1. Introduction

With the rapid development of materials science, flexible electronics, and nanotechnology, there is an urgent need for flexible sensors capable of detecting multiple signals (such as pressure, chemical, biological, etc.). These sensors have significant application prospects in artificial intelligence, medical monitoring, and human-computer interaction. Based on piezoresistive, piezocapacitive, and piezoelectric effects, pressure applied to the measured object is converted into electrical signals. Among these, piezoelectric sensors mainly rely on the piezoelectric effect, while piezocapacitive sensors are sensitive to minor forces, making them suitable for static force measurements. Piezoresistive sensors are attracting attention due to their wide detection range and simple structure. This project focuses on flexible piezoresistive sensors, conducting in-depth research on material selection, electrode preparation, and microstructure to reveal the structure-performance relationship and explore their applications in intelligent systems.

2. Introduction to Flexible Piezoresistive Sensors

Flexible piezoresistive sensors operate by converting externally applied forces into electrical signals, achieved by changing the resistance of the sensing material. Their core function is to respond to changes in external forces, with circuit designs directly measuring resistance changes to monitor force magnitude. The main advantages of these sensors are a broad detection range, simple signal acquisition, and low requirements for testing equipment. Their performance is primarily defined by sensitivity and detection range, where sensitivity measures responsiveness, and the detection range describes the range of forces the sensor can accurately measure. Material selection is critical in manufacturing these sensors, commonly using carbon-based materials (carbon black, carbon nanotubes, graphene), metal nanomaterials, polymer polymers, and protein fibers. Despite their advantages, balancing high sensitivity and high compressibility and matching the interface of hard and soft materials remain challenges. Currently, common flexible substrate materials include polyimide (PI), polyethylene terephthalate (PET), and polydimethylsiloxane (PDMS). Researchers are also exploring multi-axially stretchable composites to enhance sensor performance and application range.

Table 1. Material Selection, Electrode Preparation Methods, and Key Parameters of Novel Flexible Piezoresistive Sensors

Material Selection |

Electrode Preparation Methods |

Sensitivity |

Detection Range |

Silver nanowire |

Dip-pen technology |

16.1 kPa⁻¹ |

50 Pa – 42 kPa |

Gold nanowire |

PVD |

1.14 kPa⁻¹ |

13 Pa – 50 kPa |

Graphene nano sheet |

Dip-pen technology |

70.86 kPa⁻¹ |

0 – 5 kPa |

CNT |

Inkjet printing technology |

16.73 kPa⁻¹ |

0 – 5 kPa |

CNT and graphene oxide |

Dip-pen technology |

1.22 kPa⁻¹ |

0 – 23.4 kPa |

Graphene fiber paper |

Dip-pen technology |

17.2 kPa⁻¹ |

0 – 20 kPa |

Ti₃C₂Tₓ and graphene |

PAMD |

22.56 kPa⁻¹ |

10 Pa – 4.9 kPa |

CNT and graphene |

Screen printing technology |

8.4 kPa⁻¹ |

800 Pa – 10 kPa |

Ptl₂-TiSi polymer |

PVD |

8.4 kPa⁻¹ |

0 – 20 kPa |

(C₂H₄O₅Si) polymer |

Dip-pen technology |

11.45 kPa⁻¹ |

5 Pa – 1.5 kPa |

BOPP |

PVD |

3.73 kPa⁻¹ |

0.1 Pa – 100 kPa |

3. In-situ Characterization Techniques and Microstructural Model of Flexible Piezoresistive Sensors

3.1. In-situ Characterization Techniques

Using advanced testing techniques, we can perform detailed analyses of the microstructure, surface characteristics, pore sizes, crystal structures, and chemical compositions of materials. These analyses typically use characterization tools such as Scanning Electron Microscopy (SEM), Transmission Electron Microscopy (TEM), Scanning Tunneling Microscopy (STM), Atomic Force Microscopy (AFM), X-ray Photoelectron Spectroscopy (XPS), X-ray Absorption Fine Structure (XAFS), and Scanning Transmission X-ray Microscopy (STXM) [3]. In-situ testing methods utilizing these techniques can monitor the internal structure of sensors in real-time under specific environmental conditions, revealing the close relationship between material structure and performance. This project plans to use in-situ mechanical SEM and TEM to study the microscopic interaction mechanisms of materials and evaluate the relationship between their structure and performance.

3.1.1. SEM Measurement Techniques

In materials science, physics, and mechanics, in-situ Scanning Electron Microscopy (SEM) technology allows researchers to monitor the morphology and structural changes of materials in real-time under stress, which is particularly important for studying the micro- and nanoscale fracture, deformation, and other nonlinear behaviors of materials. Recently, researchers Yi-Xun Chen, Qian Wu, and Qian Li developed a flexible piezoresistive sensor based on MXene/PVA nanowires, exhibiting high sensitivity (442 kPa) and fast response (138 ms), capable of accurately detecting minimal forces (9 Pa) and maintaining stable performance after 10,000 tests. Using SEM technology, the research team found that under stress, the contact area of MXene-coated nanowires increased, changing the conductivity and resistance values; once the pressure was relieved, the nanowires returned to their original state, and the resistance decreased [1]. This observation not only reveals the conductive network within the sensor but also provides a dynamic perspective for analyzing the relationship between material structure and performance.

3.1.2. TEM Measurement Techniques

Transmission Electron Microscopy (TEM), with its high spatial resolution, can conduct detailed studies of nanomaterials and devices at the atomic level. With the development of Micro-Electro-Mechanical Systems (MEMS) technology, in-situ TEM has become an important tool for studying the structure and properties of micro- and nano-devices, combining static analysis and dynamic observation. Particularly in the field of flexible piezoresistive sensors, in-situ TEM can track and analyze the microstructure of materials in real-time under external forces. Researchers Jing Xu, Jingxuan Ma, and Luwen Wang developed a highly sensitive MXene piezoresistive sensor using this technology. Experiments demonstrated its high compressibility, capable of compressing the interlayer spacing from 12 nm to 0 nm. Repeated loading tests showed that the resistance varied with the interlayer spacing, displaying good cycle stability [2]. This study not only reveals the relationship between the interlayer structure and resistance of the material but also provides valuable experimental data for optimizing sensor design.

3.2. Microstructural Mechanisms of Flexible Piezoresistive Sensors

The combination of different micro- and nanomaterials, precise control of material quantities, and the adjustability of sensor structures are key factors for achieving diverse functions in flexible piezoresistive sensors. These factors synergistically influence sensor performance. To improve performance and accurately analyze related parameters, understanding the microstructure and piezoresistive effect mechanisms is crucial. The conduction mechanism of flexible piezoresistive sensors mainly includes percolation, tunneling current, and interface contact, which are particularly applicable in the study of gas-sensing mechanisms of "polymer-conductive" composite structures. In such composite materials, conductive components are uniformly distributed within the polymer matrix, forming a stable conductive network. Their conductive properties help explain the mechanisms of charge transfer and network structure formation.

3.2.1. Percolation Model

When studying the conductive network of flexible "polymer-conductive" composites, researchers use percolation theory to explain their conductive mechanisms and quantitatively analyze the relationship between the content of conductive components and material resistivity. When the content of conductive material is low, particles are dispersed within the polymer matrix without forming continuous conductive paths, resulting in high resistivity. As the content of conductive material increases, particles start to contact and gradually form conductive paths, thereby reducing resistivity. Upon reaching the percolation threshold, a complete conductive path is formed, and resistivity drops sharply. Beyond the percolation threshold, the rate of decrease in resistivity slows down and stabilizes. The relationship between conductive material content and resistivity beyond the percolation threshold can be described by specific mathematical formulas:

\( \sigma=\sigma_0{(\varphi - \varphi_c)}^t \)

In the equation, σ and σ0 represent the conductivity of the conductive material and the composite material, respectively. φ represents the volume fraction of the conductive material in the overall composition, while φc is the volume fraction of the conductive material at its percolation threshold. The coefficient t describes the relationship between the size of the conductive material and percolation behavior.

Before the conductive medium reaches the percolation critical value, only local conductive paths are formed. External pressure causes deformation of the polymer matrix, altering the contact points of the conductive network and consequently affecting resistivity. This demonstrates the application of percolation theory in the study of piezoresistive effects. The research by Shun Weng, Zhi Yue Zhang, and Ke Gao on polymer flexible sensors doped with semiconductor particles not only confirmed the applicability of the percolation model but also provided a theoretical basis for the preparation of flexible polymer composites [3]. They established a simplified mathematical model using the percolation model and conductivity index to describe how pressure affects resistance, further verifying that the percolation model can effectively explain the working principle of elastic piezoresistive sensors.

3.2.2. Tunneling Current Model

Zhiyong Huang, Hongqiang Li, and Baodeng Chen found that carbon black/rubber composites exhibited conductivity even in the absence of a complete conductive path, which exceeded the predictions of traditional percolation theory [4]. To explain this, they employed the tunneling current model, which indicates that low-energy electrons can generate current by traversing high-energy barriers even if conductive particles do not directly contact each other. Tunneling current does not occur without external excitation and if the distance between conductors is too large. However, external pressure can reduce the distance between two conductors to a non-direct contact state, allowing electrons to cross the barrier via quantum effects and produce tunneling current. When pressure increases to the point where materials come into contact, a direct conductive path is formed, and the tunneling effect is replaced by direct conduction.

The formula for the tunneling current conductivity between particles is:

\( J=[3{(2m_\varphi)}^{1/2}](e/h)^{2}Ue[ - (4πD/h)(2m_{φ})^{1/2}] \)

In this formula, J represents the current density, m and e denote the mass and charge of an electron, h is Planck's constant, φ signifies the barrier in the gap, D is the width of the gap, and U is the potential difference. This indicates that the current density J is a function of the tunnel gap width D.

Ze-Kun Wang developed a "sandwich" type flexible piezoresistive sensor constructed using silver nanowires (AgNWs) and PDMS elastomer. Preliminary studies show that despite the lack of physical contact between the nanowires, conduction junctions can be formed through quantum tunneling effects, resulting in tunnel current transfer, which aligns with theoretical expectations. This provides a new perspective for the research on conductive polymer composites[5]. The sensor's substrate exhibits good compressibility and repeatability, but due to the limitations of the conductive network, its resistance variation is primarily caused by the deformation of the polymer substrate, which limits its detection sensitivity and range. Therefore, detecting minor forces remains a challenge. Future research needs to develop new sensitive materials and structures to improve sensor performance.

3.2.3. Interface Contact Model

With the advancement of human-computer interaction technology, researchers are increasingly focusing on transmitting information by sensing external pressure to enhance the efficiency of flexible piezoresistive sensors. Currently, the performance of flexible piezoresistive sensors based on conductive networks has approached its limits, so researchers are exploring lighter, more sensitive, and more accurate force detection technologies[6]. This project focuses on the impact of direct interface contact resistance on sensor performance. Pressure changes lead to an expansion of contact points, thus affecting the resistance value: no contact resistance when there is no pressure, contact resistance forms under pressure, and contact resistance changes with the material properties as the pressure increases.

The relationship between contact resistance and interface parameters is:

\( R_c\propto(\rho/F)K \)

In this equation, ρ represents the resistivity of the contact surface, while F is the normal pressure applied to that surface. K is a function reflecting the surface roughness and elastic characteristics. Additionally, to quantify the sensitivity of this type of sensor, a new parameter, the Gaussian Factor GFc, is introduced. This Gaussian Factor GFc is used to describe the sensor's sensitivity and has a specific correlation with the interface parameters.

\( R_c\propto(\rho/F)KGF_c=dS_c/dF\propto1/\rho K \)

In this model, Sc is defined as the conductivity of the contact surface, with its value being 1 / Rc, where Rc is the contact resistance. ρ represents the resistivity of the contact surface, while F is the normal pressure applied to the contact surface. K is a variable representing the relationship between surface roughness and its elastic characteristics. From this model, it can be seen that when the surface roughness and the elastic constant K remain constant, lower contact surface resistivity ρ will lead to higher sensor sensitivity GFc. This indicates that the contact resistance model can be effectively used to develop flexible piezoresistive sensors with different sensitivity characteristics.

The research team of Xu Na, Wang Guodong, Tao Yanan, and others successfully prepared PDMS films with a fish scale structure using an air-liquid interface film-forming method and fabricated highly sensitive flexible piezoresistive sensors by introducing graphene nanoplatelets (GNPs)[6]. During the molding process of the PDMS film, the imbalance of forces caused by pressure on the side walls and water vapor evaporation from the air side formed surface scale cracks, increasing surface roughness and contact angle. By studying the surface morphology of the PDMS film under different flexing conditions, the sensitive mechanism was revealed. Additionally, by adjusting the surface morphology of the contact surface to control contact resistance, the sensor can be tailored to meet different functional requirements. This research holds promise for developing lighter, more sensitive flexible piezoresistive sensors with better response to small forces.

4. Intelligent Systems Constructed with Flexible Piezoresistive Sensors

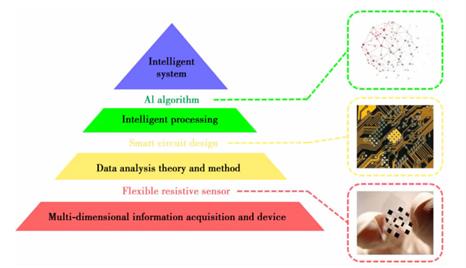

4.1. Composition of Intelligent Systems

Figure 1. Schematic diagram of intelligent system composition based on flexible piezoresistive sensors

By employing various advanced in-situ characterization techniques, researchers have revealed the relationship between the microstructure and performance of materials at the molecular level, providing a foundation for applications in the field of intelligence. With advancements in technology, flexible piezoresistive sensors exhibit advantages such as high sensitivity, wide measurement range, fast response, and high repeatability, though they come at a higher cost. Modern information technology has driven the transformation of sensors from single-function devices to integrated intelligent systems. The workflow of the new generation of intelligent systems includes: using high-performance sensors to collect multi-dimensional information, designing circuits for data transmission and preprocessing, analyzing the data through artificial intelligence algorithms, and displaying the analysis results on terminals to meet user needs. This approach transforms sensors from standalone components into complex functional systems integrated with chips and algorithms.

4.2. Applications of Intelligent Sensing Systems

4.2.1. Collection of Human Physiological Signals

With increasing attention to health, wearable medical applications have rapidly developed. Wearable electronic skin can achieve multifunctional monitoring by tracking and analyzing human physiological information in real-time. For example, the gold nanowire pressure sensor developed by Lü Shanna, with a thickness of only 1.6 mm and a response time of less than 22 ms, can effectively detect facial and arm muscle movements, vocal cord vibrations, and postures, and even monitor pulse, displaying the characteristics of the radial artery pulse at the wrist[7]. Fang Zhong developed a graphene flexible pressure sensor with a sensitivity of 25.1 kPa under a pressure range of 0-2.6 kPa, capable of real-time monitoring of foot conditions, assisting in diagnosing neurological diseases, arthritis, and more[15]. Zhengya Shi developed a flexible piezoresistive sensor with a sensitivity of up to 5.8 kPa and a response time faster than 15.6 ms, suitable for detecting subtle forces, and can monitor normal pressure during walking and running on the arm, helping to calculate walking speed[16]. Improving the efficiency and accuracy of signal acquisition in complex environments is a key direction for future research on flexible piezoresistive sensors.

4.2.2. Information Transmission and Analysis

With the rapid development of flexible sensing technology and its expanding market potential, these sensors have been widely applied in electronic skin and multifunctional devices for temperature, stress, and pressure detection. However, current testing methods often face difficulties in transmitting complex signals, especially in sensor arrays and multifunctional systems, where signal interference is a major challenge. To address this, researchers have developed new methods to accurately capture target signals and enhance system performance. For instance, Weibin Zhu developed an elastic sensor capable of highly sensitive sound recognition by reducing signal distortion through diaphragm and precise circuit design. Similarly, Fan Shi integrated 548 flexible sensors into a glove, using special circuit design and deep learning algorithms to recognize complex targets, demonstrating the application potential of high-integration sensor arrays in prosthetics, soft robots, and other fields[9]. The key challenge lies in effectively filtering interference and processing multiple sensory signals, which requires continuous innovation and optimization of circuit design to meet the demands of complex applications.

4.2.3. Algorithm Processing

As flexible sensor technology advances, its applications in human behavior recognition are expanding. This project proposes a new sensor based on deep learning, capable of real-time dynamic data processing to improve modeling efficiency. For example, Yao Feng and her team developed a flexible piezoresistive sensor array using LSTM neural networks to solve long-term dependency issues, achieving precise posture recognition in complex scenarios with an accuracy exceeding 85%[10]. Meanwhile, Xiaohui Fang and other researchers combined CNN with flexible accelerometer sensors to directly process raw signals without traditional feature extraction, achieving a recognition accuracy of 93.8%[11]. These research results, through network optimization such as adjustments to convolutional and pooling layers, effectively handle three-dimensional acceleration signals, paving the way for improving the accuracy and efficiency of human behavior recognition.

4.2.4. Novel Applications

With the development of flexible sensing technology, its application has expanded into health monitoring, daily activity tracking, electronic skin, prosthetics, human-machine interaction, and wearable robotics. These sensors can collect, transmit, and process information in real-time, integrating into intelligent systems. For instance, Qinhua Guo developed a highly sensitive tactile sensor simulating human skin, crucial for controlling soft robots[12]. Fangchun Chen integrated multiple sensors into a glove and used deep learning for precise recognition, with the technology already applied in medical assistance and high-end robotics[13]. Babangida A. designed a system combining flexible tactile sensing and visual control, capable of accurately grasping soft objects[14]. Despite these intelligent systems' wide applications across various fields, high costs and biocompatibility issues remain significant barriers to broader adoption, making research in this area of great practical significance.

5. Conclusion

This study comprehensively explores the design, performance optimization, and application prospects of flexible piezoresistive sensors based on nanocomposites. By improving the structure and function of traditional piezoresistive sensors, this research enhances sensor processing efficiency and practicality, particularly in advanced fields such as medical health monitoring and human-machine interaction. Using high-performance nanomaterials like MXene/PVA nanowires has increased the sensors' sensitivity and ability to detect minute forces. With in-situ characterization techniques (such as SEM and TEM), we can observe microstructural changes in materials under stress, gaining a deeper understanding of mechanical behavior and resistance change mechanisms. Furthermore, integrating these high-sensitivity sensors into complex intelligent systems (such as multifunctional gloves and health monitoring devices) demonstrates the broad potential of flexible piezoresistive sensors in practical applications. Although cost and biocompatibility remain current challenges, innovations in materials and system integration are gradually addressing these issues. In the future, as materials science and micro-nano technology continue to advance, flexible piezoresistive sensors are expected to play a critical role in more high-tech fields, especially in intelligent prosthetics and advanced interaction systems. This research provides new theoretical and technical support for the design and application of flexible piezoresistive sensors, laying the foundation for future research directions and technological innovations.

References

[1]. Chen, Yixun, Wu, Qian, Li, Qian, et al. "Design and Performance of Multilayer Structured Flexible Pressure Sensor Fabric" Textile Science Progress, 2024, 46(02): 14-17+22.

[2]. Xu, Jing, Ma, Jingxuan, Wang, Luwen, et al. "Compression Strain Mechanism of Graphene Flexible Piezoresistive Sensor Microstructure" China Surface Engineering, 2024, 37(01): 169-178.

[3]. Weng, Shun, Zhang, Zhiyue, Gao, Ke, et al. "Research Progress of Flexible Piezoresistive Strain Sensing Technology in Structural Health Monitoring Field" Journal of Building Structures, 2024, 45(07): 242-261.

[4]. Huang, Zhiyong, Li, Hongqiang, Chen, Baodeng, et al. "Research Progress of PDMS-based Flexible Piezoresistive Sensors" Silicone Materials, 2024, 38(01): 66-75.

[5]. Wang, Zekun. "Preparation and Performance Research of High-Temperature Resistant Fiber Membrane-based Flexible Piezoresistive Sensor" Shandong University, 2023.

[6]. Xu, Na, Wang, Guodong, Tao, Yanan. "Research Progress of Flexible Wearable Piezoresistive Pressure Sensors" Chemical Progress, 2023, 42(10): 5259-5271.

[7]. Lü, Shanna. "Research on Multifunctional Tactile Perception Methods Based on Piezoresistive Tactile Sensors" Anhui University of Architecture, 2023.

[8]. Zhu, Weibin. "Work Stability and Multifunctionality of Flexible Nanocomposite Piezoresistive Sensors" Chongqing University, 2022.

[9]. Shi, Fan. "Preparation and Application Research of Flexible Superhydrophobic Piezoresistive Sensors" Xi'an University of Science and Technology, 2022.

[10]. Feng, Yao. "Preparation and Performance Research of Different Structured Piezoresistive Flexible Pressure Sensors Based on SWCNT and Interdigitated Electrodes" Northwest University, 2022.

[11]. Fang, Xiaohui. "Design, Preparation, and Performance Research of Nanofiber-based Flexible Piezoresistive Sensors" Beijing University of Chemical Technology, 2022.

[12]. Guo, Qinhua. "Research on Flexible Proximity Perception Sensors Based on Magnetoresistive Effect and Their Applications" Shenzhen University, 2022.

[13]. Chen, Fangchun. "Development and Application Research of Flexible Sensors Based on Conductive Cotton Fabric" Southwest University, 2022.

[14]. Babangida, A.A. "Research on Piezoresistive Flexible Pressure Sensors for Human Motion Detection" Jiangsu University, 2022.

[15]. Zhong, Fang. "Construction and Application Research of Bio-adaptive Piezoresistive Sensors" Hunan University, 2022.

[16]. Shi, Zhengya. "Preparation and Performance Research of Flexible Piezoresistive Sensors Based on Biomimetic Hierarchical Structures" Zhengzhou University, 2022.

Cite this article

Liu,T. (2024). Research on flexible piezoresistive sensors based on nanocomposite materials. Applied and Computational Engineering,70,243-250.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Chen, Yixun, Wu, Qian, Li, Qian, et al. "Design and Performance of Multilayer Structured Flexible Pressure Sensor Fabric" Textile Science Progress, 2024, 46(02): 14-17+22.

[2]. Xu, Jing, Ma, Jingxuan, Wang, Luwen, et al. "Compression Strain Mechanism of Graphene Flexible Piezoresistive Sensor Microstructure" China Surface Engineering, 2024, 37(01): 169-178.

[3]. Weng, Shun, Zhang, Zhiyue, Gao, Ke, et al. "Research Progress of Flexible Piezoresistive Strain Sensing Technology in Structural Health Monitoring Field" Journal of Building Structures, 2024, 45(07): 242-261.

[4]. Huang, Zhiyong, Li, Hongqiang, Chen, Baodeng, et al. "Research Progress of PDMS-based Flexible Piezoresistive Sensors" Silicone Materials, 2024, 38(01): 66-75.

[5]. Wang, Zekun. "Preparation and Performance Research of High-Temperature Resistant Fiber Membrane-based Flexible Piezoresistive Sensor" Shandong University, 2023.

[6]. Xu, Na, Wang, Guodong, Tao, Yanan. "Research Progress of Flexible Wearable Piezoresistive Pressure Sensors" Chemical Progress, 2023, 42(10): 5259-5271.

[7]. Lü, Shanna. "Research on Multifunctional Tactile Perception Methods Based on Piezoresistive Tactile Sensors" Anhui University of Architecture, 2023.

[8]. Zhu, Weibin. "Work Stability and Multifunctionality of Flexible Nanocomposite Piezoresistive Sensors" Chongqing University, 2022.

[9]. Shi, Fan. "Preparation and Application Research of Flexible Superhydrophobic Piezoresistive Sensors" Xi'an University of Science and Technology, 2022.

[10]. Feng, Yao. "Preparation and Performance Research of Different Structured Piezoresistive Flexible Pressure Sensors Based on SWCNT and Interdigitated Electrodes" Northwest University, 2022.

[11]. Fang, Xiaohui. "Design, Preparation, and Performance Research of Nanofiber-based Flexible Piezoresistive Sensors" Beijing University of Chemical Technology, 2022.

[12]. Guo, Qinhua. "Research on Flexible Proximity Perception Sensors Based on Magnetoresistive Effect and Their Applications" Shenzhen University, 2022.

[13]. Chen, Fangchun. "Development and Application Research of Flexible Sensors Based on Conductive Cotton Fabric" Southwest University, 2022.

[14]. Babangida, A.A. "Research on Piezoresistive Flexible Pressure Sensors for Human Motion Detection" Jiangsu University, 2022.

[15]. Zhong, Fang. "Construction and Application Research of Bio-adaptive Piezoresistive Sensors" Hunan University, 2022.

[16]. Shi, Zhengya. "Preparation and Performance Research of Flexible Piezoresistive Sensors Based on Biomimetic Hierarchical Structures" Zhengzhou University, 2022.