaching SOH of 0.95 at about 591 cycles of charging. After 693 cycles, the decrease in SOH becomes much sharper.

5. Discussion

The entire wind energy bus energy storage system is in a complex dynamic process, and there are many factors that need to be considered, such as the supply and collection of wind energy, the loss of each energy transmission stage, the capacity of energy storage equipment, and the energy input required by electric buses, etc... This complex system can be visualized using simulation modeling and machine learning techniques. As shown in Figure 1, taking economy as the standard, the relationship curve between battery capacity and overall system overhead is obtained by the simulation module. It can be clearly seen that when the energy storage capacity is very small (close to or equal to 0), the cost of the entire system is extremely high, but as the energy storage volume increases, the system cost shows a sharp downward trend. This is in line with expectations and demonstrates the importance of energy storage equipment in overall system cost control. Energy storage equipment can convert unstable supply of wind energy into a more stable form, thus reducing the number of windmills required for wind energy collection side and significantly reducing system costs. When battery capacity is limited, uncertainty in wind energy supply will also have a certain impact. The significance of energy storage equipment is to store energy for a long time and prevent energy loss during low energy periods. But continuous input peaks and input troughs will still cause a series of problems. Based on the obtained wind energy data and optimized system data, the relationship curve between the remaining power in the battery and time was established, as shown in Figure 2. It can be observed from the figure that the energy storage situation of the battery is much higher than the demand, and most of the energy in the battery needs to be released only at certain times. However, it can still be observed that the battery is operating at full capacity for a lot of time, which undoubtedly causes waste on the input side. Therefore, when designing the model, the response strategy when full energy needs to be taken into consideration. In this model, the energy input beyond the full load of the battery is handled in the form of selling electric energy to the grid. However, the cost-decreasing trend is not permanent. The extreme point occurs when the battery capacity is 51004 kWh. On the collection side, it is still necessary to ensure a minimum number of windmills to provide a basic electric energy that supports the energy consumption side, and the electricity collected by these windmills is limited. Therefore, the excess energy storage capacity will be in an idle state, and for the entire system, unnecessary costs will be added out of thin air. It can be seen from the model data that the extreme point of 51004 kWh is the calculated optimal energy storage capacity, which not only ensures that enough energy can be stored for the consumption side, but also ensures the minimum number of windmills and batteries to minimize wasted.

Finally, since the design of the model is based on lithium batteries, the cyclic ag- ing of lithium batteries during long-term use must be taken into account. A machine learning model was used to predict the cycle and aging degree of lithium batteries, and the results are shown in Figure 3. After 591 cycles, the capacity of the battery will be reduced to about 95%, and then the aging phenomenon of the battery will gradually become sharp. After 693 cycles, the capacity of the battery will be reduced to about 90%, and then the battery will rapidly age and fail rapidly. Therefore, based on the actual usage of the battery, reasonable consideration of maintenance and replacement of the battery will be the key to ensuring the smooth operation of the system. This machine learning model will reliably help with that.

6. Conclusion

1) Based on wind power supply, an optimization model for wind power supply to electric vehicle systems was constructed with the volume of lithium battery energy storage equipment as the target. In addition, the cycle aging behavior of lithium battery energy storage devices was predicted using machine learning techniques.

2) Taking the battery volume as the optimization target, the excess electric energy is converted into revenue for supplying the grid. The final optimization result is 51004 kW/h as the optimal battery energy storage volume, which can ensure the lowest cost of the entire system.

3) The machine learning model of battery aging shows that the battery capacity will be reduced to about 95% of the original capacity after 591 cycles, and the battery will be reduced to about 90% of the original capacity after 693 cycles. After that, the situation deteriorates sharply, and it is obviously not suitable for continued service. Provides reference data for battery maintenance and replacement.

References

[1]. ZHENGUO “GARY”YANG. Advanced Materials for a Sustainable, Clean En- ergy future[J]. JOM,2009,61(4):35.

[2]. JORGE MORALES PEDRAZA. Is Nuclear Power a Realistic Alternative for the Production of Electricity after the fukushima daiichi nuclear accident?[J]. Inter- national journal of energy, environment and economics,2013,21(3):215-267.

[3]. Yi, S., et al., Environmental concerns in the United States: Can renewable en- ergy, fossil fuel energy, and natural resources depletion help? GONDWANA RESEARCH, 2023. 117: p. 41-55.

[4]. Mehrjerdi, H. and R. Hemmati, Stochastic model for electric vehicle charging station integrated with wind energy. SUSTAINABLE ENERGY TECHNOLO- GIES AND ASSESSMENTS, 2020. 37.

[5]. Salama, H.S., et al., Studying Impacts of Electric Vehicle Functionalities in Wind Energy-Powered Utility Grids With Energy Storage Device. IEEE ACCESS,2021. 9: p. 45754-45769.

[6]. Serrano-Gonzalez, J. and R. Lacal-Arantegui, Technological evolution of on- shore wind turbinesa market-based analysis. WIND ENERGY, 2016. 19(12): p. 2171-2187.

[7]. ohansen, K., Blowing in the wind: A brief history of wind energy and wind power technologies in Denmark. ENERGY POLICY, 2021. 152

[8]. Chong, C.H., A.R.H. Rigit, and I. Ali, Wind turbine modelling and simulation using Matlab / SIMULINK. IOP Conference Series: Materials Science and En- gineering, 2021. 1101(1): p. 012034.

[9]. Qin, R., et al., Simulation of Secondary Frequency Modulation Process of Wind Power with Auxiliary of Flywheel Energy Storage. SUSTAINABILITY, 2023. 15(15).

[10]. Pryor, S.C., R.J. Barthelmie, and T.J. Shepherd, Wind power production from very large offshore wind farms. JOULE, 2021. 5(10): p. 2663-2686.

[11]. Woo, S., et al., Economic and Environmental Benefits for Electricity Grids from Spatiotemporal Optimization of Electric Vehicle Charging. ENERGIES, 2021. 14(24).

[12]. Koohi-Fayegh, S. and M.A. Rosen, A review of energy storage types, applica- tions and recent developments. JOURNAL OF ENERGY STORAGE, 2020. 27.

[13]. Wang, M., et al., Smoothing control of wind power fluctuations with battery en- ergy storage system of electric vehicles. INTERNATIONAL TRANSACTIONS ON ELECTRICAL ENERGY SYSTEMS, 2021. 31(10).

[14]. Alegre, S., J.V. Miguez, and J. Carpio, Modelling of electric and parallel-hybrid electric vehicle using Matlab/Simulink environment and planning of charging stations through a geographic information system and genetic algorithms. RE- NEWABLE & SUSTAINABLE ENERGY REVIEWS, 2017. 74: p. 1020-1027.

[15]. Pfenninger, S., & Staffell, I. (2016b). Long-term patterns of European PV output using 30 years of validated hourly reanalysis and satellite data. Energy, 114, 1251– 1265.

[16]. Staffell, I., & Pfenninger, S. (2016). Using bias-corrected reanalysis to simulate current and future wind power output. Energy, 114, 1224– 1239.

[17]. Qiu Jingyi (2017) Research on modeling and charging strategy of electric bus driving power consumption (Doctoral dissertation, North China Electric Power University; North China Electric Power University (Baoding))

[18]. Severson, K. A., Attia, P. M., Jin, N., Perkins, N., Jiang, B., Yang, Z. J., Chen,M. H., Aykol, M., Herring, P., Fraggedakis, D., Bazant, M. Z., Harris, S. J., Chueh, W. C., & Braatz, R. D. (2019c). Data-driven prediction of battery cycle life before capacity degradation. Nature Energy, 4(5), 383–39

Cite this article

Wang,Z.;Wang,P.;Yu,M. (2024). Optimization of wind farm energy supply system costs through machine learning. Applied and Computational Engineering,84,1-8.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. ZHENGUO “GARY”YANG. Advanced Materials for a Sustainable, Clean En- ergy future[J]. JOM,2009,61(4):35.

[2]. JORGE MORALES PEDRAZA. Is Nuclear Power a Realistic Alternative for the Production of Electricity after the fukushima daiichi nuclear accident?[J]. Inter- national journal of energy, environment and economics,2013,21(3):215-267.

[3]. Yi, S., et al., Environmental concerns in the United States: Can renewable en- ergy, fossil fuel energy, and natural resources depletion help? GONDWANA RESEARCH, 2023. 117: p. 41-55.

[4]. Mehrjerdi, H. and R. Hemmati, Stochastic model for electric vehicle charging station integrated with wind energy. SUSTAINABLE ENERGY TECHNOLO- GIES AND ASSESSMENTS, 2020. 37.

[5]. Salama, H.S., et al., Studying Impacts of Electric Vehicle Functionalities in Wind Energy-Powered Utility Grids With Energy Storage Device. IEEE ACCESS,2021. 9: p. 45754-45769.

[6]. Serrano-Gonzalez, J. and R. Lacal-Arantegui, Technological evolution of on- shore wind turbinesa market-based analysis. WIND ENERGY, 2016. 19(12): p. 2171-2187.

[7]. ohansen, K., Blowing in the wind: A brief history of wind energy and wind power technologies in Denmark. ENERGY POLICY, 2021. 152

[8]. Chong, C.H., A.R.H. Rigit, and I. Ali, Wind turbine modelling and simulation using Matlab / SIMULINK. IOP Conference Series: Materials Science and En- gineering, 2021. 1101(1): p. 012034.

[9]. Qin, R., et al., Simulation of Secondary Frequency Modulation Process of Wind Power with Auxiliary of Flywheel Energy Storage. SUSTAINABILITY, 2023. 15(15).

[10]. Pryor, S.C., R.J. Barthelmie, and T.J. Shepherd, Wind power production from very large offshore wind farms. JOULE, 2021. 5(10): p. 2663-2686.

[11]. Woo, S., et al., Economic and Environmental Benefits for Electricity Grids from Spatiotemporal Optimization of Electric Vehicle Charging. ENERGIES, 2021. 14(24).

[12]. Koohi-Fayegh, S. and M.A. Rosen, A review of energy storage types, applica- tions and recent developments. JOURNAL OF ENERGY STORAGE, 2020. 27.

[13]. Wang, M., et al., Smoothing control of wind power fluctuations with battery en- ergy storage system of electric vehicles. INTERNATIONAL TRANSACTIONS ON ELECTRICAL ENERGY SYSTEMS, 2021. 31(10).

[14]. Alegre, S., J.V. Miguez, and J. Carpio, Modelling of electric and parallel-hybrid electric vehicle using Matlab/Simulink environment and planning of charging stations through a geographic information system and genetic algorithms. RE- NEWABLE & SUSTAINABLE ENERGY REVIEWS, 2017. 74: p. 1020-1027.

[15]. Pfenninger, S., & Staffell, I. (2016b). Long-term patterns of European PV output using 30 years of validated hourly reanalysis and satellite data. Energy, 114, 1251– 1265.

[16]. Staffell, I., & Pfenninger, S. (2016). Using bias-corrected reanalysis to simulate current and future wind power output. Energy, 114, 1224– 1239.

[17]. Qiu Jingyi (2017) Research on modeling and charging strategy of electric bus driving power consumption (Doctoral dissertation, North China Electric Power University; North China Electric Power University (Baoding))

[18]. Severson, K. A., Attia, P. M., Jin, N., Perkins, N., Jiang, B., Yang, Z. J., Chen,M. H., Aykol, M., Herring, P., Fraggedakis, D., Bazant, M. Z., Harris, S. J., Chueh, W. C., & Braatz, R. D. (2019c). Data-driven prediction of battery cycle life before capacity degradation. Nature Energy, 4(5), 383–39